Failure diagnosis method of power equipment

A technology for fault diagnosis and power equipment, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high accuracy of speed acquisition, high discreteness of analysis results, unfavorable promotion and application, etc., to meet the requirements of fault prediction and Effect of monitoring function, improving application range and expanding use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

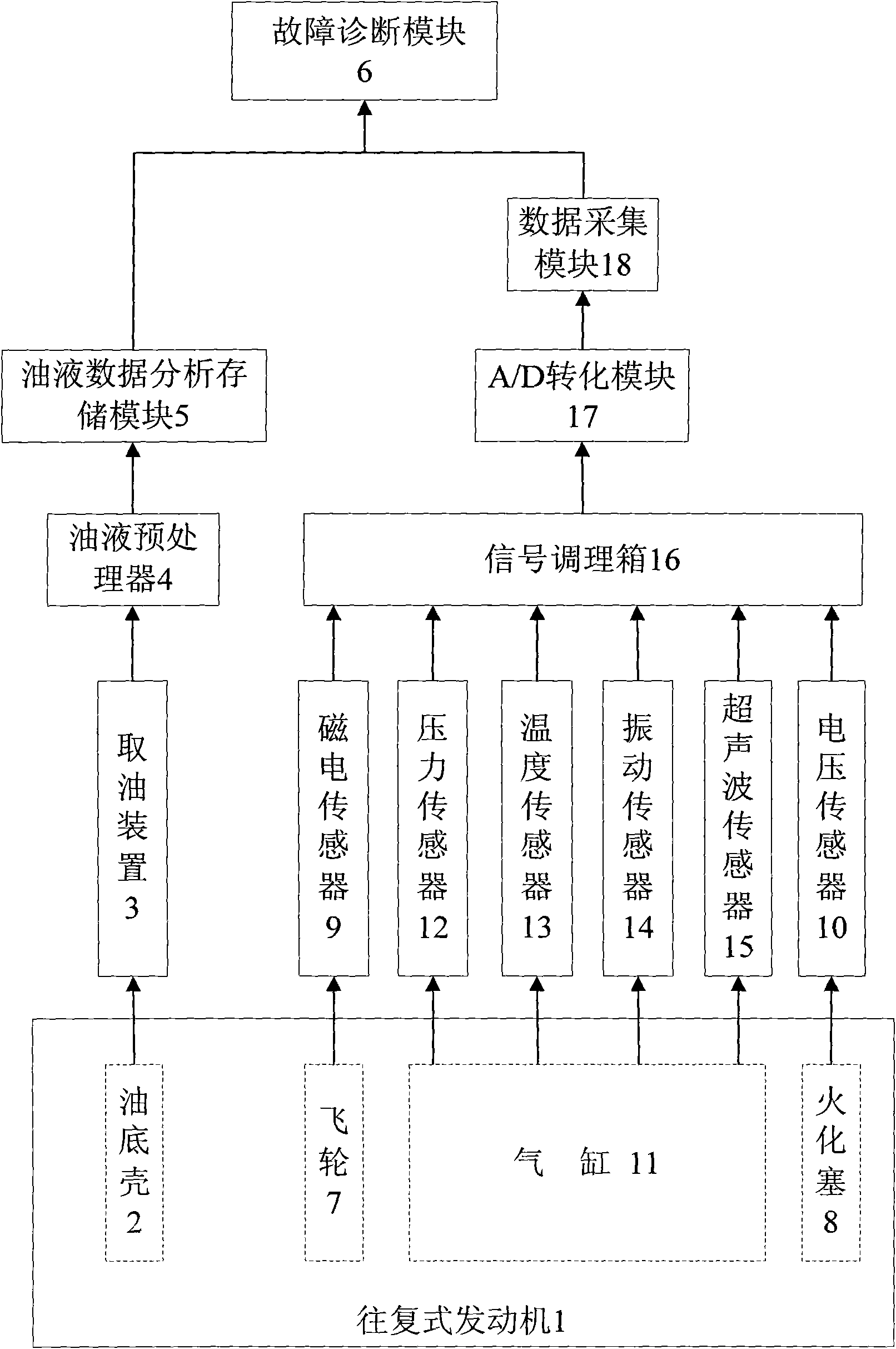

