Patents

Literature

36results about How to "Optimizing Traditional Processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method for crystallized fruit

The invention relates to a manufacturing method for crystallized fruit, which comprises the following steps: (1) preparing the following raw materials by weight percent: 20-67.7% of fruit embryos, 32.05-53.0% of sugar crops, 0.1-5% of filling materials, 0-5% of medicinal and food homologous traditional Chinese medicines, 0.05-10% of seasoning spices, 0.1-2.0% of preservatives and 0-5% of pigments; (2) pre-treating the raw materials by preparing liquid sugar, filling material liquid, traditional Chinese medicine extracts and preservative solution; (3) soaking: adding the liquid sugar material,the seasoning spices, the pigments, the liquid sugar, the filling material liquid and the traditional Chinese medicine extracts into a soaking cylinder and mixing uniformly to form the mixed materialliquid, adding the fruit embryos into the soaking cylinder, increasing the temperature of the mixed material liquid to 50-60 DEG C and keeping the temperature for 10-15 hours; (4) leaching and drying; and (5) drying to obtain the crystallized fruit. The manufacturing method for crystallized fruit is easily performed, the full utilization of fruit resource is realized, and the manufactured crystallized fruit is full of nutrition and tastes fresh and cool.

Owner:汕头市天悦轻工技术科技有限公司 +3

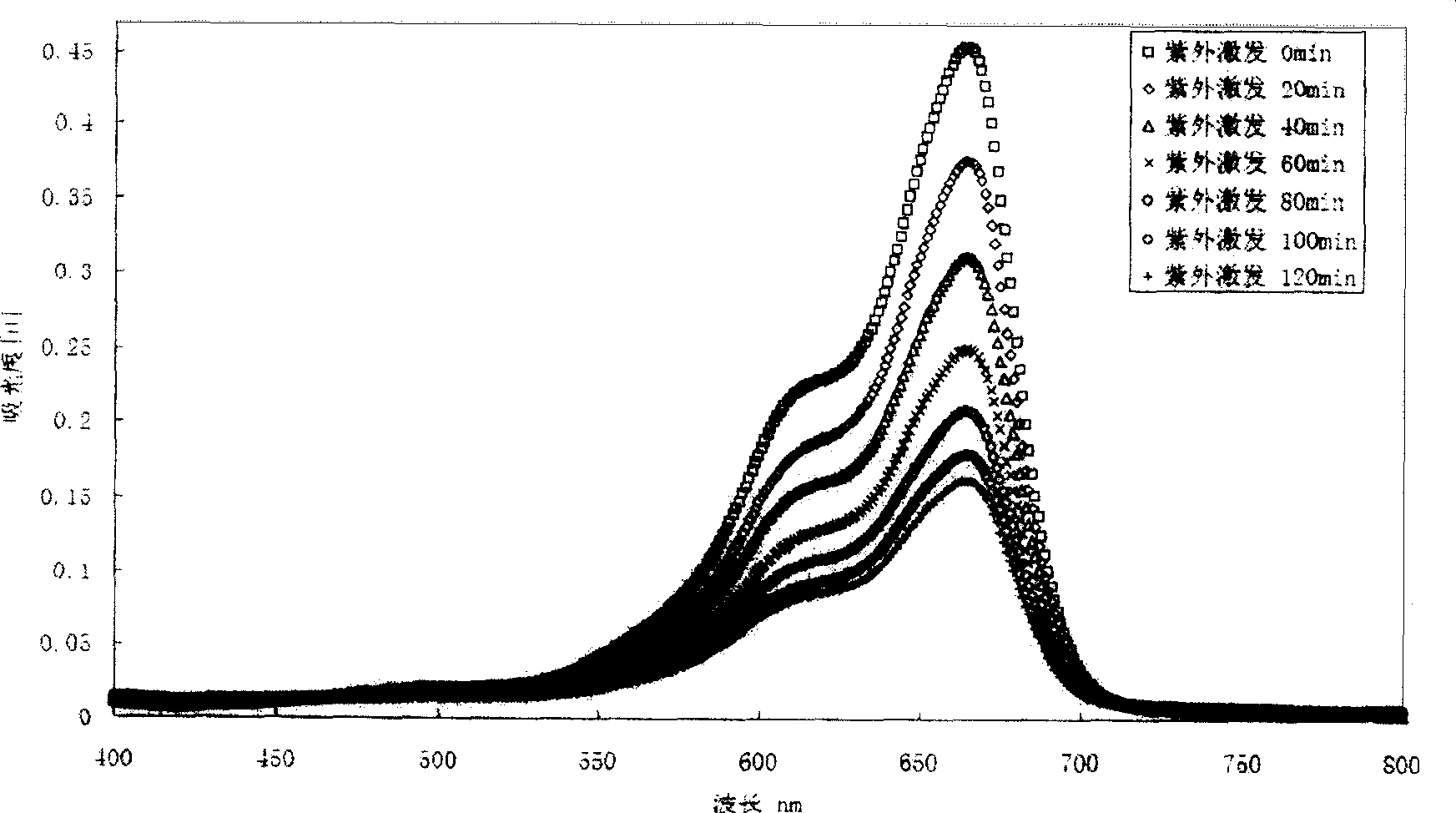

Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

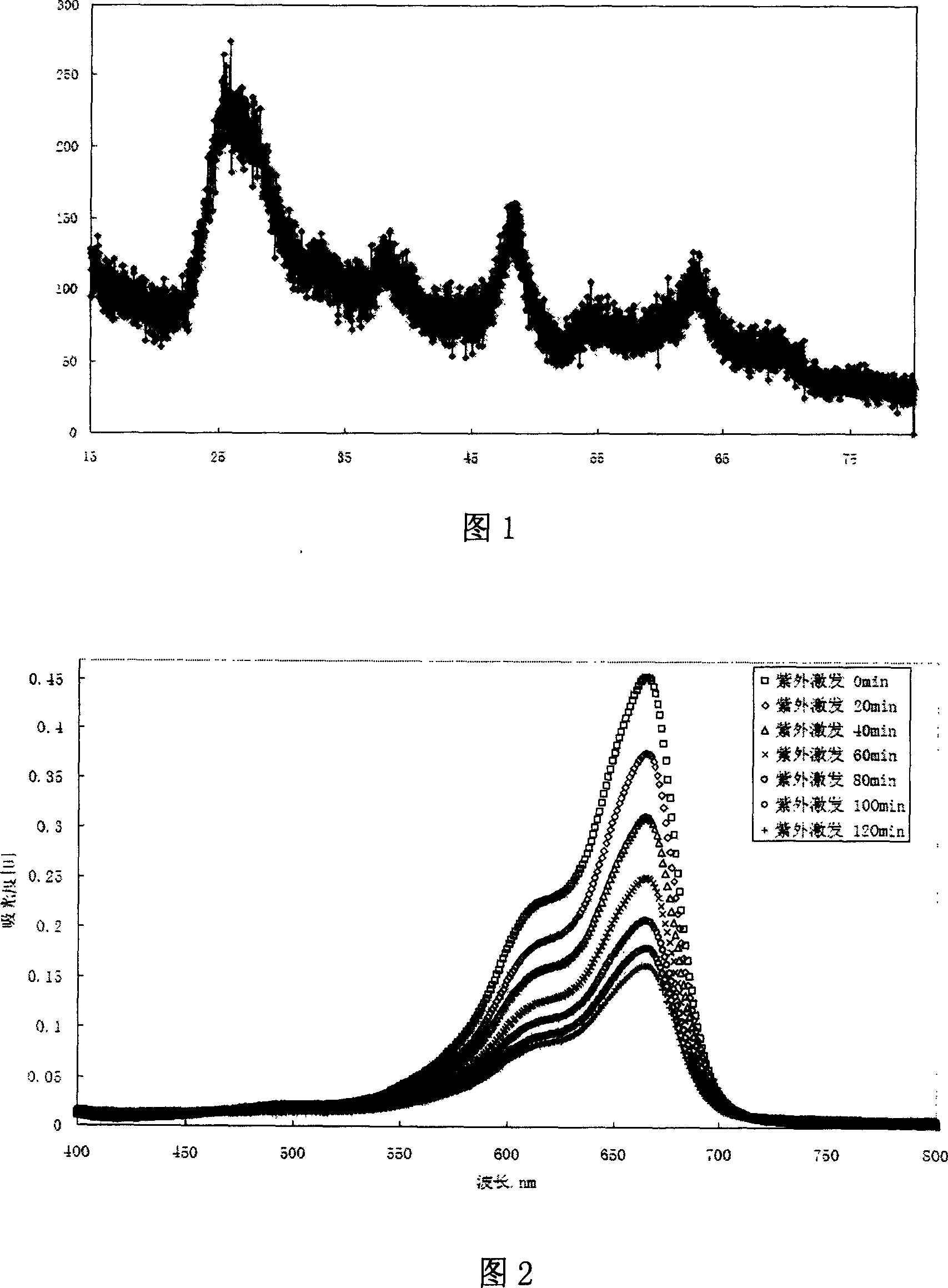

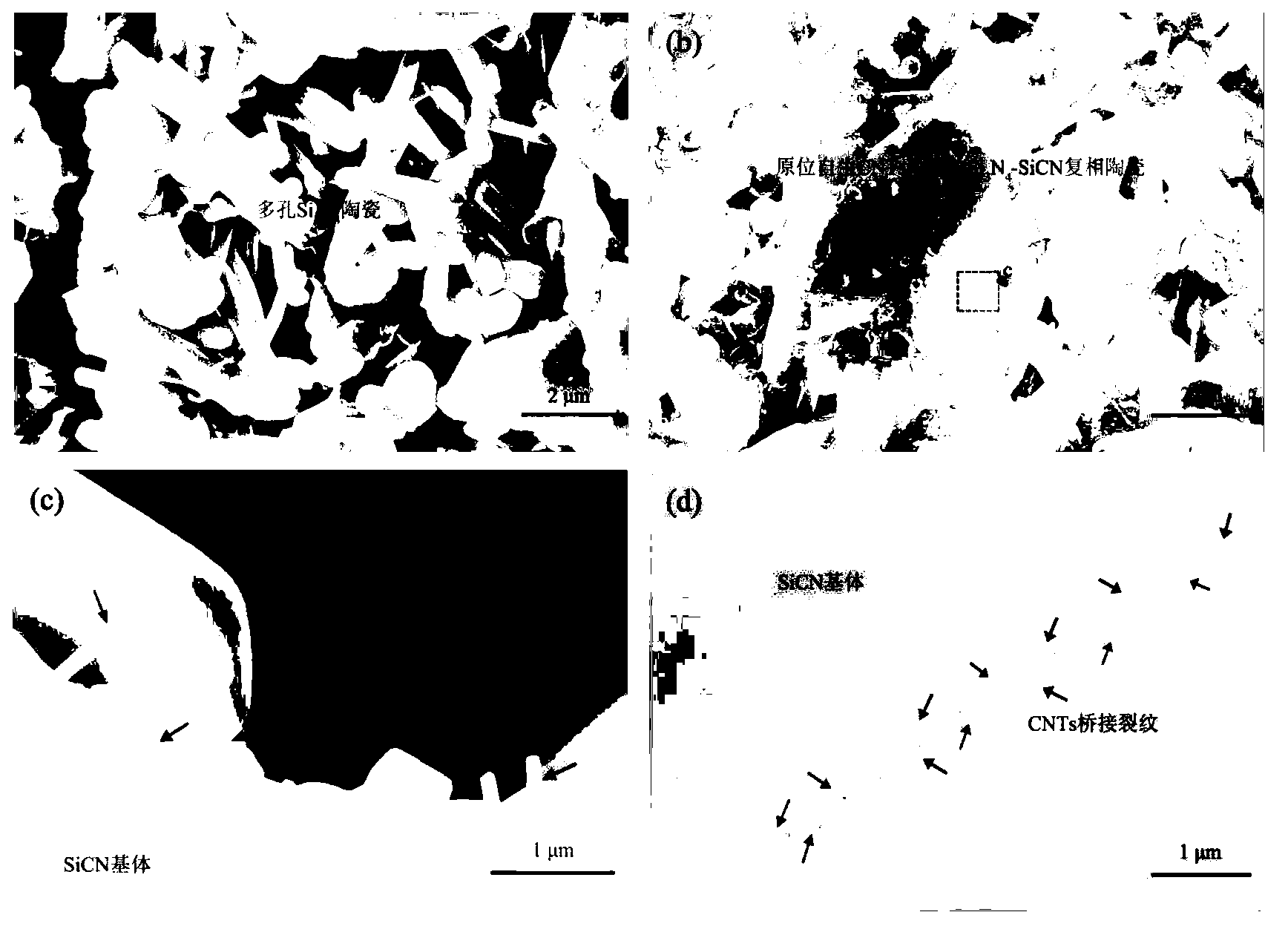

InactiveCN1935669AImprove photocatalytic activityStable storageTitanium dioxideNanocrystalTitanic acid

The invention belongs to an organic metal oxide-TiO2 photocatalyst preparing process, especially relating a synthesizing method of low temperature-crystallizing nanometer TiO powder and sol with high catalytic activity. And it obtains n-titanic acid deposit by making alkali neutralization and dilution hydrolyzation or heating hydrolyzation on titanic solution, and implements synthesizing related system nano crystal materials with normal-pressure and low-temperature liquid phases by such a processing process of re-dispersing the deposit by oxydol. And it largely reduces the cost of raw materials and avoids using titanium tetrachloride with strong corrosivity, reducing equipment requirements.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

CIGS powder, CIGS target, CIGS film and preparation method thereof

InactiveCN101613091ALow costSmall grain sizeSelenium/tellurium compundsVacuum evaporation coatingCompression moldingManufactured material

The invention provides CIGS powder, a CIGS target, a CIGS film and a preparation method thereof. The CIGS powder has a pure CuInxGa1-xSe2 phase, wherein x is more than 0 and is less than 1; and the CIGS target has a homogeneous CuInxGa1-xSe2 phase, and is obtained from the CIGS powder through cold isostatic pressing or compression molding and then sintering. The method for preparing the CIGS film comprises the steps of: depositing a layer of film by the CIGS target through a magnetron sputtering method, and then performing heat treatment on the film. The relative density of the CIGS target reaches over 95 percent, and the CIGS target has uniform components, has the homogeneous CuInxGa1-xSe2 phase, and has low production cost and steady performance. The preparation technology for the CIGS film greatly simplifies the prior process, and improves the utilization rate of raw materials and production efficiency.

