Secondary infiltration technology for gear forming

A gear and process technology, applied in the field of secondary infiltration process, can solve the problems of high process cost, low performance, poor strength and wear resistance, and achieve the effect of optimizing traditional process, simple molding process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

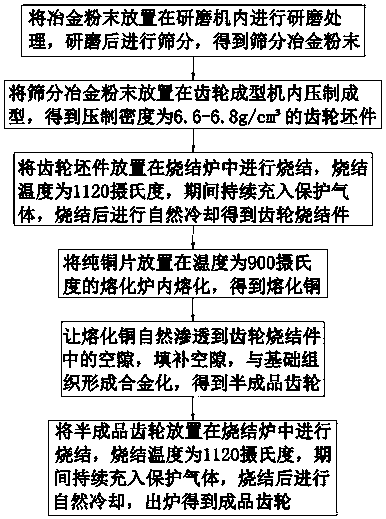

[0024] see figure 1 Shown, the technical scheme that this specific embodiment adopts is: it comprises the following steps:

[0025] Step 1, placing the metallurgical powder in a grinder for grinding, and sieving after grinding to obtain the sieved metallurgical powder;

[0026] Step 2. Place the sieved metallurgical powder in the gear forming machine for compression molding to obtain a compression density of 6.6-6.8 gear blanks,

[0027] Step 3. Place the gear blank in a sintering furnace for sintering, the sintering temperature is 1120 degrees Celsius, during which the protective gas is continuously filled, and after sintering, it is naturally cooled to obtain a gear sintered part;

[0028] Step 4, placing the pure copper sheet in a melting furnace with a temperature of 900 degrees Celsius for melting to obtain molten copper;

[0029] Step 5. Let the molten copper naturally penetrate into the gaps in the gear sintered parts, fill the gaps, form an alloy with the basic str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com