Novel brake disc for trailer axle

A brake disc, a new type of technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of poor heat dissipation performance of brake discs, hidden dangers in safe driving, etc., to avoid continuous high temperature, excellent heat dissipation performance, Increase the effect of cooling holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

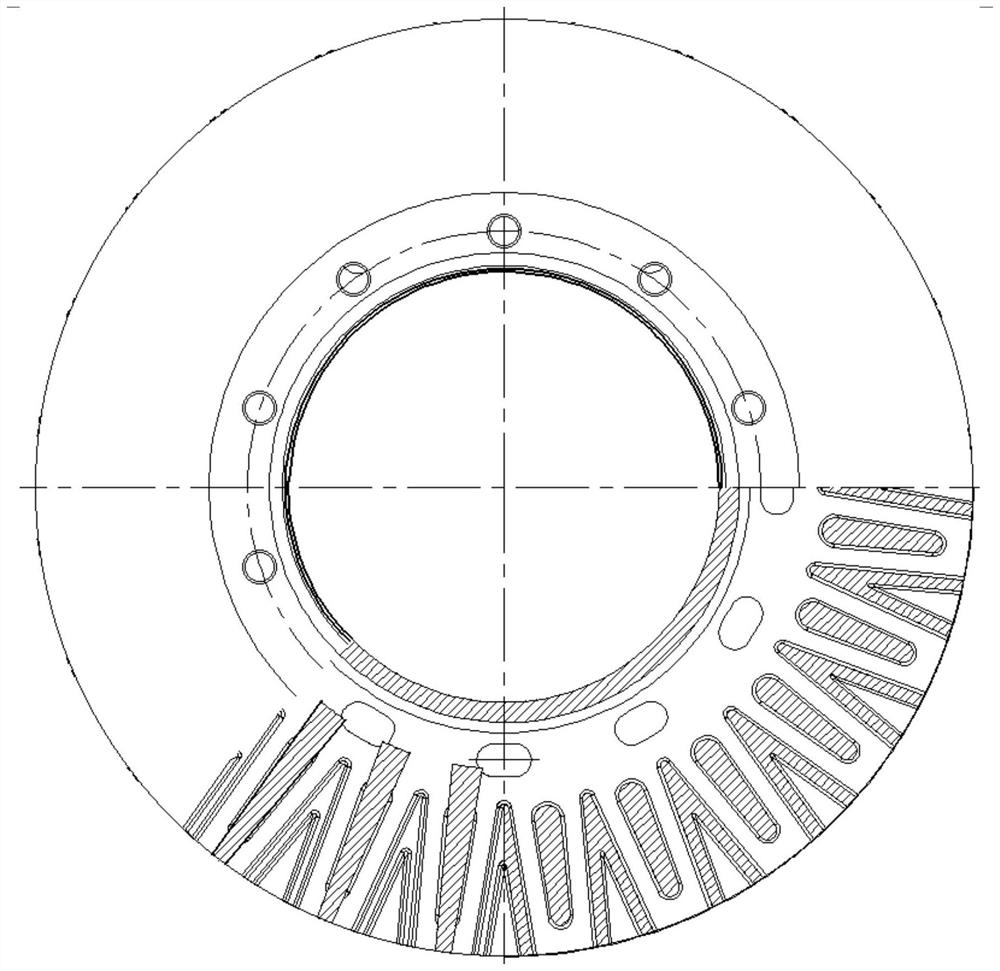

[0012] Embodiment: the invention provides a kind of technical scheme: as figure 1 As shown, a brake disc 1 is included. The brake disc is provided with 12 heat dissipation through holes along the inner circumference. The heat dissipation through holes are circular or rectangular, and the brake disc is provided with elongated ribs. The reinforcing ribs are distributed in V-shaped and I-shaped intervals, and are evenly distributed on the surface of the brake disc. The length of each reinforcing rib along the radial direction of the brake disc accounts for 1 / 2-3 / 4 of the size ratio of the brake disc

[0013] The brake disc is made of aluminum pottery, with tensile strength ≥ 330Mpa (the original material is 250Mpa) elongation

[0014] ≥5% (raw material is 1%).

[0015] The heat dissipation performance of the brake disc of this structure is more excellent, which avoids the hidden danger of the brake disc being continuously high temperature caused by continuous braking and seriou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com