Patents

Literature

72results about How to "Produced easily and cost-effectively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

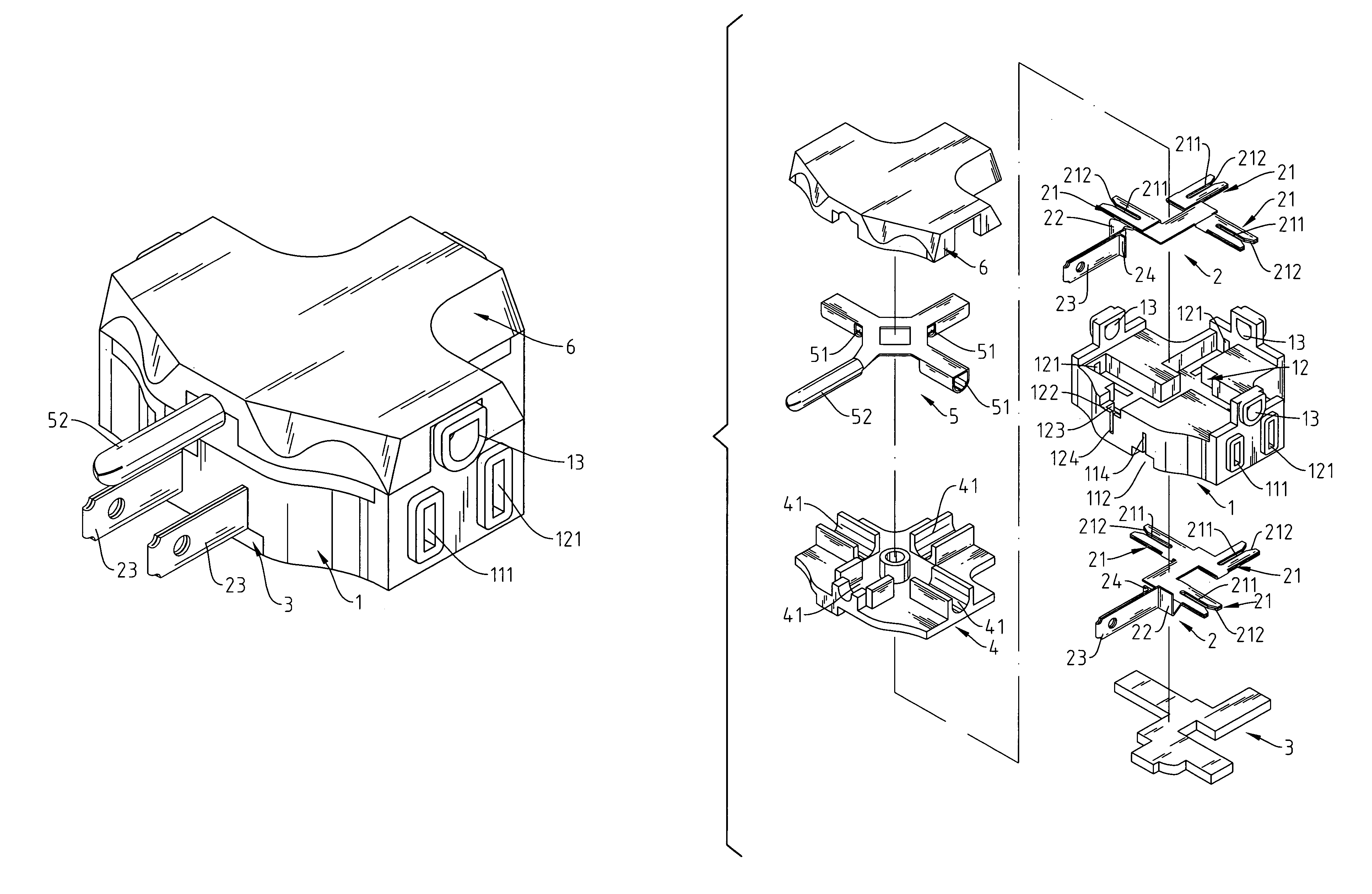

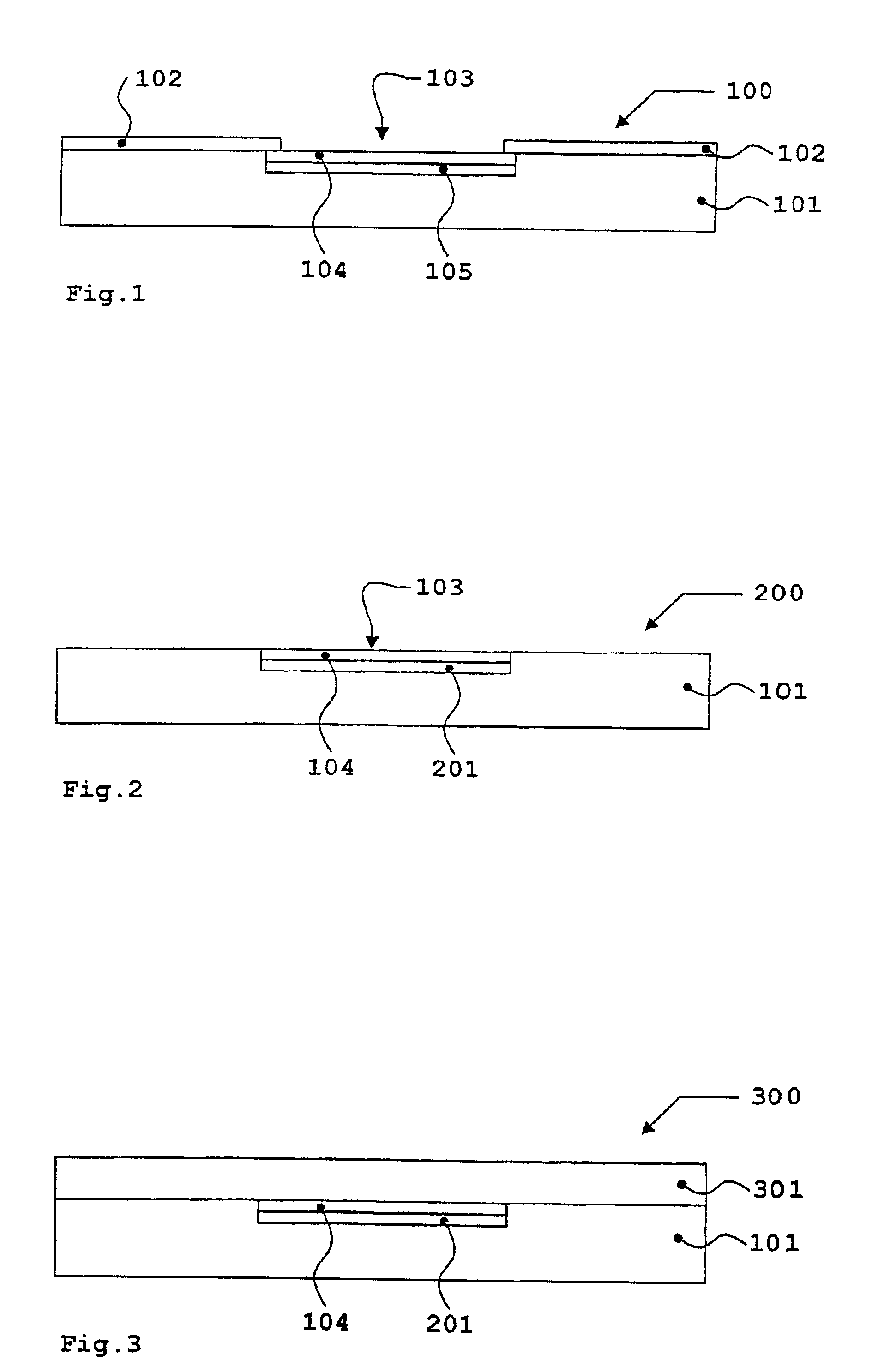

Socket with non-connecting terminal

InactiveUS6929514B1Produced easily and cost-effectivelyProduced cost-effectivelyContact member manufacturingElectric discharge tubesEngineeringTop cap

A socket with non-connecting terminal comprises a socket body, two power terminals, a bottom cover, a support, a ground terminal and a top cover in which the power terminals and the ground prong are integrally stamped without terminal tap. The power terminals are placed in the first receptacle and the second receptacle and sealed with the support and the bottom cover. The power blades are exposed outside to be connected to the wall socket. The three slots serve as a power supply to receive other plugs. The integrally stamped ground terminal is housed in the support and sealed by the top cover; the ground prong is exposed outside for linking to the power supply. The three ground slots on the ground terminal will accept the ground prongs from other plugs. When an electrical current flows through this circuit, there is no resistance encountered and no heat generated.

