A thermosiphon hot water system for recovery of exhaust energy from household air conditioners

A thermosiphon and hot water system technology, which is applied in the field of waste heat recovery in refrigeration systems, can solve problems such as unsatisfactory waste heat recovery schemes, insignificant waste heat recovery effects, and poor heat exchange effects, and achieve significant waste heat recovery effects, lower temperatures, and installation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

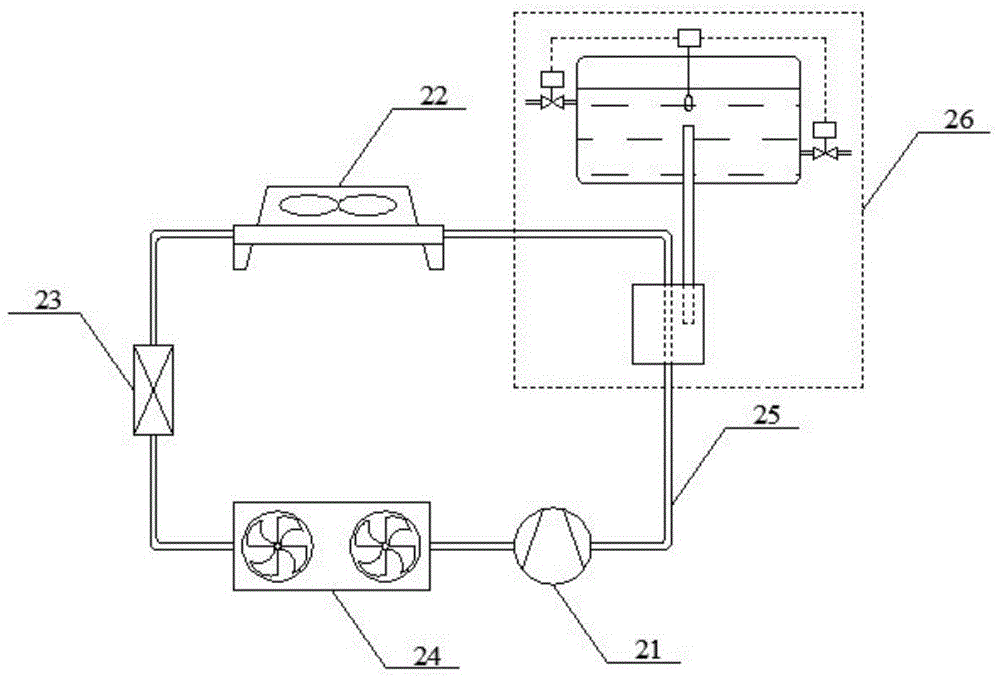

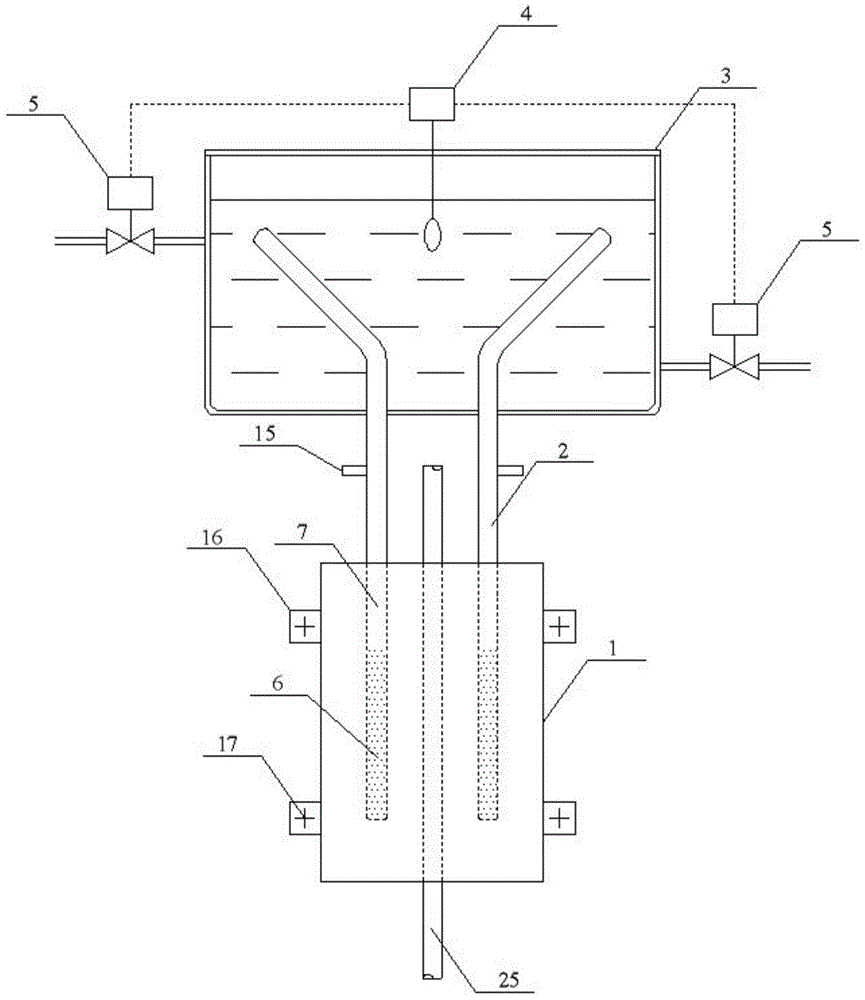

[0024] Such as Figure 1-Figure 5 As shown, a thermosiphon hot water system for recovering exhaust energy of a household air conditioner, the system includes a household air conditioner compressor 21, a compressor exhaust pipe 25, a condenser 22, a throttling device 23, and an evaporator 24 , also includes a thermosiphon hot water system 26 connected on the pipeline between the compressor outlet and the condenser inlet. The compressor 21 continuously sucks the low-pressure and low-temperature refrigerant vapor generated in the evaporator 24, compresses it into high-temperature and high-pressure refrigerant vapor, and transports it to the condenser 22 through the compressor exhaust pipe 25, and undergoes cooling and condensation in the