Method for diagnosing failure of rotary machine by fusing oil and vibration

A technology for rotating machinery and fault diagnosis, which is used in the testing of mechanical components, machine gear/transmission mechanism testing, and machine/structural component testing. It can solve problems such as unreliable diagnostic results, and improve accuracy and precision Effect

Active Publication Date: 2013-07-17

广研检测(广州)有限公司

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the diagnostic results given by a single method are not reliable in many cases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

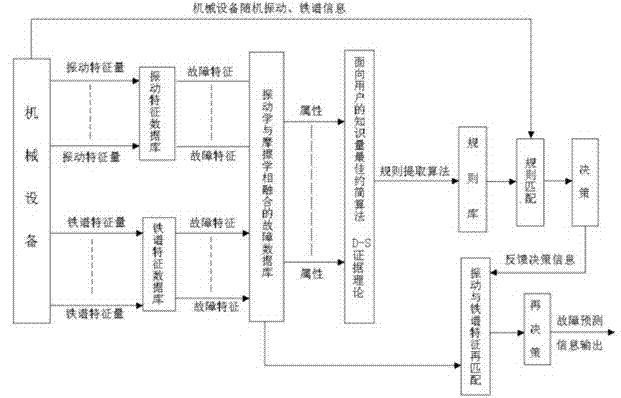

The invention discloses a method for diagnosing a failure of a rotary machine by fusing oil and vibration. The method comprises the following steps of: establishing a vibration characteristic database and a ferrographic characteristic database of the rotary machine respectively; fusing the vibration characteristic database and the ferrographic characteristic database to form a failure database; reducing and fusing the failure database to form a rule base consisting of a plurality of rules; performing rule matching to obtain a decision pre-making information; performing decision remaking for failure prediction by matching the failure database according to the decision pre-making information to obtain re-prediction information; and outputting the re-prediction information. The vibration characteristic database obtained by vibration analysis and the ferrographic characteristic database obtained by oil analysis are comprehensively used for failure diagnosis, so that failure diagnosis accuracy is improved; and in addition, a failure decision is pre-made by failure matching, and the decision pre-making information is matched with the failure database to obtain re-predicted failure diagnosis information, so that the failure diagnosis accuracy is further improved.

Description

technical field [0001] The invention relates to the field of fault diagnosis of rotating machines, in particular to a method for diagnosing faults of rotating machines combining oil and vibration. [0002] Background technique [0003] CNC machine tools generally work under heavy load or high speed, and their rotating parts and transmission systems are prone to failure. The main forms of wear failure are abrasive wear, corrosion wear and fatigue wear, and this type of failure is very harmful. The initial failure will make the machine tool work unstable and reduce the machining accuracy. If it is not dealt with in time, it will cause the entire machine tool to fail to work. [0004] Therefore, it is very important to predict and diagnose the wear of the rotating parts of the machine tool and the transmission system. On the one hand, the vibration signal of the machine tool carries a large amount of information reflecting the wear status of the parts. On the other hand, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M13/00G01M13/02

Inventor 陈堂敏

Owner 广研检测(广州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com