Owner:CENT SOUTH UNIV

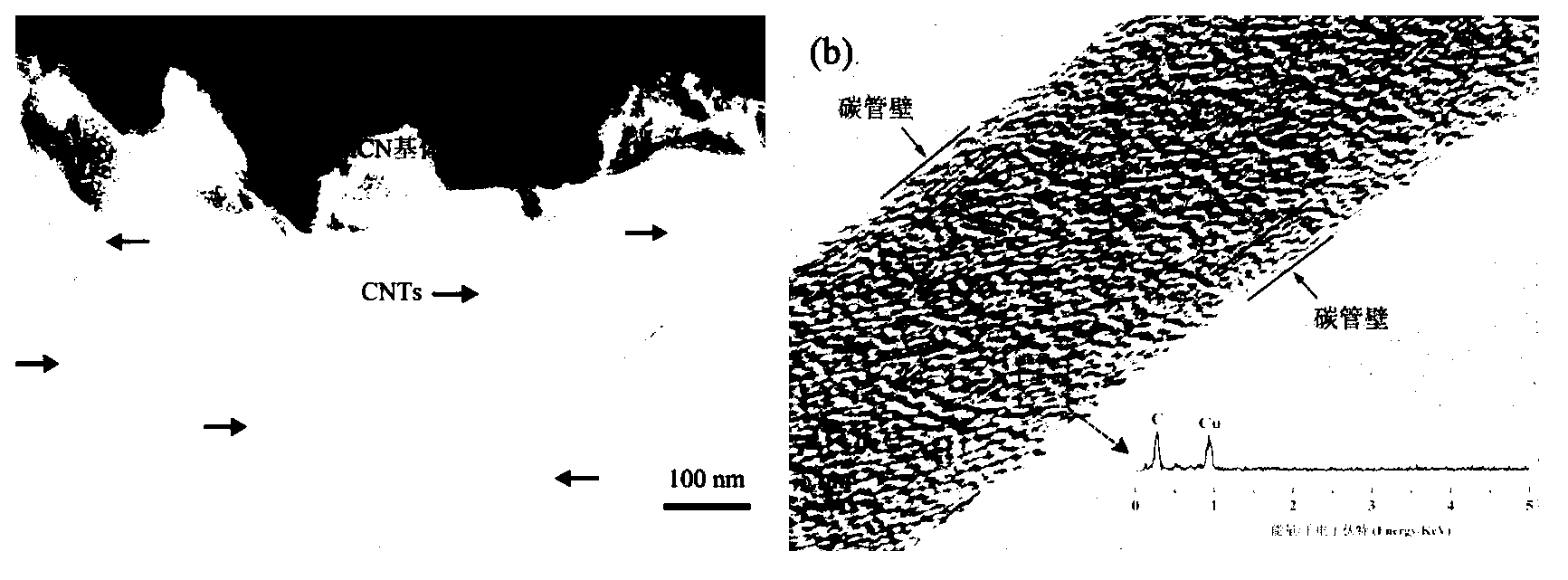

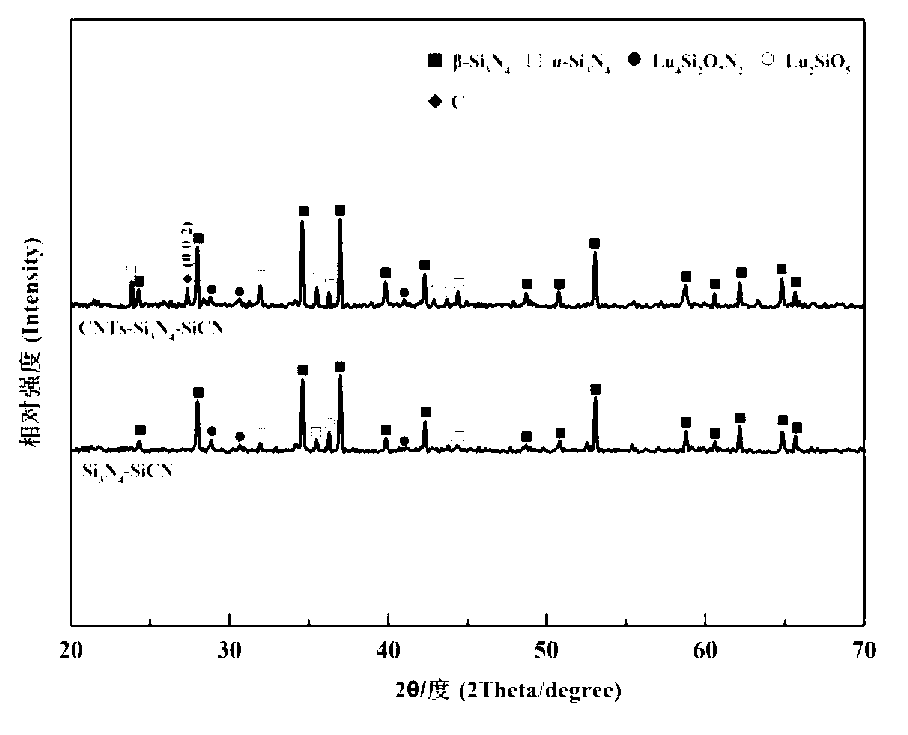

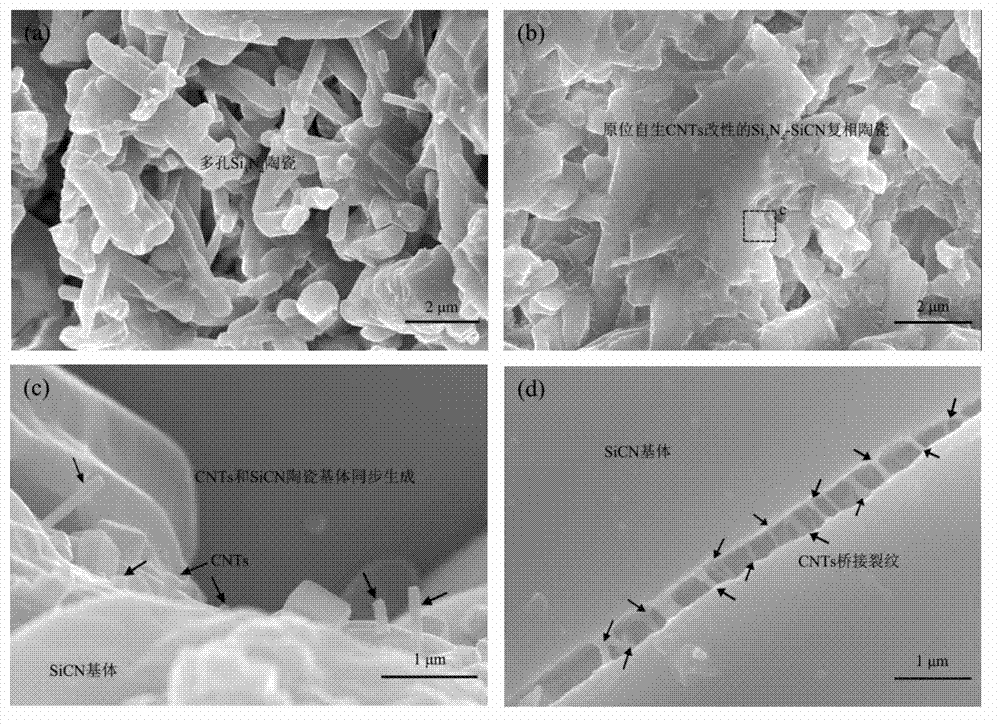

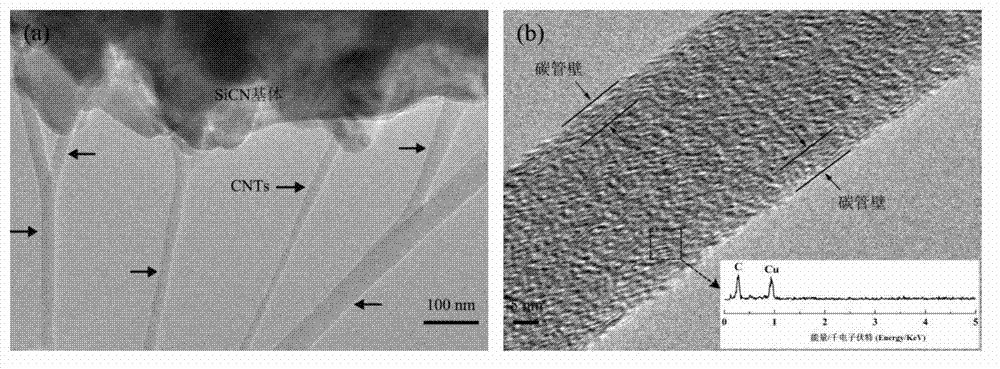

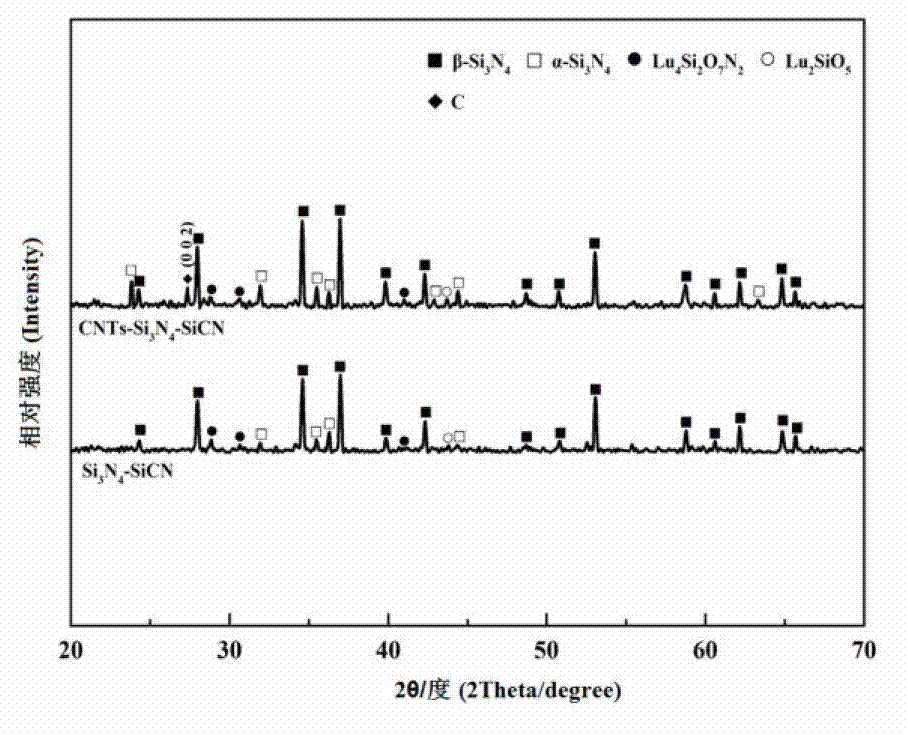

Preparation method of in-situ synthesized carbon nano-tube modified SiCN ceramic matrix composite material

ActiveCN103288466ASimultaneous Synthesis ImplementationOptimizing Traditional ProcessesNanoparticleCarbon nanotube

The invention discloses a preparation method of an in-situ synthesized carbon nano-tube modified SiCN ceramic matrix composite material so as to solve the technical problem that CNTs (carbon nano-tubes) and an SiCN ceramic matrix cannot be generated synchronously in existing CVD / CVI (chemical vapor deposition / chemical vapor infiltration) methods. According to the technical scheme involved in the invention, a CVD / CVI process is adopted, respectively, SiCl4, SiHCl3 or CH3SiCl3 is taken as a silicon source, CH4 or C3H6 is taken as a carbon source, NH3 is taken as a nitrogen source, H2 is employed as a bubbling carrier gas and reducing gas, and Ar is adopted as a diluent gas. By adding Fe(NO3)3.9H2O, Co(NO3)2.6H2O or Ni(NO3)2.6H2O and other metal salt catalysts, the Fe, Co, Ni nanoparticles produced by metal salt reduction can be utilized to capture a large number of free carbon atoms existing in the Si-C-N system, so that the purpose of synchronous synthesis of CNTs and the SiCN ceramic matrix on a base material can further be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method simultaneously extracting lipid and protein from corn plantule

InactiveCN101402670AHigh extraction rateHigh purityFatty-oils/fats refiningPeptide preparation methodsUltrasonic assistedCentrifugation

The invention discloses a method for extracting grease and protein simultaneously from cereal germs, and pertains to the technical field of comprehensive utilization of agricultural byproducts. The method comprises the comprehensive utilization of technologies of reversed micellar extraction, ultrasonic-associated extraction, protein refining, grease refining, drying and so on. Cereal germs are sieved after crushing, added into reversed micellar solution, stirred or ultrasonic forward extracted and centrifugated to obtain forward extraction solution, and the forward extraction solution is processed by ultrasonic backward extraction and centrifugation, the upper layer is extracted by ethanol to remove a residual surfactant, a solvent is removed to obtain grease and after water, salt and the surfactant are removed from the lower layer, cereal germ protein product is obtained; or the solvent in the forward extraction solution is directly removed, protein in a residual solid substance is precipitated by a mixed solvent, and then washing and drying are carried out to obtain the cereal germ protein product. The method has simple technology and low cost, solves the problem that the traditional grease production causes damage to protein, improves reutilization value of cereal germ protein, and is an environmental friendly production method. The product has the advantages of high yield rate, high purity, low chemical modification and the like.

