Treatment process of reusing crab and shrimp shell

A treatment process and shrimp skin technology, which is applied in the field of crab shell and shrimp skin processing technology, can solve the problems of emission, protein, calcium carbonate waste, environmental pollution, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

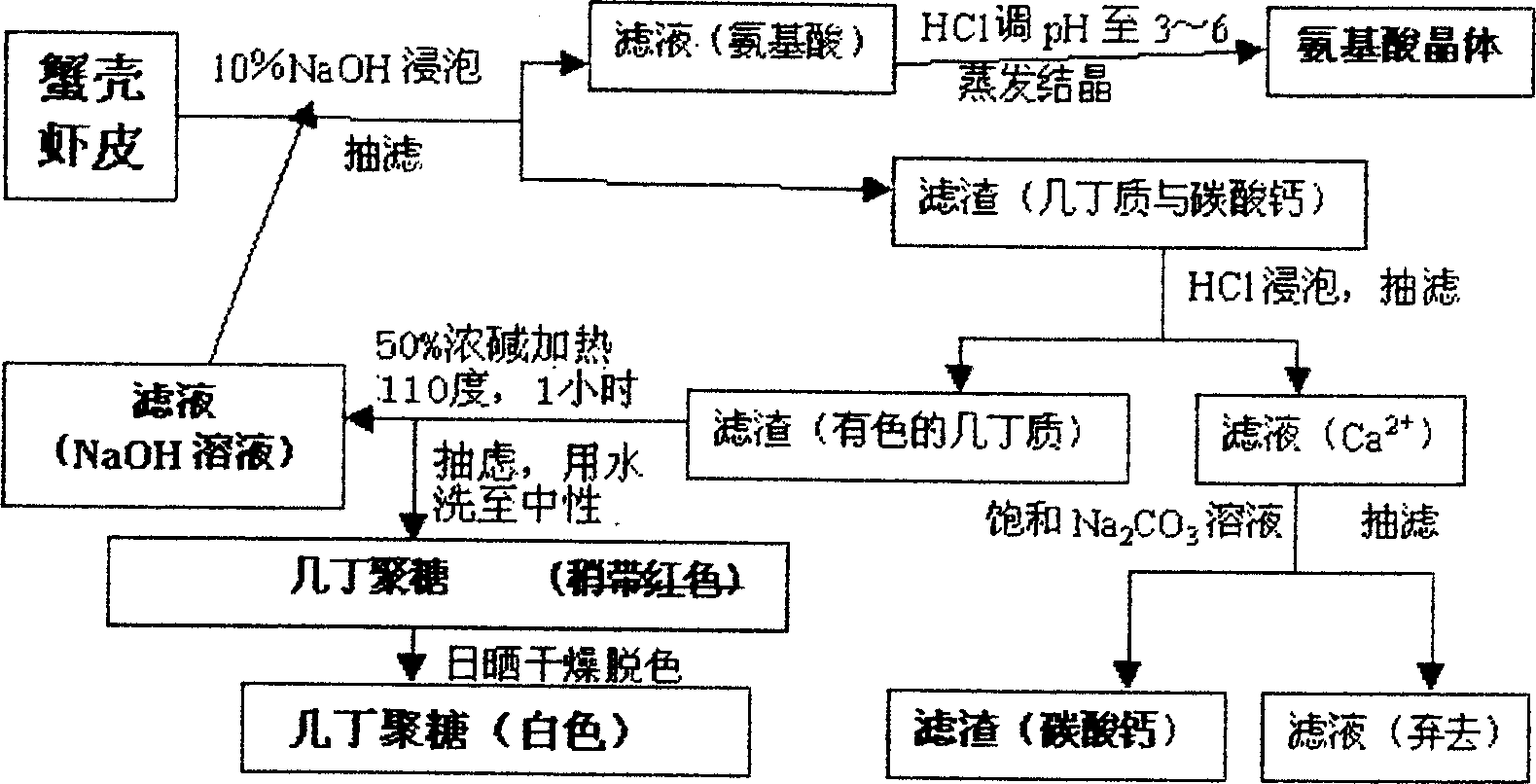

[0034] see figure 1 , a treatment process for reusing crab shells and shrimp skins, comprising the steps of:

[0035] 1. Take 15 grams of crab shell and shrimp skin, add a small amount of 10% NaOH solution to make it just submerge the crab shell and shrimp skin, heat to 100-110°C and soak for 1 hour, stir, and suction filter to obtain filtrate A and filter residue B;

[0036] 2. Use 1mol / L HCl in filtrate A to adjust the pH value of filtrate A to about 5. White turbidity occurs. Part of the water is evaporated and cooled to precipitate a small amount of slightly orange-yellow amino acid crystals.

