Half-portal scraper reclaimer

A reclaimer and scraper technology, applied in conveyors, loading/unloading, containers, etc., can solve the problems of rail gnawing and jamming at both ends, so as to reduce the failure rate, reduce the probability of damage, and reduce the risk of chain breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

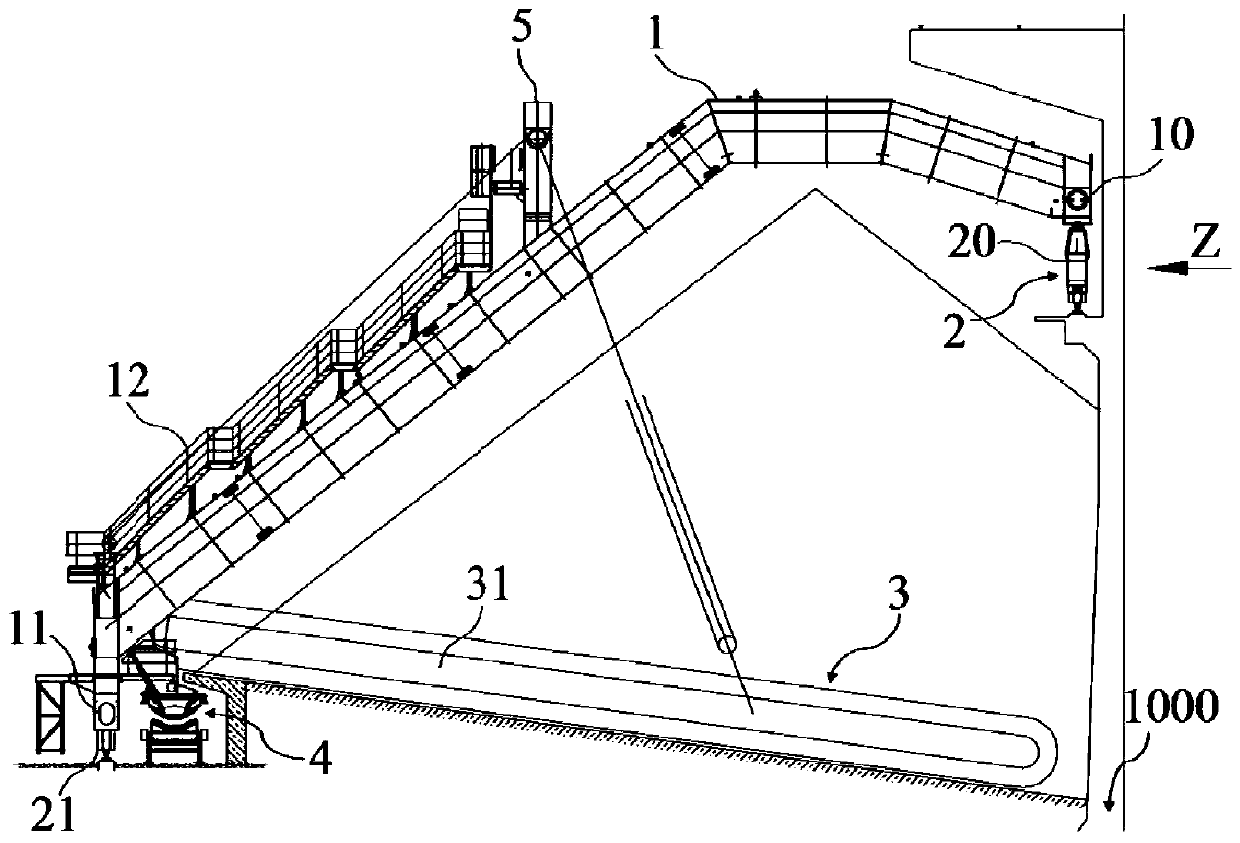

[0071] Such as figure 1 and figure 2 As shown, the half-gantry scraper reclaimer of the present embodiment includes,

[0072] Half gantry 1, which is placed above the stockyard 1000;