Owner:JIANGNAN UNIV

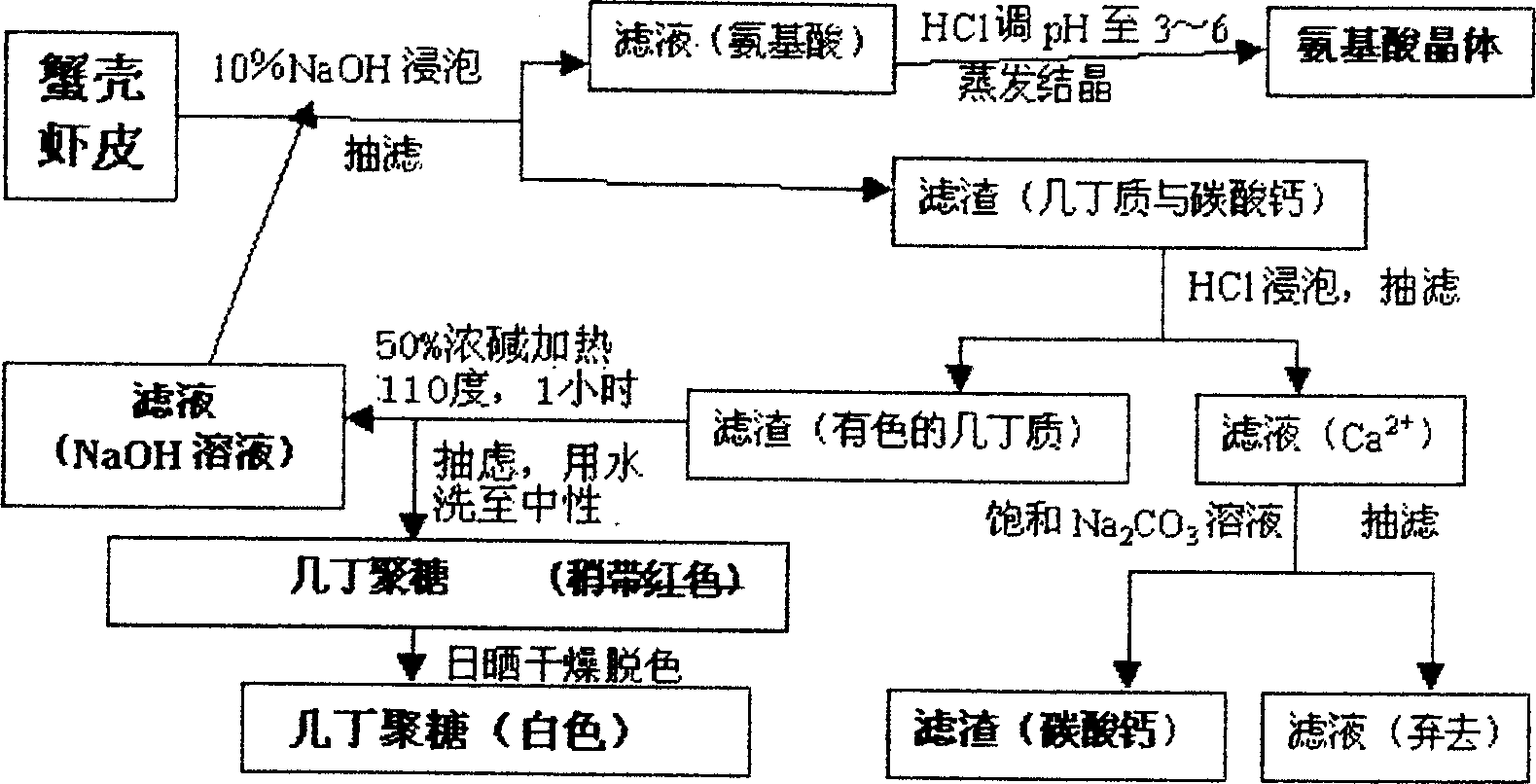

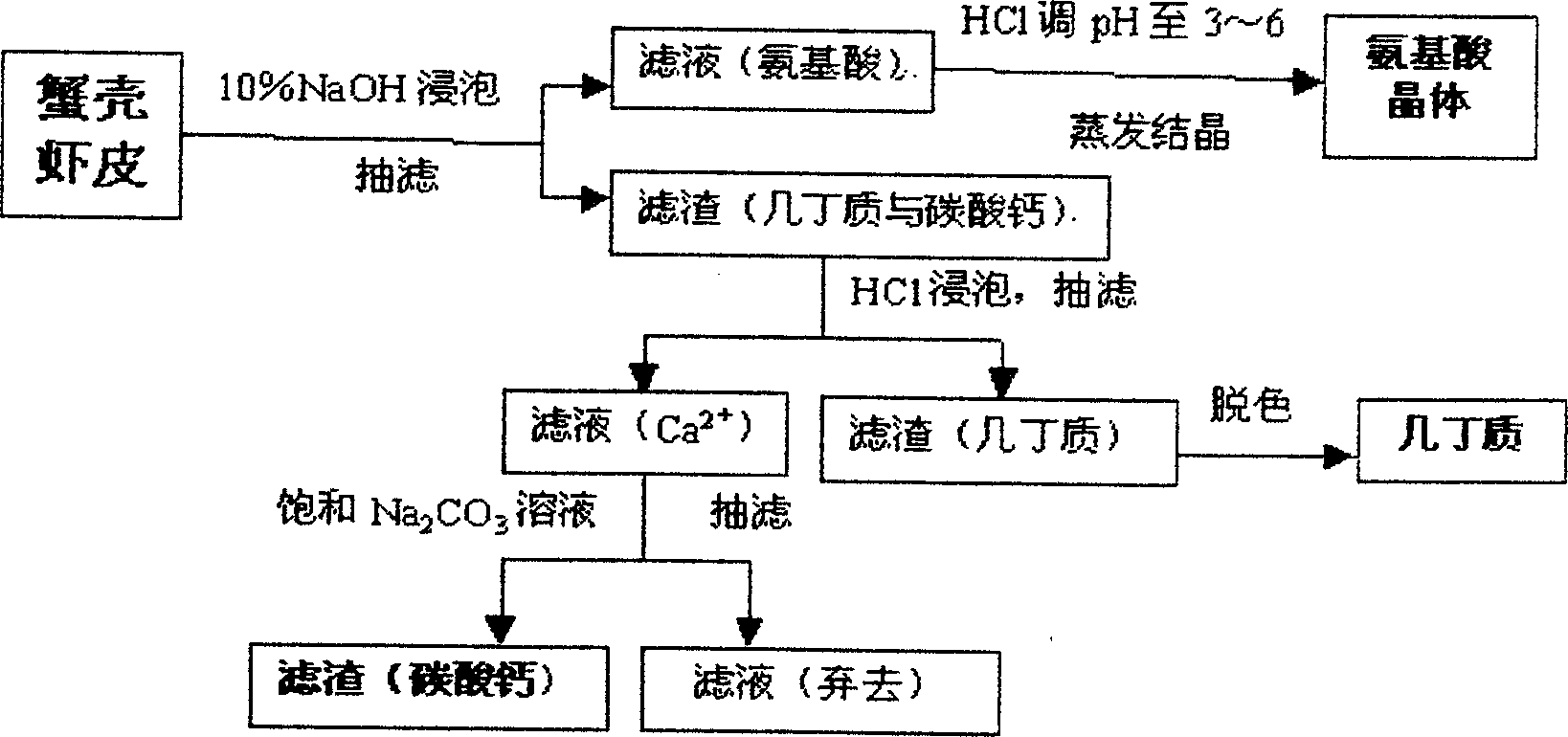

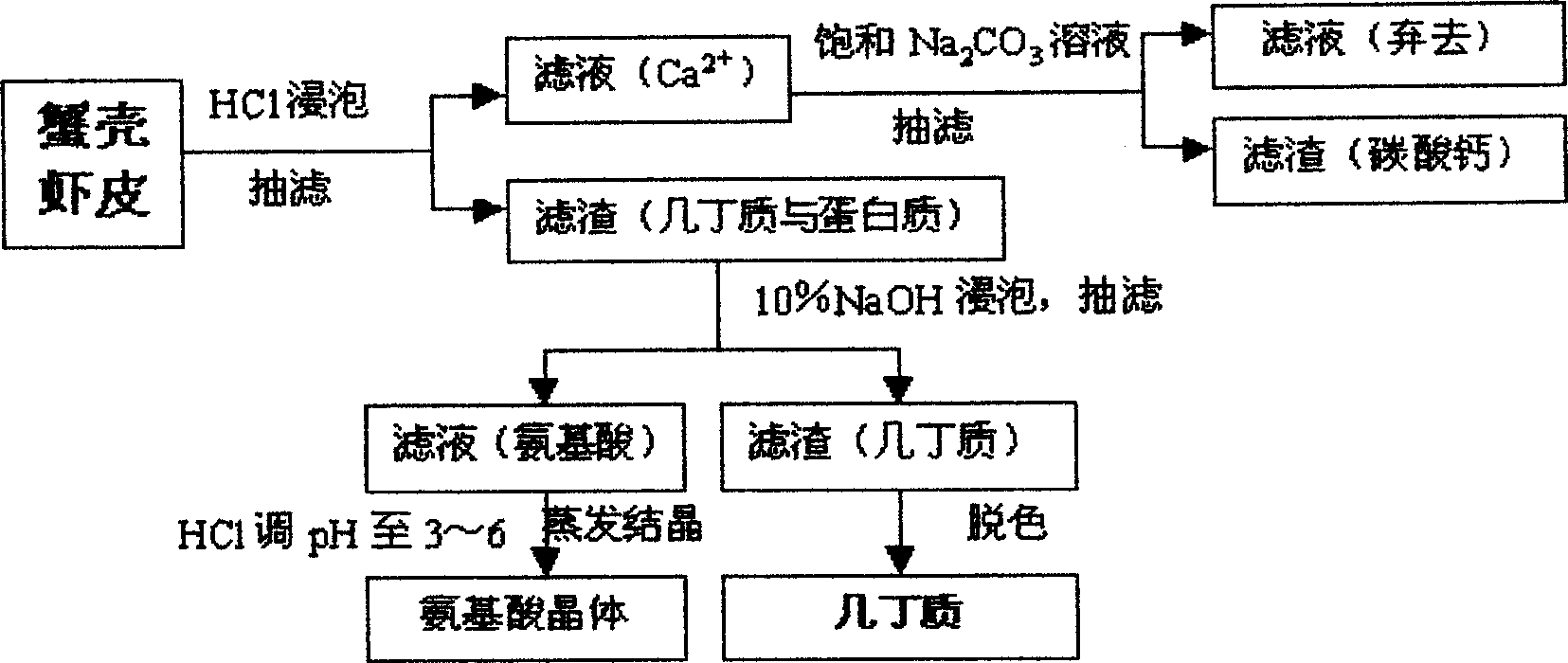

Treatment process of reusing crab and shrimp shell

InactiveCN1772769ATake advantage ofFully reflect the valueCalcium/strontium/barium carbonatesFood scienceChitin formationChloride

The treatment process of reusing crab and shrimp shell includes soaking crab and shrimp shell, eliminating calcium, filtering to obtain filtrate containing great amount of calcium chloride, adding sodium carbonate for reaction with calcium chloride to obtain calcium carbonate precipitate, filtering, water washing and drying to obtain white fine food level calcium carbonate powder; or, eliminating protein after the soaking step, filtering to obtain filtrate containing great amount of amino acids, regulating pH value of the filtrate to 3.5-6 to separate amino acids. The present invention can obtain chitin, edible calcium carbonate and protein from crab and shrimp shell in low sodium carbonate consumption. The present invention utilizes acid and base fully, has no toxic exhaust and is environment friendly.

