Measuring device capable of achieving real-time measuring of geometric dimensioning of cross section of sample and application thereof

A technology for measuring device and geometric dimension, applied in the field of measuring device, which can solve the problems of large dimensional change, very large deviation between engineering stress and true stress, and unable to represent true stress-strain behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

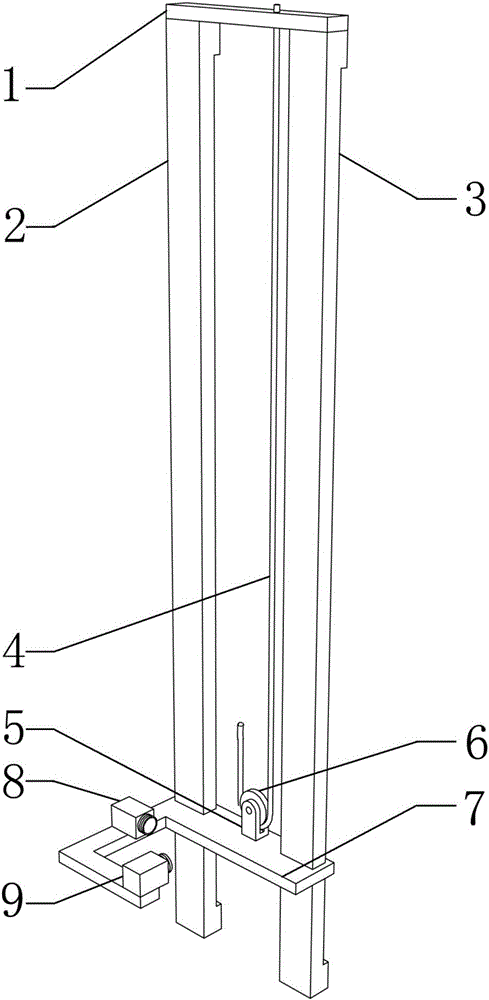

[0058] The transmission form of the driving device of the measuring device is a belt transmission, and its driving device is composed of a steel wire rope 4, a pulley seat 5, and a pulley 6. The bracket is composed of a top plate I1, a guide rail I2, and a guide rail II3. The top plate I1 is connected to the guide rail I2 and the guide rail II3 respectively. The upper end is fixedly connected, the guide rail I2 and the guide rail II3 are arranged in parallel, the pulley seat 5 is fixed on the mobile platform I7, the pulley 6 is fixed on the pulley seat 5 through the rotating shaft, and can rotate freely around the rotating shaft, and the steel wire rope 4 passes through the pulley as shown in the figure 6. One end of the steel wire rope 4 is fixedly connected to the movable part 22 of the tensile tester, and the other end is fixedly connected to the top plate I1. The guide rail I2 and the guide rail II3 pass through the two through holes on the mobile platform I7 to slide and co...

