Manufacturing technology of binding basketball by machine and its special mould

A technology for making crafts and basketballs, which can be applied to home appliances, other home appliances, ball games, etc. It can solve problems such as low production efficiency, unstable quality, and high labor intensity, so as to reduce labor intensity, advance ideas, and improve effective efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

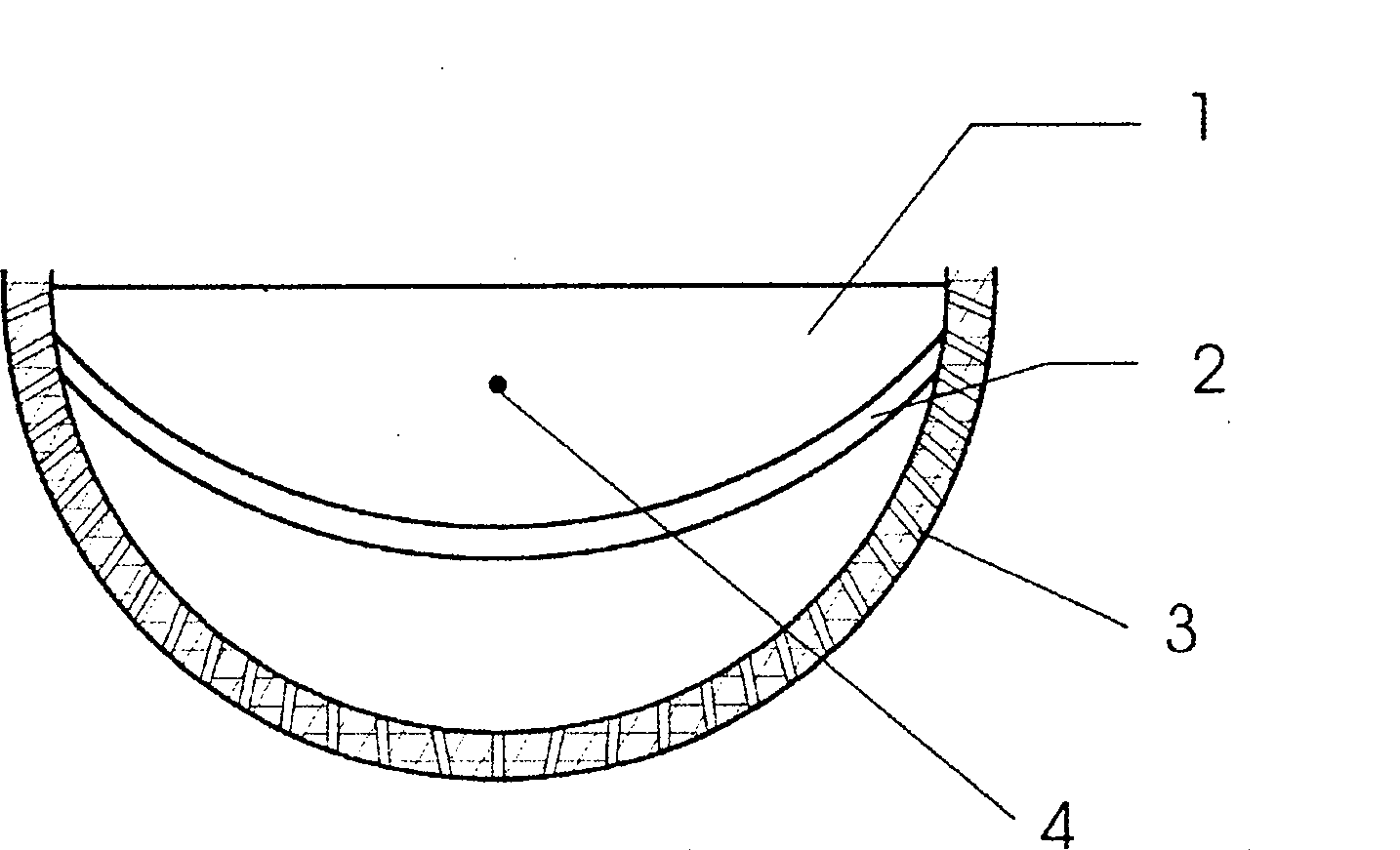

[0014] As shown in the figure: taking the production of a standard basketball as an example, the present invention is composed of two hemispherical molds 1, and the surface of the mold is evenly distributed with vacuum pumping holes 3, which are respectively connected with the vacuum pump, and the surface of the mold is also provided with inner tube inflation holes 4. The inner wall of the mold is provided with a ball piece and a ball stem groove 2; the main body of the mold is made of aluminum or steel;

[0015] Its manufacturing process includes the following steps:

[0016] 1) Firstly, add a winding layer to the bladder after winding, then cover the winding layer with a rubber layer of 0.8-1.2cm, and put the liner wrapped and covered with the rubber layer into the inner tank of the corresponding standard size. In the bladder mold, inflate 0.8-1.0Mpa, and at the same time maintain the mold temperature at 140-150°C, 5-10 minutes, release the mold to become an inner tube, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com