Method for cleaning falling coal on operating platform of stamp-charged coke oven

A technology for tamping coke ovens and operating tables, which is used in coke ovens, furnaces to prevent/remove scale deposits, and petroleum industry. , The effect of small scraper gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

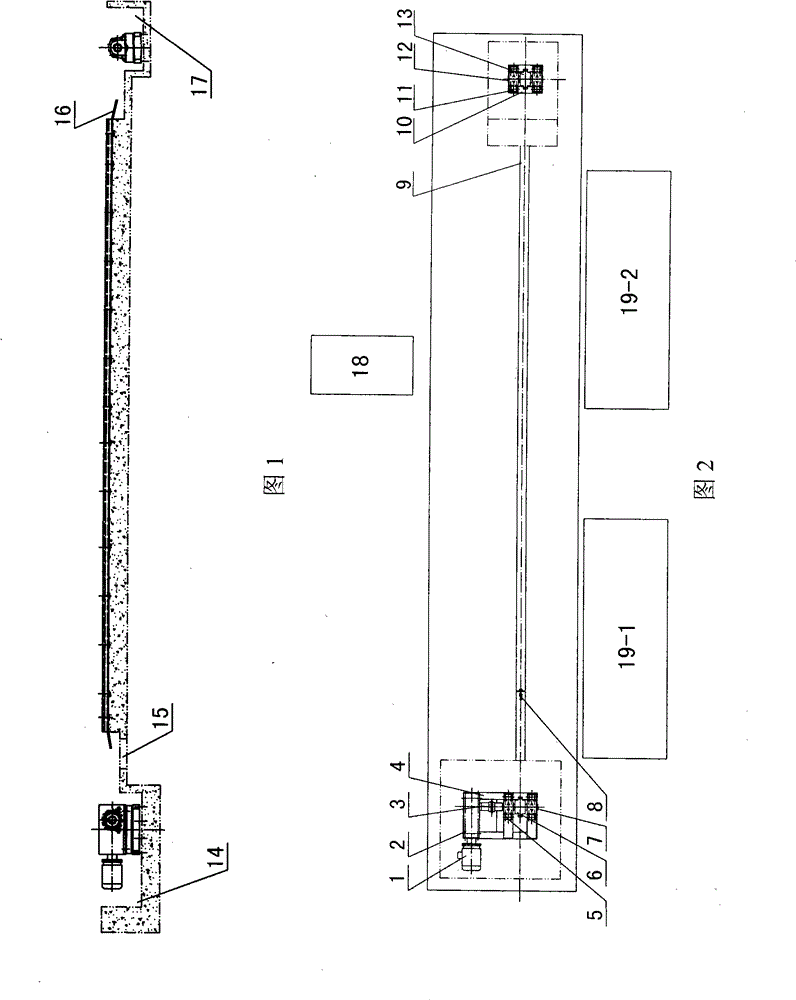

[0034] Describe the concrete content of the present invention in detail below in conjunction with accompanying drawing:

[0035] A method for cleaning the falling coal on the tamping coke oven operation platform, the method is through the longitudinal operation platform on the center line between the tamping cart 18 and two coke ovens (coke oven 19-1, coke oven 19-2) A scraper conveyor is set, and the scraper is driven by the movement of the scraper conveyor to clean up the falling coal and transport it to the end and enter the discharge chute 15 to the collection chamber. The longitudinal length of a single coke oven is mostly greater than 100 meters. According to the current technological layout of two coke ovens arranged longitudinally in sequence, the length of the scraper conveyor is required to be greater than 200 meters.

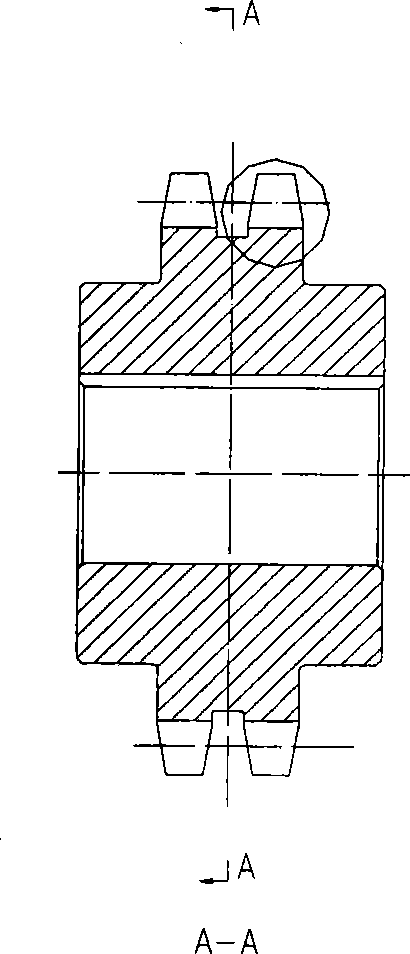

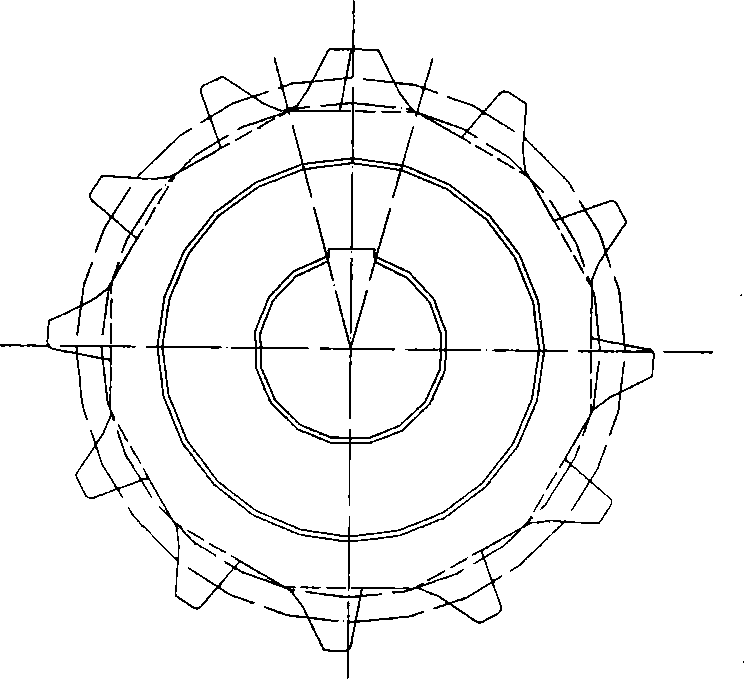

[0036] See figure 1 , figure 2 , the scraper conveyor that described method adopts is made of pallet groove 9, chain, scraper 8, chain head wheel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com