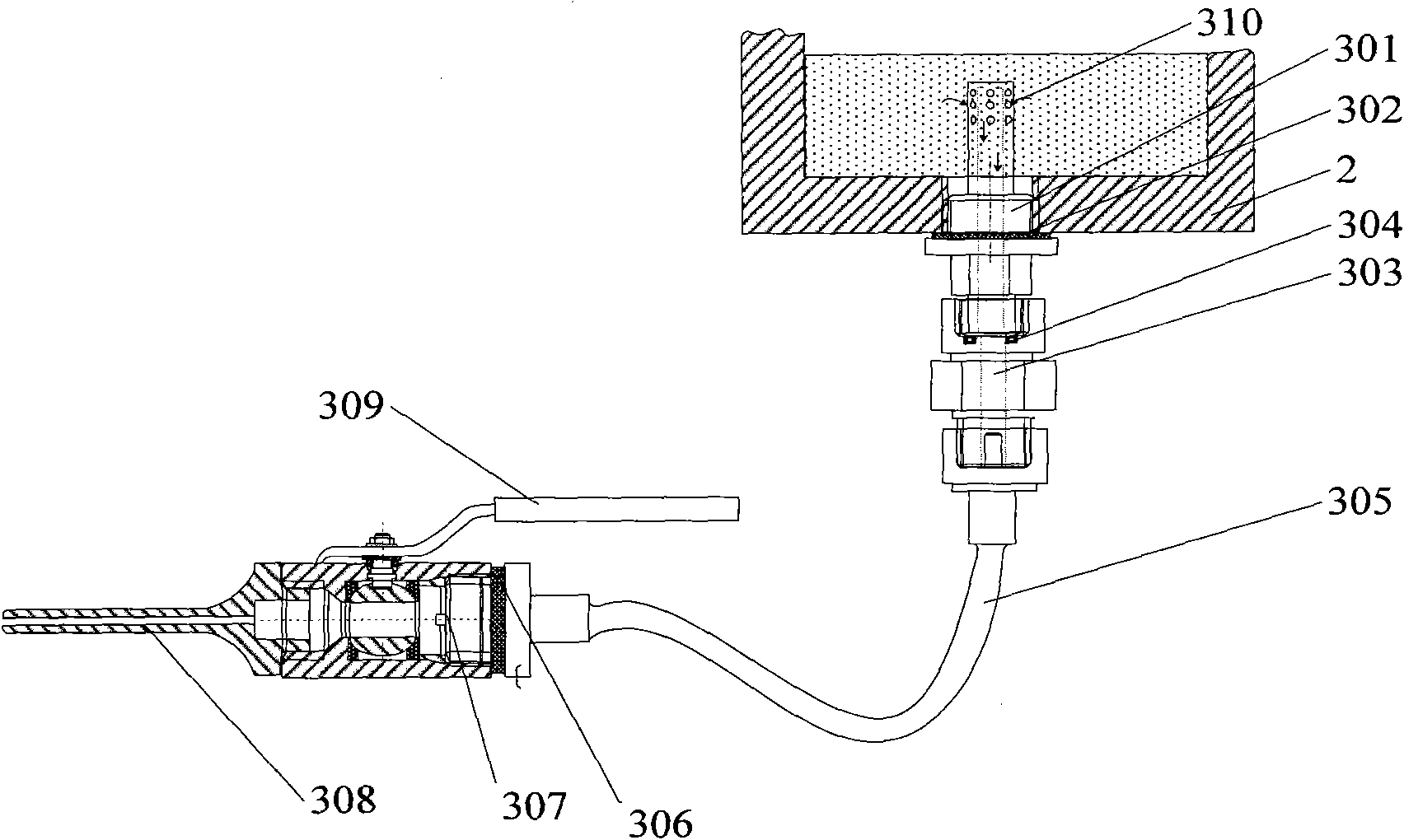

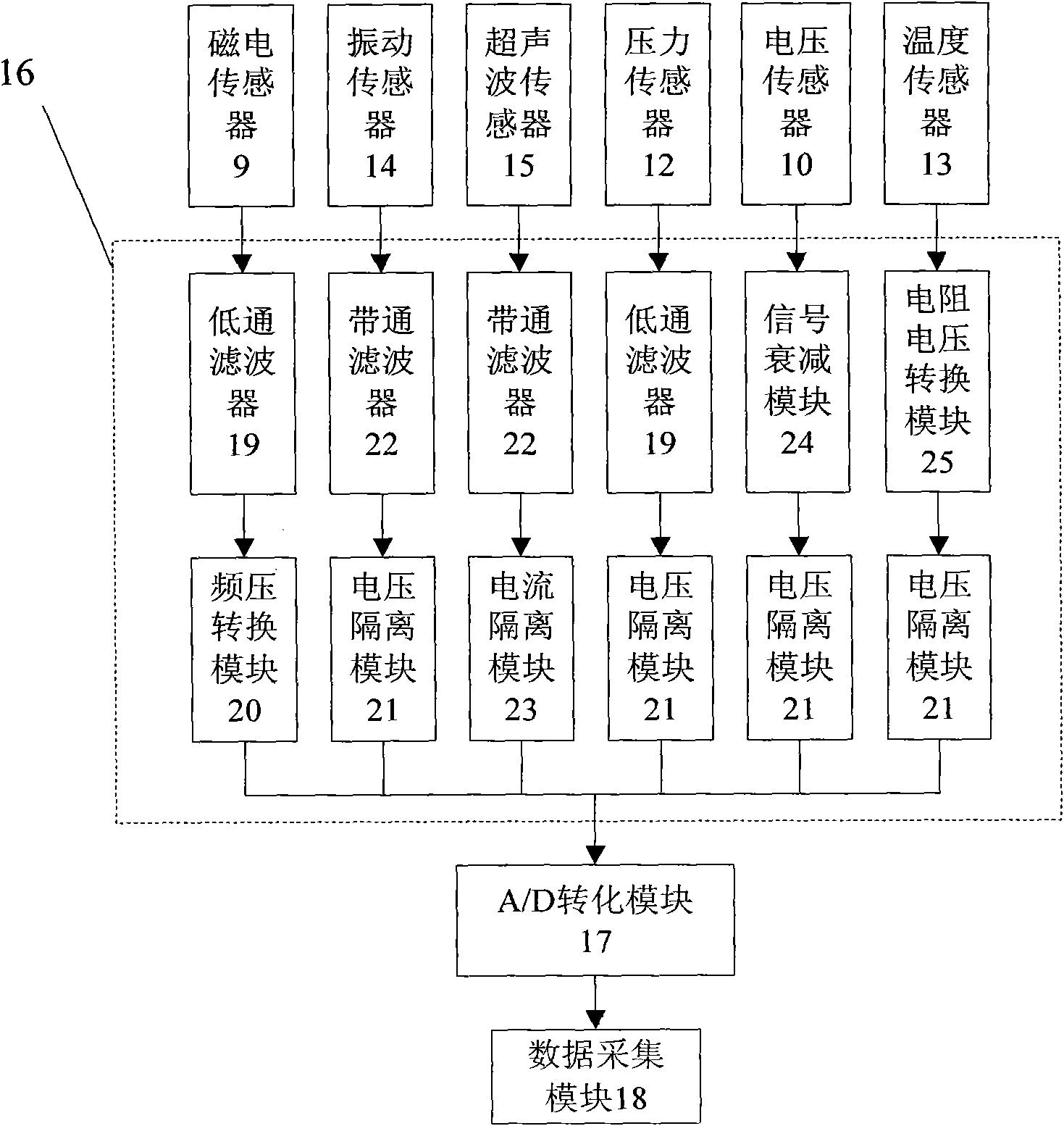

[0015] like figure 1 As shown, the present invention includes a reciprocating engine 1, which is arranged on a test bench support (not shown in the figure). The oil outlet of the oil pan 2 in the reciprocating engine 1 is connected to the input end of an oil extraction device 3, and the output end of the oil extraction device 3 passes through an oil preprocessor 4 and an oil data analysis storage module 5 in sequence Connect to a fault diagnosis module 6. Flywheel 7 and spark plug 8 in the reciprocating engine 1 are connected with a magnetoelectric sensor 9 and a voltage sensor 10 respectively; Temperature sensor 13, the top of cylinder 11 connects a vibration sensor 14 and an ultrasonic sensor 15, and all the signals that all sensors detect are all input in a signal conditioning box 16 through cable, remove signal interference. The processed signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com