On-line three-phase flow evaporation concentration device with solid particle for preventing liquid on wall

A technology of evaporation concentration and anti-hanging wall, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of unfavorable crystal growth, aggravated environmental pollution, complicated device system, etc., so as to reduce labor intensity of workers and strengthen evaporation. Concentration process, the effect of reducing the amount of cleaning solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

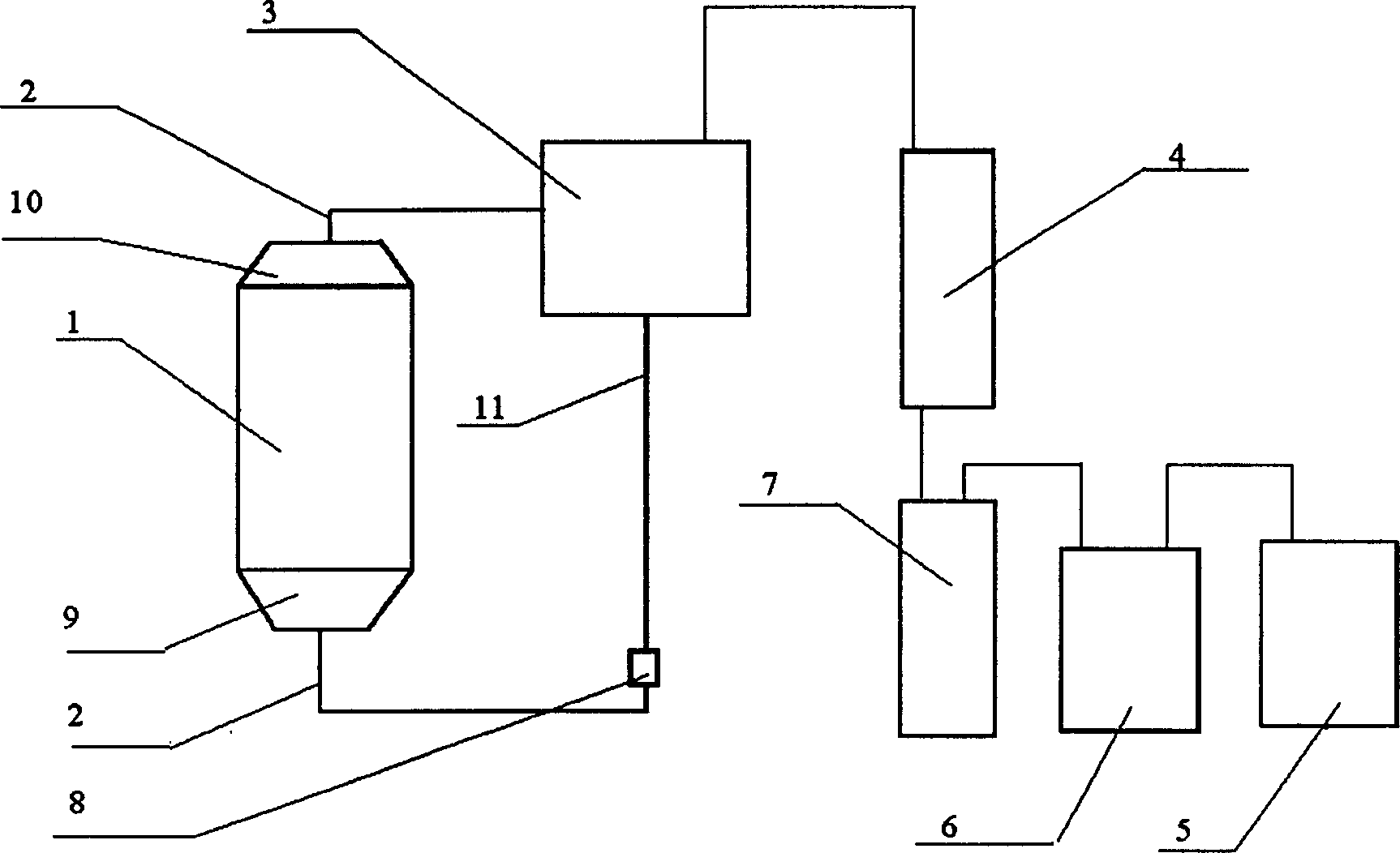

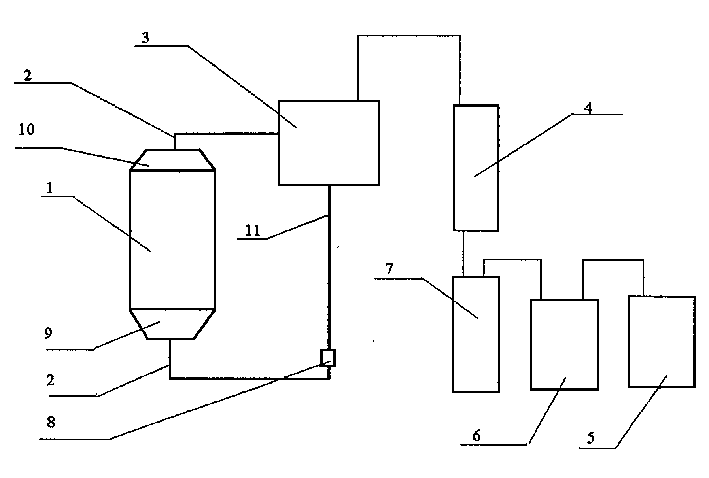

[0018] The device and operation method of the present invention will be introduced in more detail below in conjunction with the accompanying drawings.

[0019] The material liquid to be evaporated and concentrated and the physiologically inert solid particles enter the heating tube in the heater 1, and under the action of natural circulation driving force, a natural circulation flow of vapor-liquid-solid three-phase is formed, relying on the continuous flow of solid particles in a fluidized state. Disturb the flow boundary layer in the heating tube of the evaporative concentrator, so as to realize the on-line enhanced evaporative concentration process, and eliminate the scale layer on the wall surface to prevent the occurrence of wall hanging phenomenon. Because there is no wall-hanging phenomenon, it can reduce the amount of cleaning liquid and waste liquid discharge, and protect the environment; because of stable operation, it can also reduce the wall temperature of the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com