[0037] 3. Add 40ml of 3mol / L HCl solution to filter residue B, make it submerged in filter residue B, stir, and suction filter to obtain filtrate C and filter residue D.

[0038] 4. Add a little excess saturated sodium carbonate solution dropwise to the filtrate C to completely precipitate the calcium ions. After the reaction, filter with suction to obtain the filtrate E and filte...

Embodiment 2

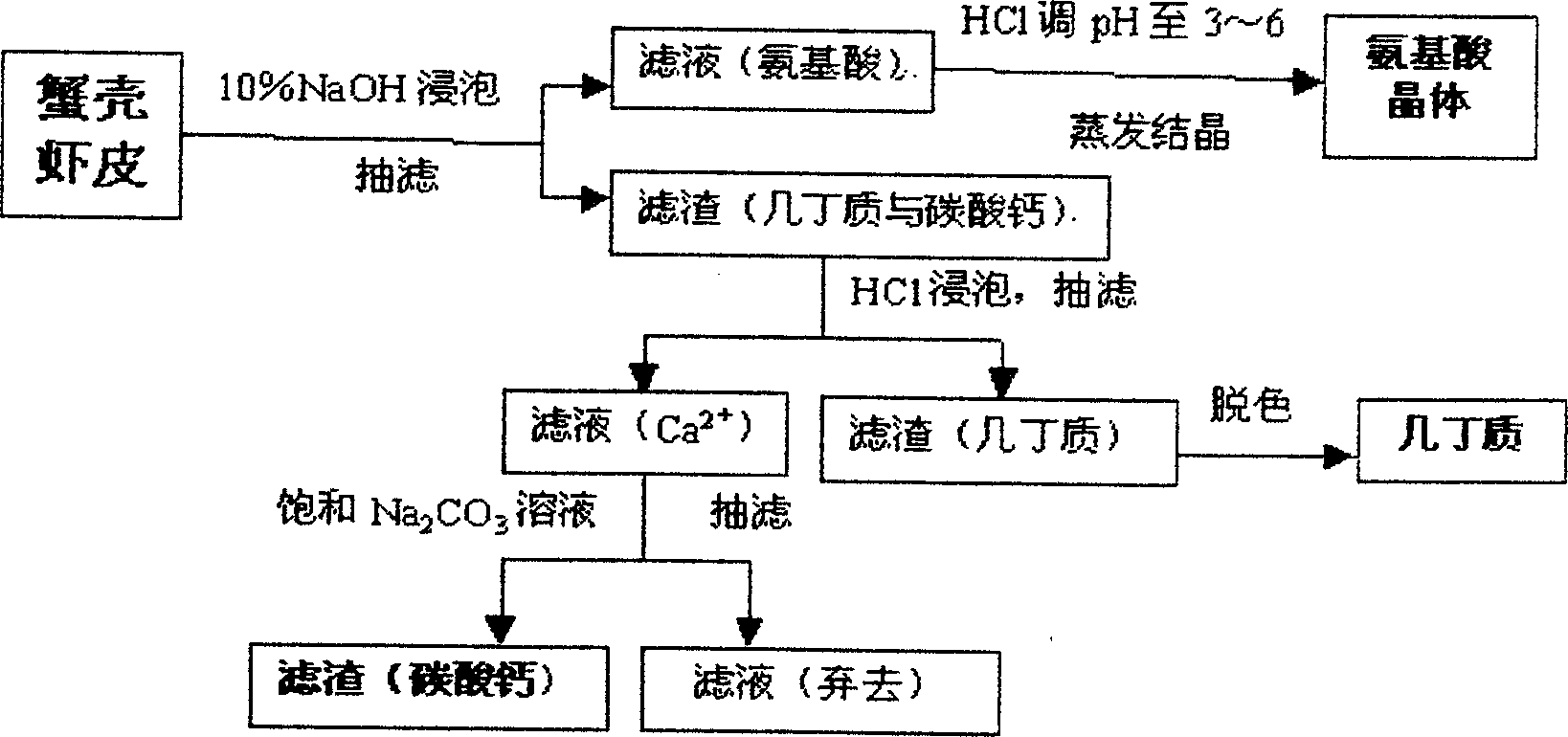

[0045] see figure 2 , a treatment process for reusing crab shells and shrimp skins, comprising the steps of:

[0046] 1. Take 15 grams of crab shell and shrimp skin, add a small amount of 10% NaOH solution to make it just submerge the crab shell and shrimp skin, heat to 100-110°C and soak for 1 hour, stir, and suction filter to obtain filtrate A and filter residue B;

[0047] 2. Use 1mol / L HCl in filtrate A to adjust the pH value of filtrate A to about 5. White turbidity occurs. Part of the water is evaporated and cooled to precipitate a small amount of slightly orange-yellow amino acid crystals.