Owner:CHAO TRADING

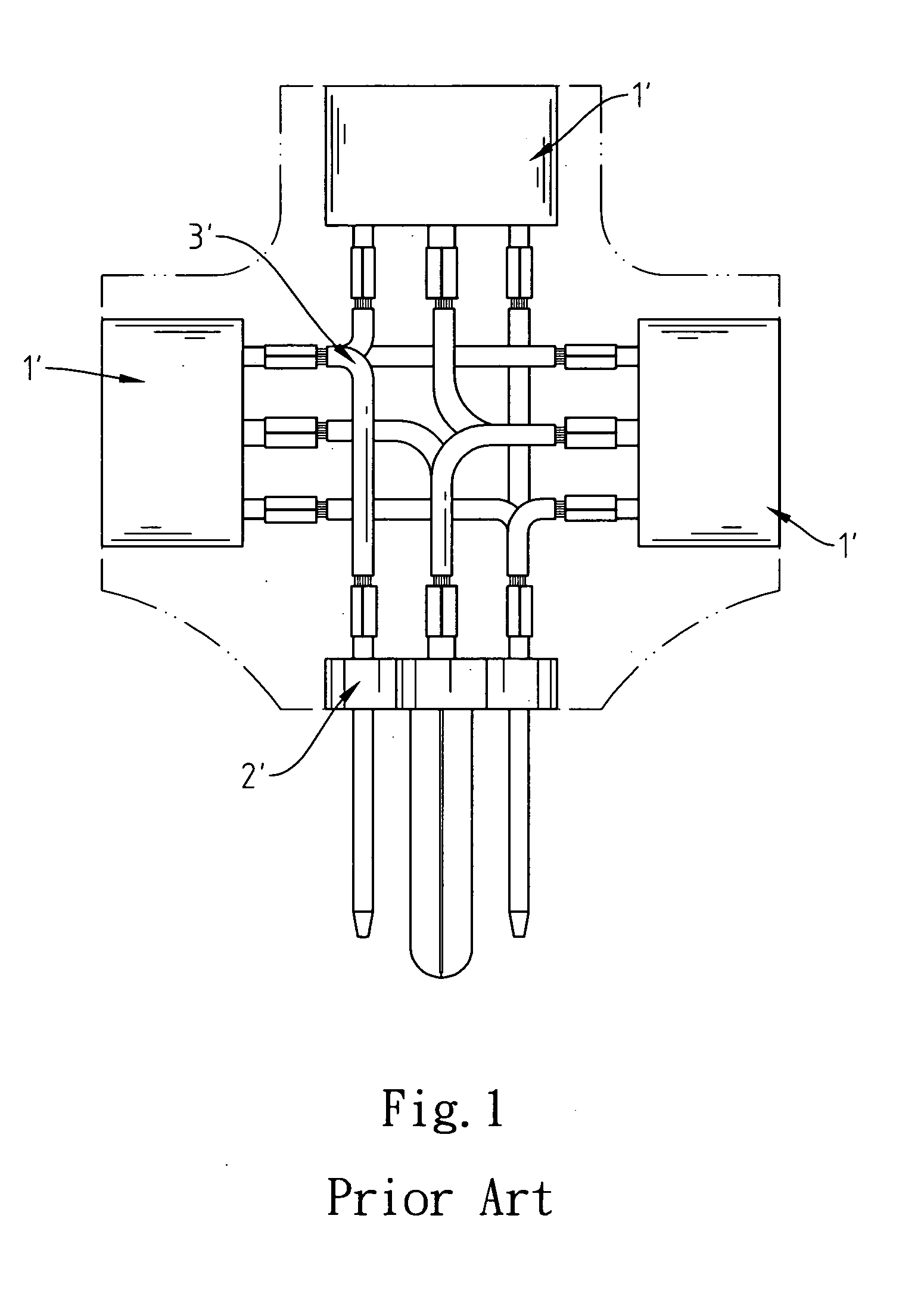

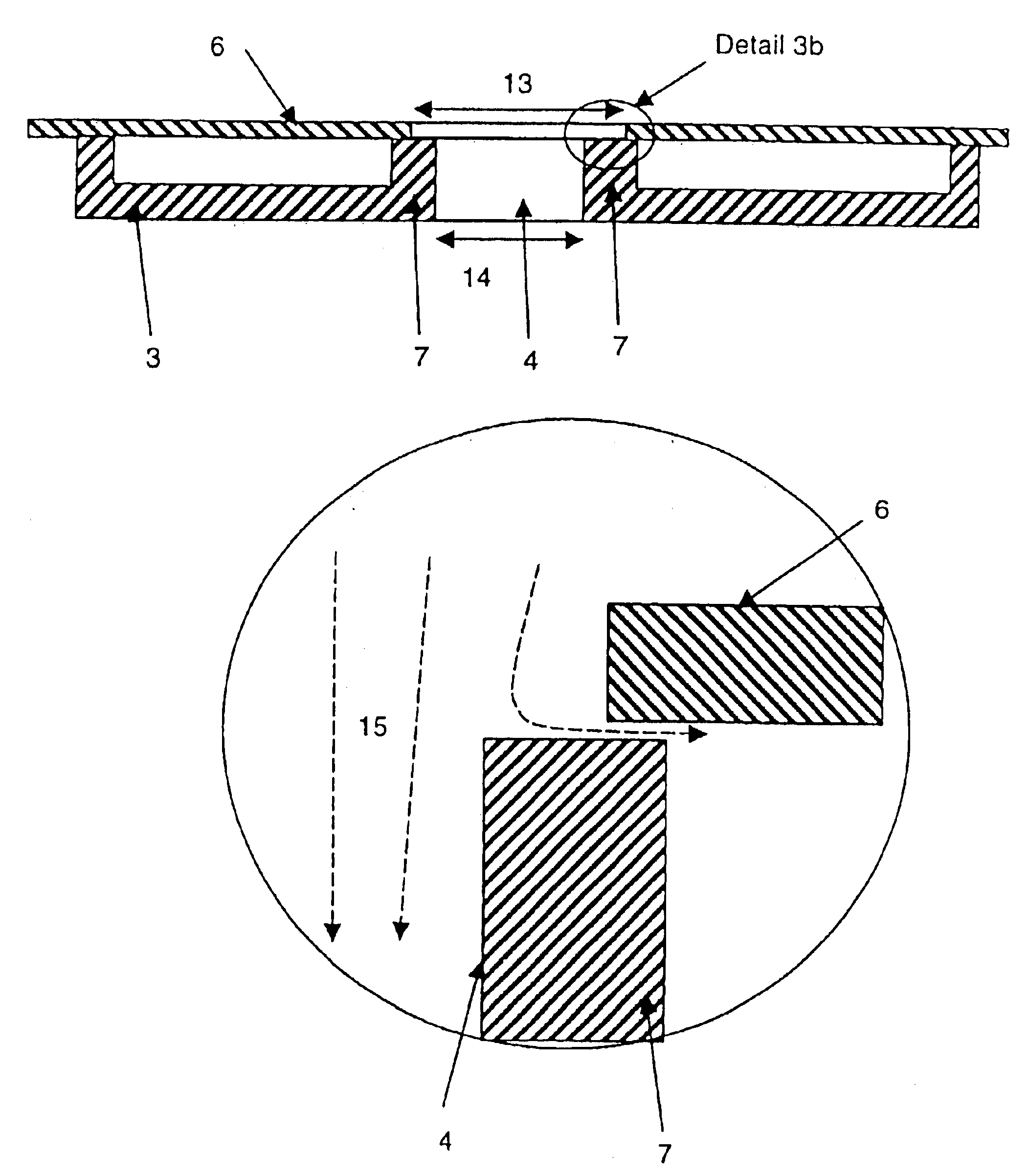

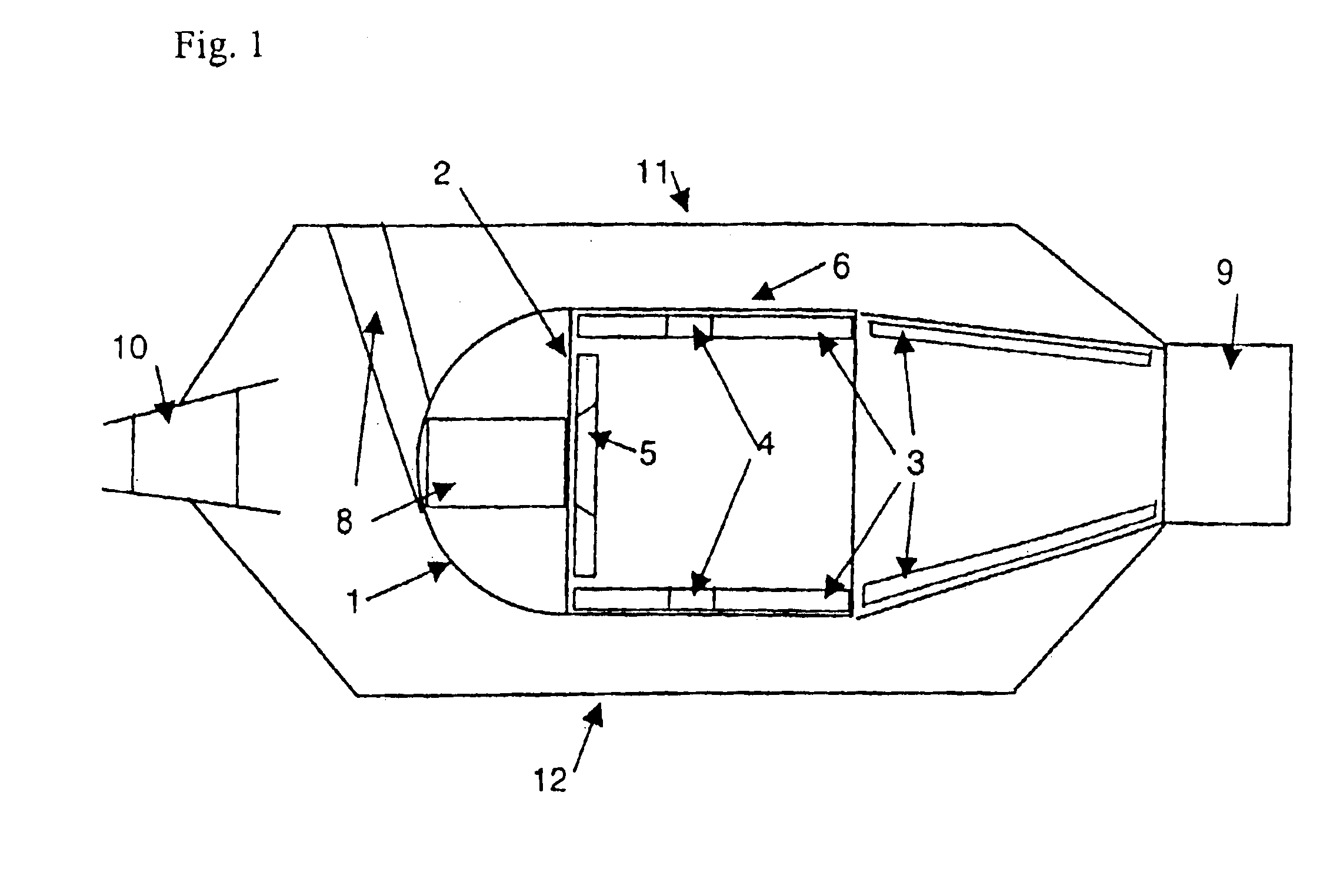

