Optimization method of diesel oil refining efficiency

An efficiency optimization and diesel oil technology, which is applied in the fields of hydrocarbon oil cracking, petroleum industry, and hydrocarbon oil treatment, can solve the problems of low production efficiency of light diesel oil, high production cost, and high price of light diesel oil, so as to avoid hydrogen mixing in advance steps, save time, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

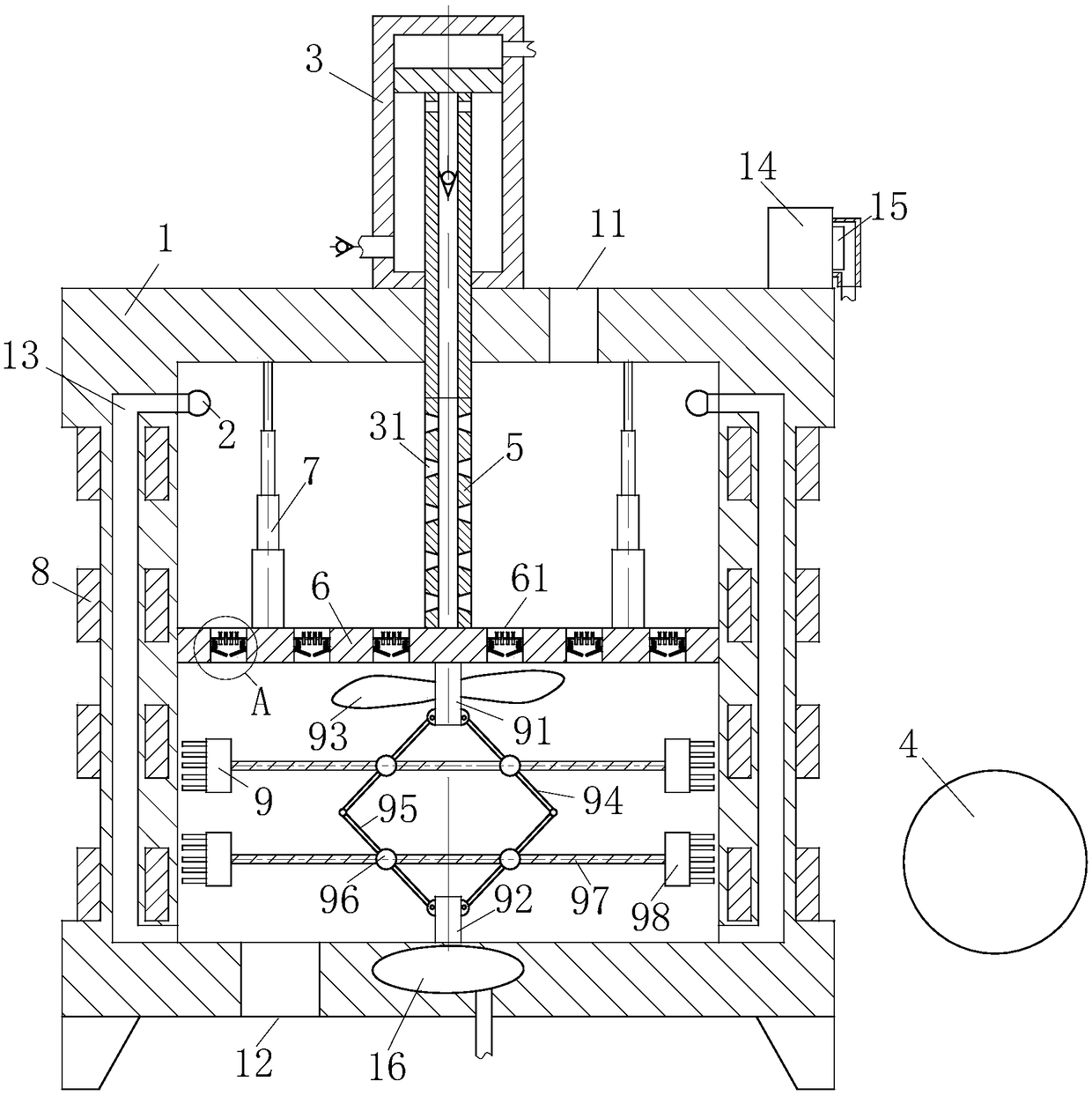

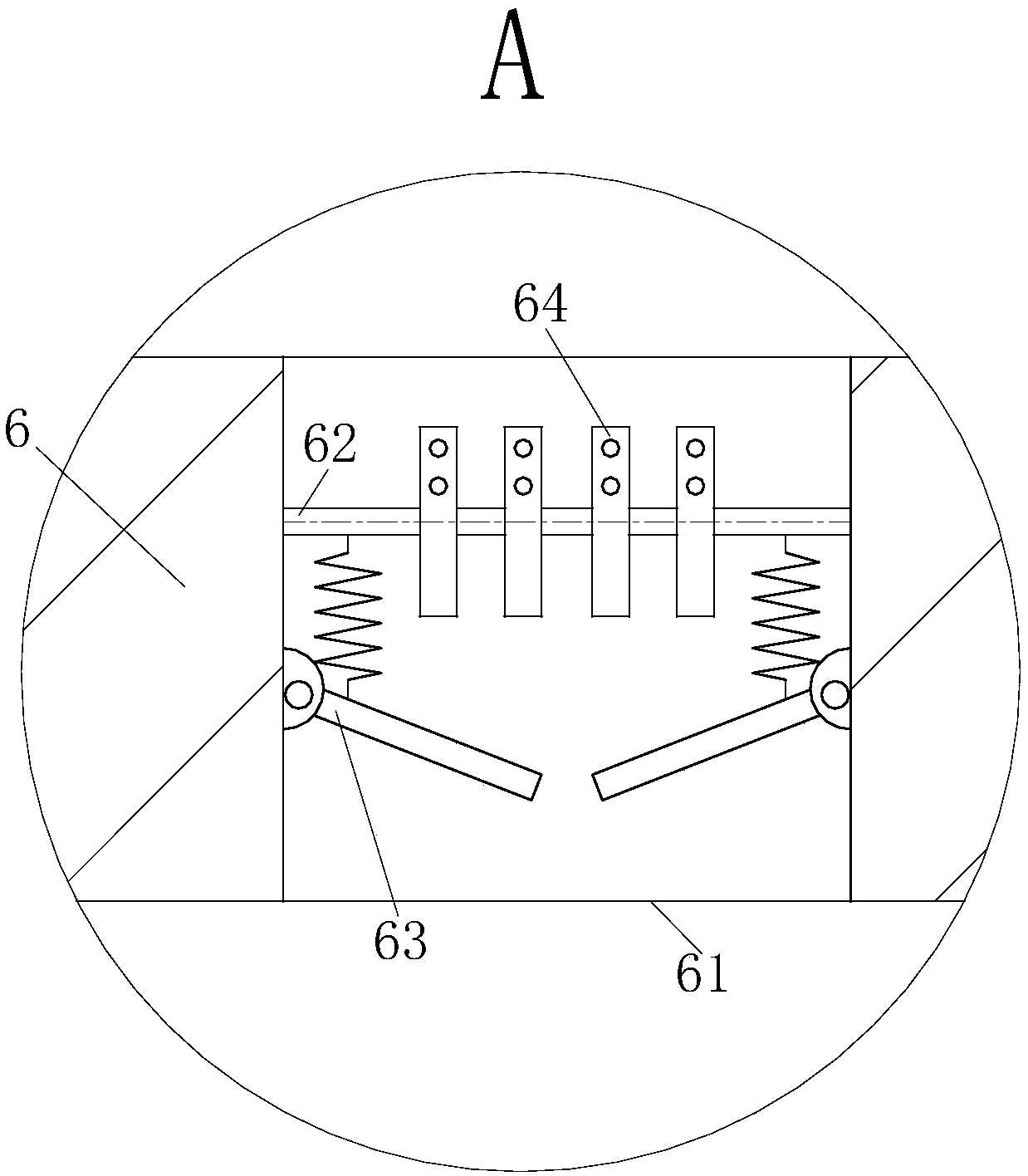

[0023] use Figure 1-Figure 3 The method for increasing the diesel oil refining rate according to one embodiment of the present invention will be described below.

