Process for manufacturing glass goblets by machine blowing and machine pressing in sequence

A goblet and glass technology, which is applied in the field of making glass goblets by machine blowing and then machine pressing, can solve the problems of low authenticity rate, bulky products, and less shape change of cup holders, etc., so as to increase varieties of designs and reduce production Cost, the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

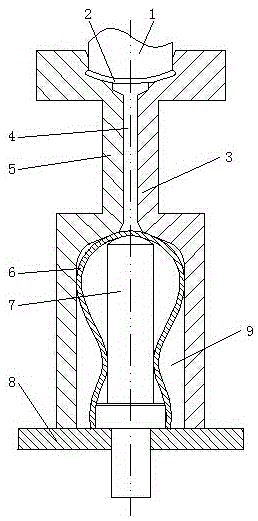

[0018] A process of making glass goblets by machine blowing and then machine pressing. The glass goblet is composed of a cup body, a cup stem and a cup holder. Its production process is: glass raw material→furnace melting material→feeding machine for cup body material → Blowing machine blows the cup body → Manually transfer the cup body to the fire cutting start-up incision → Manually transfer the cup body to the mold of the compression molding machine → The feeding machine supplies the cup stem and cup holder material → The compression molding machine presses and forms the cup stem And the cup holder and connect the cup stem with the outer bottom of the cup body→manually transfer the cup to the fire polishing machine for polishing→manually transfer the polished cup to the annealing furnace for annealing→exit the annealing furnace→inspect→package. The mold of the compression molding machine has two open molds. When the left module 5 and the right module 3 are closed, the inside...

Embodiment 2

[0020] A process of making glass goblets by machine blowing and then machine pressing. The glass goblet is composed of a cup body, a cup stem and a cup holder. Its production process is: glass raw material→furnace melting material→feeding machine for cup body material → Blowing machine blows the cup body → Manually transfer the cup body to the fire cutting start-up incision → Manually transfer the cup body to the mold of the compression molding machine → The feeding machine supplies the cup stem and cup holder material → The compression molding machine presses and forms the cup stem And the cup holder and connect the cup stem with the outer bottom of the cup body→manually transfer the cup to the fire polishing machine for polishing→manually transfer the polished cup to the annealing furnace for annealing→exit the annealing furnace→inspect→package. The mold of the compression molding machine has two open molds. When the left module 5 and the right module 3 are closed, the inside...

Embodiment 3

[0022] A process of making glass goblets by machine blowing and then machine pressing. The glass goblet is composed of a cup body, a cup stem and a cup holder. Its production process is: glass raw material→furnace melting material→feeding machine for cup body material → Blowing machine blows the cup body → Manually transfer the cup body to the fire cutting start-up incision → Manually transfer the cup body to the mold of the compression molding machine → The feeding machine supplies the cup stem and cup holder material → The compression molding machine presses and forms the cup stem And the cup holder and connect the cup stem with the outer bottom of the cup body→manually transfer the cup to the fire polishing machine for polishing→manually transfer the polished cup to the annealing furnace for annealing→exit the annealing furnace→inspect→package. The mold of the compression molding machine has two open molds. When the left module 5 and the right module 3 are closed, the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com