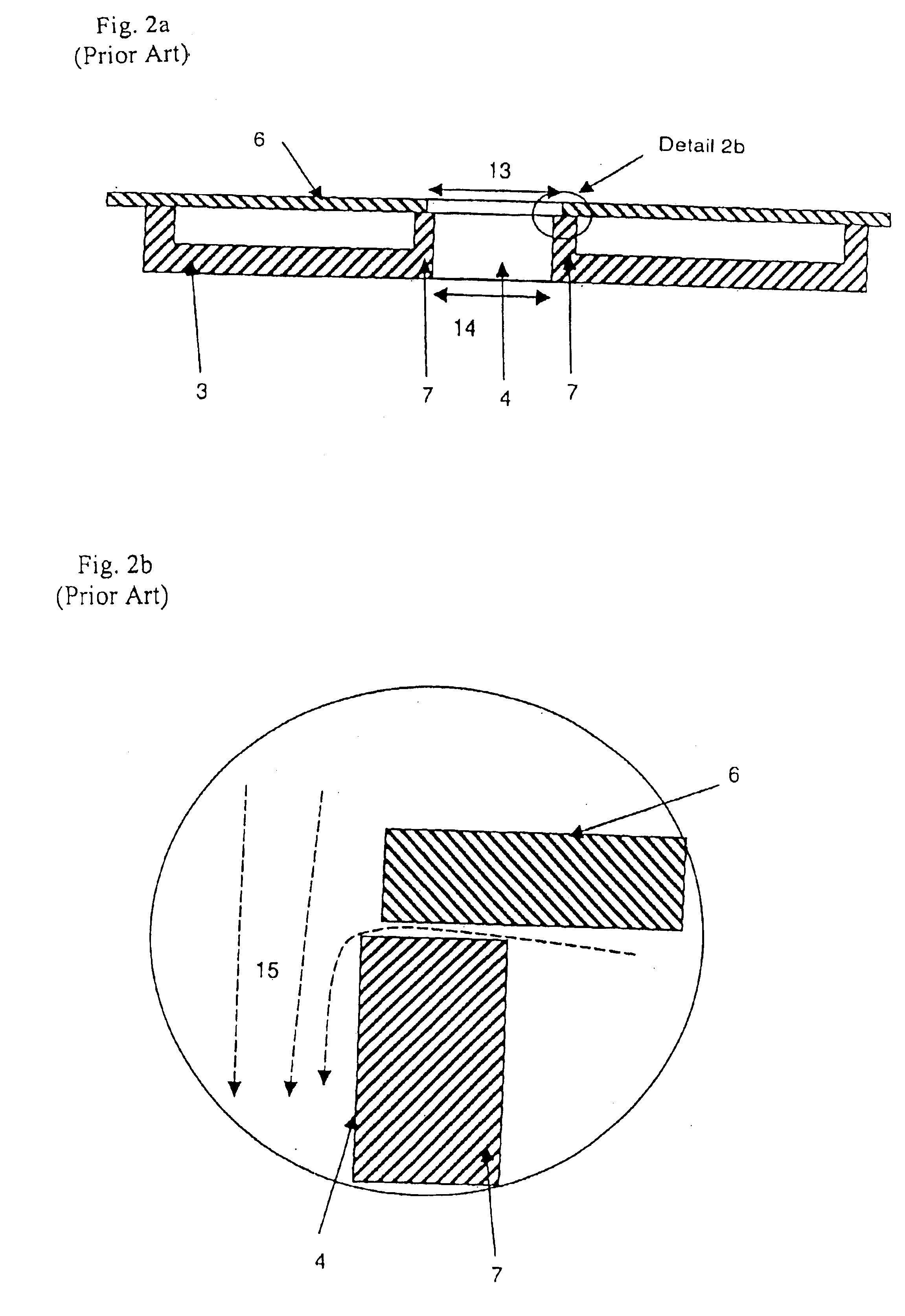

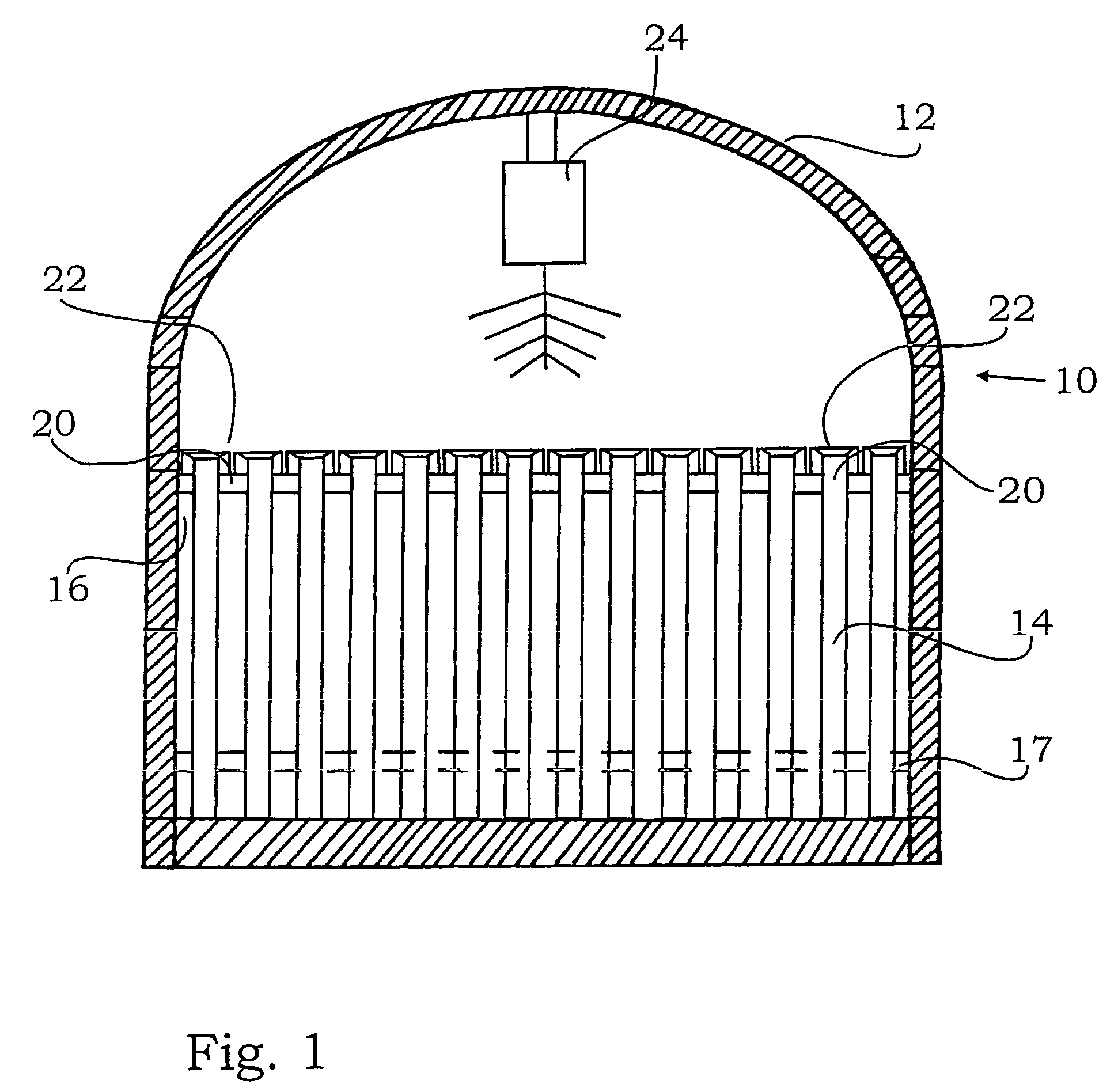

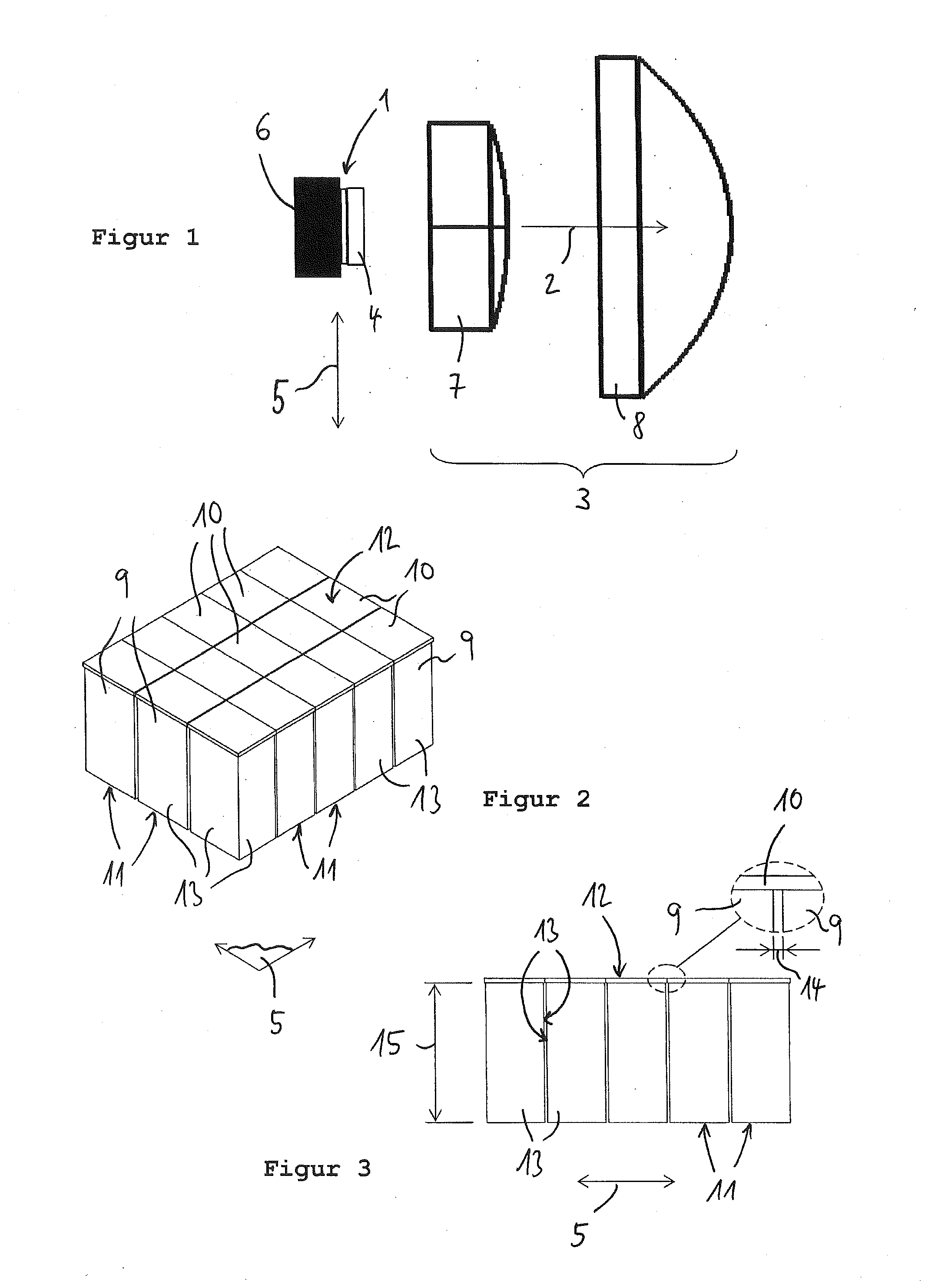

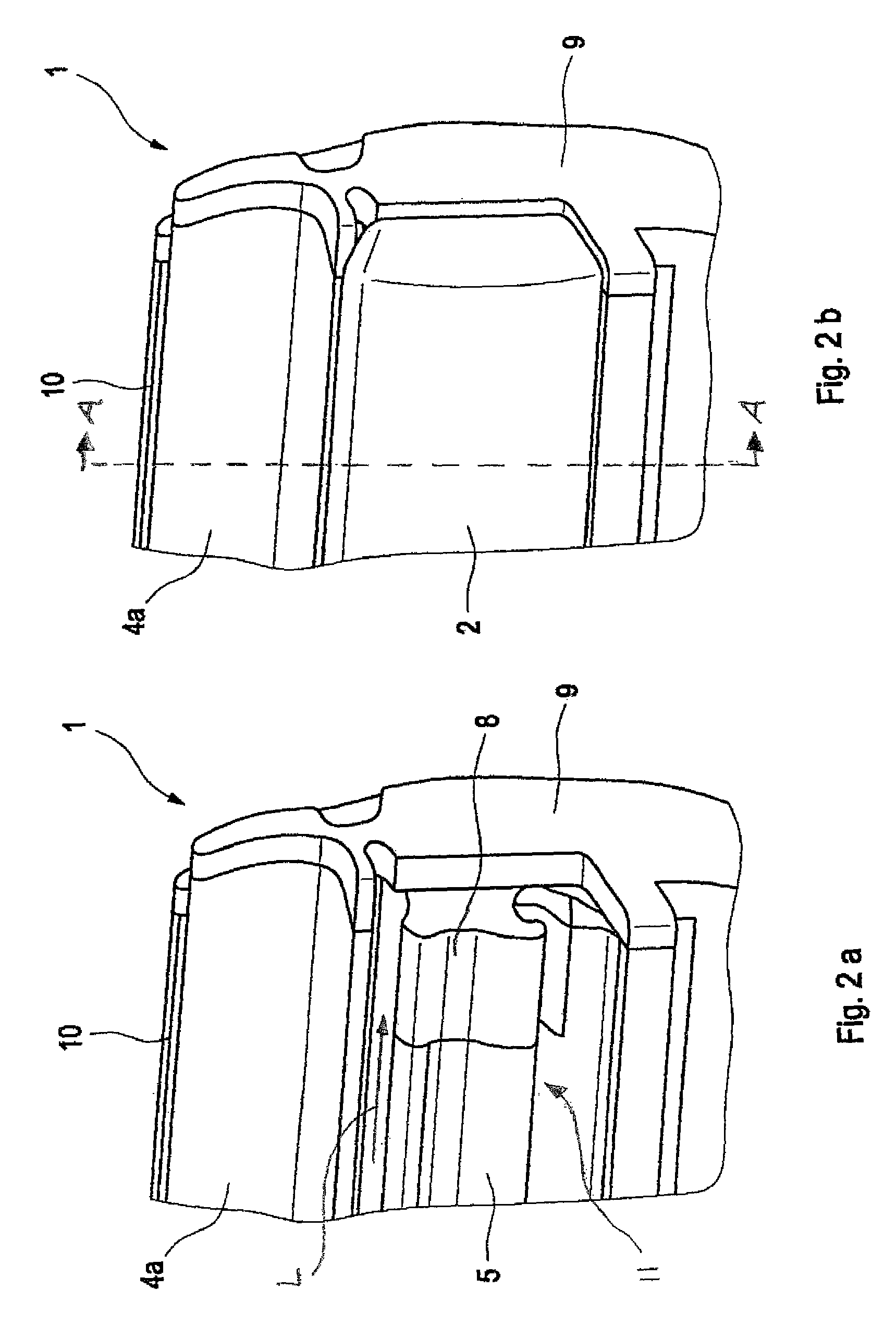