condenser 22. The refrigerant turns into a normal temperature and high pressure liquid, passes through the throttling device 23 into a normal temperature and low pressure refrigerant liquid, and flows into the evaporator 24. The refrigerant liqui...

Embodiment 2

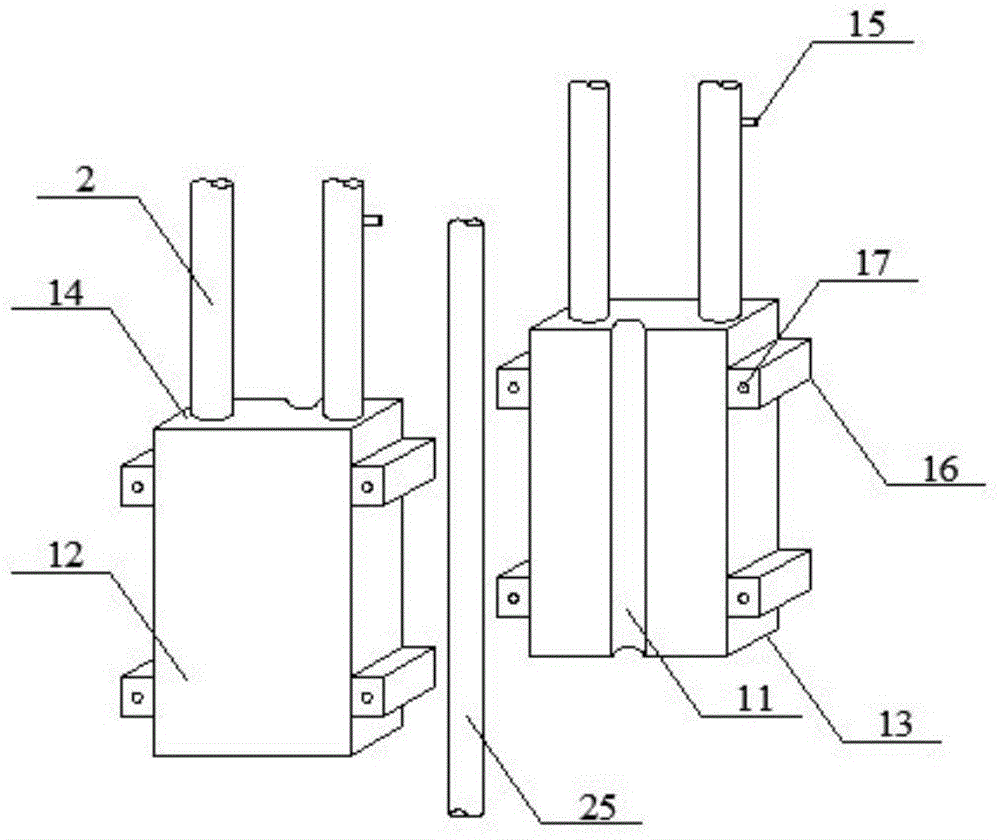

[0036] Figure 6 Shown is the schematic diagram of the thermosiphon hot water system of the second embodiment. In this embodiment, the exhaust pipe 25 of the compressor of the air conditioner is located at a horizontal position.

[0037] The heat absorbing module 1 is a sleeve structure outside the compressor exhaust pipe 25, and the sleeve is made of a metal material (such as copper or aluminum) with good thermal conductivity.

[0038] The lower end cover 13 of the thermosiphon heat exchanger and the upper end cover 14 of the thermosiphon heat exchanger are brazed with the bushing and the exhaust pipe 25 of the compressor. The tube heat exchanger 8 is connected; the thermosiphon 2 includes thermosiphon a2.1, thermosiphon b2.2, thermosiphon c2.3; the gaseous thermosiphon working fluid 6 goes up along the thermosiphon a2.1 and thermosiphon b2.2 To the vertical tube heat exchanger 8, after condensation, it flows back into the casing along the thermosiphon c2.3.

[0039] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com