Calcinator for industrial by-product gypsum

A technology of industrial by-product gypsum and calciner, which is applied in the field of industrial by-product gypsum calciner, can solve the problems of less than 30% comprehensive utilization rate, unstable product quality, and unsound supporting facilities, and achieve moderate air volume, constant temperature, The effect of small amount of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

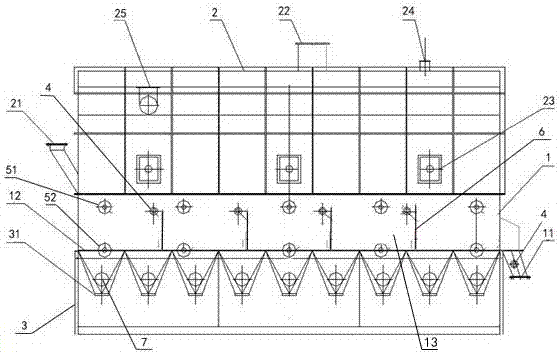

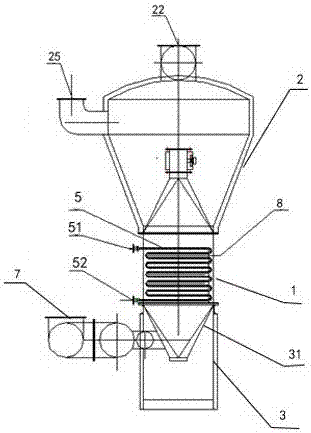

[0025] Such as figure 1 and 2 As shown, an industrial byproduct gypsum calciner includes a calciner 1 . The upper end of one side of the calcining chamber 1 is equipped with a material inlet 21 , and the lower end of the other side is equipped with a material outlet 11 . The calciner 1 is provided with a plurality of overflow regulating plates 6 . The plurality of overflow regulating plates 6 are uniformly installed in the calcining chamber 1 . The overflow regulating plate 6 divides the calcining chamber 1 into a plurality of calcining chambers 13 . A heat exchange system is installed in the calcining chamber 13 . The heat exchange system includes a steam pipe 5 and fins installed outside the steam pipe 5 . There is a certain gap between the fins to ensure the smooth displacement of the material, and the heat exchange area of the fins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com