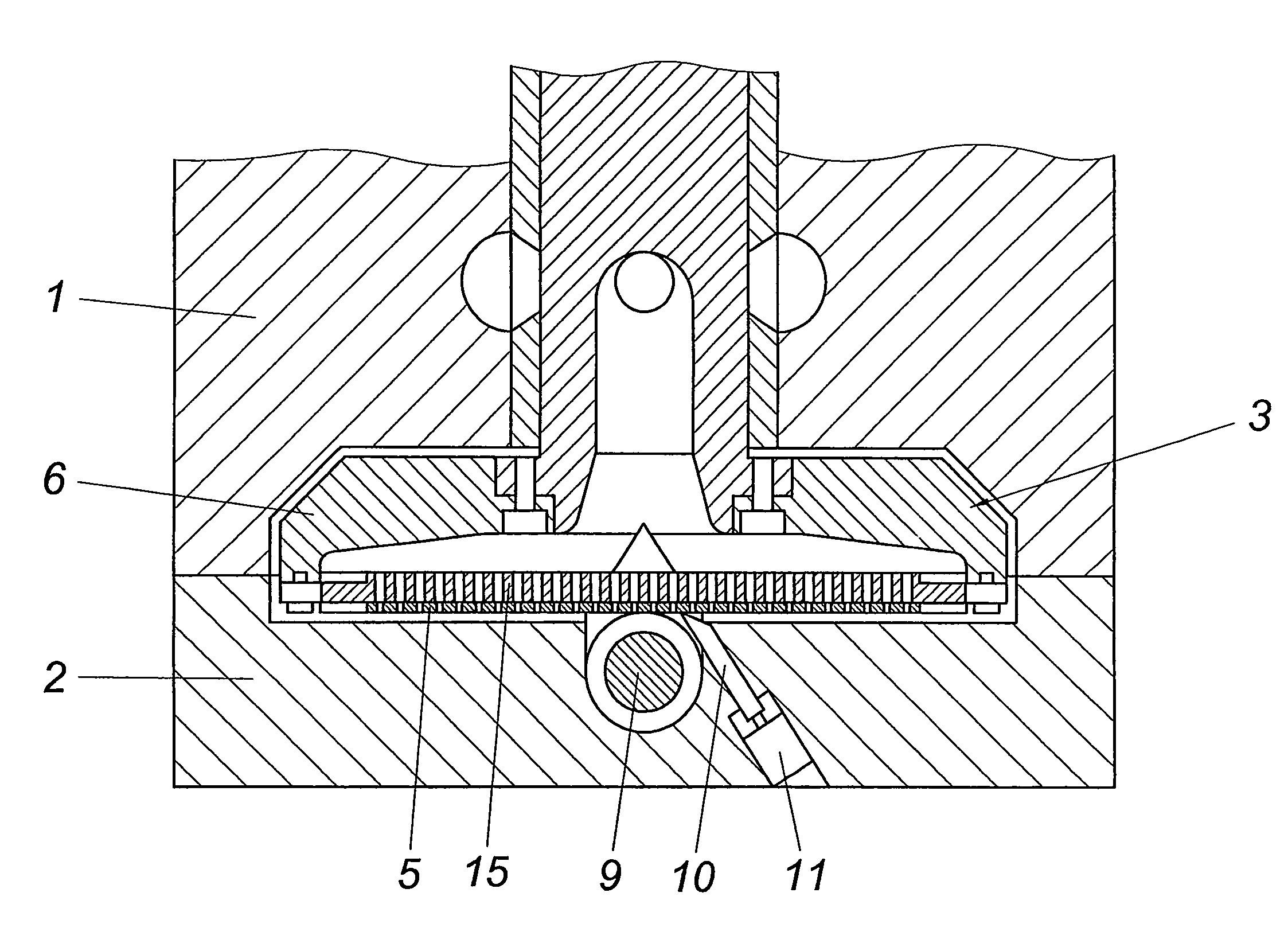

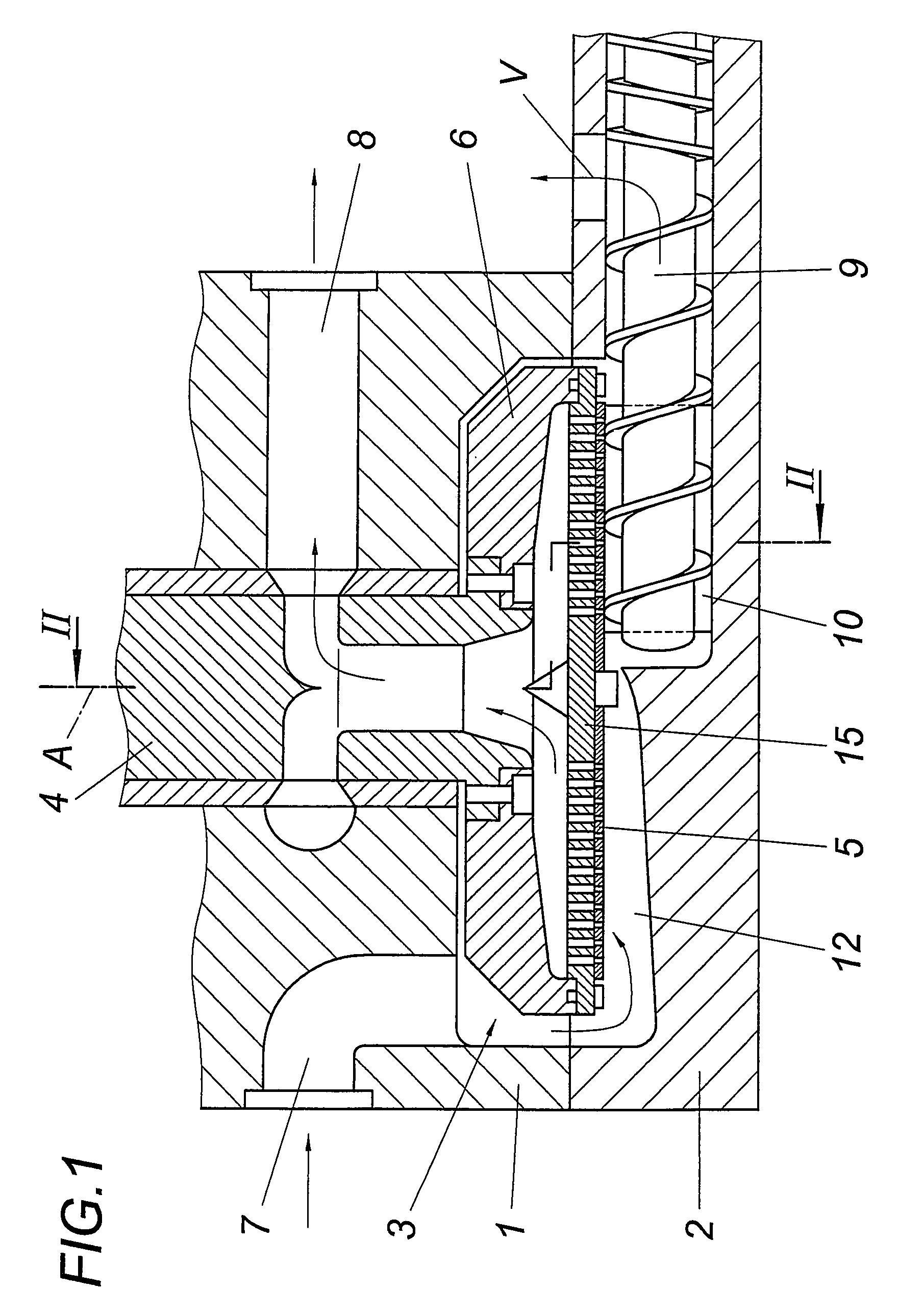

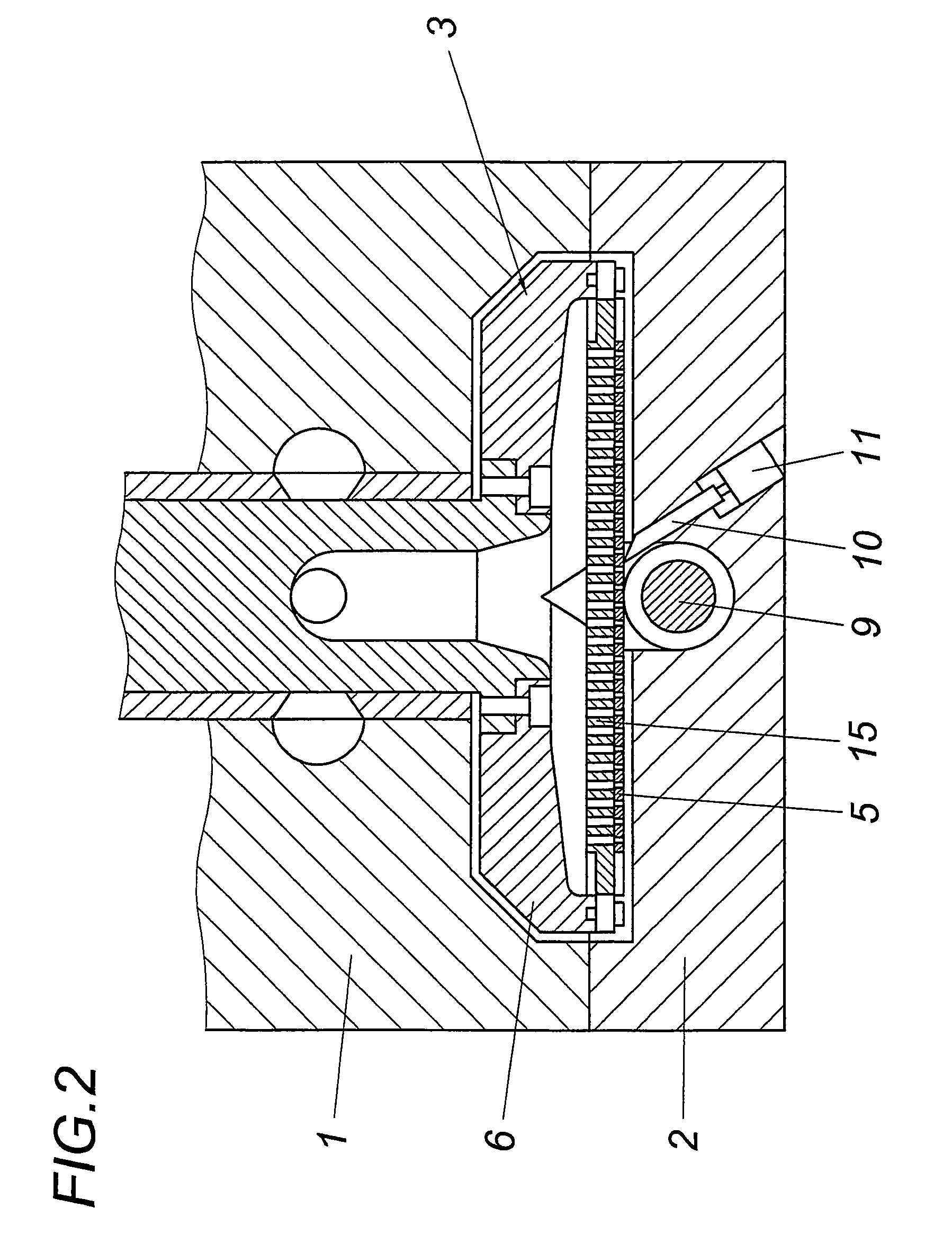