Embodiment 2

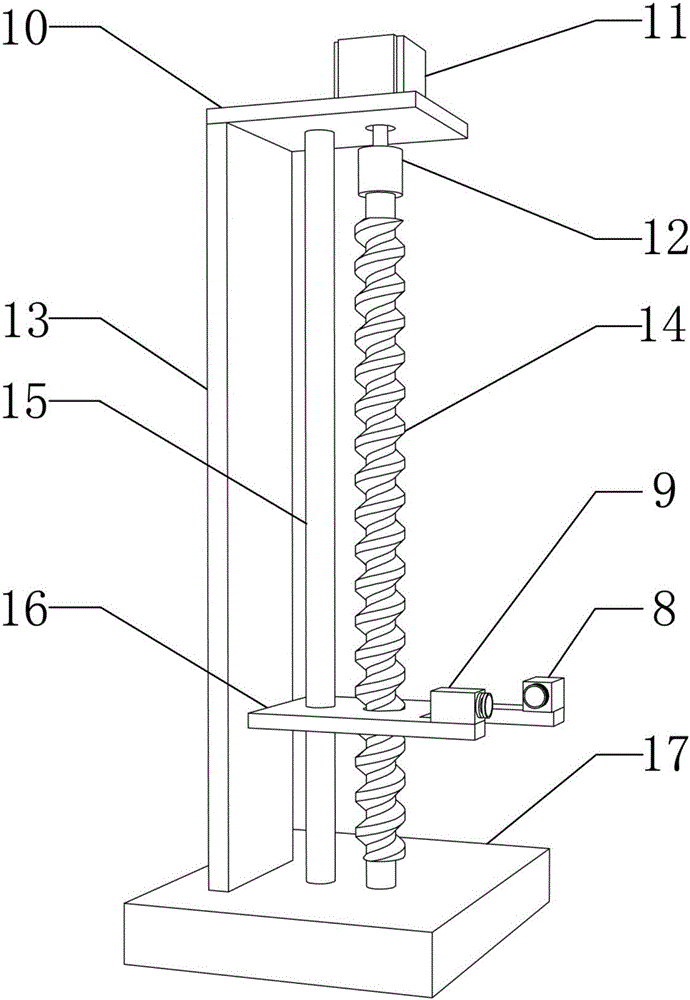

[0061] The transmission form of the driving device of the measuring device is a screw drive, and its driving device is a stepping motor 11, a shaft coupling 12, a screw rod 14, and the support is a top plate II10, a side plate 13, a cylindrical guide rail 15, a base 17, and the top plate II10 and The top of the side plate 13 and the cylindrical guide rail 15 are fixedly connected, the base 17 is fixedly connected with the bottom end of the side plate 13 and the cylindrical guide rail 15, the cylindrical guide rail 15 passes through the through hole on the mobile platform II 16 and is slidably connected with it, and the stepping motor 11 is fixed on the On the top plate II10, the coupling 12 fixedly connects the output shaft of the stepping motor 11 to the upper end of the screw rod 14, the screw rod 14 passes through the matching screw hole on the mobile platform II16, and the bottom end of the screw rod 14 is rotationally connected to the base 17.

[0062] When the stepper mot...

Embodiment 3

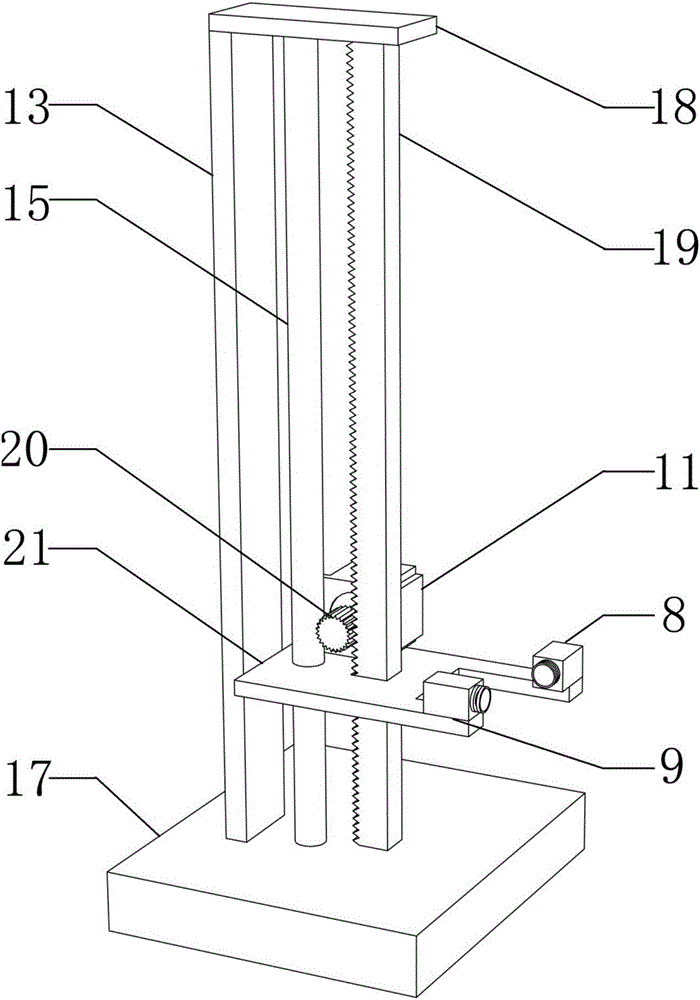

[0064] If the transmission form of the driving device of the measuring device is a gear transmission, its driving device is a stepper motor 11, a rack 19, a gear 20, and the support is a top plate III18, a side plate 13, a cylindrical guide rail 15, a base 17, and the top plate III18 and The top of the side plate 13 and the cylindrical guide rail 15 are fixedly connected, the base 17 is fixedly connected with the bottom end of the side plate 13 and the cylindrical guide rail 15, the cylindrical guide rail 15 passes through the through hole on the mobile platform III 21 and is slidably connected with it, and the stepping motor 11 is fixed on the On the mobile platform III21, the gear 20 is fixedly connected to the output shaft of the stepping motor 11, the teeth on the rack 19 mesh with the teeth on the gear 20, the top of the rack 19 is fixedly connected to the top plate III18, and the bottom of the rack 19 Fixedly connected with the base 17, the rack 19 passes through the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com