Device for adding solid organic surface treatment agent for titanium dioxide

A surface treatment agent, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, chemical industry, etc., can solve the problems of wasting energy, increasing steam energy consumption, and performance degradation of finished products, so as to avoid the quality of finished products Decrease, avoid the increase of steam energy consumption, and avoid the effect of unstable addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

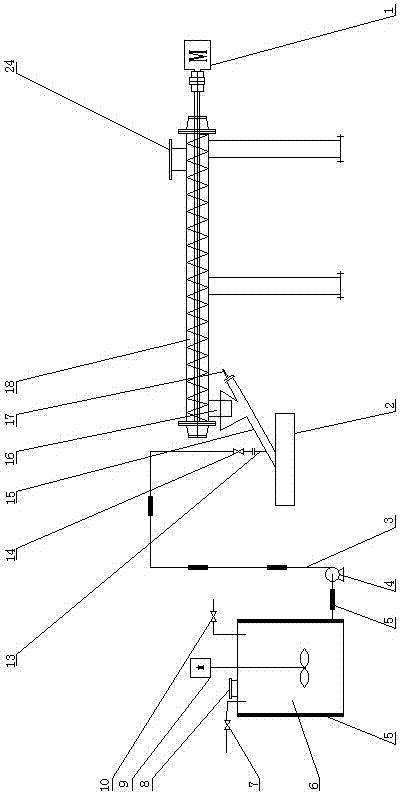

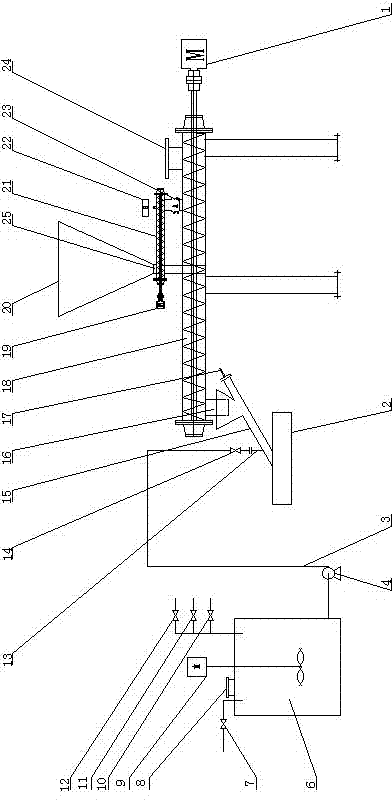

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 2 , a device for adding a solid organic surface treatment agent for titanium dioxide, comprising a steam powder machine feeding screw frequency conversion motor 1, and the steam powder machine feeding screw frequency conversion motor 1 is connected with a steam powder machine feeding screw 18, a steam powder machine feeding The material screw 18 is provided with a titanium dioxide feed port 24 and a steam powder machine feeding port 16, and the steam powder machine feeding port 16 below is provided with a steam powder machine 2, and the steam powder machine feeding port 16 is connected with the steam powder machine 2 connected by a feeding pipeline 15, the upper end of the feeding pipeline 15 is equipped with a high-pressure steam pipeline 17, and also includes a configuration storage tank 6, and the configuration storage tank 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com