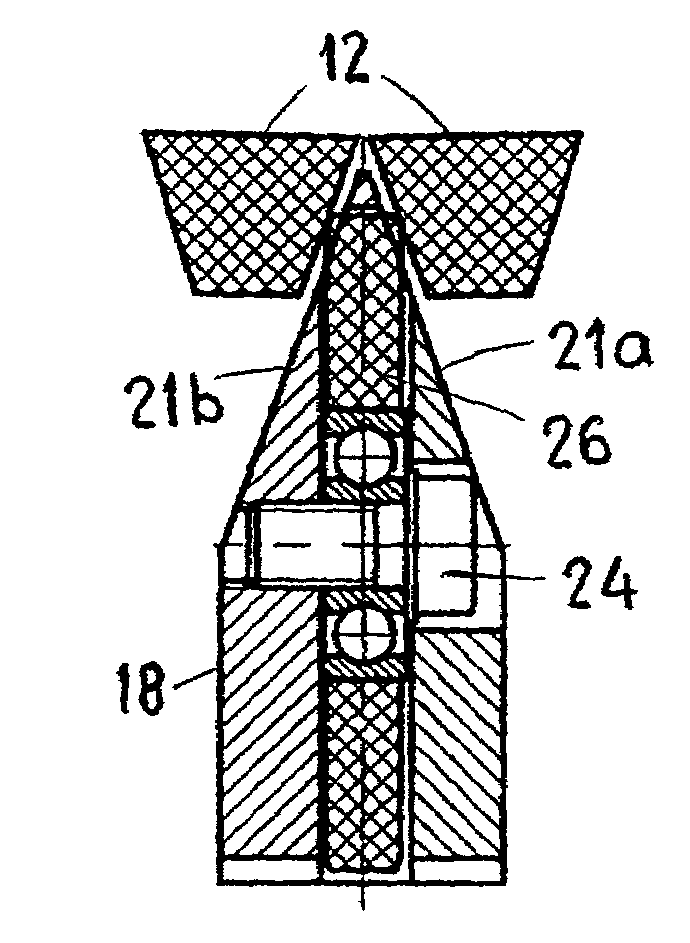

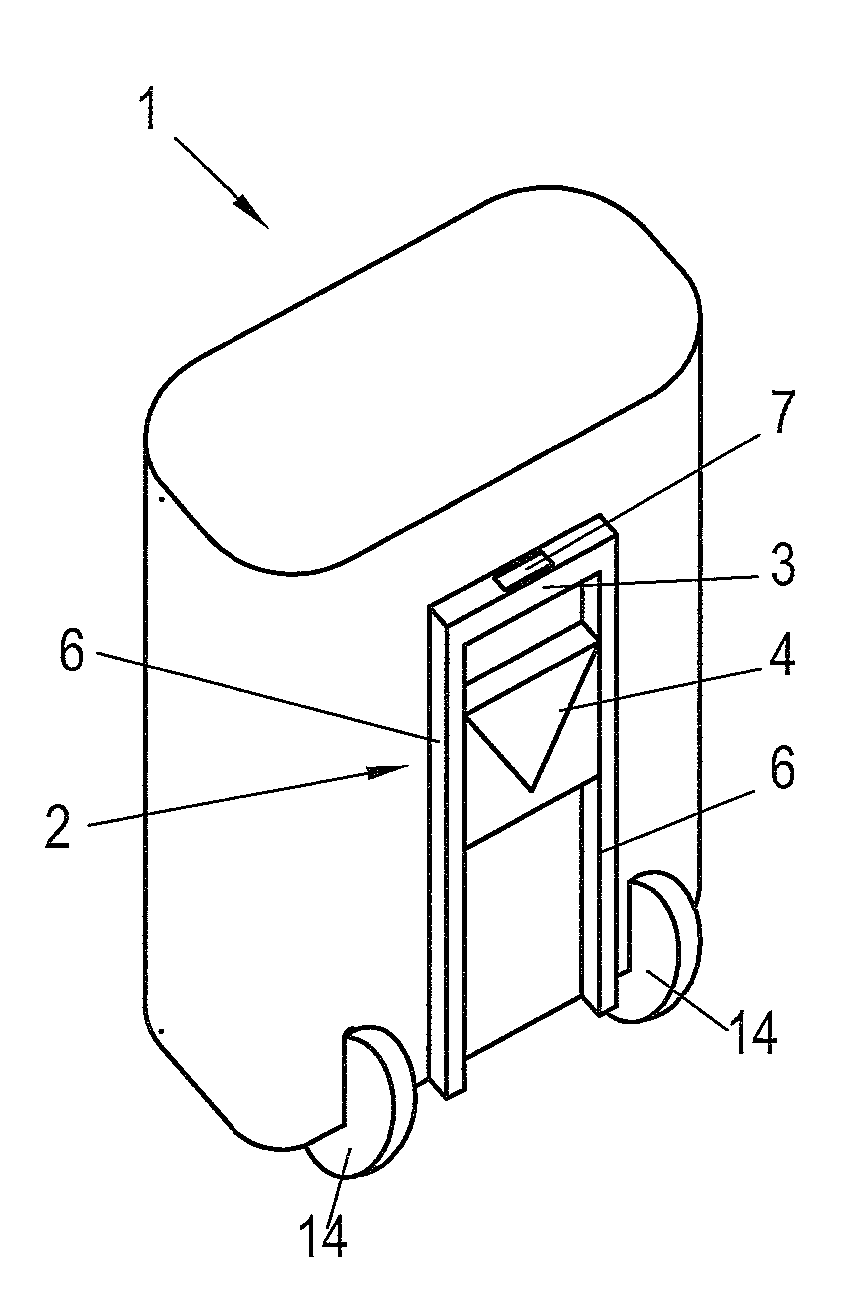

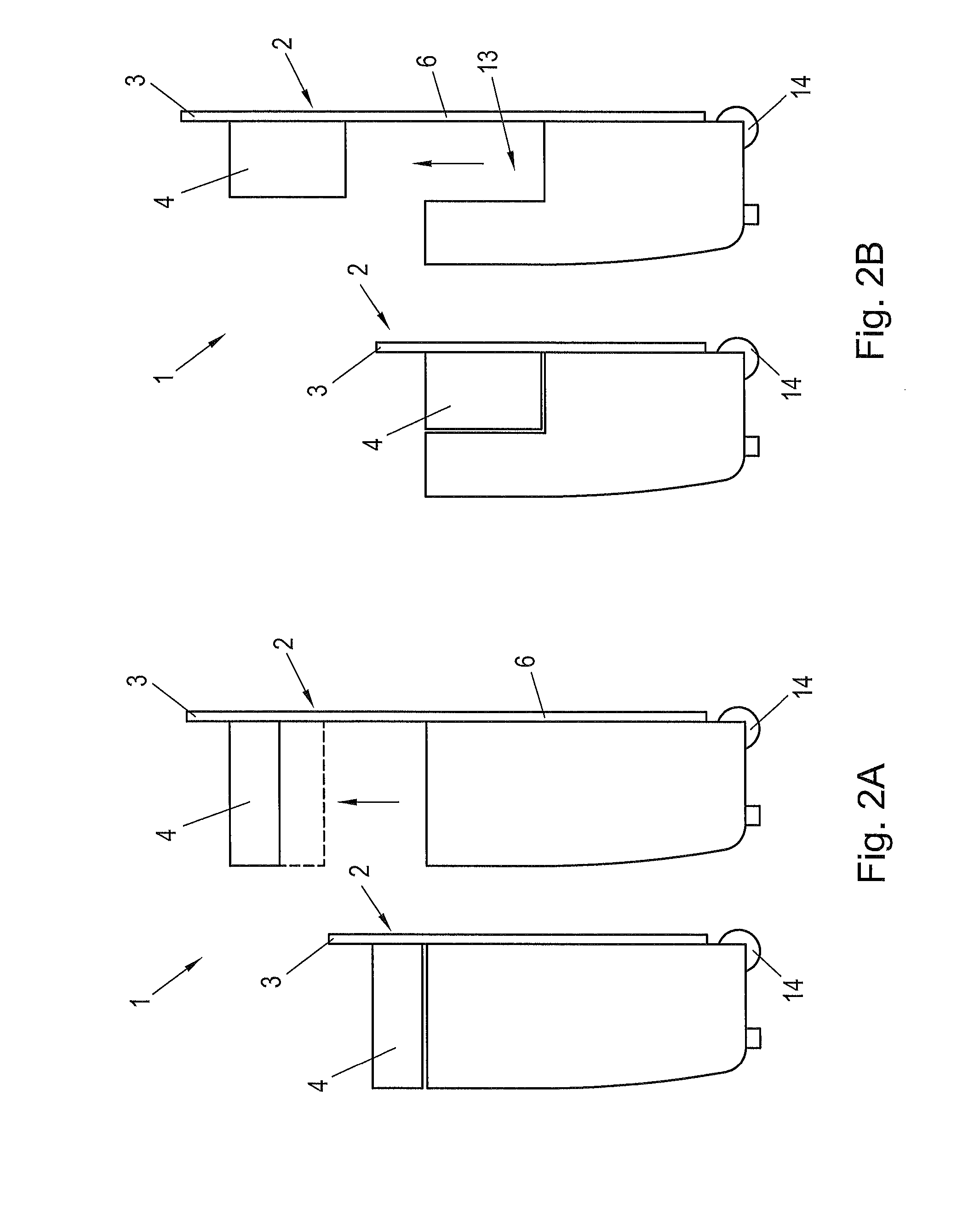

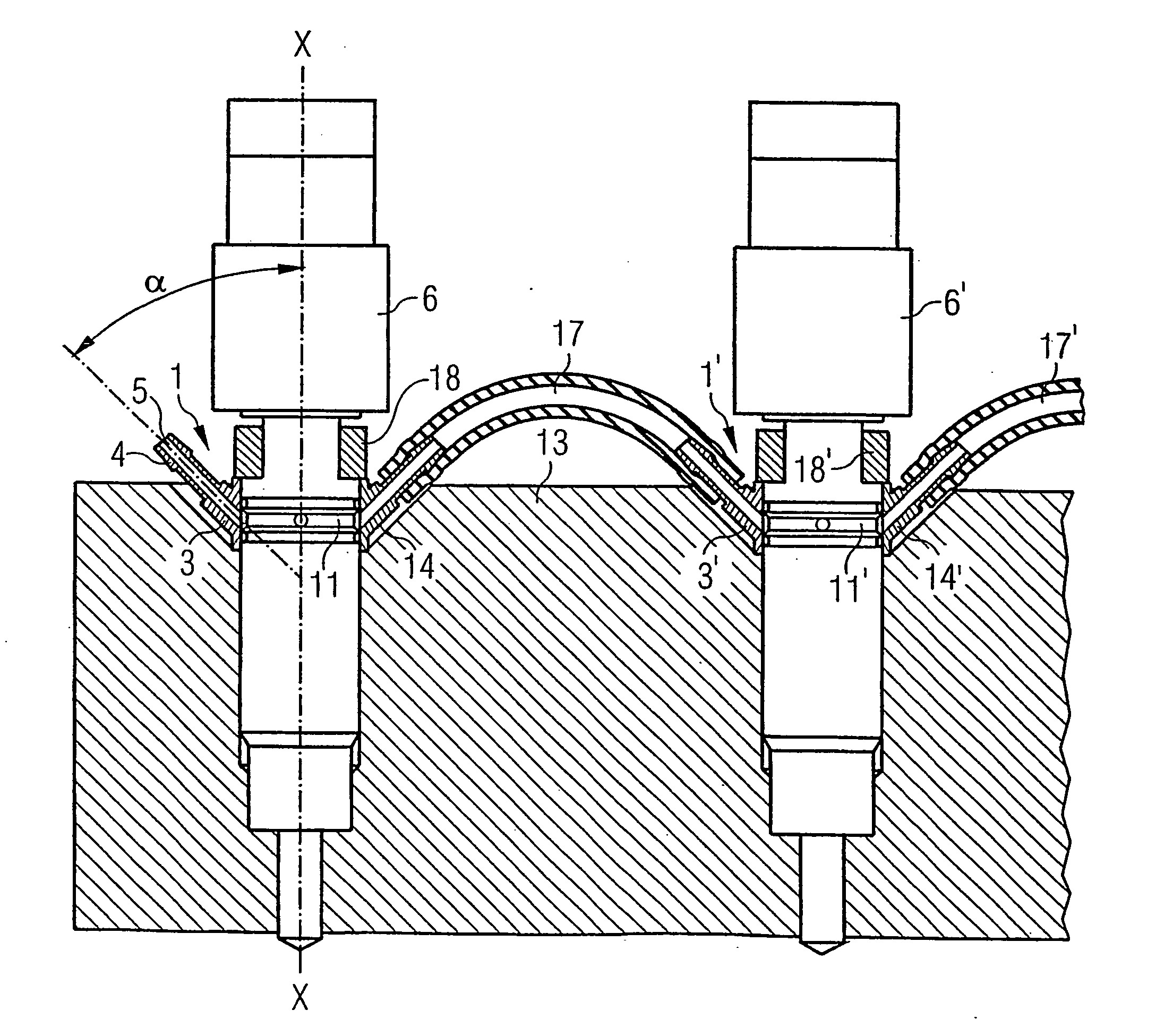