Owner:SHANGHAI QIBAO HIGH SCHOOL

Producing process for crab foodstuff

InactiveCN1907130AGood effectImprove food safetyFood preparationManufacturing technologyElectric potential

The invention discloses a manufacturing technology of wine preserved crab can, which comprises the following steps: immersing crab in the acidifying oxide electric potential water for 30-60 min; washing through pure water; soaking through 16-22% ozone water for 1-3 h; washing through pure water; immersing through 30-40% edible salt for over 8 h; repairing crab; washing salt; adding allocated wine; sealing; freezing.

Owner:ZHEJIANG UNIV OF TECH

Method for producing flavor fermented blank bean

The invention relates to a method for producing flavor fermented blank bean. The flavor fermented blank bean comprises the following raw materials in parts by weight: 50-60 parts of original-flavor fermented blank bean, 1-5 parts of white spirits, 5-15 parts of edible salt, 1-5 pars of dried momordica grosvenori, 1-5 parts of glycyrrhiza uralensis, 0.25-1.25 parts of white sugar, 0.05-0.25 part of monosodium glutamate, 1-5 parts of radix puerariae, 1-5 parts of honeysuckle, 5-15 parts of red peppers, 5-15 parts of a ginger juice, and 10-15 parts of mashed garlic. With the raw materials and the improved fermented blank bean process, the prepared fermented blank bean has good taste and strong and pervasive bean fragrant, is suitable for different groups of people, and also can clear heat and remove toxicity.

Owner:李世权

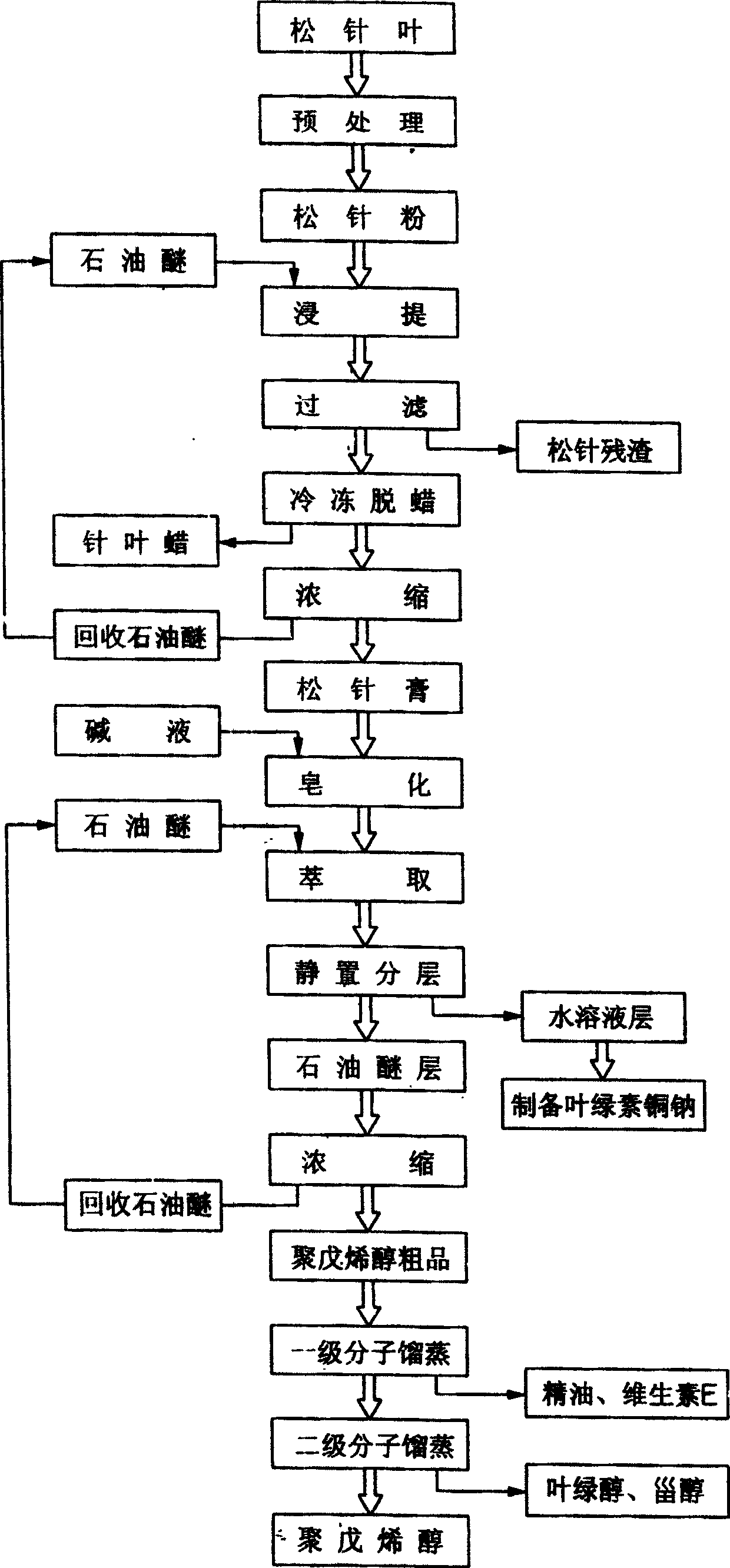

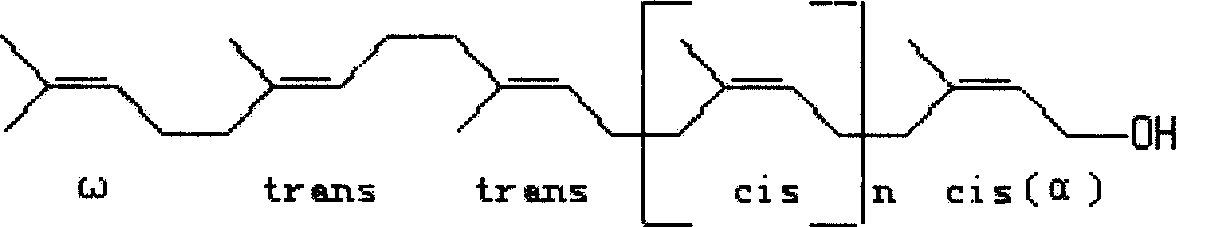

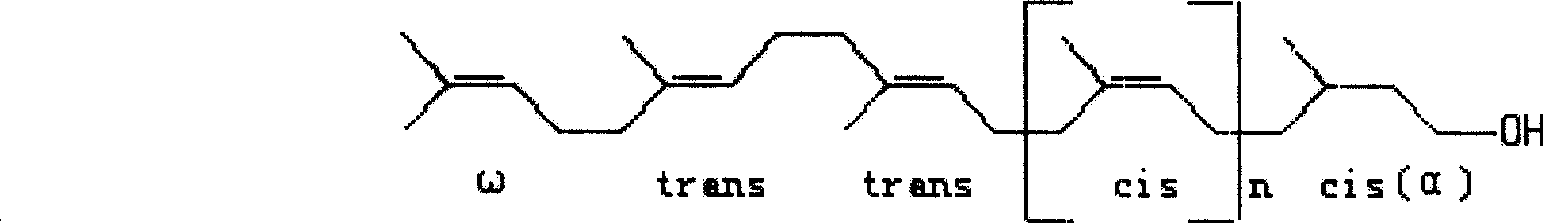

Method for preparing needle polyprenols by using solvent extraction method

InactiveCN101397239AHigh purityHigh yieldOrganic compound preparationChemical industryPharmaceutical industryDistillation method

The invention relates to a method for preparing coniferous polypentenol by adopting the solvent extraction method and the molecular distillation method; fresh pine branch tender leaves are dried and smashed into pine needle powder with 16 to 30 meshes as a raw material, petroleum ether is used for extraction, then the freezing dewaxing is carried out at the temperature of 0 to 25 DEG C, and a polyprenol crude product is prepared by concentration, saponification and extraction; the polyprenol crude product is separated and purified through a first-stage molecular distillation device and a second-stage molecular distillation device, thereby preparing a high-purity polyprenol finished product. The raw material is sufficient, the solvent extraction method and the molecular distillation method are projects with high efficiency, energy conservation and environmental protection; the prepared product has no solvent residue, and the purity thereof is high, thereby being in line with the modern requirements of green and environmental protection; and the method can not only improve the purity and the yield of the polyprenol, but also can be in line with the industrial production requirements, improve the traditional process and realize the clean production. The polyprenol product produced by the technology has higher purity and can be widely used in health care foods, nutrition supplements and bio-pharmaceutical industry.

Owner:中健行集团有限公司

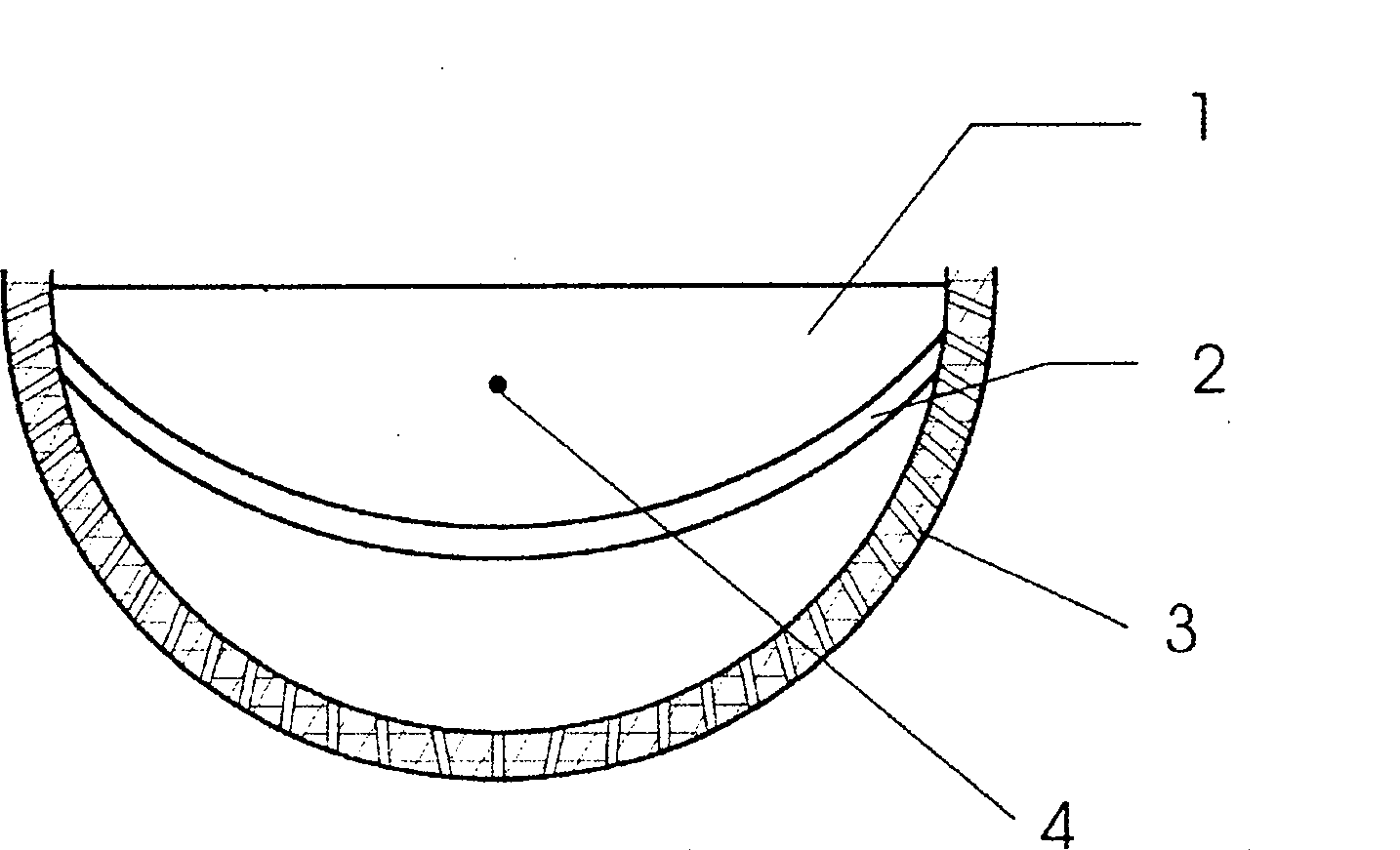

Manufacturing technology of binding basketball by machine and its special mould

ActiveCN100491101CReduce pollutionReduce labor intensityHollow inflatable ballsDomestic articlesManufacturing technologyVulcanization

A technology for making basket balls by mechanical sticking includes winding thread on an internal ball to form a wound thread layer, sticking rubber layer, sulfurizing, coating adhesive, arranging prefabricated 8 surficial pieces and the spacing strips in a dedicated mould, heating the mould while vacuumizing it for attaching them on the inner surface of said mould, putting said internal ball in mould, closing mould, and inflating the internal ball while heating the mould.

