Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

A nano-titanium dioxide and crystallization technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high production cost and high equipment requirements, and achieve the effect of reducing equipment requirements, high photocatalytic activity and white particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Sulfuric acid with a concentration of 80% is heated to dissolve ilmenite (mass ratio ilmenite: sulfuric acid = 1: 2), and the obtained solid phase sediment is obtained by leaching with water to obtain titanium liquid, and the titanium liquid is filtered to remove insoluble slag, frozen and recrystallized The ferrous sulfate is removed by filtration to obtain a titanium-containing precursor solution; the pH value of the precursor solution is adjusted to 7 with ammonia water to obtain orthotitanic acid precipitation. Take 80g of orthotitanic acid precipitate and add 20ml of 30% hydrogen peroxide solution to dissolve, use 30% HNO3 to adjust pH=2, dilute the resulting solution to 200ml, and reflux at 100°C for 6 hours to obtain a yellow-orange transparent titanium dioxide nanosol.

Embodiment 2

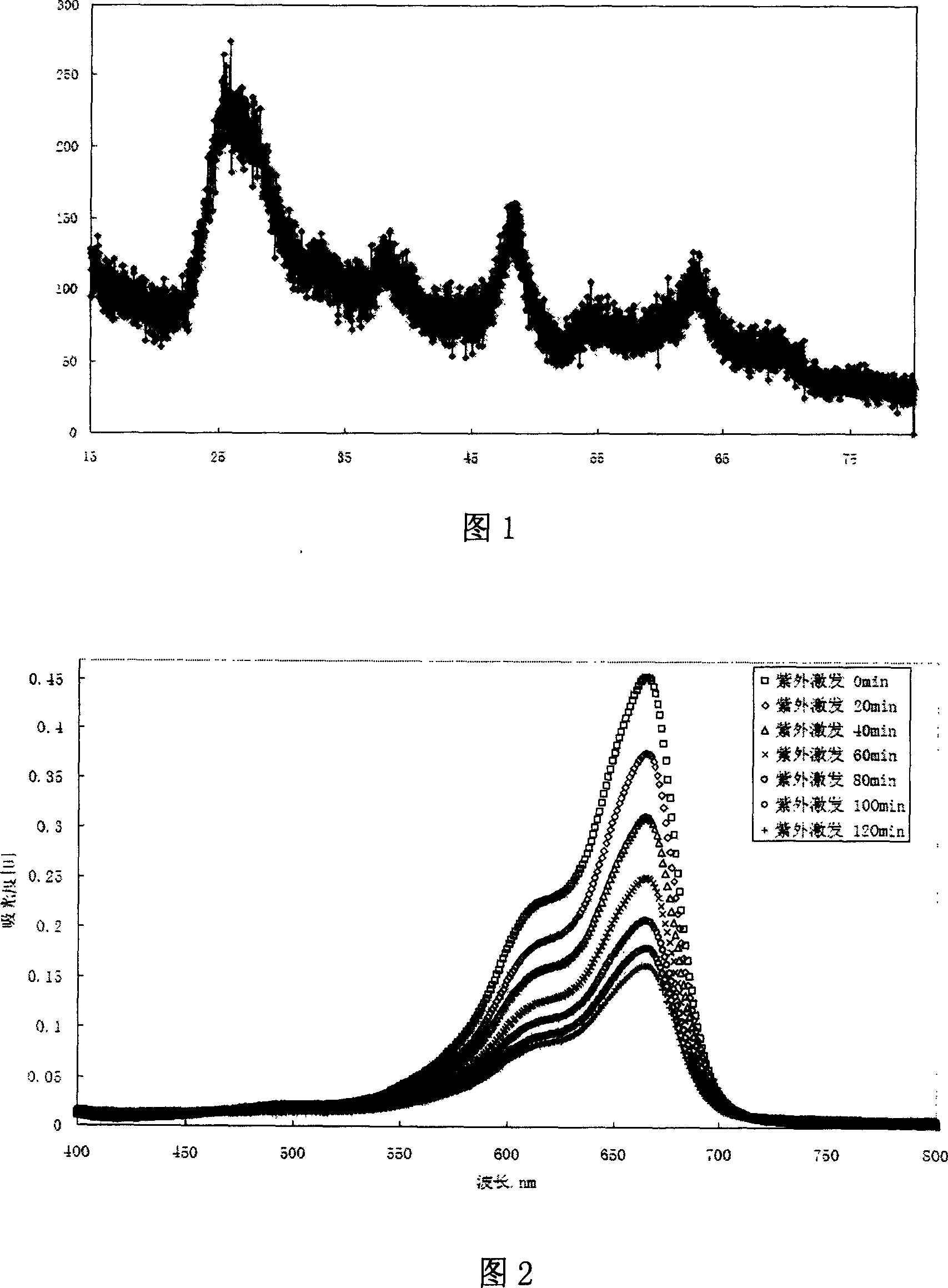

[0052] Orthotitanic acid precipitate was obtained in the same manner as in Example 1. Take 80g of orthotitanic acid precipitate and add 20ml of 30% hydrogen peroxide solution to dissolve, adjust the pH to 0.5 with 30% nitric acid, dilute the resulting solution to 200ml with pure water, reflux at 100°C for 6 hours to obtain a milky white precipitate, and obtain nano titanium dioxide after vacuum drying Powder, XRD spectrogram measurement result confirms that it is anatase type titanium dioxide crystal, see accompanying drawing 1.

Embodiment 3

[0054] Sulfuric acid with a concentration of 80% is heated to dissolve aluminum titanate, and the obtained solid-phase deposit is leached with water to obtain titanium liquid, the titanium liquid is filtered to remove insoluble slag, and frozen and recrystallized to filter and remove aluminum sulfate to obtain a titanium-containing precursor solution; Precipitation of orthotitanic acid is obtained by heating the precursor solution. Take 80g of orthotitanic acid precipitate and add 20ml of 30% hydrogen peroxide solution to dissolve, use 30% HCl to adjust pH=2, dilute the resulting solution to 200ml, and reflux at 100°C for 6 hours to obtain a yellow-orange transparent titanium dioxide nanosol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com