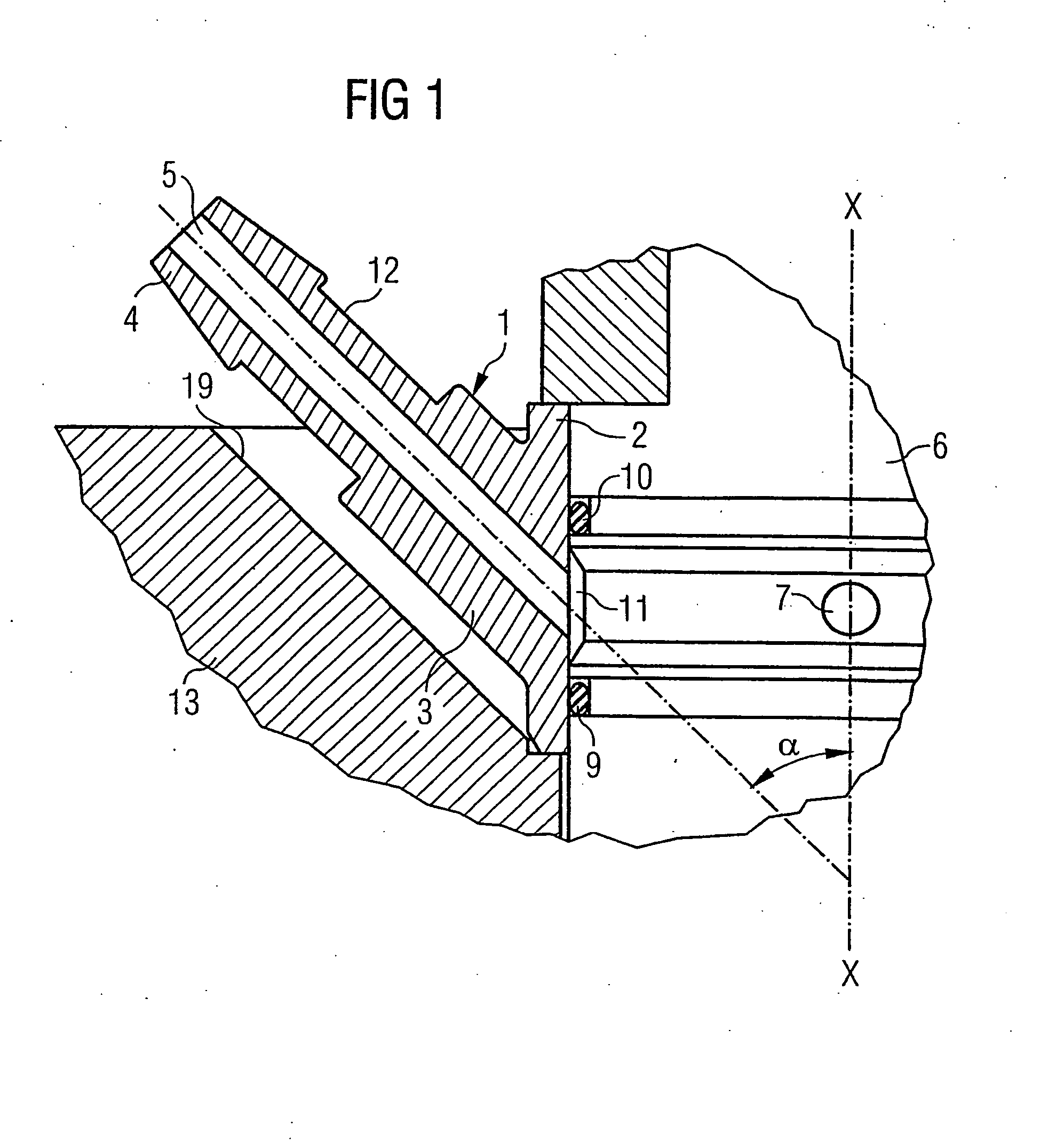

Dilution air hole in a gas turbine combustion chamber with combustion chamber tiles