Owner:天津南华利生体育用品有限公司

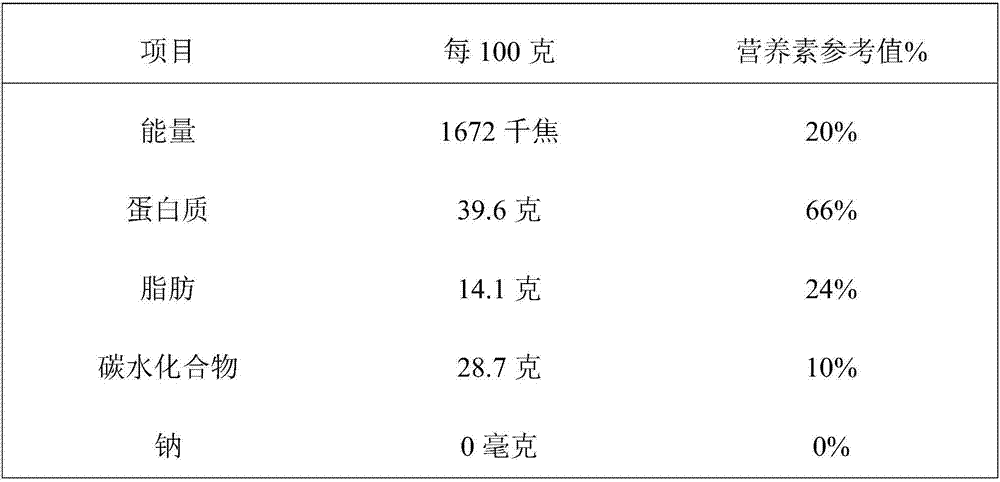

Method for extracting protein and dietary fibers from tea leaves

ActiveCN107475338AHigh purityReduce wasteDough treatmentPeptide preparation methodsFiberFood hygiene

The invention provides a method for extracting protein and dietary fibers from tea leaves. The protein and the dietary fibers are prepared in one step through subtractive extraction, enzymatic extraction and other methods. The method provided by the invention uses tea leaves as raw materials, extracts the tea protein and the dietary fibers under the assistance of the ultrasonic technique, and has advantages of high extraction rate of protein and fibers, high purity, low cost, simple and easy implementation, and easy popularization; the quality of products meets food hygiene standards; the invention provides a new way for value-added transformation and reuse of the tea leaves, develops a novel plant-derived protein and dietary fiber product, and realizes comprehensive utilization and intensive processing of tea leaf resources.

Owner:湖南省玉友林农业开发有限公司

Manufacturing method for crystallized fruit

ActiveCN102599321BNutritional diversityRefreshing tasteConfectionerySweetmeatsFilling materialsPreservative

The invention relates to a manufacturing method for crystallized fruit, which comprises the following steps: (1) preparing the following raw materials by weight percent: 20-67.7% of fruit embryos, 32.05-53.0% of sugar crops, 0.1-5% of filling materials, 0-5% of medicinal and food homologous traditional Chinese medicines, 0.05-10% of seasoning spices, 0.1-2.0% of preservatives and 0-5% of pigments; (2) pre-treating the raw materials by preparing liquid sugar, filling material liquid, traditional Chinese medicine extracts and preservative solution; (3) soaking: adding the liquid sugar material,the seasoning spices, the pigments, the liquid sugar, the filling material liquid and the traditional Chinese medicine extracts into a soaking cylinder and mixing uniformly to form the mixed materialliquid, adding the fruit embryos into the soaking cylinder, increasing the temperature of the mixed material liquid to 50-60 DEG C and keeping the temperature for 10-15 hours; (4) leaching and drying; and (5) drying to obtain the crystallized fruit. The manufacturing method for crystallized fruit is easily performed, the full utilization of fruit resource is realized, and the manufactured crystallized fruit is full of nutrition and tastes fresh and cool.

Owner:汕头市天悦轻工技术科技有限公司 +3

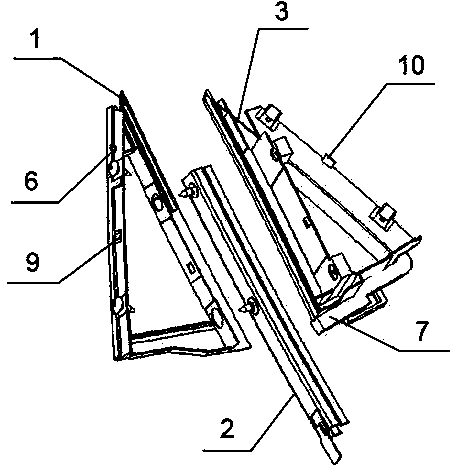

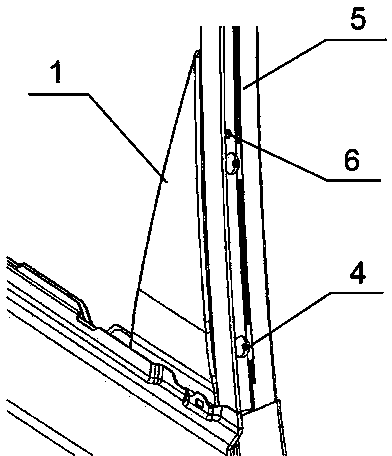

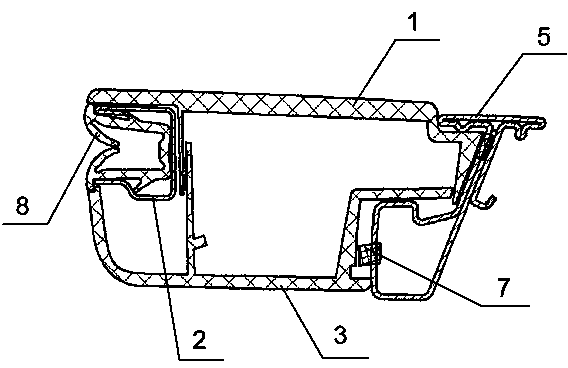

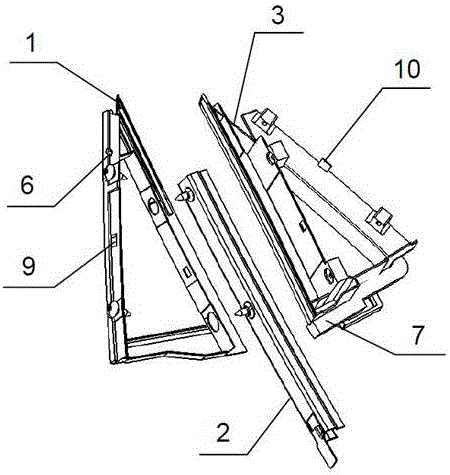

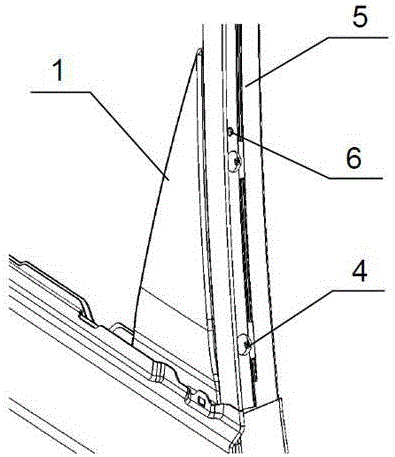

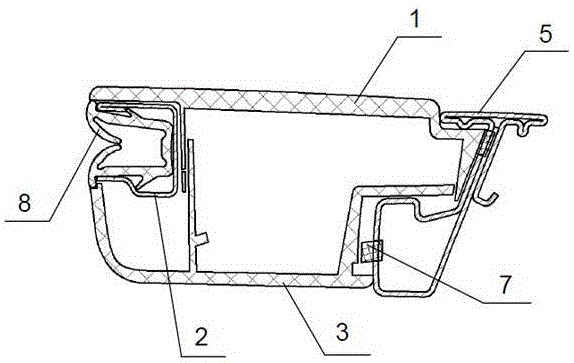

Automobile rear door triangular block assembly

ActiveCN104118302AReduce the difficulty of assemblyOptimizing Traditional ProcessesEngine sealsVehicle sealing arrangementsManufacturing technologyEngineering

The invention discloses an automobile rear door triangular block assembly, and relates to the technical field of automobile spare part manufacturing. The automobile rear door triangular block assembly comprises a rear door rear upper guide rail arranged between a triangular block outer plate and a triangular block inner plate, reinforcing rib plates are arranged on the triangular block outer plate and the triangular block inner plate respectively, clamping positions and clamping hooks are arranged on the reinforcing rib plates of the triangular block outer plate and the triangular block inner plate respectively, the clamping positions are paired with the clamping hooks, and the triangular block outer plate and the triangular block inner plate are connected into a whole through the clamping positions and the clamping hooks. Compared with the prior art, the automobile rear door triangular block assembly is simple in structure and capable of solving the problems that an existing rear door triangular block assembly is high in cost, difficult to assemble and poor in fit precision, fit clearance surface differences between the automobile rear door triangular block assembly and a rear automobile door window frame and glass are poor, natural beauty of transition of peripheral parts is influenced, rear door glass is difficult to assemble, and lifting resistance is large.

Owner:DONGFENG LIUZHOU MOTOR

Preparation method of in-situ synthesized carbon nano-tube modified SiCN ceramic matrix composite material

ActiveCN103288466BSimultaneous Synthesis ImplementationOptimizing Traditional ProcessesNanoparticleCarbon nanotube

The invention discloses a preparation method of an in-situ synthesized carbon nano-tube modified SiCN ceramic matrix composite material so as to solve the technical problem that CNTs (carbon nano-tubes) and an SiCN ceramic matrix cannot be generated synchronously in existing CVD / CVI (chemical vapor deposition / chemical vapor infiltration) methods. According to the technical scheme involved in the invention, a CVD / CVI process is adopted, respectively, SiCl4, SiHCl3 or CH3SiCl3 is taken as a silicon source, CH4 or C3H6 is taken as a carbon source, NH3 is taken as a nitrogen source, H2 is employed as a bubbling carrier gas and reducing gas, and Ar is adopted as a diluent gas. By adding Fe(NO3)3.9H2O, Co(NO3)2.6H2O or Ni(NO3)2.6H2O and other metal salt catalysts, the Fe, Co, Ni nanoparticles produced by metal salt reduction can be utilized to capture a large number of free carbon atoms existing in the Si-C-N system, so that the purpose of synchronous synthesis of CNTs and the SiCN ceramic matrix on a base material can further be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Processing technology for fermented dioscorea esculenta (Lour.) burkill freeze-drying sugar-free food

InactiveCN111567771AOptimize sweet and sour tasteSpecial sweet and sour tasteFood homogenisationFood dryingBiotechnologyProcess engineering

The invention discloses a processing technology for a fermented dioscorea esculenta (Lour.) burkill freeze-drying sugar-free food. The processing technology comprises the following steps of dioscoreaesculenta (Lour.) burkill raw material cleaning, curing, peel removing, pulping, inoculating, fermenting, homogenizing, freezing, dewatering, slicing and finished product packaging. In the step of dioscorea esculenta (Lour.) burkill raw material cleaning, pollutants on the surface of a dioscorea esculenta (Lour.) burkill raw material are washed by clear water. In the step of curing, the whole dioscorea esculenta (Lour.) burkill is put in a steamer tray, and the dioscorea esculenta (Lour.) burkill is completely cooked through steaming by water vapor; and in the step of peel removing, the temperature of the dioscorea esculenta (Lour.) burkill to be cooked by steaming is lowered to 50 DEG C, and the surface peel of the dioscorea esculenta (Lour.) burkill is removed with hands or scraped by astainless steel knife. The fermented dioscorea esculenta (Lour.) burkill freeze-drying sugar-free food which adopts the above processing technology has the advantages of a peculiar flavor, a crispy taste, small nutrient loss and no sugar.

Owner:BEIJING AGRI TECH PROMOTION STATION

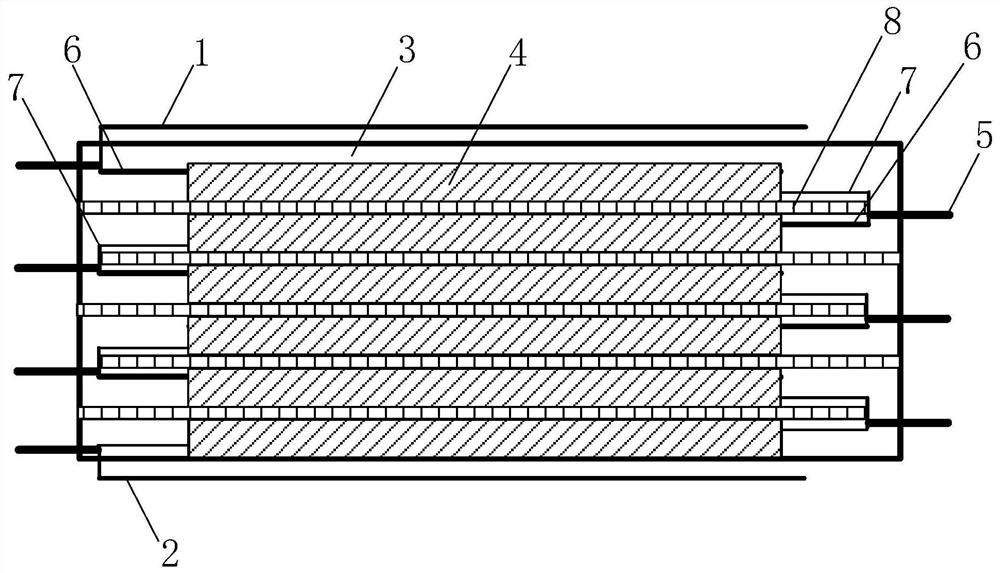

Preparation method of liquid lithium ion pole piece battery pack

PendingCN111628228ARealize serializationImprove performanceFinal product manufactureSecondary cells charging/dischargingPhysical chemistryEngineering

The invention discloses a preparation method of a liquid lithium ion pole piece battery pack. The preparation method comprises the following steps: 1, preparing a pole piece capacity unit; 2, preparing a to-be-injected activated lithium ion pole piece battery pack; 3, injecting a lithium ion electrolyte; 4, performing activation; and 5, after activation, forming a filling type sealed packaging shell for completely sealing and packaging the periphery of the exterior of the battery pack and filling all residual spaces in the battery pack through filling type sealed packaging, so as to realize the isolation of the battery pack from the external environment and the fixation of components of the battery pack, thereby obtaining the liquid lithium ion pole piece battery pack. Compared with the complex traditional process route, the traditional battery pack manufacturing process is simplified into stacking, welding, liquid injection, activation and packaging, so that the process route is shortened, the productivity is improved, the preparation of the battery pack is easier to control, meanwhile, the series formation of the whole battery pack in the same environment is realized, the consistency between single battery cells is improved, and the performance of the battery pack is improved.

