a range hood

A technology for range hoods and fans, which is used in the removal of range hoods, household stoves/stoves, heating methods, etc., can solve the problems of inconvenient cleaning, coating peeling, and inconvenient spraying of plastic coatings, achieving a wide range of cleaning and easy production and implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

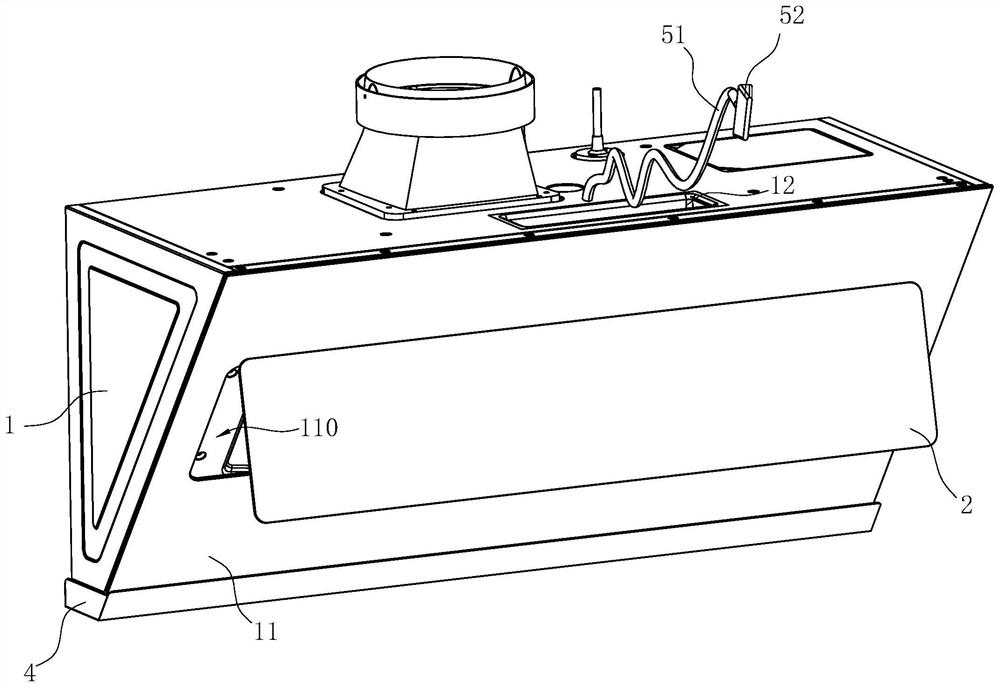

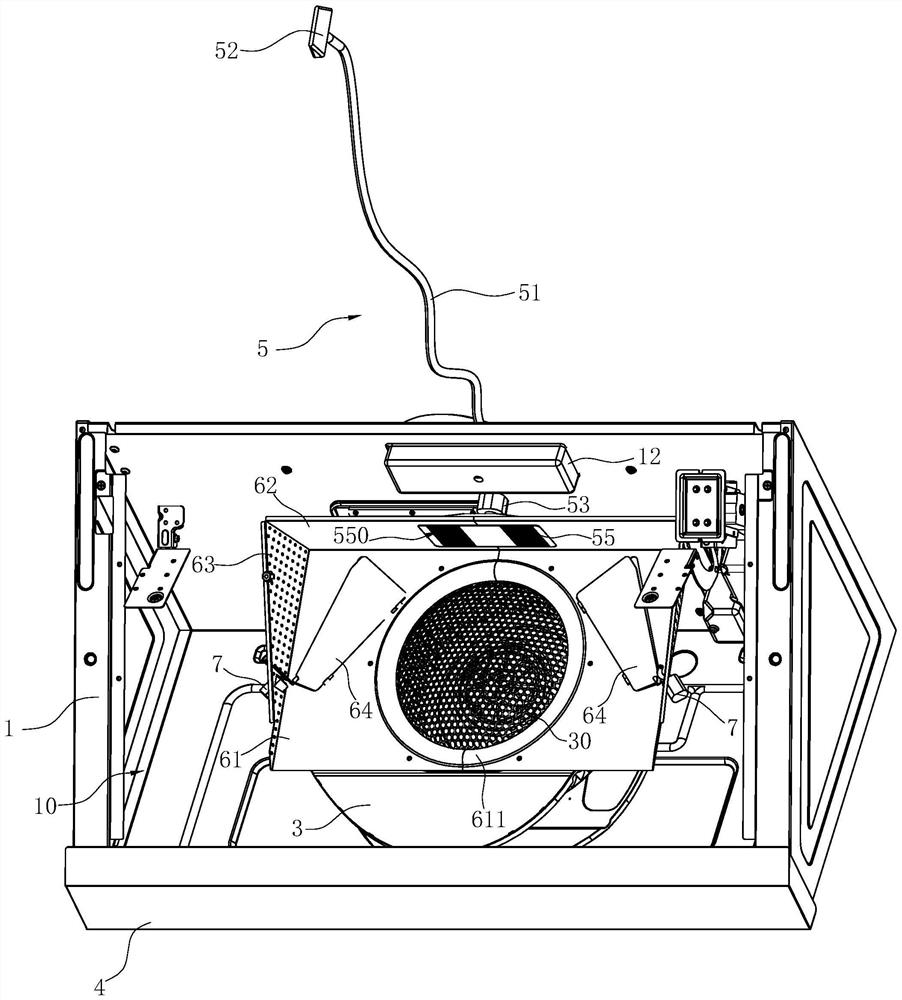

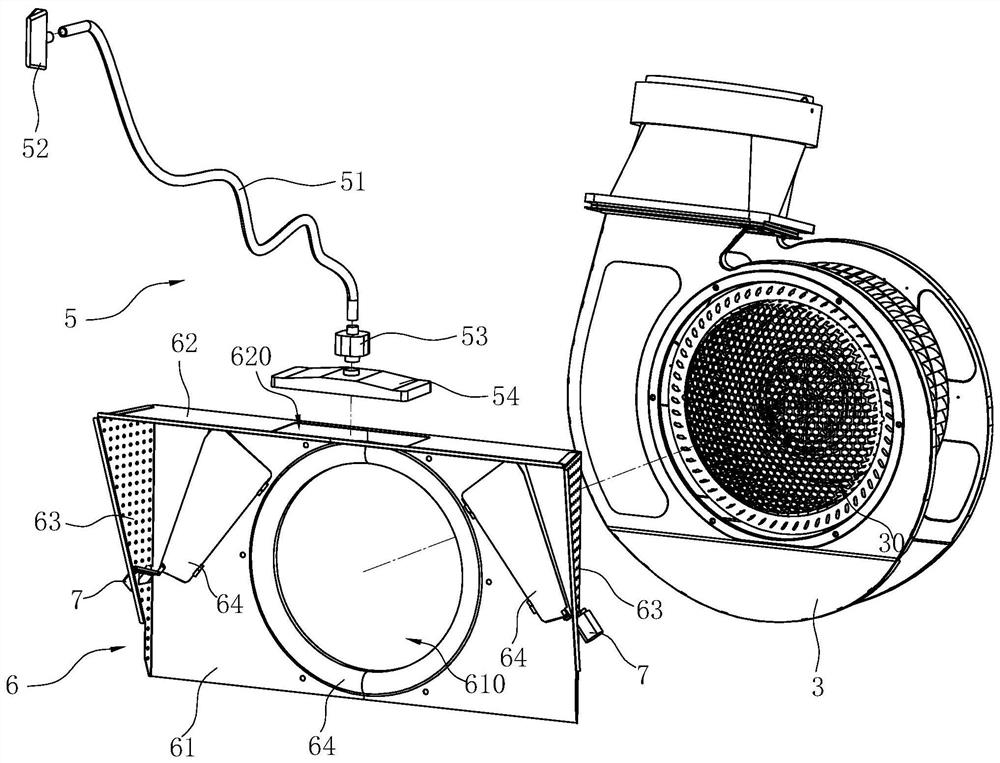

[0043]Such as Figure 1-7 Shown is a preferred embodiment 1 of a range hood of the present invention, which includes a housing 1 , a smoke baffle 2 , a fan 3 , an oil cup 4 , an oil suction assembly 5 , and an oil guide frame 6 .

[0044] Wherein, a smoke inlet chamber 10 is formed inside the housing 1, a panel 11 is provided on the front side of the housing 1, and a smoke inlet 110 communicating with the smoke inlet chamber 10 is opened on the panel 11 (the range hood in this embodiment is Side-suction range hoods, of course, can also be European-style range hoods). The smoke baffle 2 is arranged on the panel 11 to open and close the smoke inlet 110. The structure of the smoke baffle 2, the connection method with the panel 11 and the way of driving the smoke baffle 2 to open and close the smoke inlet 110 can refer to existing The technical design will not be repeated here. The above-mentioned fan 3 is arranged in the casing 1 , and the air inlet 30 of the fan 3 is arranged ...

Embodiment 2

[0051] Such as Figure 8 As shown, it is a preferred embodiment 2 of a range hood of the present invention. This range hood is basically the same as Embodiment 1, the difference is that in this embodiment, each baffle plate 64 is opposite to each group of grill holes 550, and each The angle α between the baffle plate 64 and the vertical plane is greater than the angle β between the corresponding grid holes and the vertical plane; the projection of each group of grid holes 550 on the horizontal plane falls into the corresponding baffle plate 64 at within the projection on the horizontal plane. So that the oil from the grill hole 550 can flow to the baffle 64 and flow down along the baffle 64 to prevent the oil from entering the fan 3 .

Embodiment 3

[0053] Such as Figures 9 to 11 As shown, it is the third preferred embodiment of a range hood of the present invention, the range hood is basically the same as the first embodiment, the difference is that there is no baffle plate and grille in this embodiment, in this embodiment, Below the dirt inlet hole 620, there is a deflector 8 for guiding the oil to the front wall of the vertical plate 61; Afterwards, it gradually inclines downward, and the rear end edge of the deflector 8 abuts against the front wall of the vertical plate 61 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com