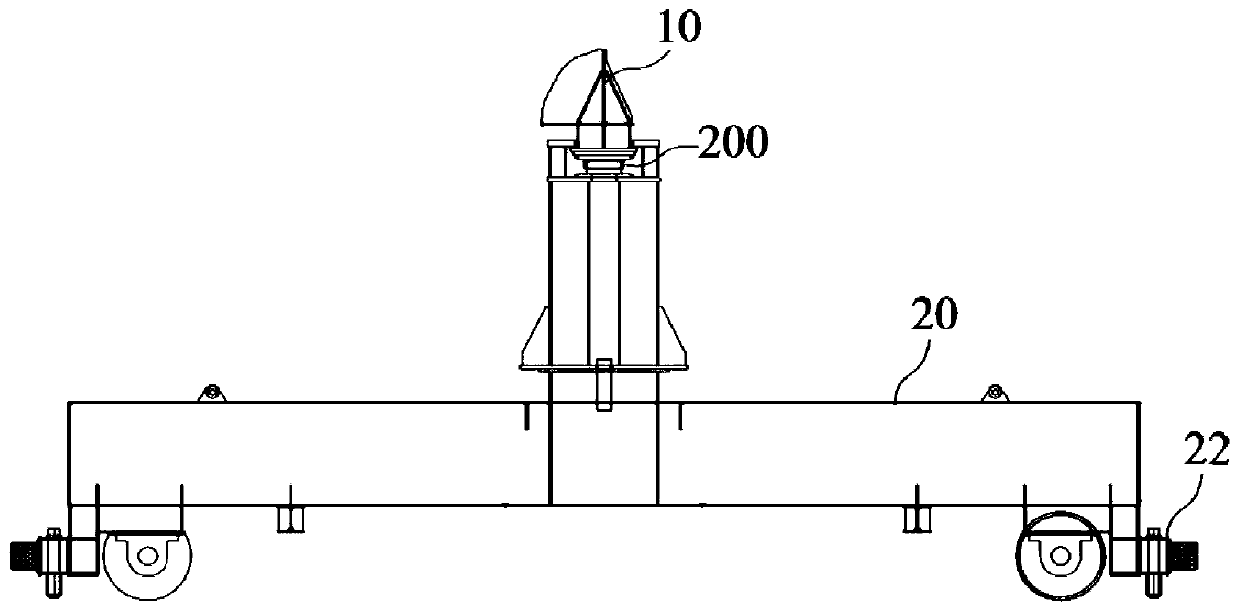

[0073] Walking system 2, which includes an upper traveling mechanism 20 and a lower traveling mechanism 21, which are respectively connected to the upper end beam 10 and the lower end beam 11 of the half mast 1;

[0074] Reclaiming system 3, which is located under the half-gantry 1, and reclaims materials through scrapers;

[0075] The unloading system 4, which is located next to the lower end beam 11 of the semi-gantry 1, receives and unloads the materials output by the reclaiming system 3;

[0076] Pitching system 5, which is set on the semi-gantry 1 and is connected to the reclaiming system 3 in transmission, to control the lifting of the reclaiming system 3;

[0077] The upper traveling mechanism 20 is movably connected with the upper end beam 10 of the half mast 1 through a spherical f...

Embodiment 2

[0081] Such as figure 1 and figure 2 As shown, the semi-gantry scraper reclaimer of the present embodiment is further improved on the basis of Embodiment 1, the traveling system 2 is driven by a plurality of motors 22, and the upper traveling mechanism 20 is driven by two motors 22 drive, the lower traveling mechanism 21 is driven by four motors 22, and all motors 22 are driven by a variable frequency drive.

[0082] The applicant found that the two traveling mechanisms connected to the two end beams of the semi-gantry 1 received different loads from the gravity of the semi-gantry 1, and the load on the lower traveling mechanism 21 was greater than that on the upper traveling mechanism 20. The load is much larger, which causes the power loss of the two traveling mechanisms to be different when driving, which will cause the displacement speeds of the beams at both ends of the half-gantry 1 to be inconsistent when moving, and also cause the half-gantry 1 to gnaw to death. 1. ...