Owner:萨姆蒂萨集成设备设计(邢台)有限公司

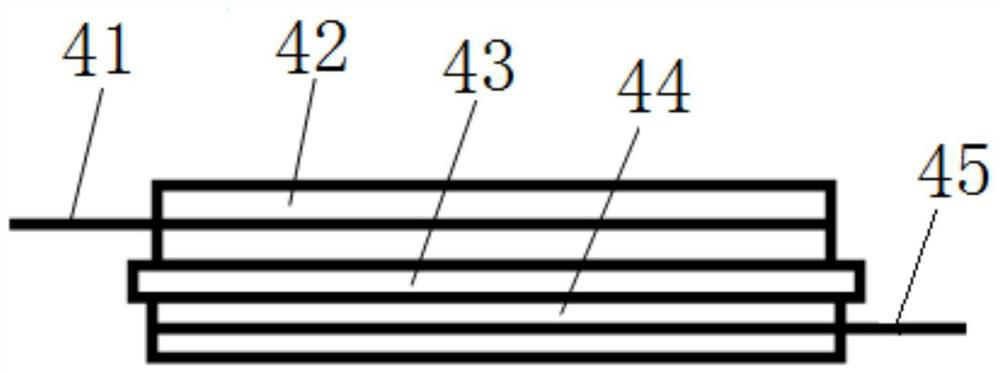

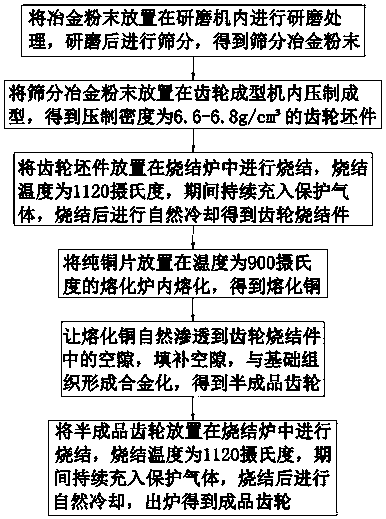

Secondary infiltration technology for gear forming

InactiveCN109926592AImprove mechanical propertiesImprove densification performanceShielding gasProduct gas

The invention discloses a secondary infiltration technology for gear forming, and relates to the technical field of the gear machining technology. According to the work principle of the secondary infiltration technology, metallurgy powder is placed in a grinding machine to be subjected to grinding treatment, screening is conducted after grinding, and screened metallurgy powder is obtained; and thescreened metallurgy powder is placed in a gear forming machine to be pressed and formed, a gear blank with the pressing density being 6.6-6.8 is obtained, the gear blank is placed in a sintering furnace to be sintered, the sintering temperature is 1,120 DEG C, and protective gas is continuously inflated in the process. After the above technical scheme is adopted, the secondary infiltration technology has the beneficial effects that a traditional technology is optimized, the forming technology is simplified, the usage value is high, the technology cost is low, the mechanical performance of a formed gear is excellent, compactness of the gear is improved, strength and abrasion resistance can be improved by 15%-30%, and the requirements of customers for products can be met; and compared withconventionally treated and manufactured gears, the mechanical performance is improved by 50%, the performance in the same industry field is excellent, and generalization performance is high.

Owner:广州市光铭金属制品有限责任公司

Making method of fermented soybeans

The invention discloses a making method of fermented soybeans, belonging to the field of food. The method comprises the following steps: selecting beans, steaming the beans, soaking the beans, steaming again and winnowing the beans, carrying out natural fermentation, washing mold, carrying out secondary fermentation, naturally drying and preserving. The process provided by the invention improves the traditional technique, pays attention to details, control of the time, temperature and humidity of all links and selection of tools and instruments, is free from additive in a whole processing process, and can better maintain the nutritional ingredients of the fermented soybeans while enabling the fermented soybeans to be green and healthy; furthermore, the made fermented soybeans have fragrance striking the nose, and are soft and waxy, sweet in taste and good in mouthfeel.

Owner:贺州市杨晋记豆豉有限公司

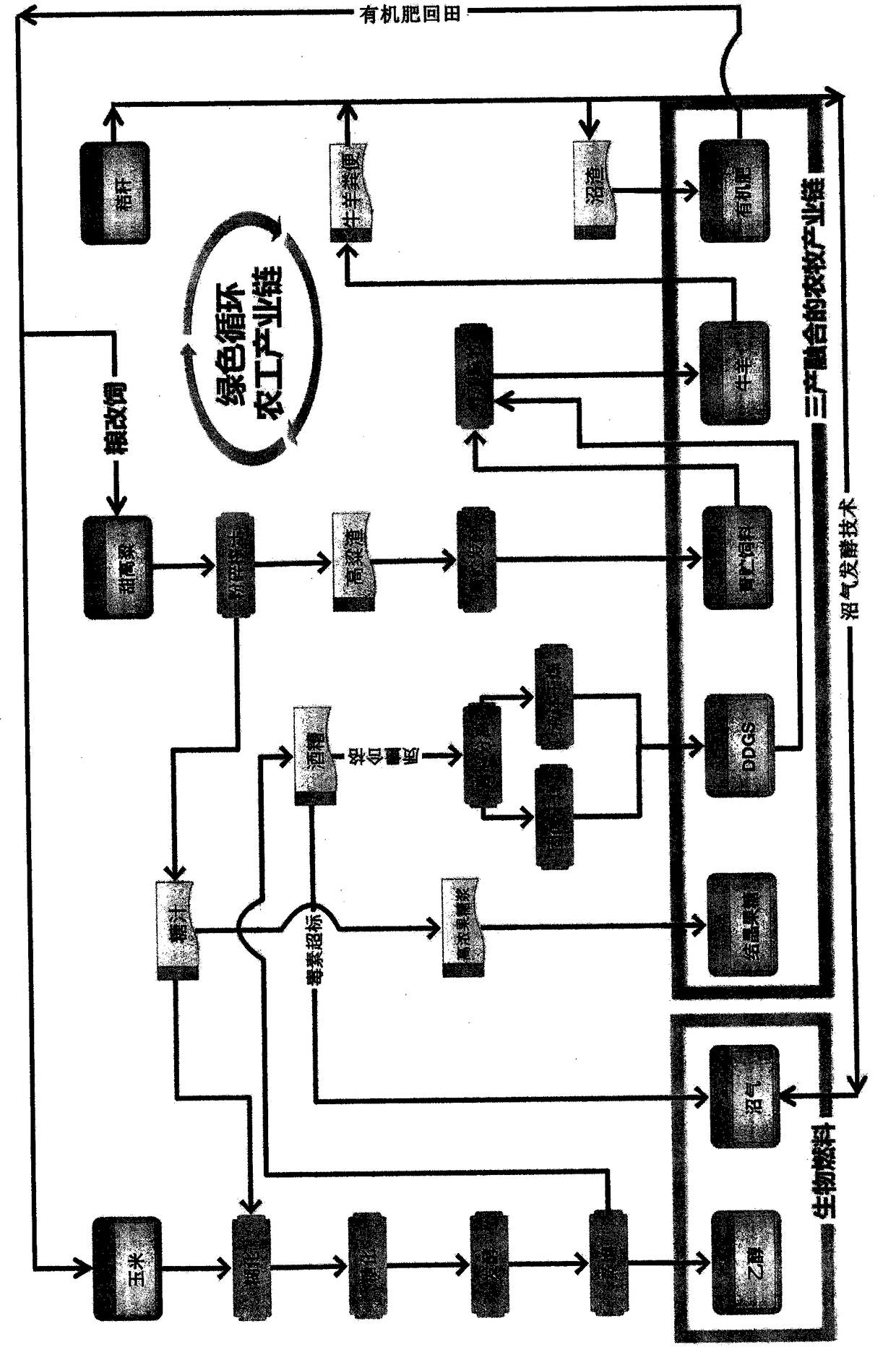

Multi-product co-production process such as ethanol and the like

InactiveCN109266694AReduce consumptionRealize multi-level utilizationBy-product recoveryProductsDistillationSweet sorghum

The invention discloses a multi-product co-production process of ethanol and the like, which is characterized in that the required raw materials include corn, sweet sorghum and straw; It uses corn andsweet sorghum as raw materials to produce fuel ethanol. The qualified liquor from ethanol production was processed into DDGS, and the unqualified distiller's grains were mixed with some cattle and sheep manure and residual straw for biogas power generation. The residues of sweet sorghum juice were fermented into silage for feeding cattle and sheep. Biogas residue, and part of cattle and sheep manure, residual straw into organic fertilizer, applied to farmland; after purification and distillation, the food grade CO2 was produced. Compared with the traditional technology, the invention shortensthe production time and improves the production efficiency. Taking ethanol production as an example, the sugar content of fermented mash and the proportion of mature mash were 3-5% higher than thoseof traditional corn fermentation. The fermentation time is effectively shortened and the alcohol yield is increased.

Owner:冯长林

Preparation method of chestnut and kiwi fruit peptide wine

InactiveCN105695271BImprove immunityTo promote metabolismAlcoholic beverage preparationWater bathsActinidia

The invention relates to a preparation method of Chinese chestnut / kiwi fruit peptide wine. The method comprises the following steps: 1) respectively peeling Chinese chestnuts and kiwi fruits, cleaning, pulverizing, and uniformly mixing to obtain a mixture; 2) sending the mixture into a microwave treatment facility, carrying out intermittent microwave treatment under the microwave frequency of 2450 MHz and the power of 500W; 3) adding water into the mixture subjected to microwave treatment according to the weight ratio of 1:(12-18), immersing in a 75-DEG C water bath for 1.5 hours, adding papain, stirring uniformly, and leaching at 40-60 DEG C for 1-4 hours, thereby obtaining an extracting solution for later use; 4) carrying out vacuum filtration by using a circulating-water multipurpose vacuum pump to obtain a peptide solution subjected to vacuum filtration; 5) adding 60-500g of unblended white wine and 30g of esterification enzyme bacterium solution into 200g of the peptide solution, carrying out natural association, transferring the wine solution into a ceramic storage tank; 6) putting the wine-solution-filled ceramic storage tank in a temperature control chamber, and oscillating the wine solution in the ceramic storage tank by using an ultrasonic oscillator; and 7) after the oscillation finishes, storing for 6-12 months, thereby obtaining the peptide wine.

Owner:安徽徽真堂健康科技有限公司

Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

InactiveCN100484880CImprove photocatalytic activityStable storageTitanium dioxideNanocrystalTitanic acid

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method simultaneously extracting lipid and protein from corn plantule

InactiveCN101402670BHigh extraction rateHigh purityFatty-oils/fats refiningPeptide preparation methodsUltrasonic assistedCentrifugation

The invention discloses a method for extracting grease and protein simultaneously from cereal germs, and pertains to the technical field of comprehensive utilization of agricultural byproducts. The method comprises the comprehensive utilization of technologies of reversed micellar extraction, ultrasonic-associated extraction, protein refining, grease refining, drying and so on. Cereal germs are sieved after crushing, added into reversed micellar solution, stirred or ultrasonic forward extracted and centrifugated to obtain forward extraction solution, and the forward extraction solution is processed by ultrasonic backward extraction and centrifugation, the upper layer is extracted by ethanol to remove a residual surfactant, a solvent is removed to obtain grease and after water, salt and the surfactant are removed from the lower layer, cereal germ protein product is obtained; or the solvent in the forward extraction solution is directly removed, protein in a residual solid substance is precipitated by a mixed solvent, and then washing and drying are carried out to obtain the cereal germ protein product. The method has simple technology and low cost, solves the problem that the traditional grease production causes damage to protein, improves reutilization value of cereal germ protein, and is an environmental friendly production method. The product has the advantages of high yieldrate, high purity, low chemical modification and the like.