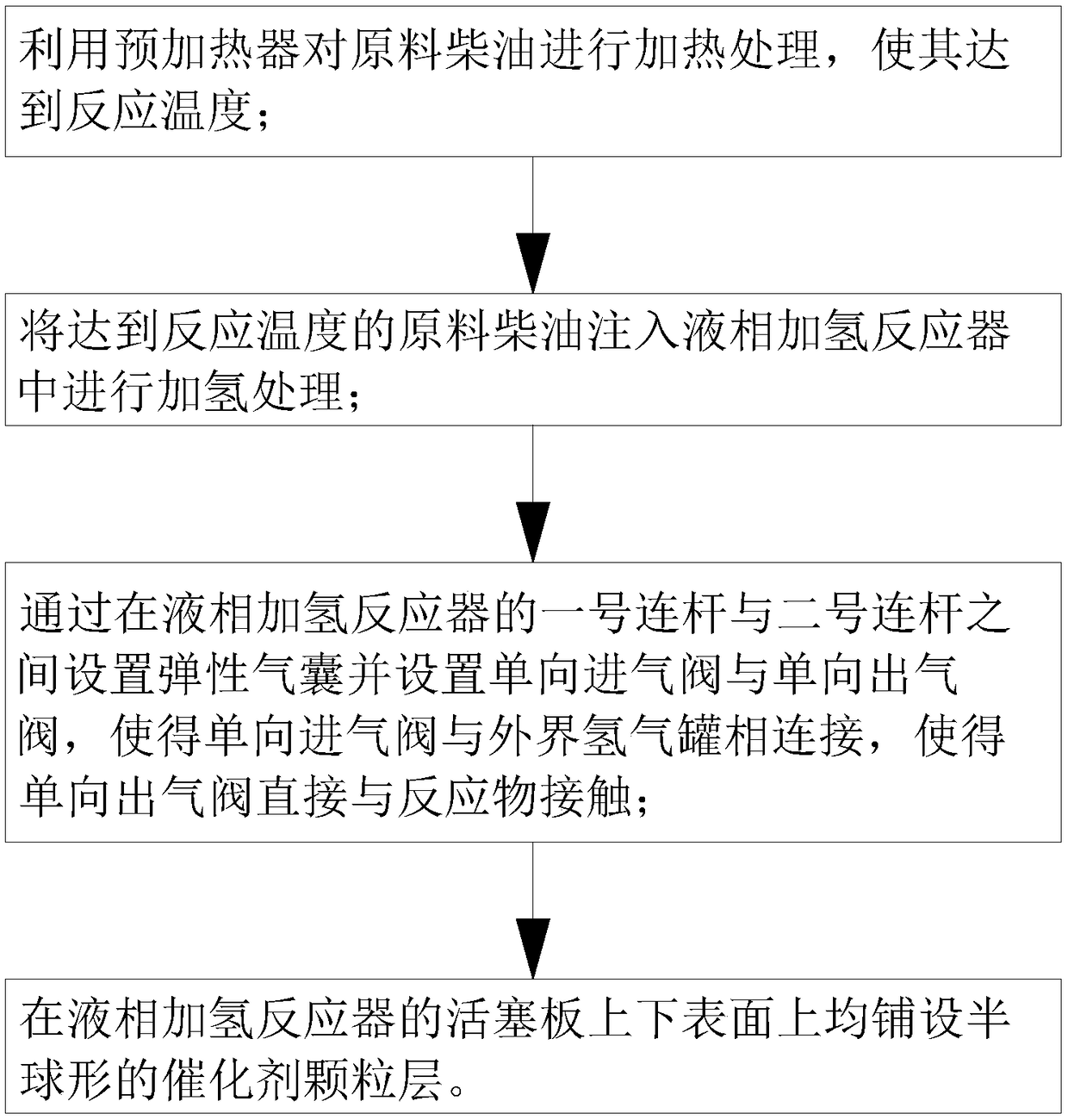

[0024] Such as Figure 1-Figure 3 Shown, a kind of diesel oil refining efficiency optimization method described in the present invention, this method comprises the steps:

[0025] S1: Use the heater to preheat the raw diesel to make it reach the reaction temperature, so that the diesel can have a faster reaction speed immediately after entering the liquid phase hydrogenation reactor, thereby shortening the speed of diesel refining;

[0026] S2: After heating in S1, inject the raw diesel oil that has reached the reaction temperature into the liquid phase hydrogenation reactor for hydrogenation treatment, so that the diesel oil can be hydrocracked rapidly, and the speed of diesel oil refining can be effectively improved;

[0027] S3: After the raw material diesel in S2 enters the liquid-phase hydrogenation reactor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com