Sludge treatment heat exchange system

A technology of heat exchange system and sludge treatment, which is applied in the direction of biological sludge treatment, water/sludge/sewage treatment, special treatment targets, etc., to achieve the effect of reducing compaction, reducing water cost, and reducing water consumption for soft water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

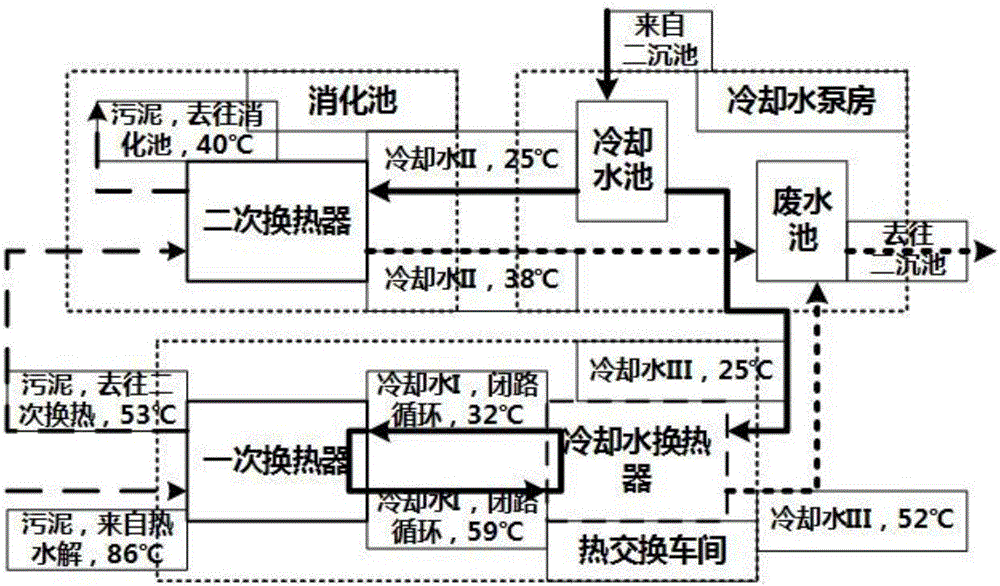

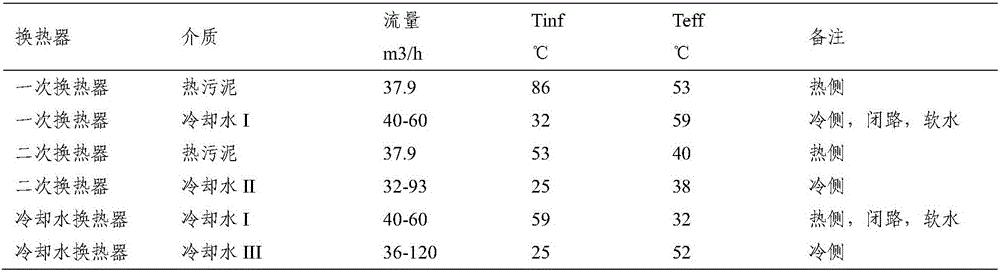

[0019] Concrete composition and working principle of the present invention refer to figure 1 shown. A heat exchange system for sludge treatment, including a primary heat exchanger, a secondary heat exchanger, a cooling water heat exchanger, a cooling water pool and a waste water pool; the inlet of the primary heat exchanger is the input end of the thermally hydrolyzed sludge, At the outlet of the primary heat exchanger, the sludge whose temperature drop after passing through the heat exchanger of this stage is 65%-75% of the difference between the temperature of the sludge after thermal hydrolysis treatment and the set temperature of the anaerobic digestion process is sent to the secondary connected to it. The inlet of the secondary heat exchanger; the outlet of the secondary heat exchanger sends the sludge whose temperature drops to the set temperature for the anaerobic digestion process after passing through the heat exchanger of this stage to the digester connected to it; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com