Horizontal homotaxial self-cleaning film evaporator

A thin-film evaporator, self-cleaning technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of agglomeration, limited effective heat exchange area, large dead angle of scraper materials, etc., and increase the melt ratio Effect of surface area, increase in surface renewal rate, and increase in productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

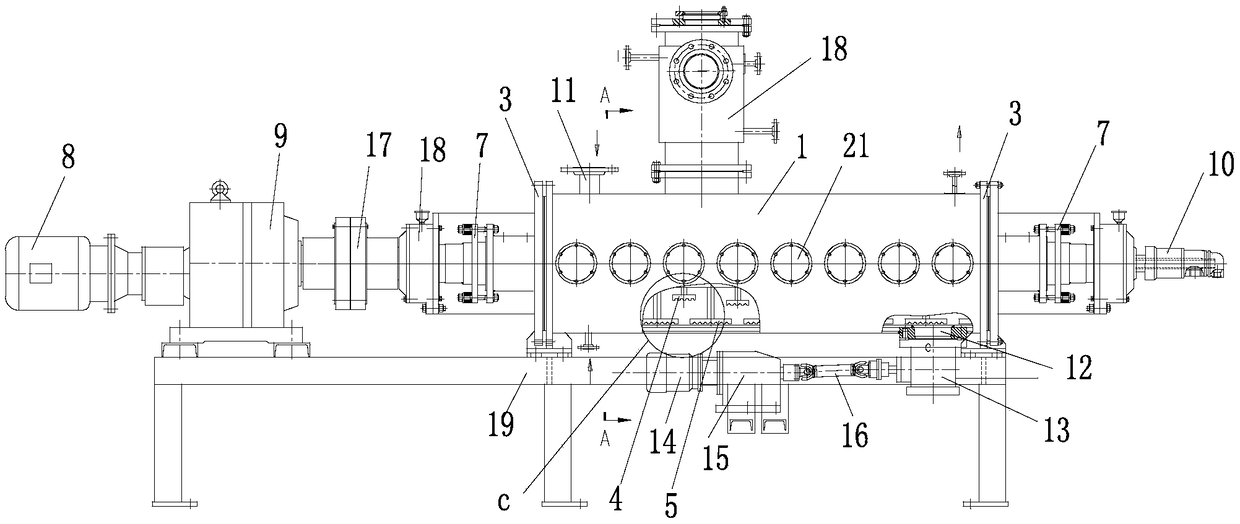

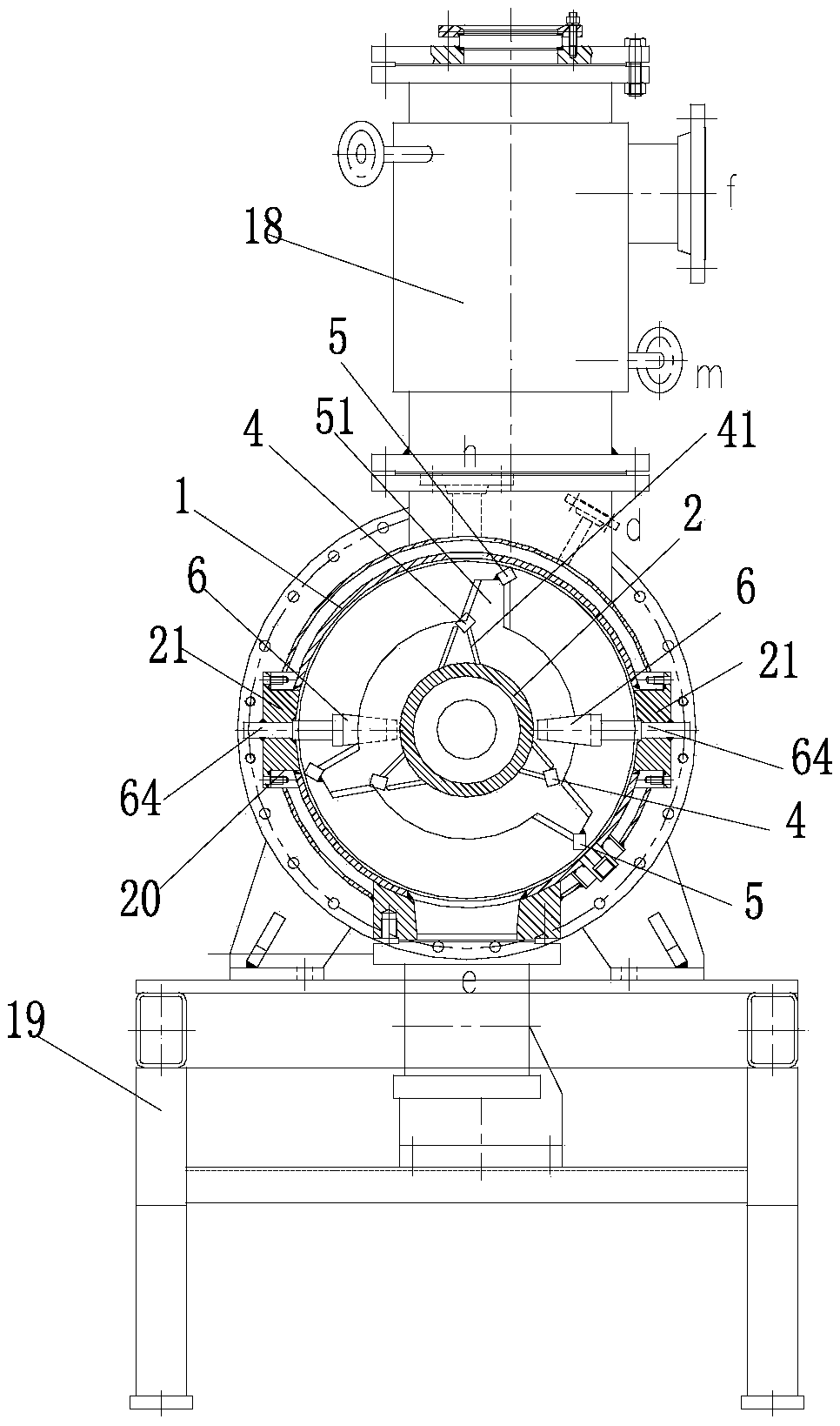

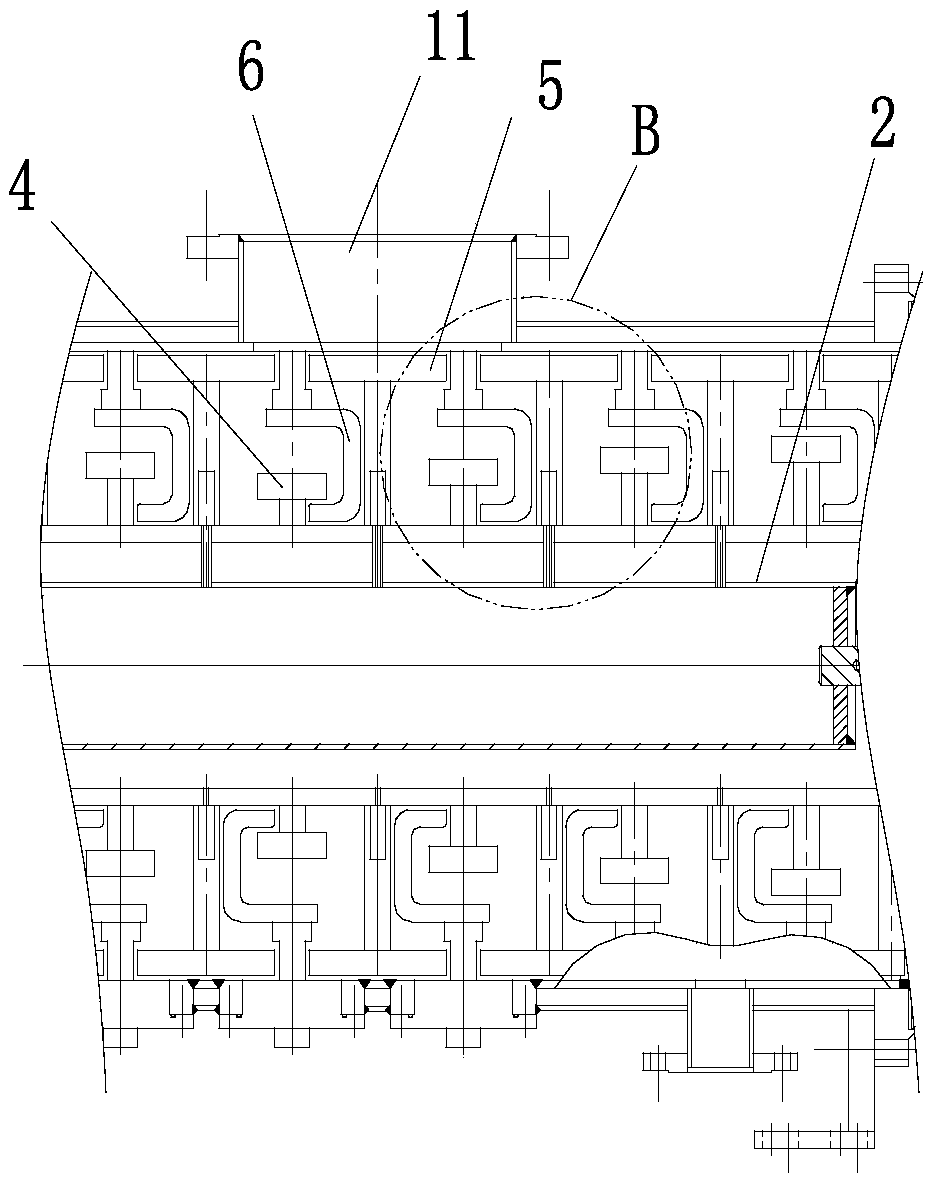

[0027] Embodiment 1: refer to figure 1 and 2 . A horizontal uniaxial self-cleaning thin film evaporator, comprising a cylinder 1, a hollow main shaft 2 is arranged horizontally in the inner cavity of the cylinder 1, and a number of spirally arranged inner scrapers 4 are axially distributed on the hollow main shaft 2 of the cylinder 1 and A number of spirally arranged outer scrapers 5 along the wall, and each inner scraper 4 and outer scraper 5 along the wall are arranged at intervals from each other, and one side, two sides or several sides of the inner wall of the cylinder 1 are provided with a number of fixed scrapers 6 arranged in parallel in the axial direction One or more sets of fixed scrapers 6 in the same radial section in the cylinder 1 are located between the inner scraper 4 and the outer scraper 5 along the wall, each fixed scraper 6 is connected to the inner wall of the cylinder 1 through a handle 64, and the inner scraper 4 The paddle plate 41 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com