Ceramic tile micropowder distributing method

A cloth and micro-powder technology, applied in the direction of forming conveyors, etc., can solve the problems of lack of practicability, inability to achieve beneficial effects, lack of necessary technical conditions, etc., and achieve the effect of broad market economic benefits, good cloth effect, and reduced mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with specific embodiment the present invention is described in further detail:

[0039] The ceramic tile micropowder distributing method has the following process steps: (1) adopts the secondary distributing process of the bottom material; (2) adopts the anti-beating micropowder distributing process; (3) adopts the line distributing process; (4) adopts a special distributing device for distributing;

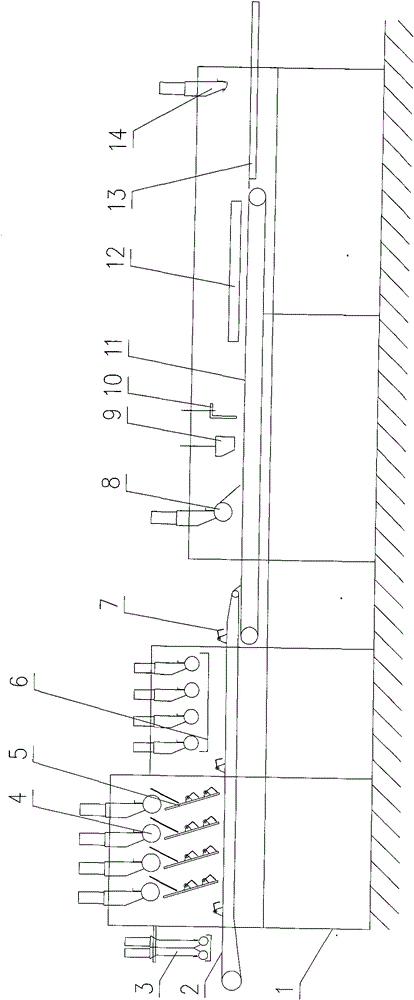

[0040] The special distributing device in step (4) comprises a frame 1, an inclined conveyor belt mechanism 2 is arranged above the frame 1, and a sieve line mechanism 3 and a roller mechanism 4 are successively arranged above the inclined conveyor mechanism 2, and the roller mechanism 4 There is a glass-distributing shutter device 5 below the glass-distributing shutter device 5, a vibrating screen device 6 and a shutter device 7 are provided behind the shutter device 7, and a mopping and repairing device is arranged sequentially above the horizontal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com