Preparation method of liquid lithium ion pole piece battery pack

A technology for battery packs and liquid lithium, which is used in secondary batteries, battery pack components, and secondary battery repair/maintenance, etc., can solve problems such as low energy density and power density, poor consistency of finished batteries, and complex and tedious preparation processes. , to achieve the effect of low manufacturing cost, poor safety, and shortened process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

[0019] The invention provides a kind of preparation method (abbreviation method) of liquid lithium ion pole piece battery pack, it is characterized in that the method comprises the following steps:

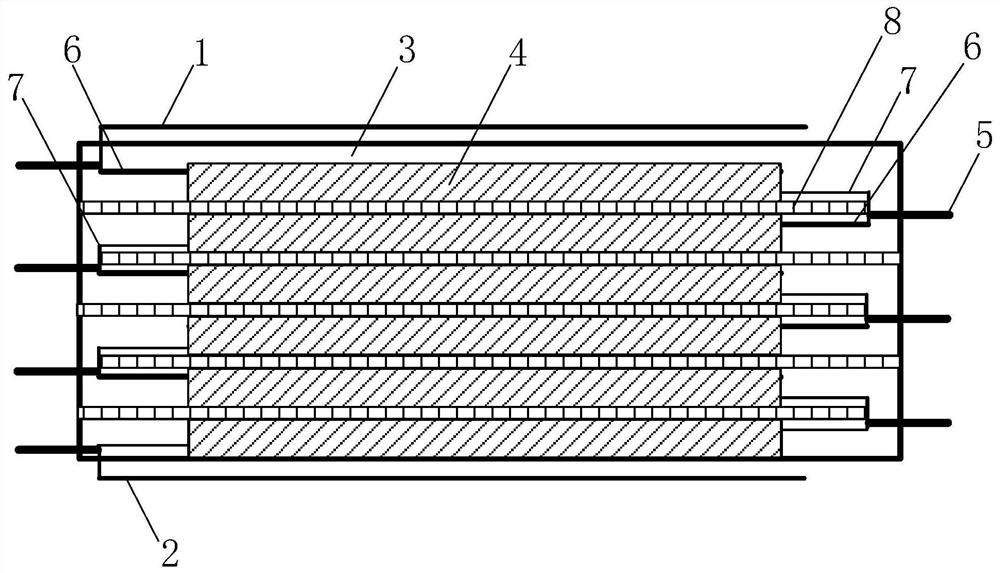

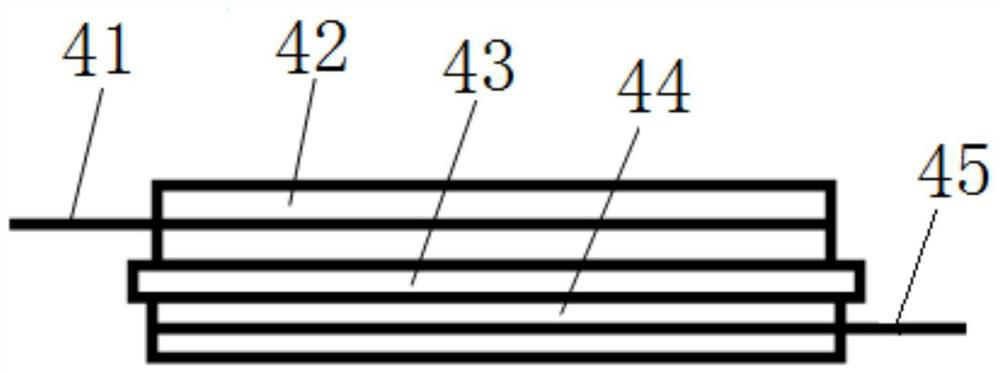

[0020] Step 1, preparation of the pole piece capacity unit 4: After cutting several positive pole pieces 42, several negative pole pieces 44 and several separators 43, the end of the positive pole piece 42 is the pole piece positive ear 41, and the end of the negative pole piece 44 is The part is the pole piece negative tab 45, and a separator 43 is bonded between the positive pole piece 42 and the negative pole piece 44, and stacked in this way to obtain a stacked unit; several stacked units are connected in parallel to form a pole piece capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com