Raw meal homogenizer for cement production

A raw material homogenization and cement technology, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting normal use, affecting the effective volume of raw material storage, wall hanging, etc., and achieve air pressure Small size, good homogenization effect, and increased effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

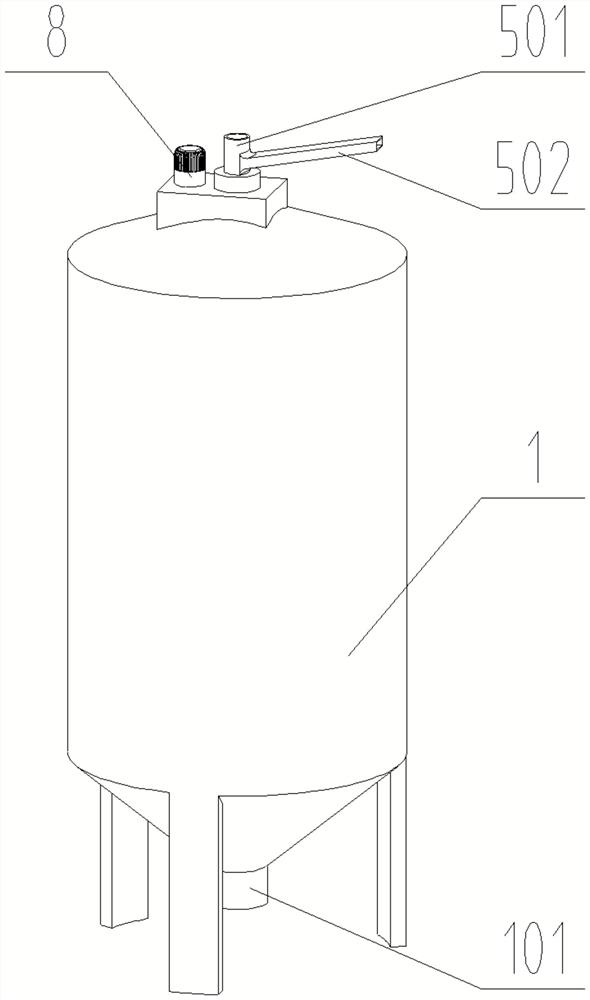

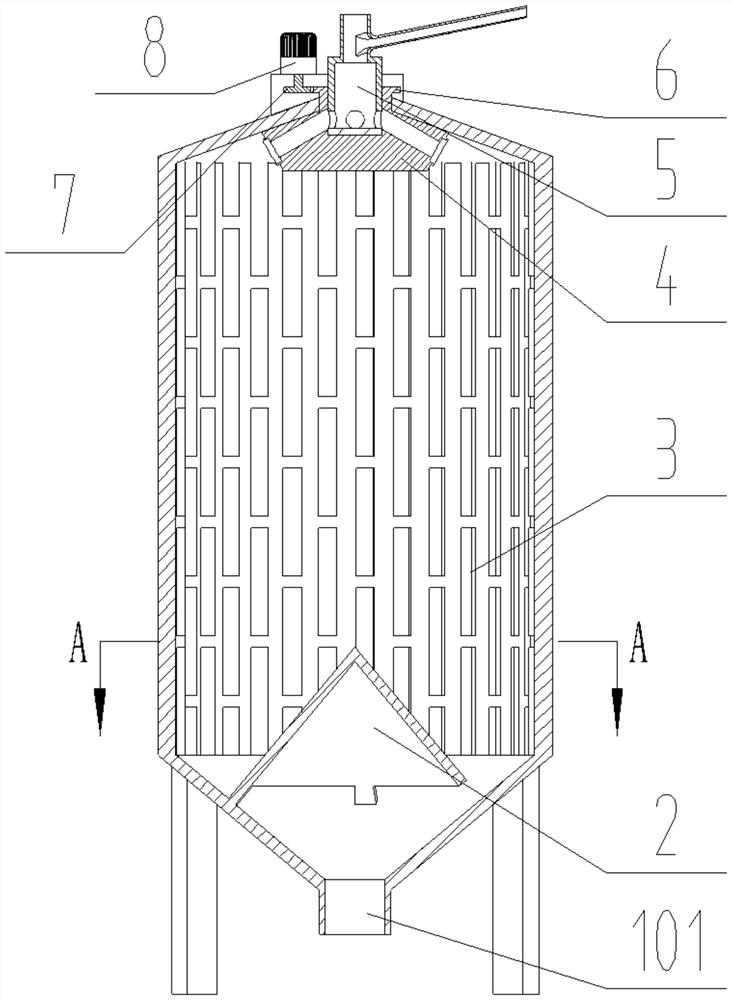

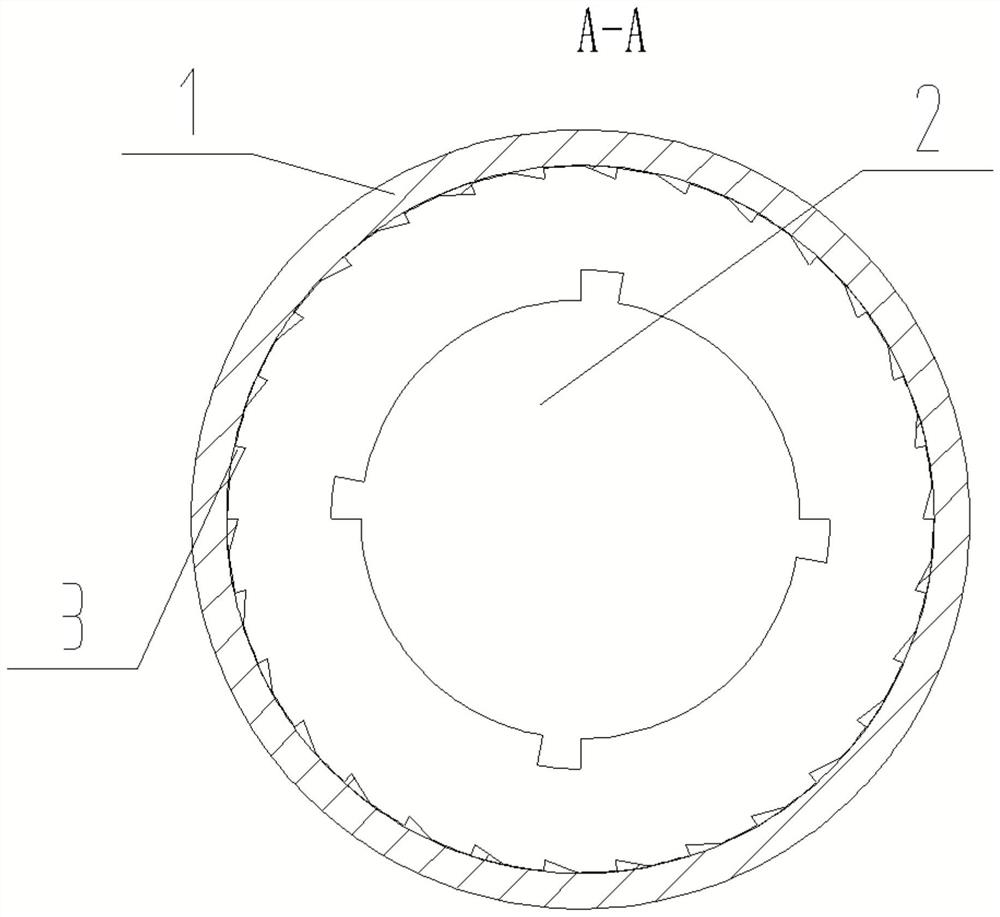

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The invention provides a raw material homogenization device for cement production, including: a raw material storehouse 1, a raw material outlet 101, a decompression cone 2, an inflatable box 3, a power air pipe 301, an anti-wall hanging air pipe 302, and a power air pressure chamber 303 , anti-wall air pressure cavity 304, power air hole 305, anti-wall air hole 306, synthetic fiber mixed polyester breathable layer 307, rotary feeder 4, feed port 401, feed collector 5, first collection port 501, the second collection port 502, the material distribution port 503, the driven gear 6, the driving gear 7 and the motor 8; the bottom of the raw meal storehouse 1 is provided with a group of raw meal outlets 101; the bottom of the raw meal storehouse 1 is fixedly connected with a group of Decompression cone 2; multiple groups of inflatable boxes 3 are evenly arranged on the inner wall of raw meal storage 1; a group of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com