Application method of various enzyme preparations in solid-state acetic acid fermentation of whole grain aged vinegar

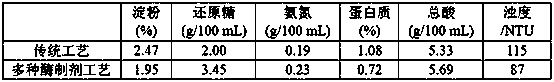

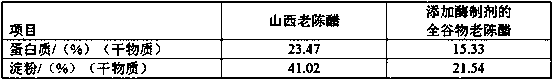

A solid-state acetic acid fermentation and application method technology, which is applied in the field of various enzyme preparations, can solve the problems of not using various enzyme preparations to improve the enzyme system, and achieve the effects of improving product precipitation, increasing yield, and optimizing traditional processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below.

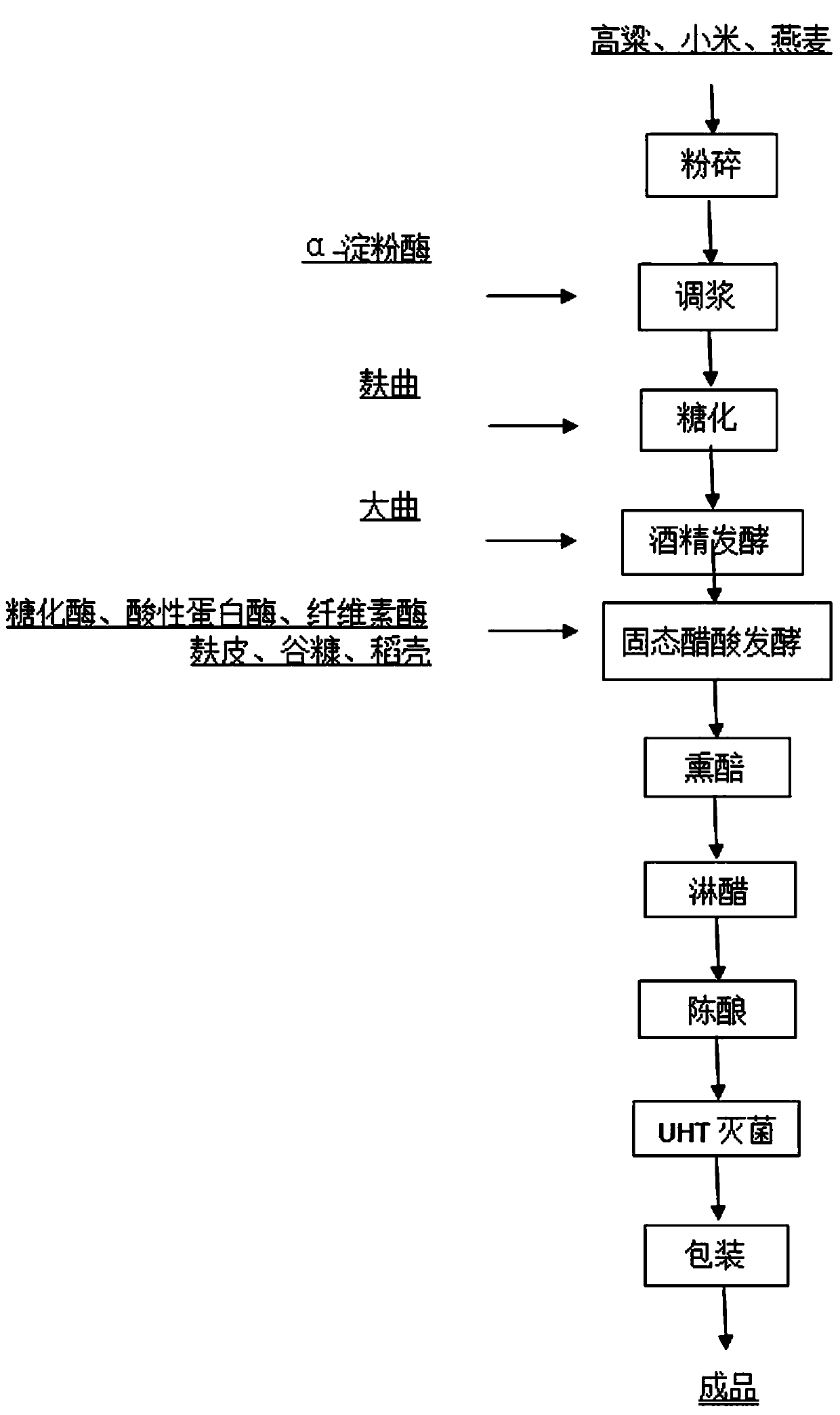

[0037] A method for reducing the sediment of whole grain mature vinegar by using a variety of enzyme preparations in the solid-state acetic fermentation process of whole grain mature vinegar, such as figure 1 shown, including the following steps:

[0038] (1) Raw material crushing: selected whole grain sorghum, millet and oats after impurity removal, accounting for 55%, 30% and 15% respectively, crushed to 40 mesh;

[0039] (2) Slurry liquefaction: add water according to the material-to-water ratio of 1:4, and keep the water at 45°C to moisten the material for 2 hours. Put in 0.20% α-amylase by mass of the raw material, mix well and control the temperature at 95°C-98°C for 60min.

[0040] (3) Saccharification: After cooling down to 60°C-65°C, add bran yeast with a proportion of 20% of the raw material, and saccharify for 1 hour. Then transfer to alcoholic fermentation, while saccharifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com