Mold for manufacturing goblet on presser

A technology for goblets and moulds, applied in glass blowing machines, glass production, etc., can solve the problems of high production cost, low output, and large labor volume, and achieve increased production capacity, increased color varieties, and reduced labor volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

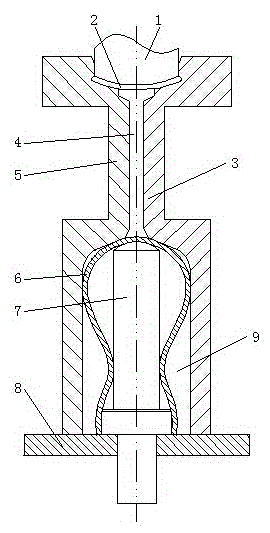

[0017] A mold for making a goblet with a press. The mold has two openings. When the left module 5 and the right module 3 are closed, the inside of the mold forms a cup holder cavity 2, a cup stem cavity 4, and a cup body shape from top to bottom. Cavity 9, the cup body cavity 9 is provided with a push rod 7, the push rod 7 is connected to the chassis 8, and the punch 1 is located on the cup holder cavity 2. The left module 5 and the right module 3 are provided with manual opening and closing latches. The shape of the cup stem cavity 4 can be a geometric shape that the left module 5 and the right module 3 can be demolded after the cup stem is formed. The shape of the cup holder cavity 2 can be a geometric shape in which the left module 5 and the right module 3 can be demolded after the cup holder is formed. Patterns are engraved on the position of the cup holder surface in the cup holder cavity 2 . Pressing machine is a station or a plurality of stations, and a mold is instal...

Embodiment 2

[0019] A mold for making a goblet with a press. The mold has two openings. When the left module 5 and the right module 3 are closed, the inside of the mold forms a cup holder cavity 2, a cup stem cavity 4, and a cup body shape from top to bottom. Cavity 9, the cup body cavity 9 is provided with a push rod 7, the push rod 7 is connected to the chassis 8, and the punch 1 is located on the cup holder cavity 2. The shape of the cup stem cavity 4 can be a geometric shape that the left module 5 and the right module 3 can be demolded after the cup stem is formed. The shape of the cup holder cavity 2 can be a geometric shape in which the left module 5 and the right module 3 can be demolded after the cup holder is formed. Patterns are engraved on the position of the cup holder surface in the cup holder cavity 2 . A connecting rod for automatic opening and closing is connected to the left module 5 and the right module 3 . During automatic mold opening, the left module 5 and the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com