Method for preparing needle polyprenols by using solvent extraction method

A molecular distillation and polypentenol technology, applied in the chemical industry, can solve the problems of high production cost, large solvent residue, low production efficiency, etc., and achieve the effects of low price, improved purity and sufficient price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

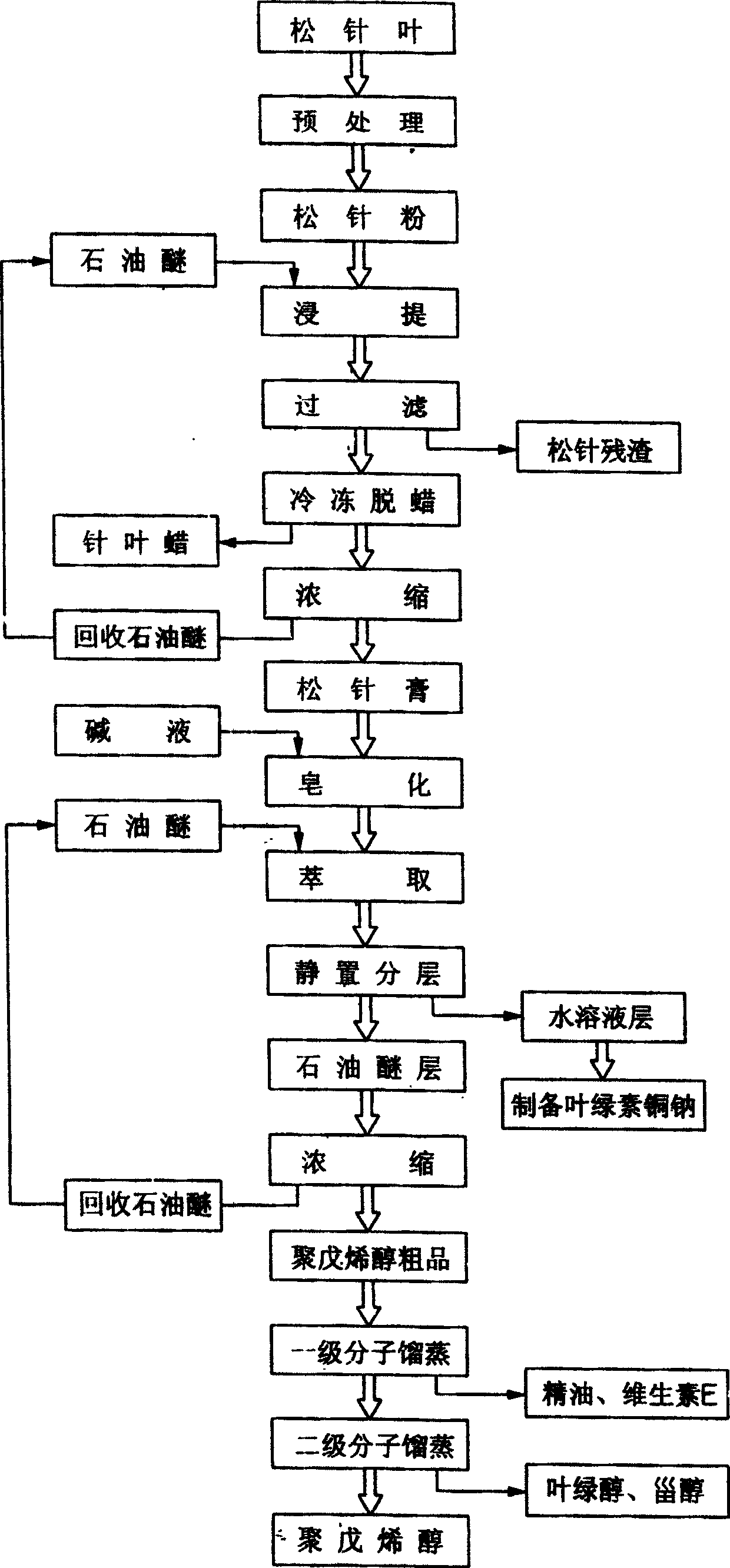

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0020] see figure 1 , a method for preparing coniferous polyprenol by solvent extraction and molecular distillation. Fresh pine branches and young leaves are dried and pulverized into pine needle powder with a particle size of 16 to 30 meshes as raw materials, and extracted with petroleum ether. The technological conditions used are: the ratio of the weight of the pine bark raw material to the volume of the liquid is 1:5-1:10, the temperature is 40-70°C, and the extraction is performed twice, each time for 1.5-2 hours; The final material is frozen and dewaxed at a temperature of 0-25°C, and then concentrated under the conditions of a temperature ≤ 60°C and a vacuum of -0.07-0Mpa; the concentrated material is adjusted to a pH of 8 ~10 for saponification; then extract the saponified material. During extraction, use petroleum ether:saponification extract 2:1~6:1, ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com