Material washing device and cooking utensil

A technology for cleaning devices and cooking utensils, which is applied to the structure of cooking utensils, cooking utensils, household utensils, etc. It can solve the problems of incomplete rice, sticking to the inner wall of the cleaning cavity, and easy caking of rice grains, so as to improve integration degree, improve the effect of thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment one (not shown in the figure)

[0063] The unloading structure is a vibrating device, and the vibrating device is in contact with the plunger 10 to make the cleaning cavity 11 vibrate, so as to promote the discharge of the materials in the cleaning cavity 11.

[0064] The blanking structure is a vibrating device, which is in contact with the plunger 10 and can vibrate the cleaning cavity 11. The vibrating cleaning cavity 11 can separate the materials accumulated or stuck on its inner wall surface, and vibrate The materials detached from the inner wall of the cleaning cavity 11 will be discharged from the discharge port 12 and the discharge port 21 under the action of gravity, thereby effectively improving the thoroughness of the discharge.

[0065] Wherein, the vibrating device includes an electromagnet 30 , and the iron core of the electromagnet 30 can strike the plunger 10 to make the cleaning cavity 11 vibrate.

[0066] The vibrating device includes an el...

Embodiment 2

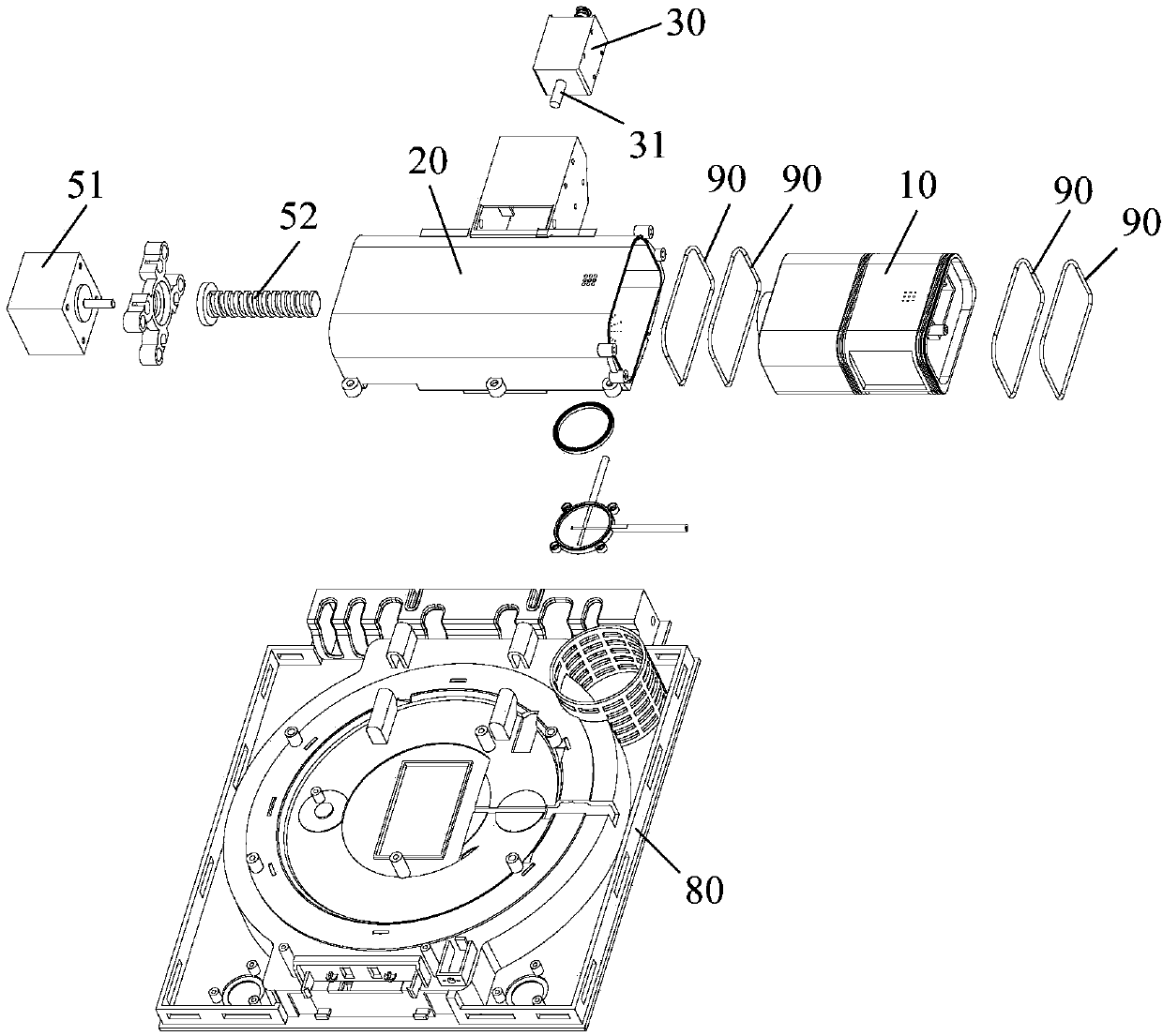

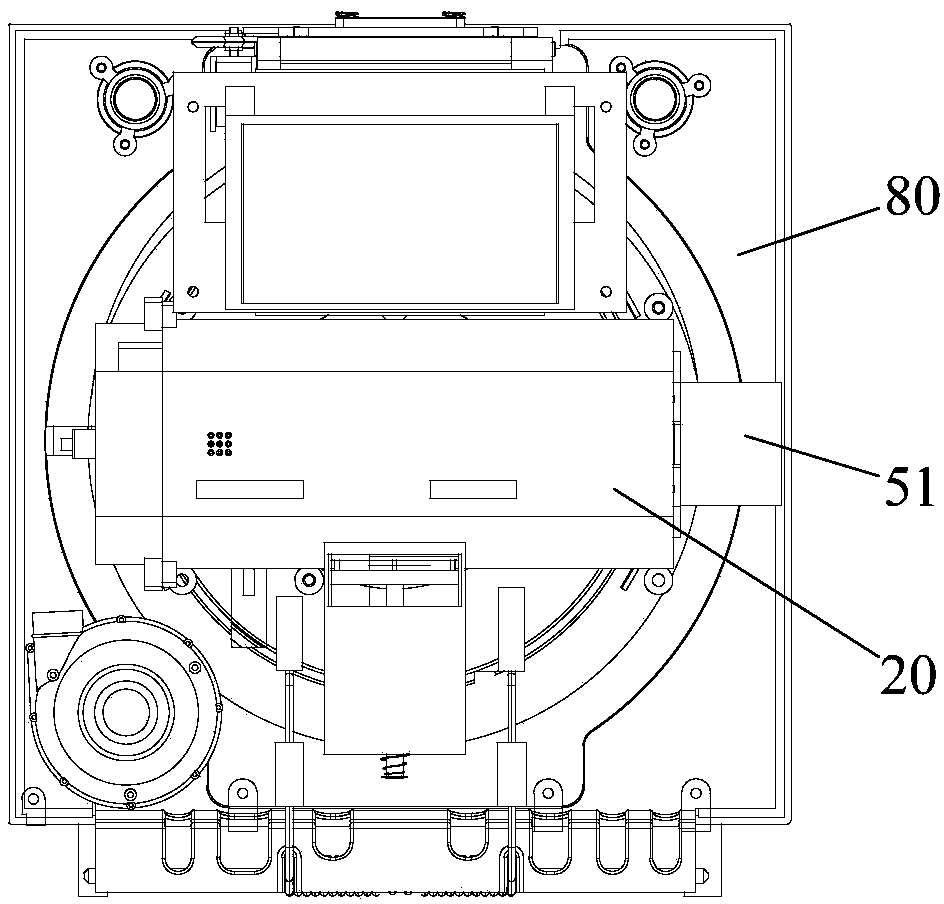

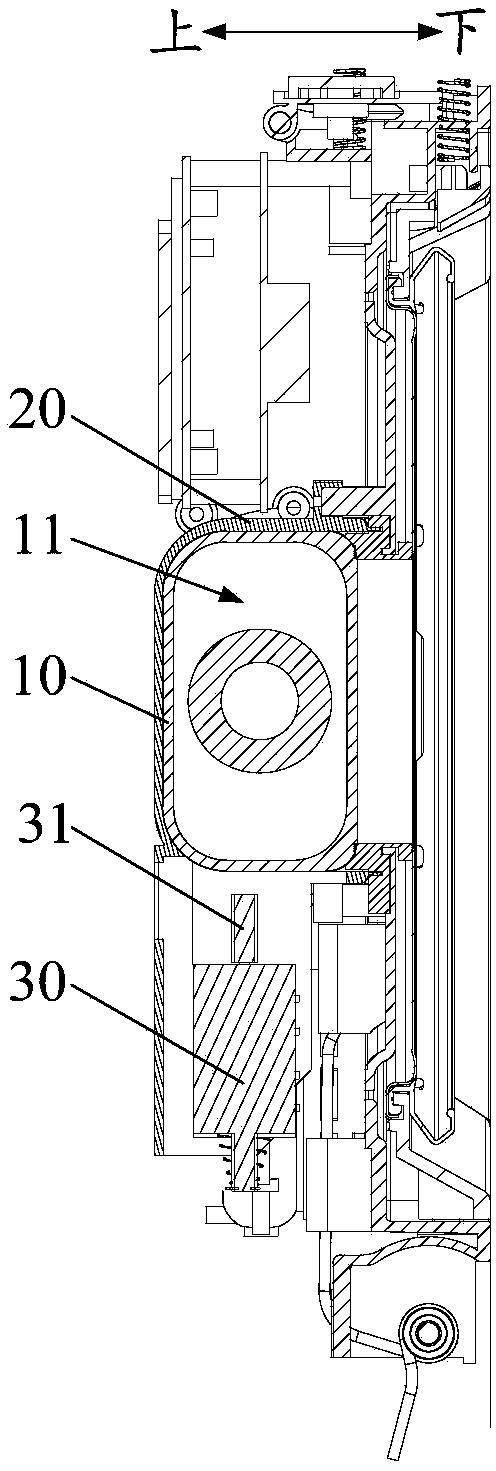

[0067] Embodiment two (as Figure 1 to Figure 7 shown)

[0068] The difference with Embodiment 1 is that the vibrating device includes an electromagnet 30 and a beating bar 31 connected to the electromagnet 30, and the beating bar 31 can hit the plunger 10 under the drive of the electromagnet 30, as Figure 6 As shown, the cleaning chamber 11 is vibrated.

[0069] The vibrating device includes an electromagnet 30 and a beating rod 31 connected to the electromagnet. When the electromagnetic coil is powered on and off, its iron core will drive the beating rod 31 to move instantaneously along its central axis, thereby causing the beating rod 31 to hit the plunger 10 , The beating rod 31 further increases the strength of hitting the cleaning chamber 11, thereby increasing the vibration amplitude of the cleaning chamber 11, and further improving the thoroughness of blanking.

Embodiment 3

[0070] Embodiment three (as Figure 8 shown)

[0071] The difference from Embodiment 1 is that the vibrating device includes an ultrasonic vibrator 40, such as Figure 8 shown.

[0072] Preferably, the vibration frequency of the ultrasonic vibrator 40 is in the range of 15KHz-60KHz.

[0073] The vibrating device includes an ultrasonic vibrator 40. The ultrasonic vibrator 40 can generate high-frequency vibration and transmit it to the cleaning cavity 11 to drive the cleaning cavity 11 to generate high-frequency vibration, thereby vibrating the materials accumulated or stuck on the inner wall of the cleaning cavity 11. Falling, impels the material in the cleaning cavity 11 to be discharged quickly.

[0074] Preferably, the vibration frequency of the ultrasonic vibrator 40 is within the range of 15KHz-60KHz, which not only avoids the situation that the effect of promoting the blanking is not obvious due to the low vibration frequency, but also avoids the cleaning of the struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com