Multi-shaft mixer for materials of high viscosity or low viscosity

A mixer and viscous technology, which is applied in mixers, mixers, chemical/physical processes and other directions with rotating mixing devices, can solve problems such as uniform mixing of non-viscous materials, product quality decline, and product quality impact, and achieve shortened time. The effect of mixing time, improving product quality, and preventing wall hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

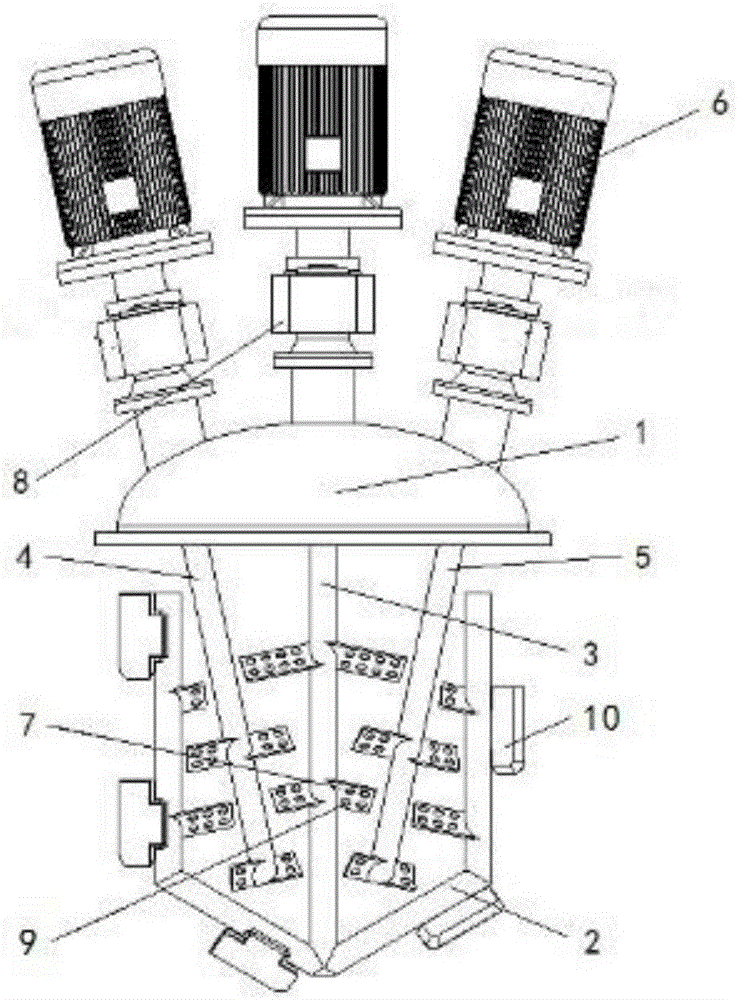

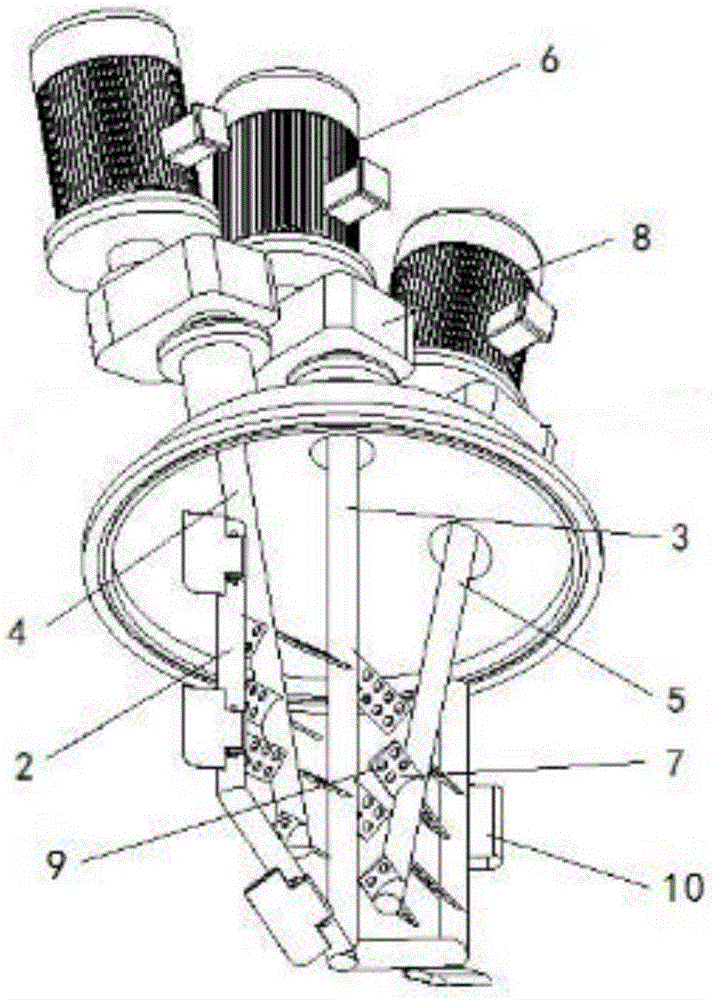

[0014] Such as figure 1 and figure 2 As shown, a multi-axis mixer for high and low viscosity materials includes a machine cover 1, a U-shaped stirring paddle 2, a first straight paddle 3, a second straight paddle 4, a third straight paddle 5, a reducer 8 and The motor 6, the transmission ends of the first straight stirring paddle 3, the second straight stirring paddle 4 and the third straight stirring paddle 5 respectively pass through the machine cover 1 and are fixed on the bearing seat. The opening of the U-shaped stirring paddle 2 is vertically arranged on the Right below the machine cover 1, the upper opening of the U-shaped stirring paddle 2 reduces the degree of tumbling of the upper layer of the material and prevents air from being involved in the material and causing deterioration. The angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com