Circular comb fitting

A technology of card clothing and carding needles, which is applied in the field of cylinder rollers, can solve problems such as fiber fret defects that cannot be ruled out, and achieve the effects of improving machine operation performance, reducing the number of bonding errors, and soft fiber handover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

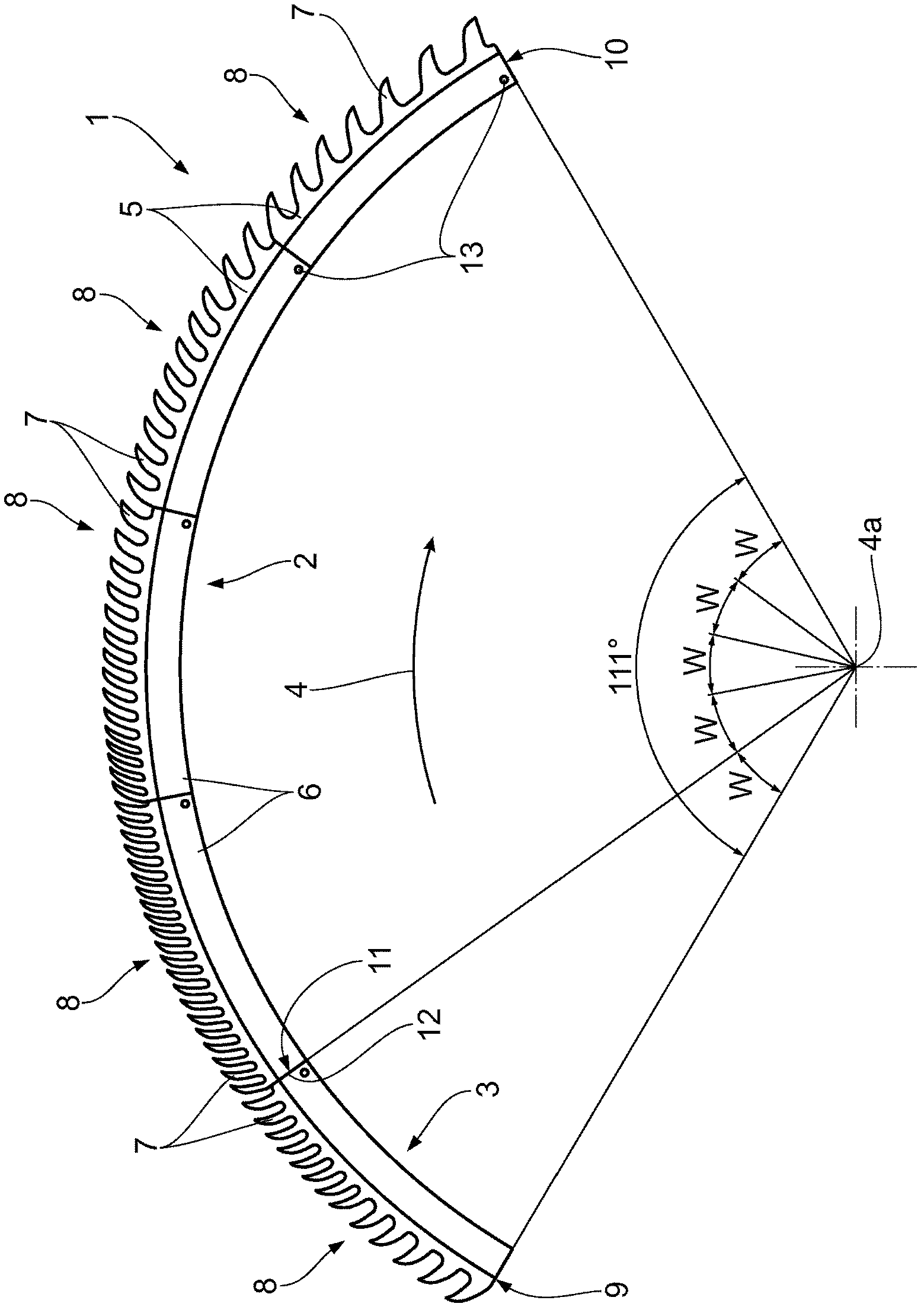

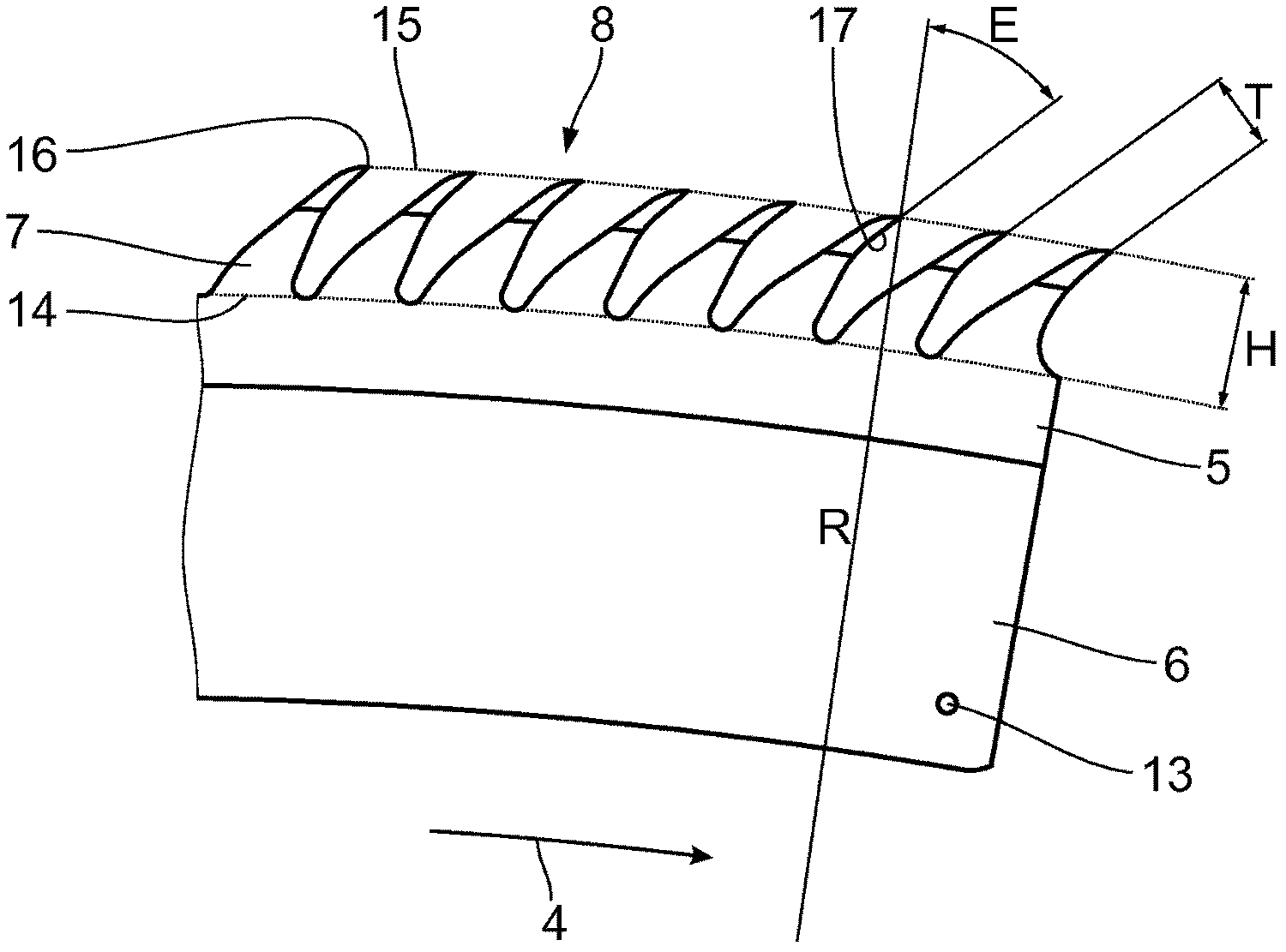

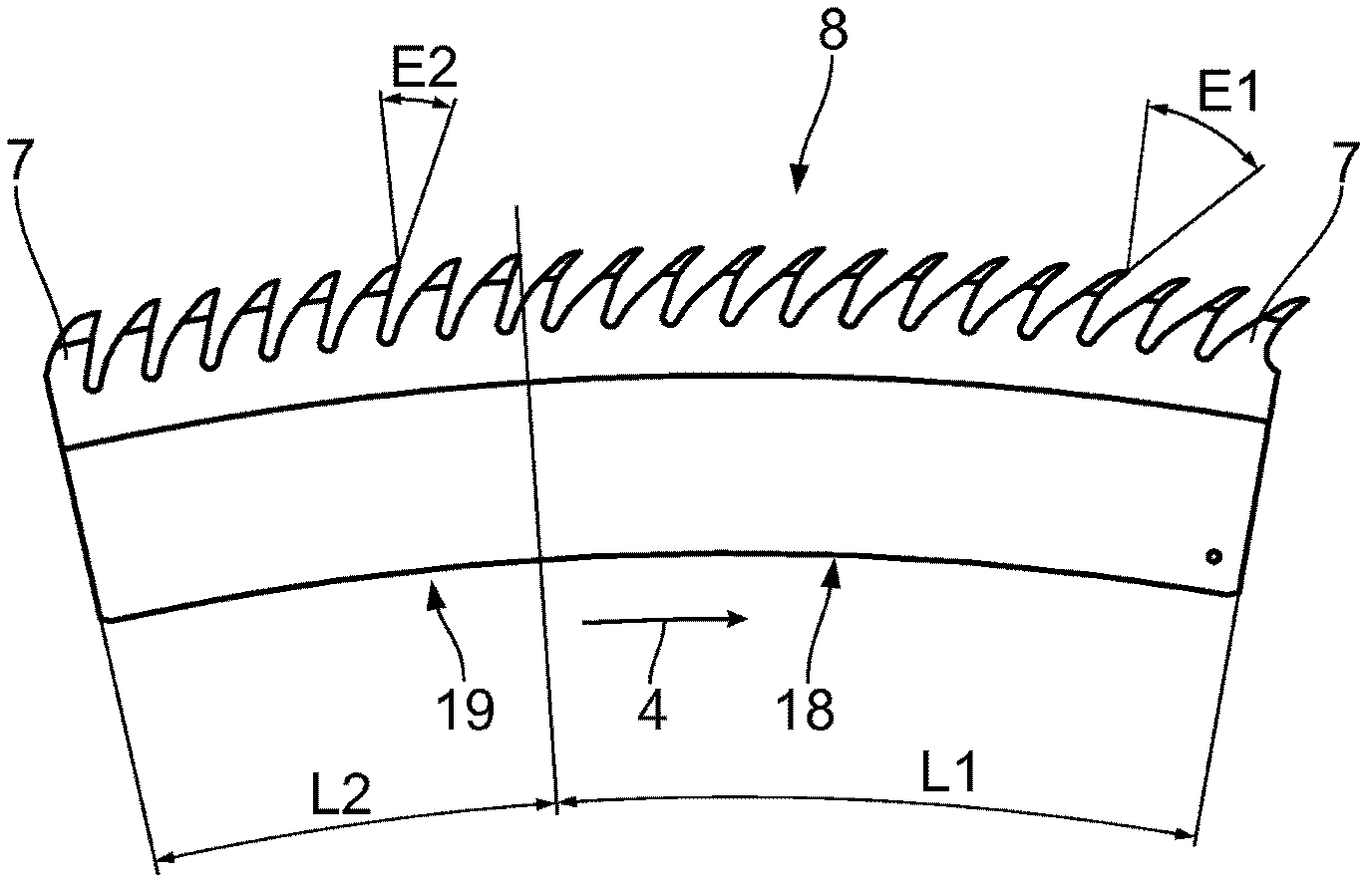

[0021] exist figure 1 The card clothing 1 of the circular comb of the textile combing machine shown in includes a first cylinder needle seat area 2 and a second cylinder needle bar seat area 3 . Two cylinder needle plate seats 2, 3 are arranged side by side along the direction of the rotation axis 4a of a cylinder roller not shown, and are formed by zigzag stamping parts 5 arranged sequentially along the direction of the rotation axis 4a of the cylinder roller, which The saw-tooth stamping 5 has teeth 7 extending away from the root 6 . The saw-tooth stamped part 5 , also called ring gear or tooth plate, can also be made of a saw-toothed strip.

[0022] The configuration of the card clothing in the axial direction, ie in the direction of the axis of rotation 4a, will be described below. By using spacers without teeth and / or of different thicknesses, ie can have dimensions along the axis of rotation 4a, the sawtooth stampings 5 can be positioned at a distance from one anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com