Owner:JIANGNAN UNIV

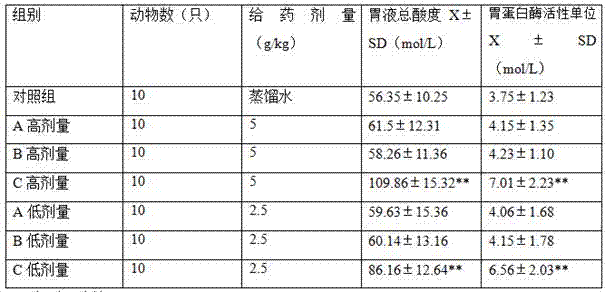

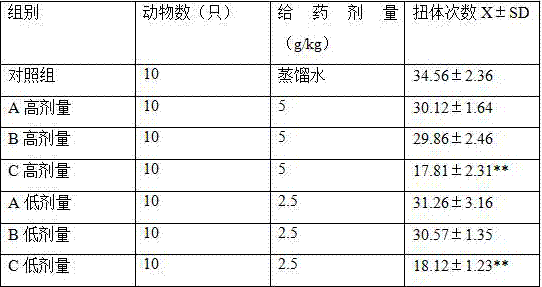

Method for preparing refined celery extract

InactiveCN101978979BOptimizing Traditional ProcessesNervous disorderMetabolism disorderCelery extractAdditive ingredient

The invention discloses a method for preparing a refined celery extract, relates to a method for preparing an extract from chemical ingredients in a plant and solves the problems of low ingredient purity and poor application effect of a flavonoid in the conventional celery extract. The method for preparing the refined celery extract comprises the following steps of: 1, preparing a crude celery extract; 2, adsorbing the prepared celery extract by using AB-8 macro-porous resin; and 3, drying the celery extract in vacuum so as to obtain the refined celery extract. In the refined celery extract, a flavonoid ingredient has high purity and good application effect. The method is widely applied to the extraction and separation of the chemical ingredients in the plant and is an effective method for separating and purifying plant ingredients.

Owner:隋焕平

A method for extracting protein and dietary fiber in tea

ActiveCN107475338BHigh purityReduce wasteDough treatmentPeptide preparation methodsBiotechnologyFood hygiene

The invention provides a method for extracting protein and dietary fibers from tea leaves. The protein and the dietary fibers are prepared in one step through subtractive extraction, enzymatic extraction and other methods. The method provided by the invention uses tea leaves as raw materials, extracts the tea protein and the dietary fibers under the assistance of the ultrasonic technique, and has advantages of high extraction rate of protein and fibers, high purity, low cost, simple and easy implementation, and easy popularization; the quality of products meets food hygiene standards; the invention provides a new way for value-added transformation and reuse of the tea leaves, develops a novel plant-derived protein and dietary fiber product, and realizes comprehensive utilization and intensive processing of tea leaf resources.

Owner:湖南祖狮岭生物科技有限公司

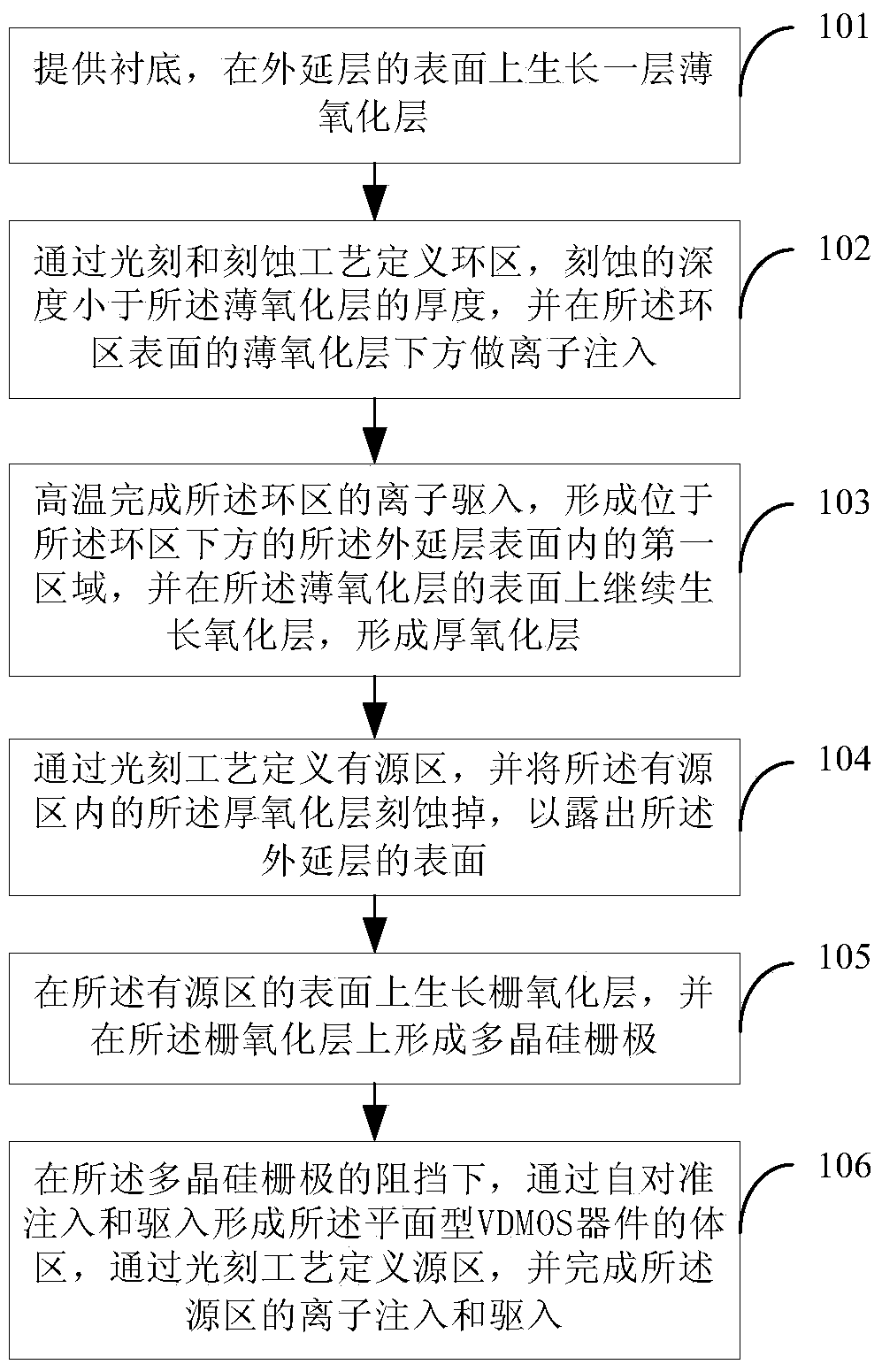

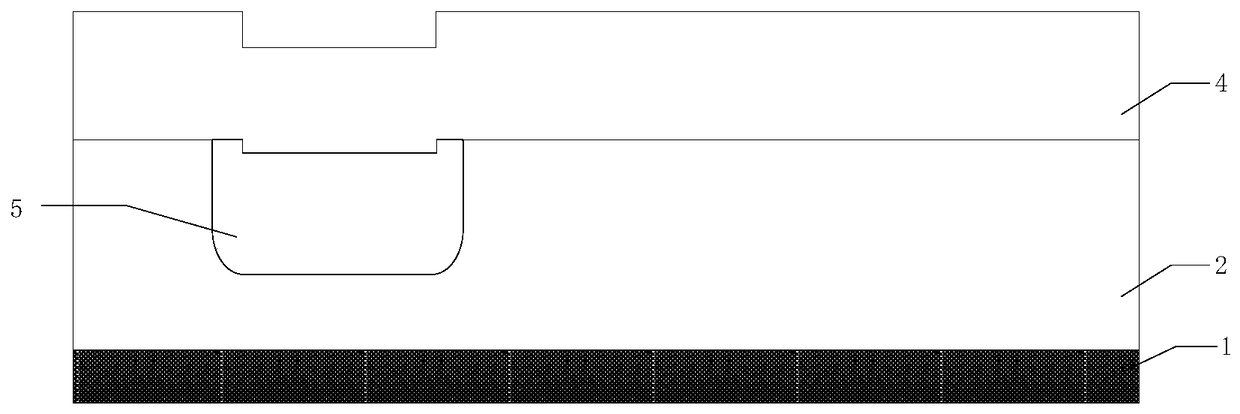

How to make a flat vdmos

ActiveCN106158653BReduce heat treatment processOptimizing Traditional ProcessesSemiconductor/solid-state device manufacturingPolysilicon gateBody region

The invention provides a planar VDMOS manufacturing method. The planar VDMOS manufacturing method comprises the steps of: growing a thin oxidation layer on the surface of an epitaxial layer; defining a loop region through photoetching and etching processes, and carrying out ion implantation under the thin oxidation layer on the surface of the loop region, wherein the etching depth is less than the thickness of the thin oxidation layer; carrying out ion drive-in in the loop region to form a first region in the surface of the epitaxial layer under the loop region, and growing an oxidation layer on the surface of the thin oxidation layer continuously to form a thick oxidation layer; defining an active region, and etching out the thick oxidation layer in the active region; growing a gate oxidation layer on the surface of the active region, and forming polysilicon gates on the gate oxidation layer; and forming a body region through self-aligned implantation and drive-in, defining source regions, and completing ion implantation and drive-in, wherein the body region surrounds the source regions, partial regions of the body region and the source regions extend below the polysilicon gates, and the depth of the body region is less than that of the first region. The planar VDMOS manufacturing method only needs two long-time high-temperature heat treatment processes, reduces cost and shortens manufacturing period.

Owner:FOUNDER MICROELECTRONICS INT

Ceramic tile micropowder distributing method

InactiveCN101879749BImprove textureNatural textureShaping conveyorsEngineeringMechanical engineering

Owner:FOSHAN SAIKE TECH

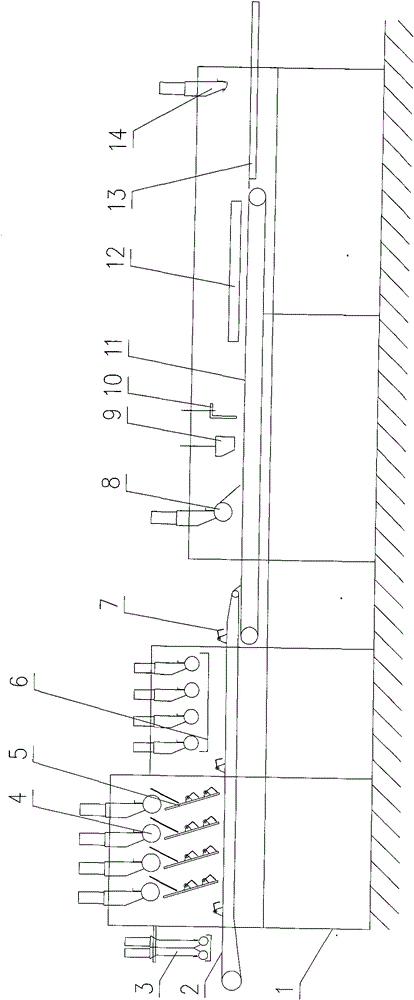

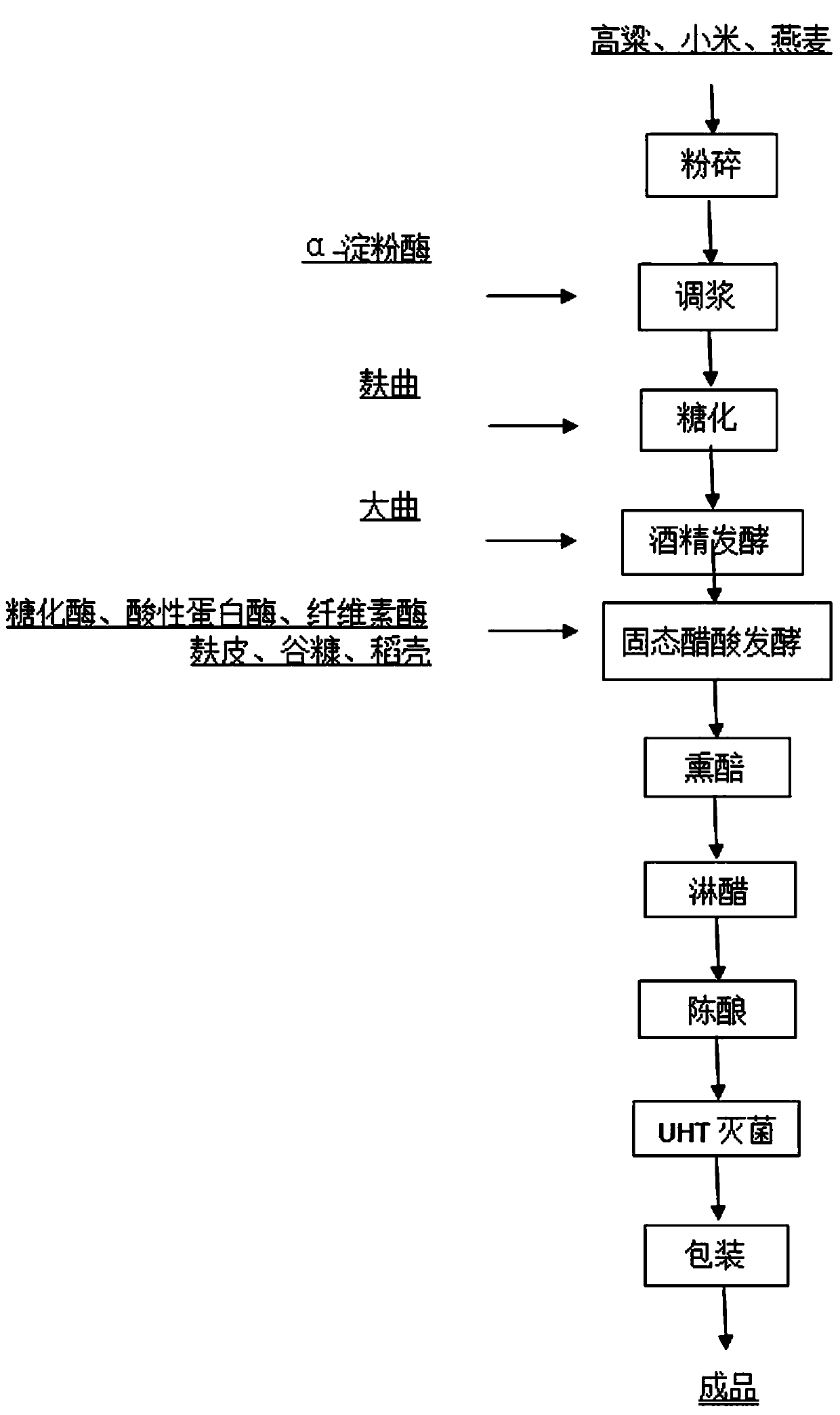

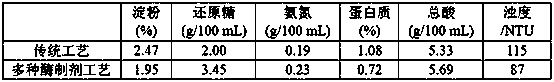

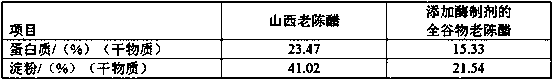

Application method of various enzyme preparations in solid-state acetic acid fermentation of whole grain aged vinegar

