Car rear door triangle block assembly

A triangular block and rear door technology, which is applied to vehicle parts, engine sealing, sealing devices, etc., can solve the problems of difficult assembly, large lifting resistance of rear door window glass, and high production cost, so as to reduce the glass lifting resistance and improve the aesthetic effect. , The effect of high installation and matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

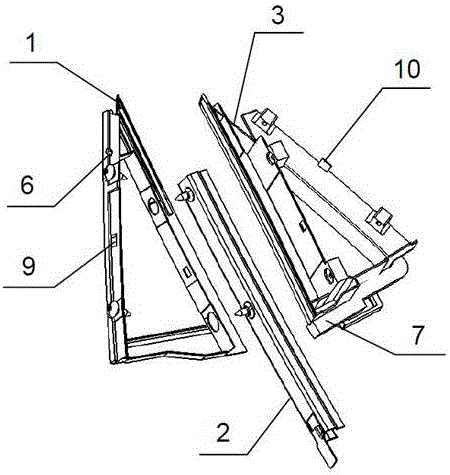

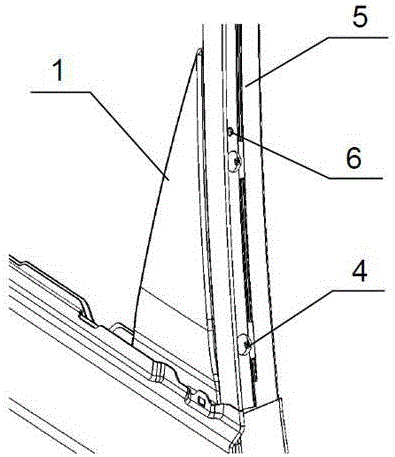

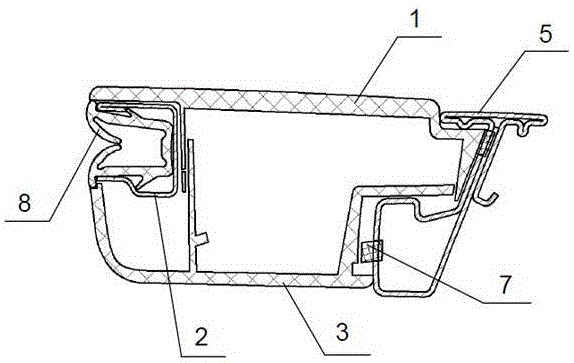

[0017] Such as Figure 1 to Figure 3 The described automobile rear door triangular block assembly includes a rear upper guide rail 2 arranged between the triangular block outer panel 1 and the triangular block inner panel 3, and the rear door upper guide rail 2 is arranged between the triangular block outer panel 1 and the triangular block inner panel 3. Ribs are provided on the top, such as figure 1 As shown, two triangular block inner plate hooks 10 are provided on the rib plate of the triangular block inner plate 3, and the rib plate of the triangular block outer plate 1 is provided to match with the triangular block inner plate hooks 10. The two triangular block outer plate clamping positions 9, the triangular block outer plate 1 and the triangular block inner plate 3 are buckled together by the triangular block outer plate hook 10 and the triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com