Gas-solid/gas-gas phase plasma tubular reactor process and device

A tubular reactor, plasma technology, applied in the direction of plasma, electrical components, chemical/physical/physical-chemical processes of applying energy, etc., can solve the problems of high cost, discontinuous reaction, complex process, etc. Fast, uniform and normal discharge, and the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

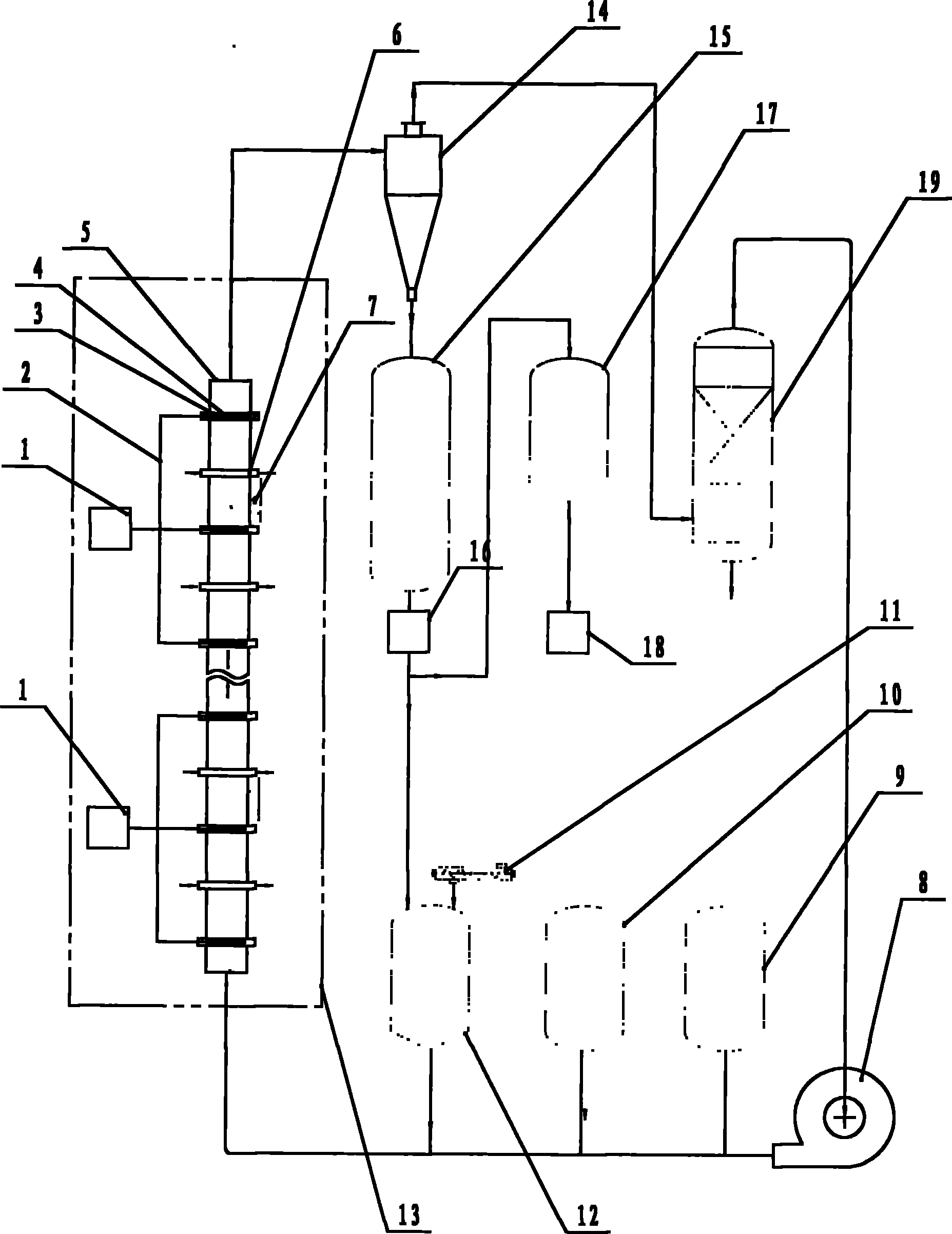

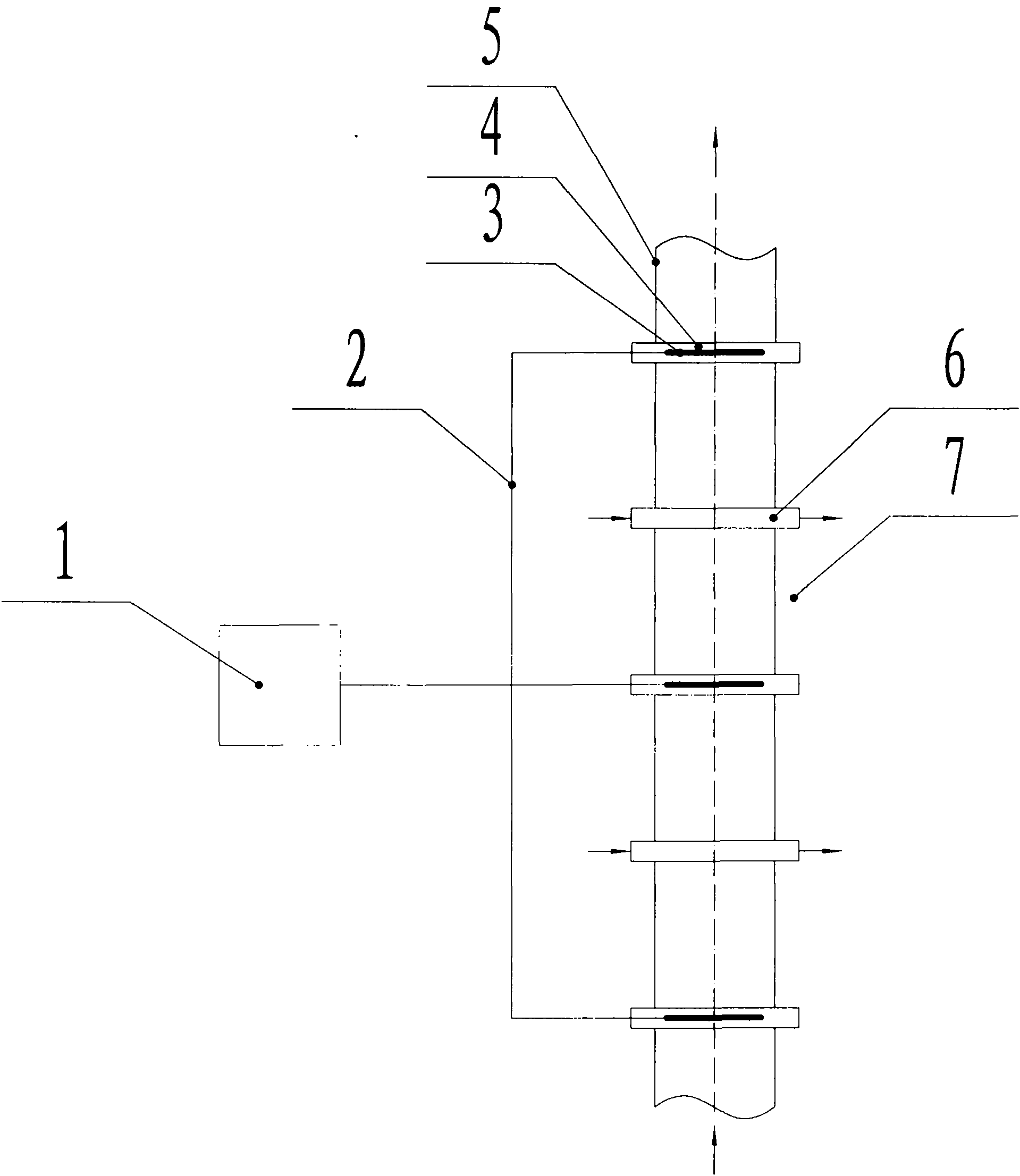

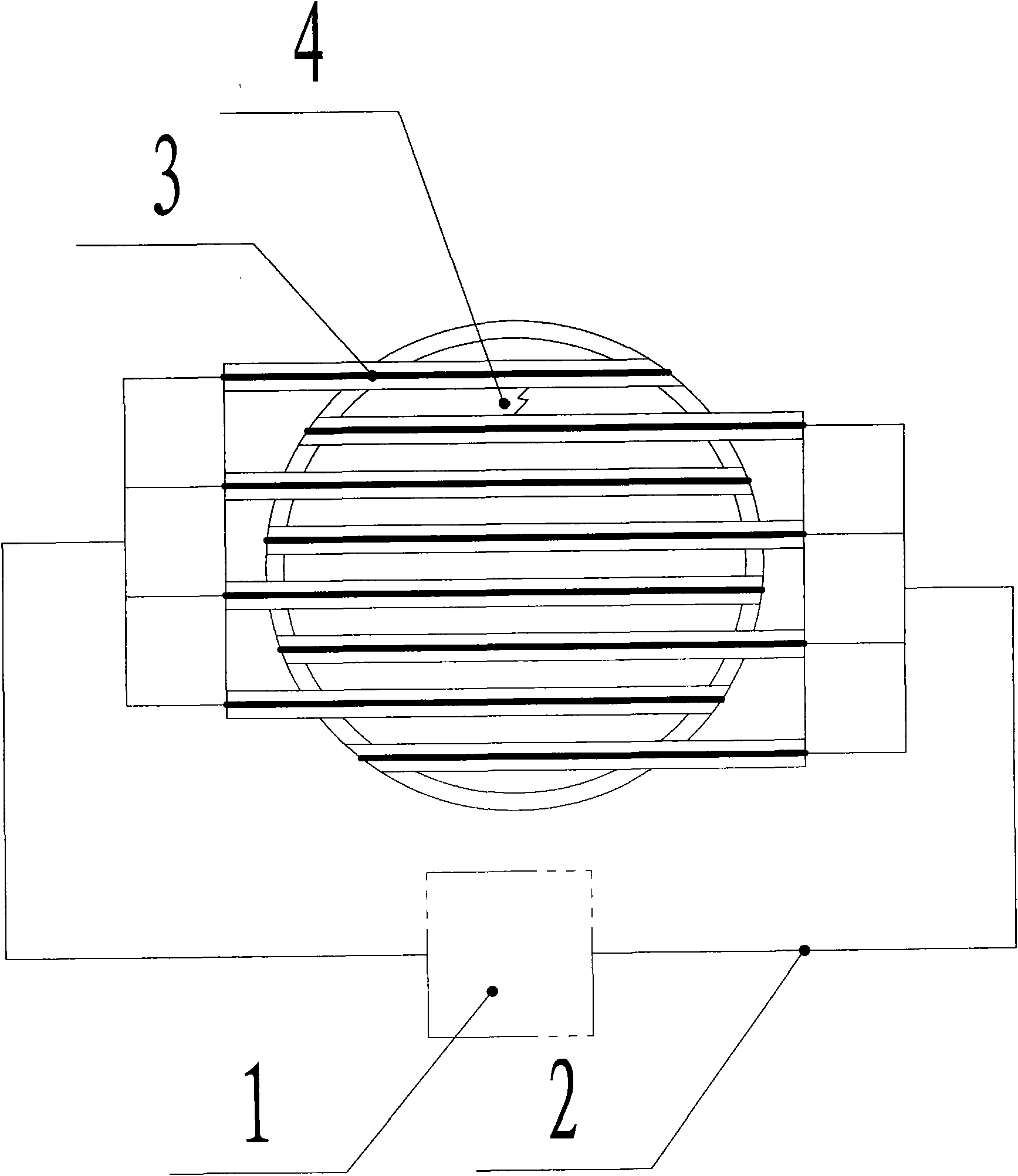

[0023]Embodiment 2 of the present invention is that the hydrogen chloride gas in the reaction gas tank 9 and the nitrogen in the auxiliary gas tank 10 are pressurized with the polyvinyl chloride in the reaction powder equipment 11 after being pressurized by the circulating booster fan 8 whose gas velocity is controlled at 15m / s. The monomers are mixed and sent into the plasma tube reactor 13, chlorine and nitrogen generate low-temperature plasma in the plasma region, and the chlorine-containing gas in the low-temperature plasma state reacts with polyvinyl chloride (PVC), and generates reaction heat at the same time, in order to control the reaction The temperature of the plasma tube reactor 13 is provided with a heat exchange tube 6, and the outer wall of the plasma tube reactor 13 is provided with a tube reactor shell heat exchange insulation layer 7 to ensure that the reactor temperature is controlled at 80 -110°C; the reacted gas and PVC are discharged from the top of the pl...

Embodiment 3

[0024] The difference between embodiment 3 and embodiment 1 or 2 is that the auxiliary gas can be argon or hydrogen.

Embodiment 4

[0025] Embodiment 4 is different from Embodiment 1 or 2 in that: the gas velocity of the blower is 4m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com