A Design Method to Solve the Inconsistency of the Highlights of the Body Shape

A design method and body technology, applied in geometric CAD, special data processing applications, etc., can solve problems such as time-consuming and labor-intensive, low work efficiency, uncontrollable profile quality, etc., to avoid half-way rework, save manpower, shorten The effect of the project cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

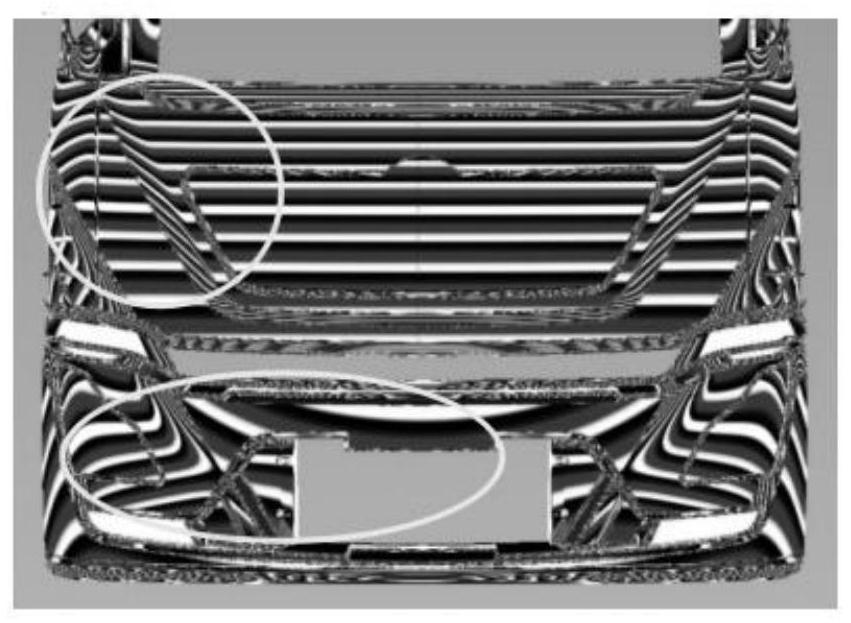

[0040] like figure 1 As shown, the front cover is not related to the highlight trend of the bumper face, the mask system is straight from the middle and then goes down to both ends, the bumper is concave from the middle to the two ends and gradually descends, and the highlight trend tends to be the same after the change (such as figure 2 shown).

Embodiment 2

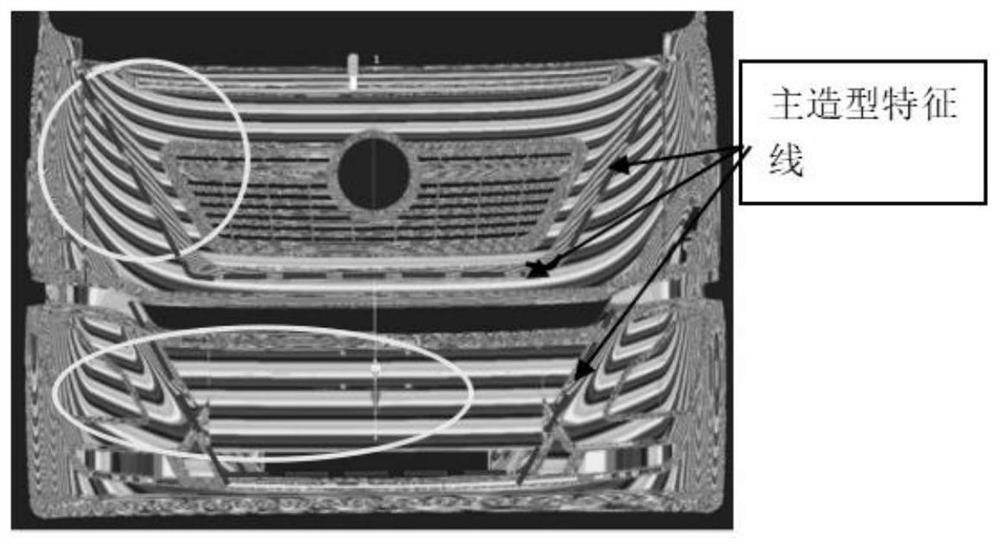

[0042] The trend of D320 side wall system profile highlights gradually descends from the front of the car to the rear of the car (such as image 3 In terms of modeling concept, the trend of highlight should be consistent with the trend of the main modeling feature line (waist line, side contour line). the trend is consistent (such as Figure 4 In terms of profile feel, the light and shadow flow freely with the body characteristics, regular and orderly, gorgeous and colorful, and the profile quality feels good, and the latter image is obviously better than the former.

Embodiment 3

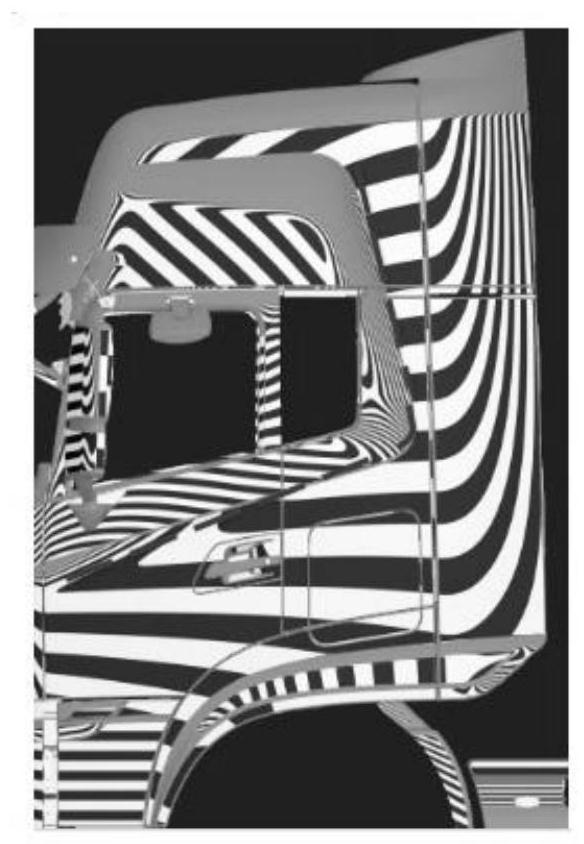

[0044] Step 1: Take the basic surface of the mask as an example, the initial light and shadow are as follows Figure 5 As shown (the light source in the next step is the Z direction, and the Z direction light source is very important for the highlight inspection of the profile quality), according to the light and shadow effect, it shows that the U\V is straight without radian, and there is no feature change, and the profile design rules require U, The radian in the V direction is required to ensure that the appearance of the appearance parts is full and powerful.

[0045] The second step: as Image 6 Light and shadow, two control points (select) are arranged horizontally in the U direction of the profile and pulled up along the Z direction. The size of the pull-up vector can be determined according to the change of light and shadow and the designer's expectation of light and shadow. The control point vector is attenuated as a whole. Changes, the V-direction flat radian is 1mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com