InactiveUS7059133B2Operational securityLarge quantity of airContinuous combustion chamberGas turbine plantsBrickCombustion chamber

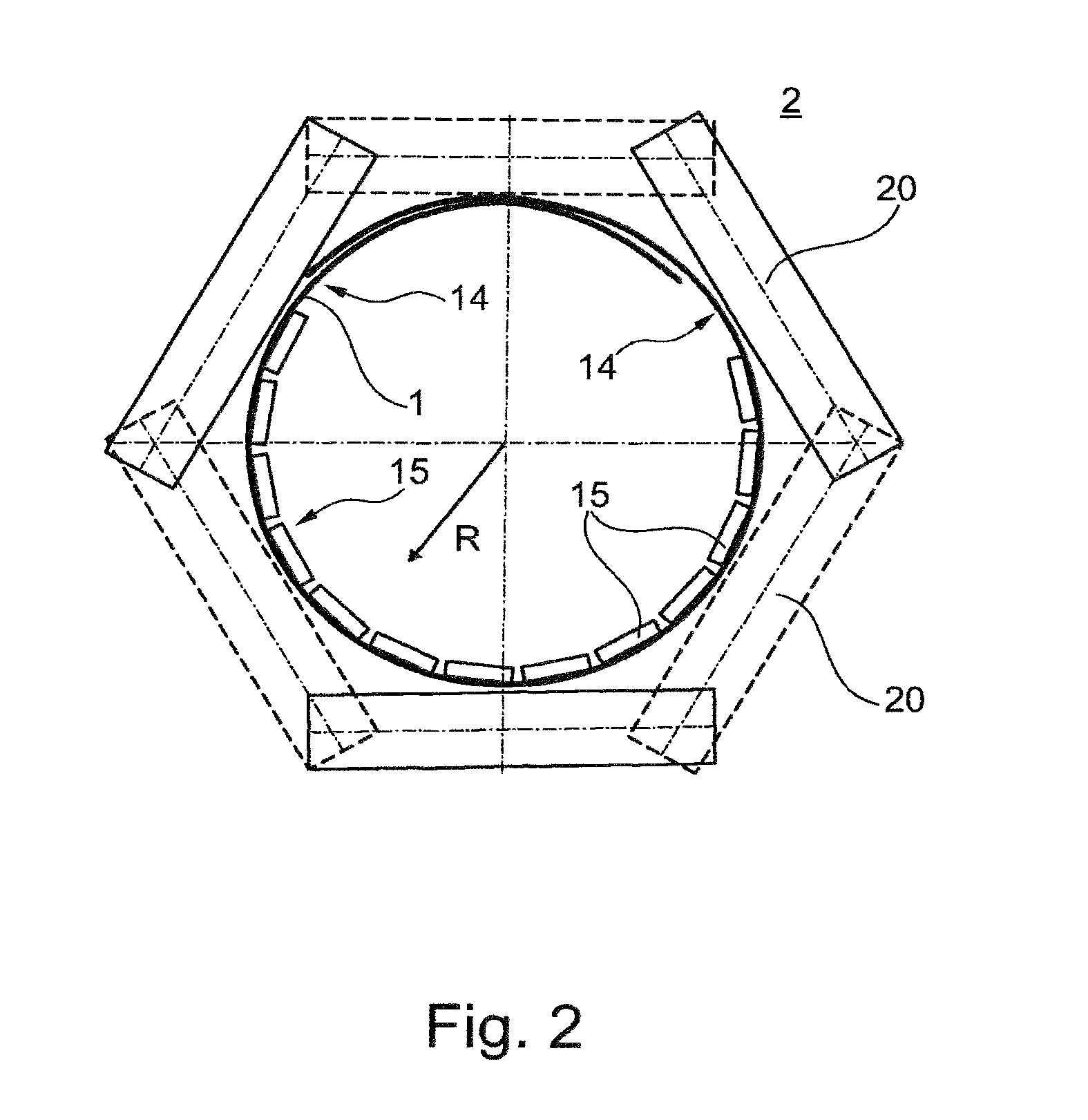

A gas turbine combustion chamber includes combustion chamber tiles 3 attached to a supporting structure 6 of the gas turbine combustion chamber, with each tile possessing at least one dilution air hole 4 which is flush with a dilution air hole of the supporting structure 6, wherein a diameter of the dilution air hole of the supporting structure 6 is considerably larger than a diameter 14 of the dilution air hole 4 of the combustion chamber tile 3.