Embodiment 3

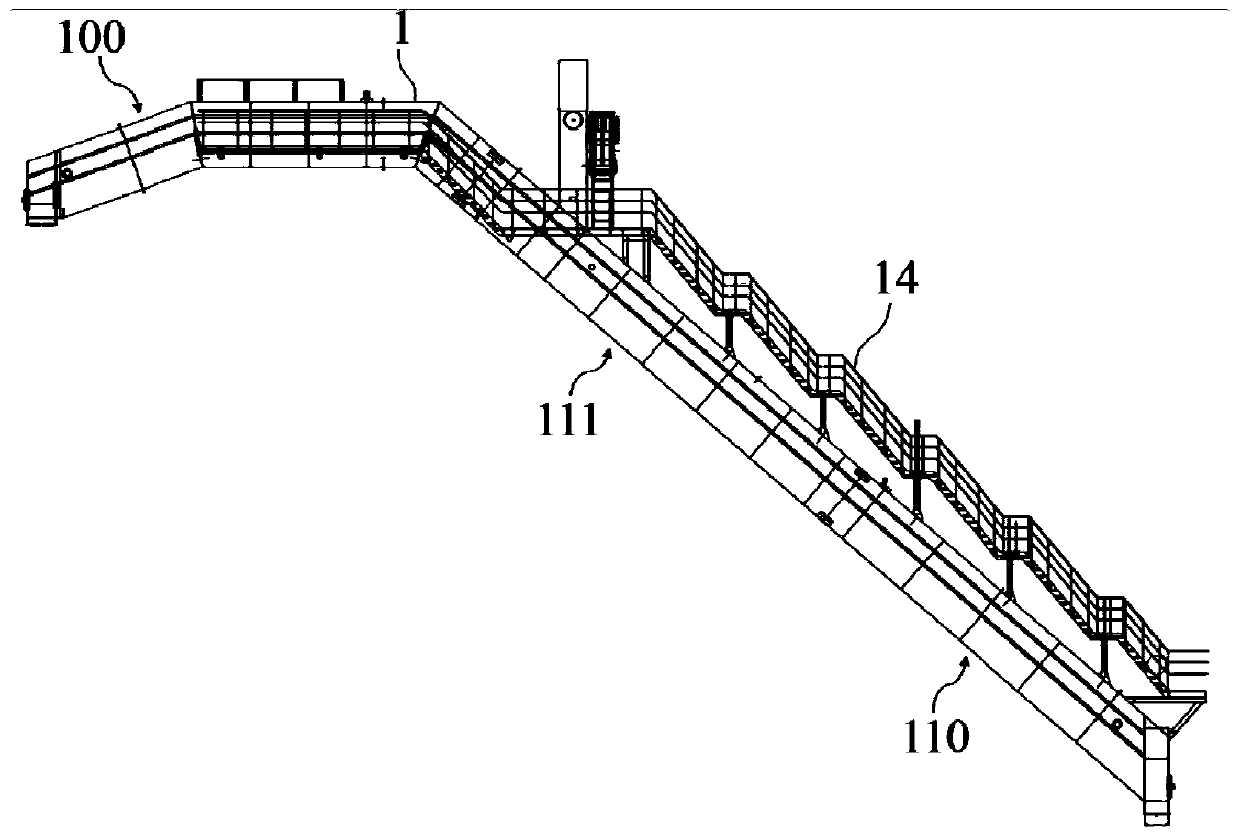

[0084] Such as image 3 with Figure 4 As shown, the half-gantry scraper reclaimer of this embodiment is further improved on the basis of Embodiment 2, and the half-gantry 1 is composed of an upper end beam part 100, an upper end beam upper part 111 and a lower end beam lower part 110 in sequence. , Welding and fixing between adjacent parts.

[0085] Due to the large structural size of the half-gantry 1, transportation and on-site installation are relatively difficult. The structure of the half-gantry 1 in this embodiment is composed of three-stage assembly, which can effectively reduce the difficulty of installation and transportation of the half-gantry 1. 1 The three-stage structure is a sealed box structure, which can reduce the weight and prevent dust from entering and accumulating. After the adjacent parts are connected by high-strength bolts and connecting plates, they are welded and fixed, thereby ensuring the stability of the connecting structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com