ActiveCN106635734BRetain nutritional valueIncrease profitVinegar preparationBiotechnologyAcetic acid

The invention discloses an application method of various enzymic preparations in the solid acetic fermentation process of full-grain mature vinegar. The application method comprises the following steps: during the solid acetic fermentation process, adding bran, chaff and rice husk into wash at a certain ratio, adding with acid proteinase with the amount being 3-5% of that of vinegar brewing mass, cellulase with the amount being 0.4-0.5 of that of vinegar brewing mass, and saccharifying enzyme with the amount being 0.20-0.25 of that of vinegar brewing mass, carrying out mixing, and carrying out uniform stir-mixing, wherein the water is kept to be 65-68 %, and the alcoholic strength is greater than or equal to 4.5%; placing the mixture into a jar, and inoculating caustic brewing mass, wherein the inoculation amount of the caustic brewing mass is 10% of the amount of vinegar brewing mass, after inoculation of the caustic brewing mass, covering the surrounding new brewing mass, and stacking the new brewing mass in the shape of Chinese character 'Tu'; turning over the brewing mass each day, wherein the temperature is controlled to be 35-40 DEG C for the first three days, and the temperate is controlled to be 45 DEG C or above at the fermentation medium term; after acetic fermentation is carried out for 9-12 days, carrying out natural cooling till the temperature is 38 DEG C or below, wherein the total acid is more than 4.5g / 100mL, the alcoholic strength is smaller than 0.2%, and then the acetic fermentation is completed. According to the method, the various enzymic preparations are added during the fermentation process, so that the problem that the product is muddy and has sedimentation is alleviated, the clarity of the product is improved, and the sedimentation problem of the product is improved.

Owner:SHANXI ZILIN VINEGAR

Car rear door triangle block assembly

ActiveCN104118302BReduce the difficulty of assemblyOptimizing Traditional ProcessesEngine sealsVehicle sealing arrangementsEngineeringBack door

The invention discloses an automobile rear door triangular block assembly, and relates to the technical field of automobile spare part manufacturing. The automobile rear door triangular block assembly comprises a rear door rear upper guide rail arranged between a triangular block outer plate and a triangular block inner plate, reinforcing rib plates are arranged on the triangular block outer plate and the triangular block inner plate respectively, clamping positions and clamping hooks are arranged on the reinforcing rib plates of the triangular block outer plate and the triangular block inner plate respectively, the clamping positions are paired with the clamping hooks, and the triangular block outer plate and the triangular block inner plate are connected into a whole through the clamping positions and the clamping hooks. Compared with the prior art, the automobile rear door triangular block assembly is simple in structure and capable of solving the problems that an existing rear door triangular block assembly is high in cost, difficult to assemble and poor in fit precision, fit clearance surface differences between the automobile rear door triangular block assembly and a rear automobile door window frame and glass are poor, natural beauty of transition of peripheral parts is influenced, rear door glass is difficult to assemble, and lifting resistance is large.

Owner:DONGFENG LIUZHOU MOTOR

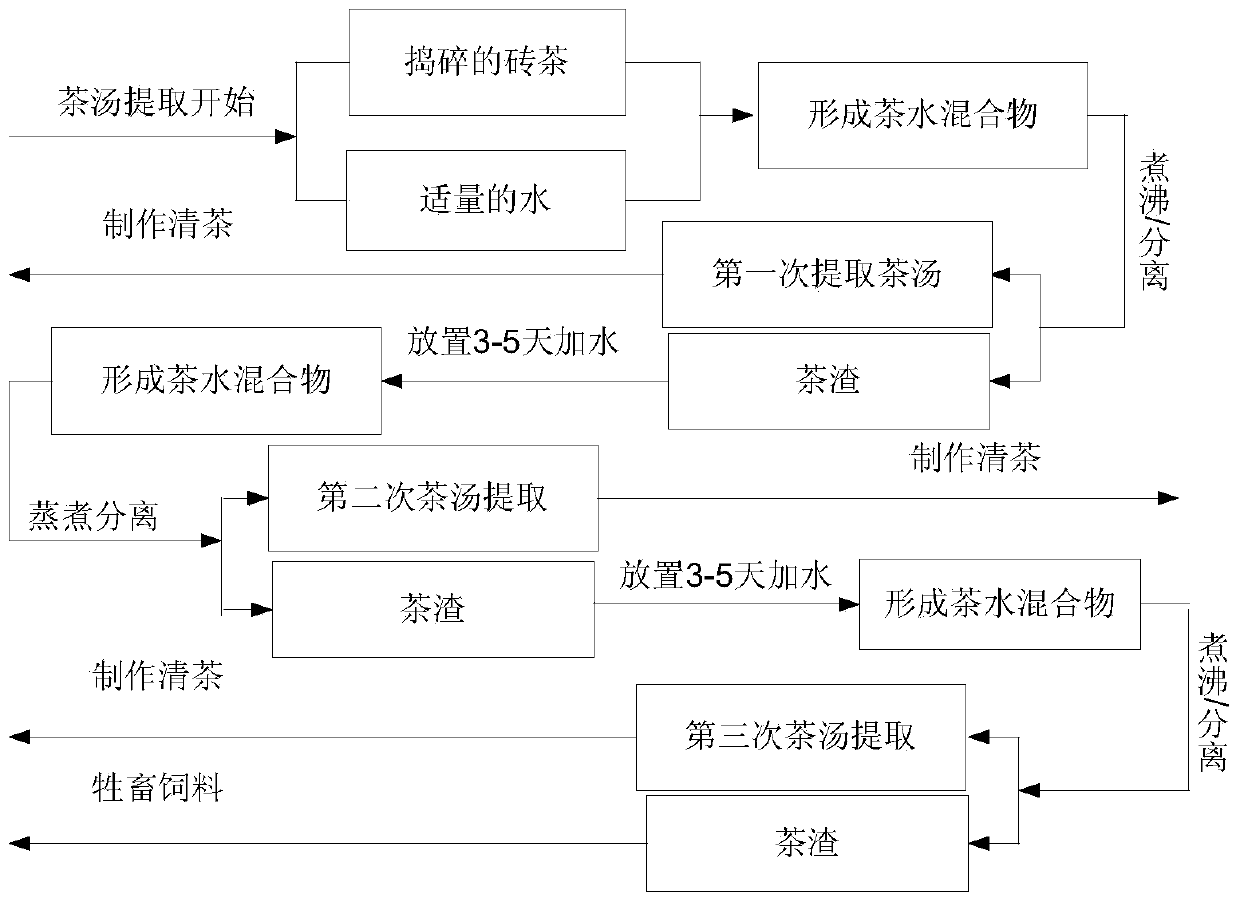

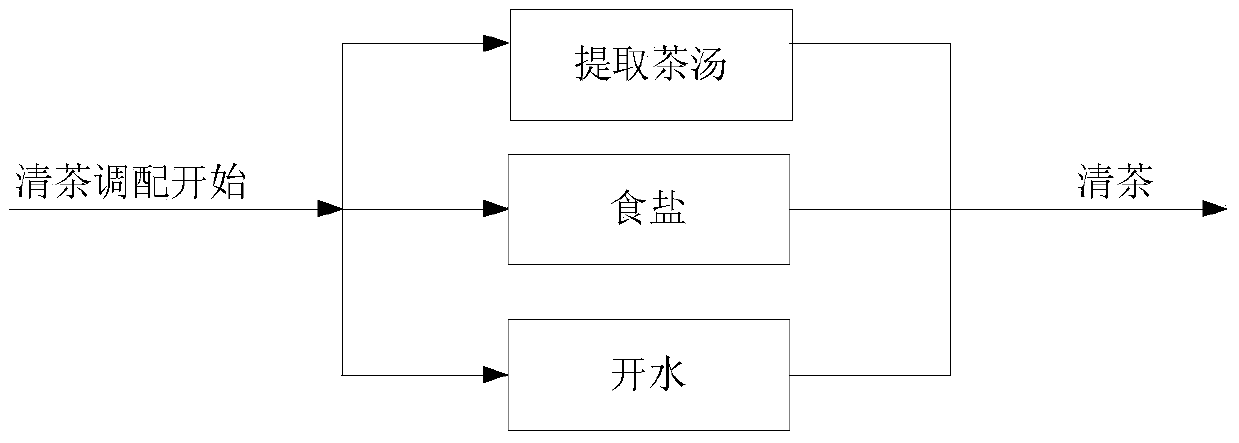

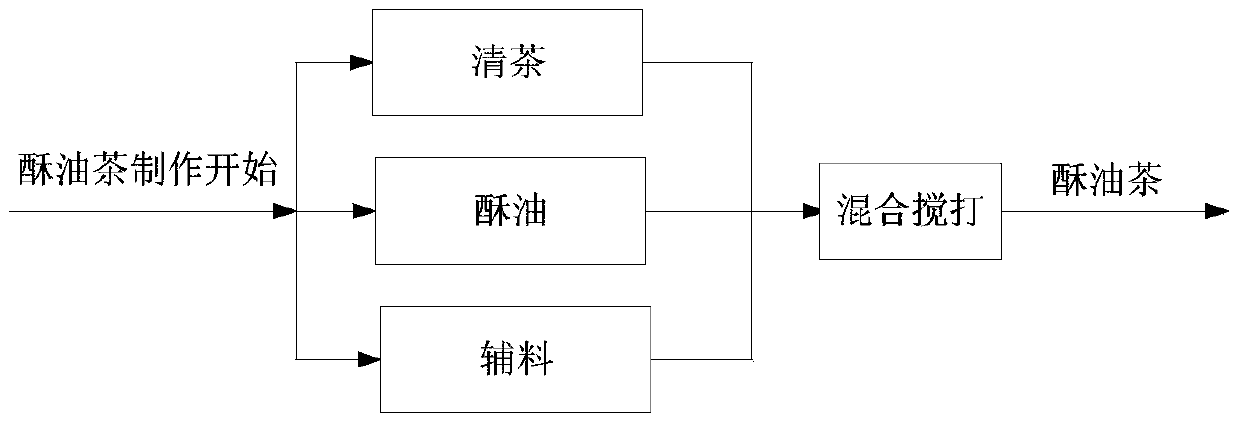

An automatic processing device for butter tea/clear tea

InactiveCN105395054BIncrease productivitySimple structureBeverage vesselsControl systemAgricultural engineering

The invention discloses a butter tea / clear tea automatic processing device, which comprises a tea soup extraction device, a tea soup storage device, a boiling water heating device, a butter tea / clear tea whipping device and a control system; the butter tea / clear tea whipping device includes a whipping tank, auxiliary materials Adding device and ghee feeding device, the tea soup outlet of the tea soup extraction device is connected with the tea soup inlet of the tea soup storage device, the tea soup outlet of the tea soup storage device is connected with the tea soup inlet of the whipping tank, and the boiling water outlet of the boiling water heating device is connected with the tea soup inlet of the whipping tank The boiling water inlet is connected, the auxiliary material outlet of the auxiliary material adding device and the ghee outlet of the ghee feeding device are respectively connected with the auxiliary material inlet and the ghee inlet of the whipping tank. A whipping motor for stirring, a first heater is provided on the inner wall of the whipping tank, and a buttered tea / clear tea outlet is provided on the side wall of the whipping tank. The invention can complete the automatic processing of clear tea and butter tea.

Owner:TIBET AGRI & ANIMAL HUSBANDRY COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com