[0048] 3. Add 40ml of 3mol / L HCl solution to filter residue B, make it submerged in filter residue B, stir, and suction filter to obtain filtrate C and filter residue D.

[0049] 4. Add a little excess saturated sodium carbonate solution dropwise to the filtrate C to completely precipitate the calcium ions. After the reaction, filter with suction to obtain the filtrate E and filte...

Embodiment 3

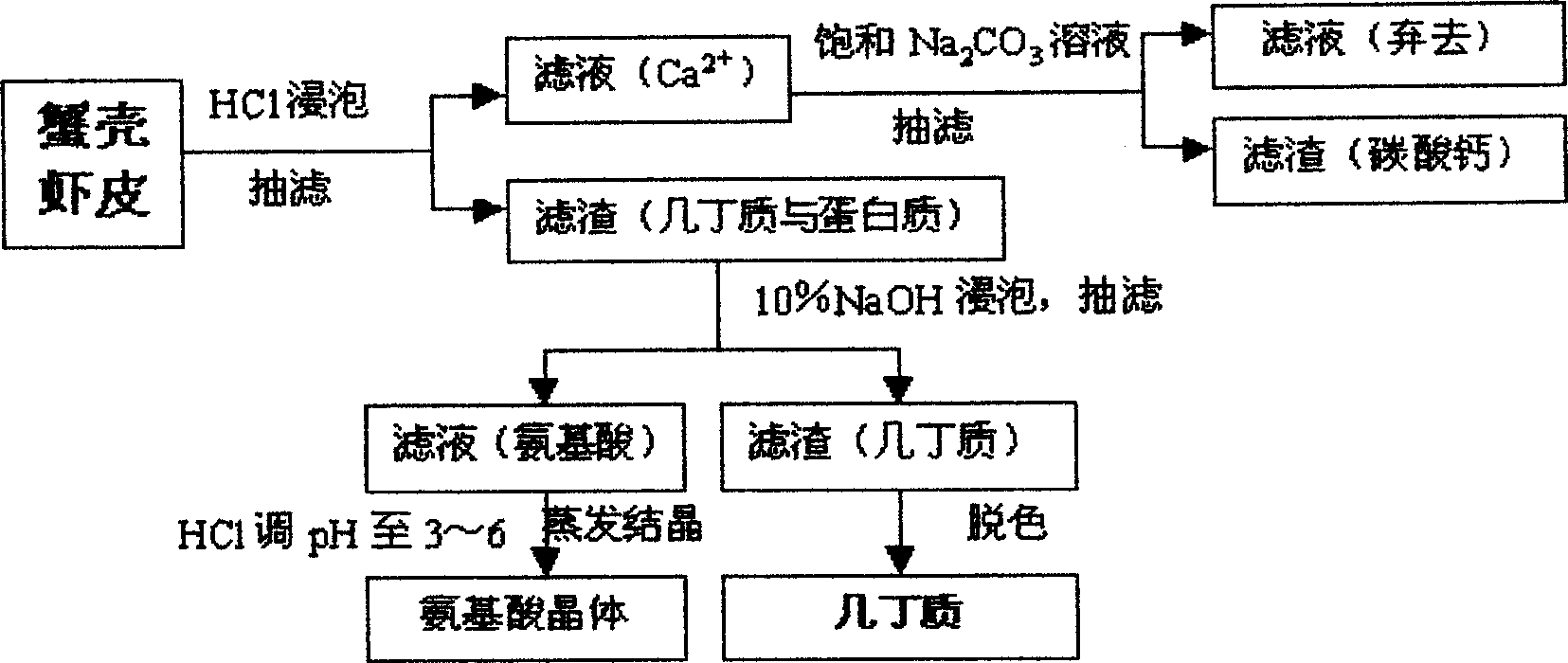

[0054] see image 3 , a treatment process for reusing crab shells and shrimp skins, comprising the steps of:

[0055] 1. Take 15 grams of crab shells and dried shrimps, crush them and put them into a beaker, add 40ml of 3mol / L HCl solution (Note: It is estimated that the crab shells and dried shrimps contain 12 grams of calcium carbonate, and 0.12mol HCl is required for a complete reaction), so that it is immersed in the crab shells and dried shrimps , soaked for 1 hour, stirred and soaked for 1 hour, and suction filtered to obtain filtrate C and filter residue B;

[0056] 2. Add a little excess saturated sodium carbonate solution dropwise to the filtrate C to completely precipitate calcium ions. After the reaction, suction filter to obtain filtrate E and filter residue F, discard the filtrate E, and dry the filter residue F to obtain white calcium carbonate. ;

[0057] 3. Add a small amount of 10% NaOH solution to the filter residue B, make it just submerge the crab shell and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com