Eye-brow shaping corrugated blade automatic assembly production equipment and eye-brow shaping corrugated blade automatic assembly method

An automatic assembly and production equipment technology, applied in metal processing equipment, packaging, transportation packaging, etc., can solve the problems of large labor cost burden, operator injury, poor product consistency, etc., to reduce the staff's work force and work intensity , the effect of high size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

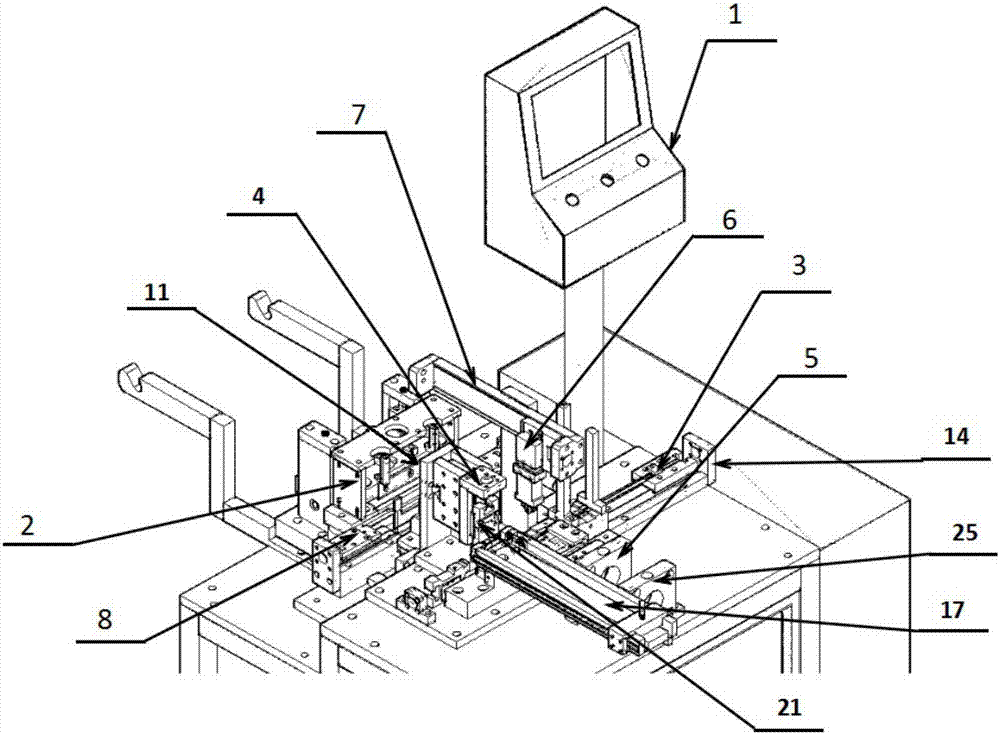

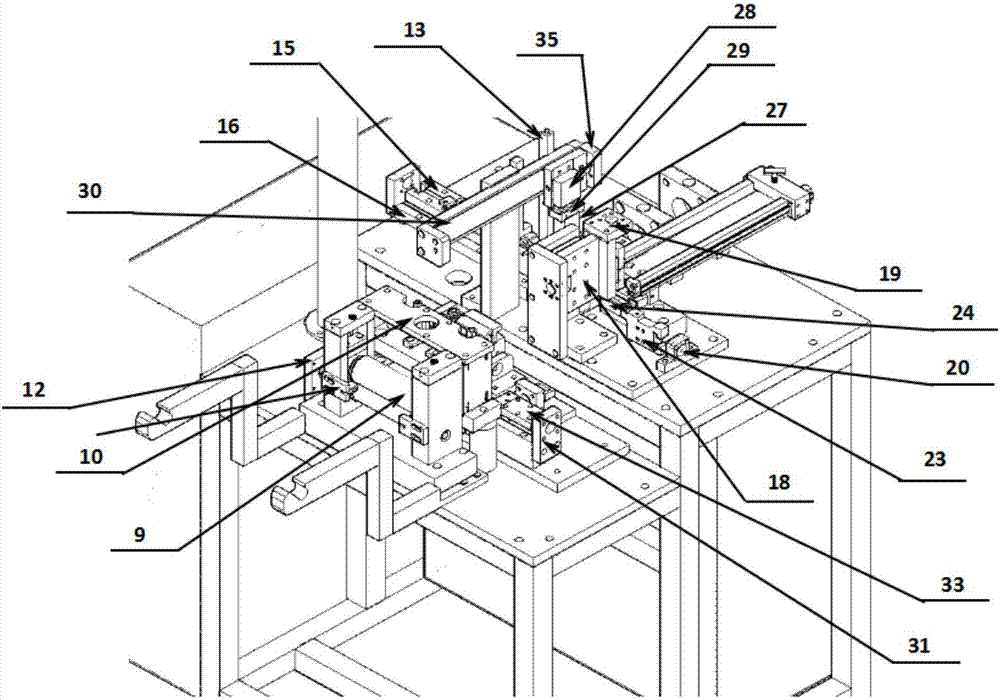

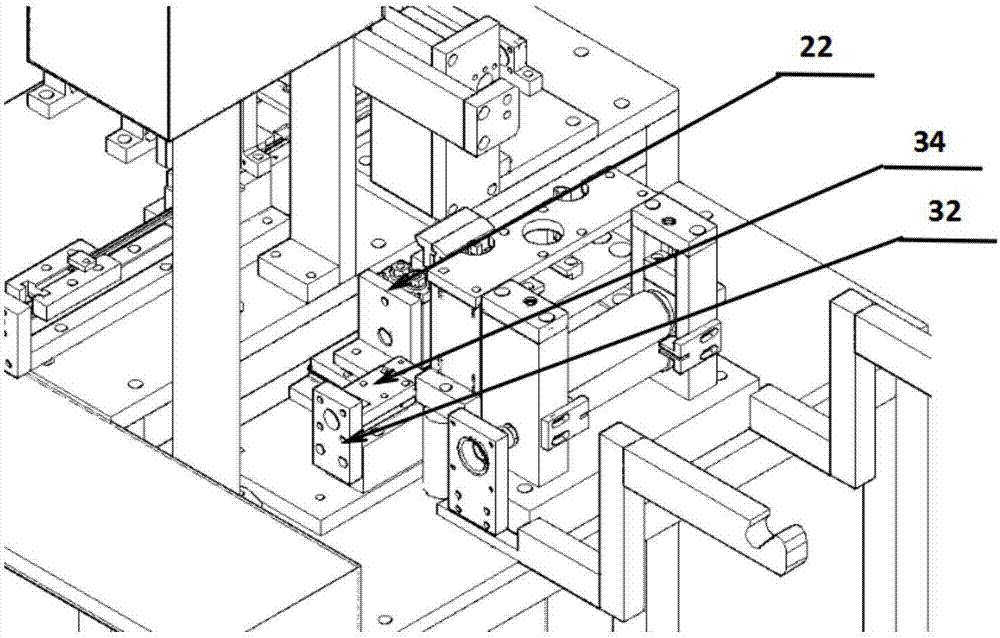

[0050] as attached figure 1 To attach Figure 11 As shown, an automatic assembly production equipment for eyebrow trimming corrugated blades in this embodiment includes a control unit 1, a wrapping paper cutting mechanism 2, a corrugated blade clamp feeding mechanism 3, a corrugated blade feeding mechanism 4, a corrugated blade clamp buckling mechanism 5, Clamping transport mechanism, dispensing machine and packaging mechanism 8;

[0051] Described wrapping paper cutting mechanism 2 comprises feeding roller 9, the first air cylinder fixed seat 10, shearing mold 11 and motor fixed seat 12, is respectively installed with corresponding first cylinder fixed seat 10, motor fixed seat 12. A cylinder and motor;

[0052] The corrugated blade clamp feeding mechanism 3 includes a guide rod 13, a second cylinder fixing seat 14, a first pushing block 15 and a first guide rail 16 matched with the first pushing block 15, and the second A corresponding second cylinder is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com