Painted veneered plywood bending device and use thereof

A veneer plywood and bending device technology, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of difficult construction due to material color difference, easy cracking of edge sealing interface, etc., to improve the decorative effect and The effect of quality, overall consistency, and smooth oil finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

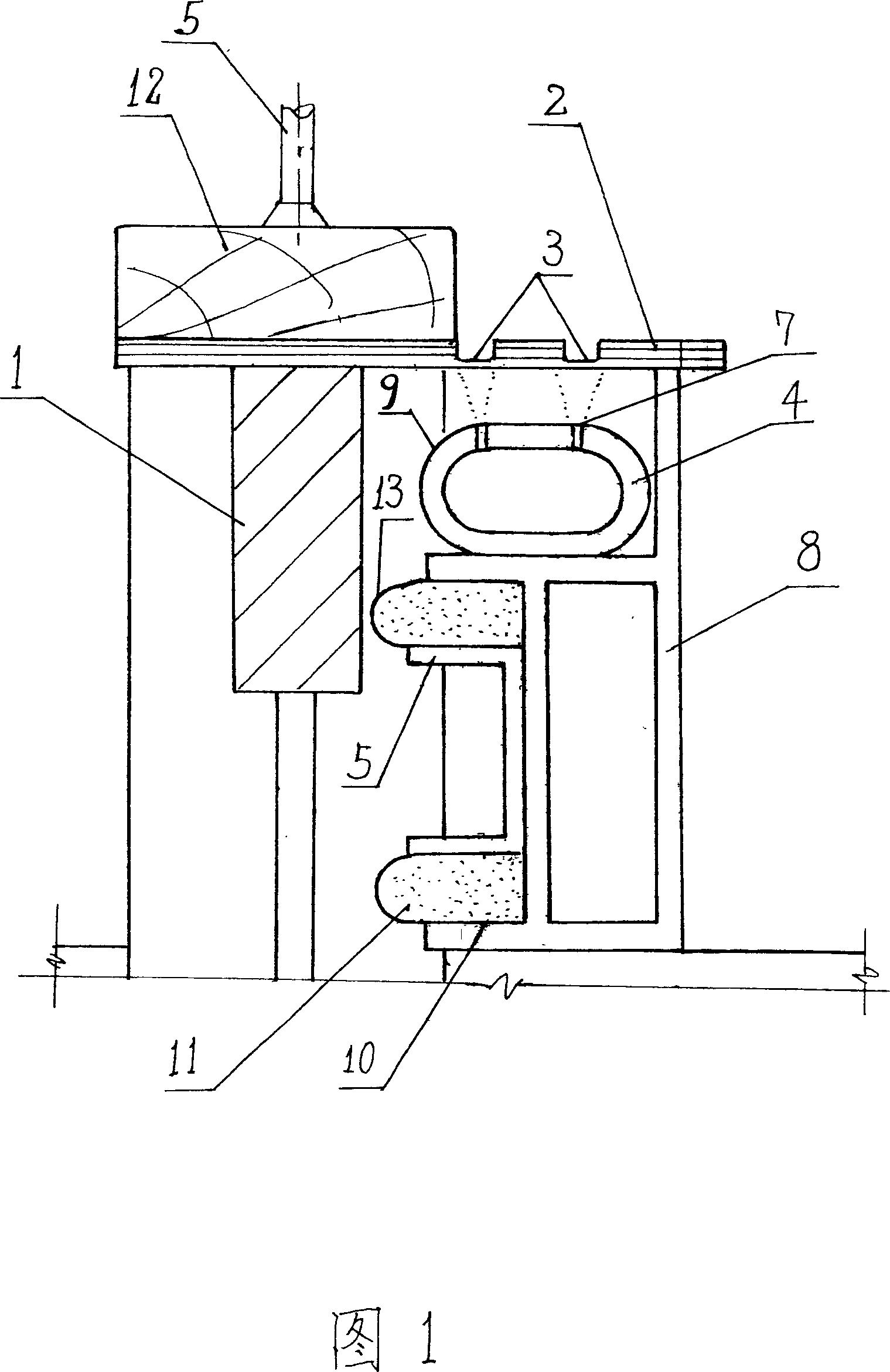

[0032] Fig. 1 is a schematic structural diagram of a first preferred embodiment of the present invention. Suitable for board processing. As shown in Figure 1, the present invention includes a pallet 1 for placing plywood veneers that need to be bent, and a bending groove 3 for plywood 2 that needs to be bent is provided on one side of the pallet 1. Heating device for steam heating 4.

[0033] In the above embodiment, it also includes a shaper 5 for pressing the bent part of the plywood 2 tightly against the core material for edge sealing to shape the bent part of the plywood.

[0034] In the above embodiment, it also includes a positioning device 6 for fastening and positioning the plywood; the positioning device 6 can be used to fasten and position the plywood after placing the core material to be veneered and edge-sealed on the plywood; The heating device can be divided into electric heating device or steam heating device for plywood with different thickness and different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com