Washing machine and inter-tub cleaning method thereof

A washing machine and cleaning technology, which can be applied to cleaning methods and utensils, other washing machines, cleaning hollow objects, etc., can solve problems such as pollution between buckets, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

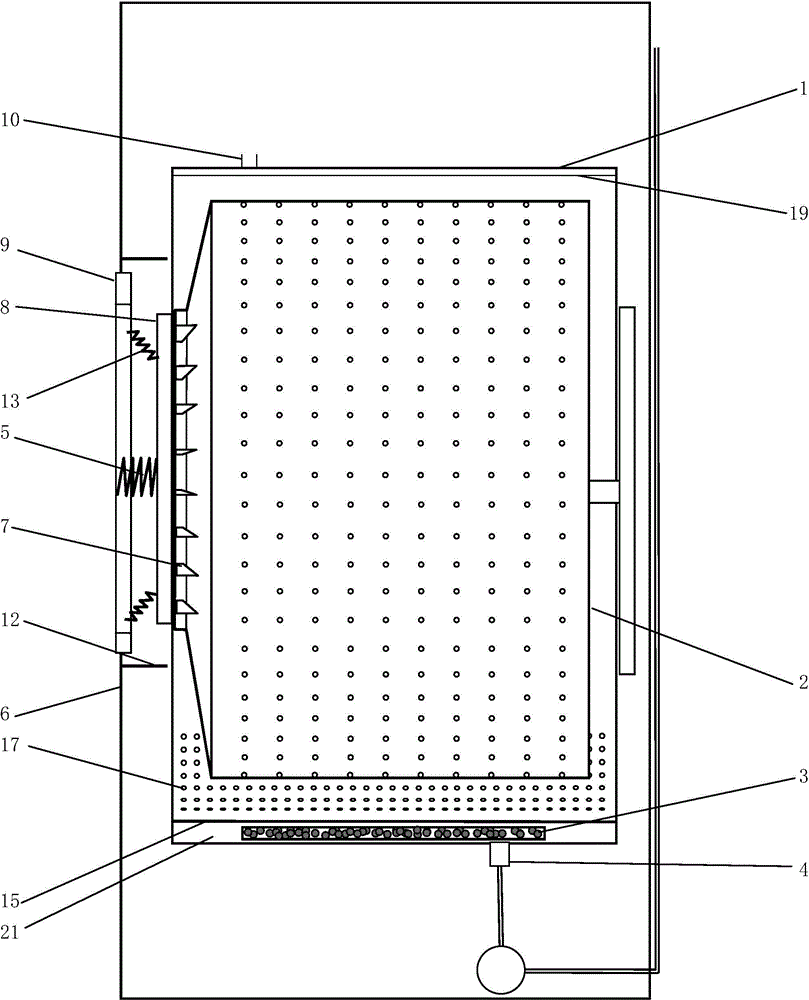

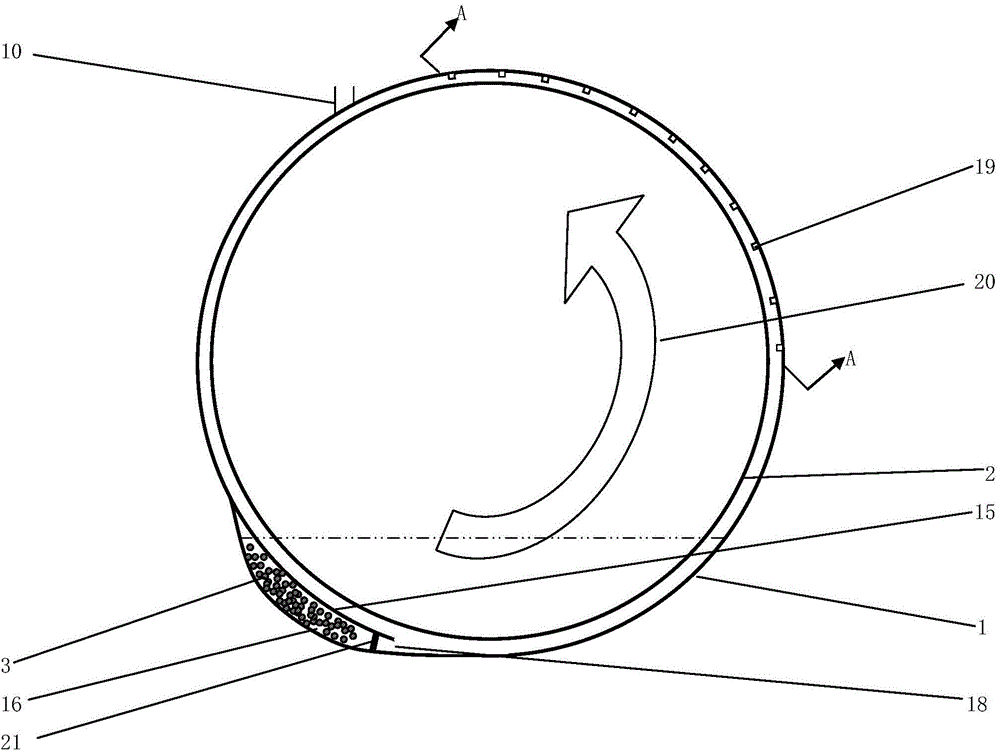

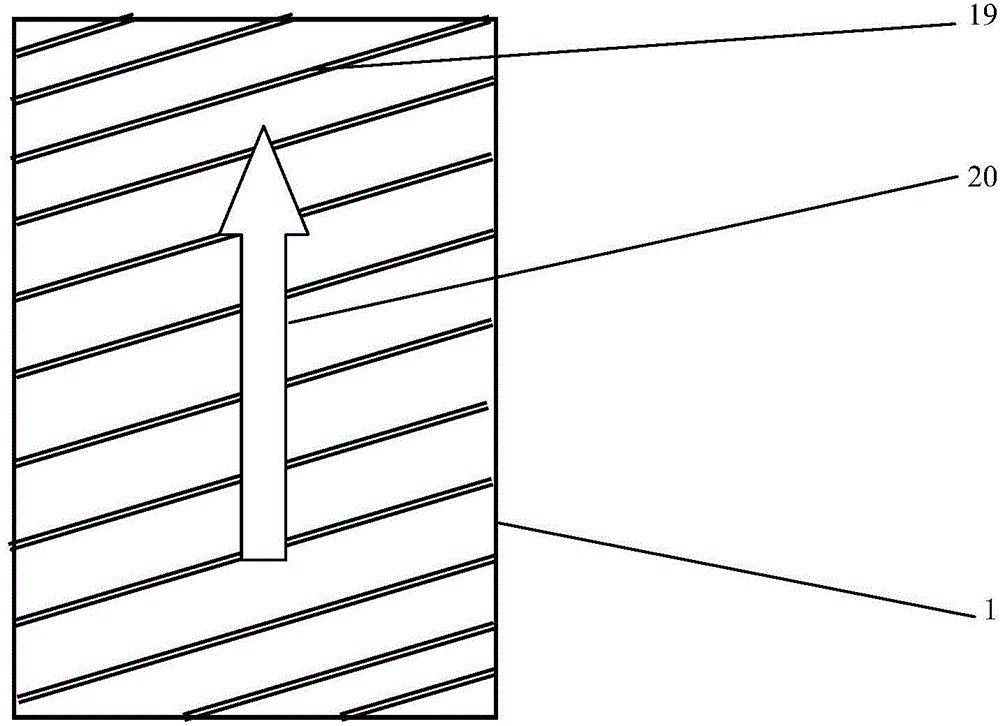

[0022] figure 1 , figure 2 , image 3In the example shown. Approximately spherical cleaning particles 3 with a diameter of about 0.4 cm are arranged between the outer barrel 1 and the inner barrel 2. The material is silica gel. The number is 20,000 or the weight is 500 grams. The cleaning particles are regular polyhedrons, and each side matches the inner surface of the outer barrel. The diameter of the dehydration hole is slightly smaller than the diameter of the cleaning particles 3 . The barrel walls around each dehydration hole on the cylindrical side wall of the inner barrel 2 protrude outwards by about 0.2cm so that the washing water can be driven to rotate more effectively when the barrel is cleaned. At about 0.2 cm, there are no dehydration holes on the front and rear walls of the inner barrel 2 to prevent the cleaning particles 3 from accumulating at the dehydration holes. A check valve 4 is installed at the water outlet of the outer barrel 1, and the check valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com