Owner:ROLLS ROYCE DEUT LTD & CO KG

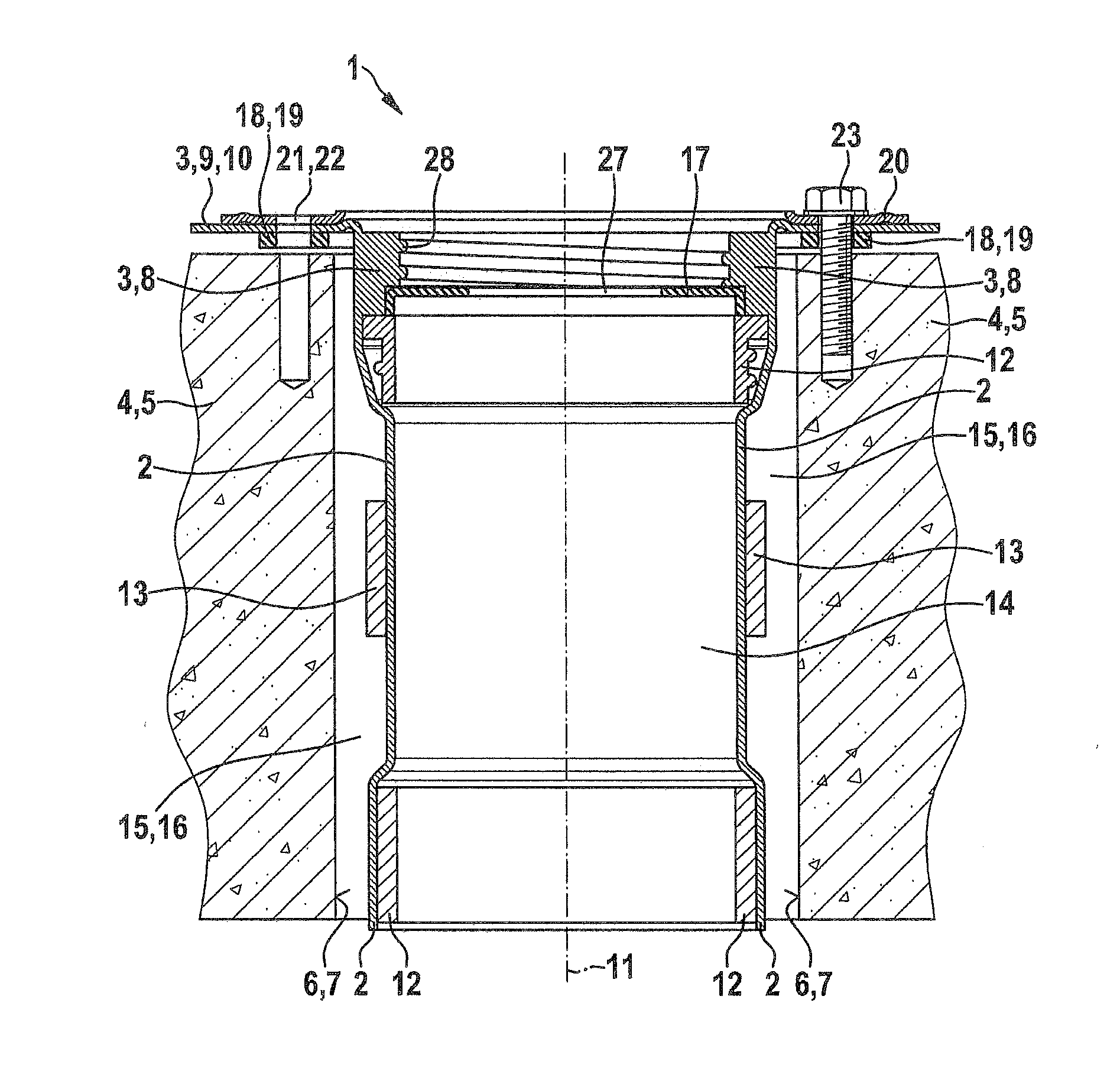

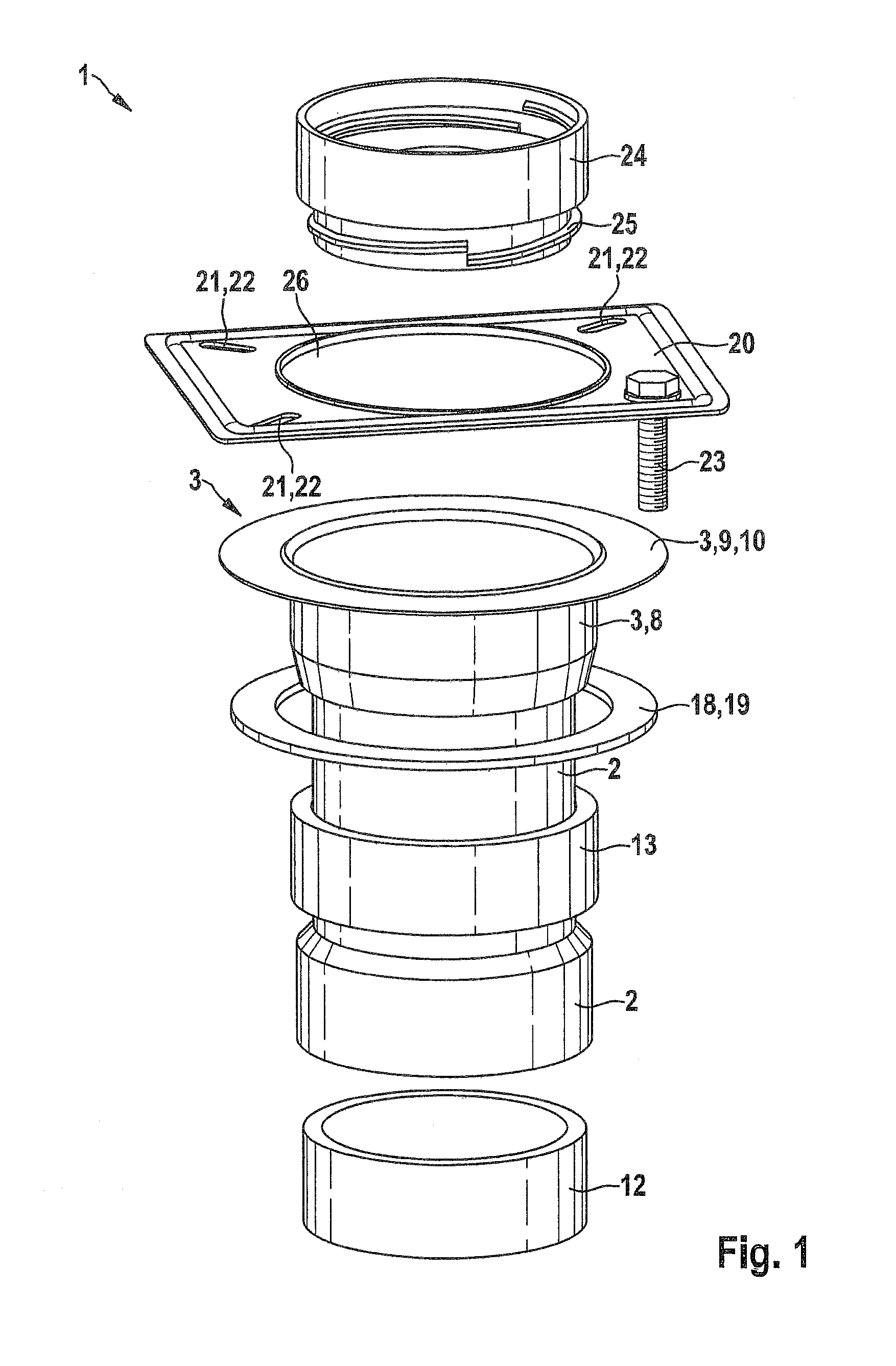

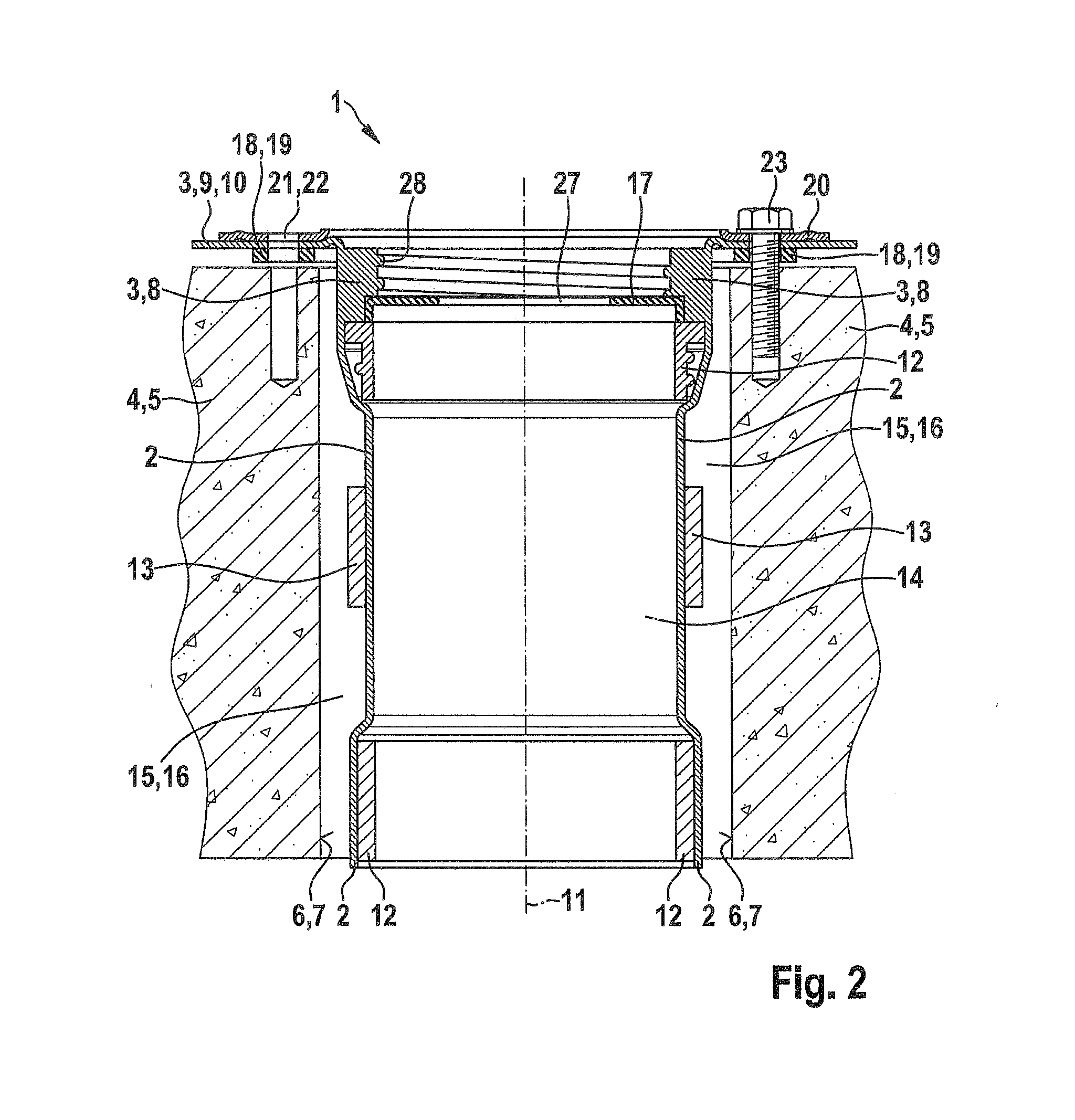

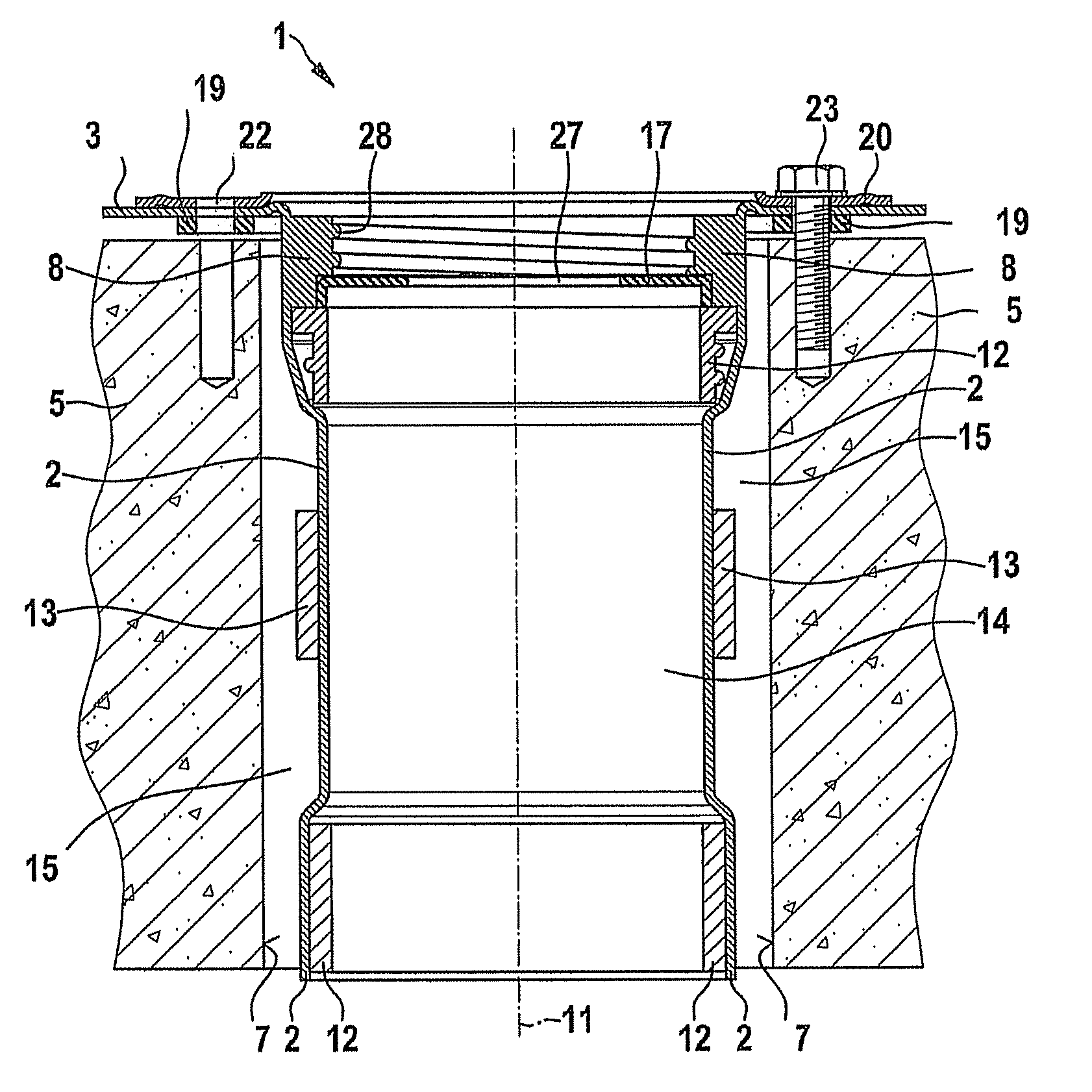

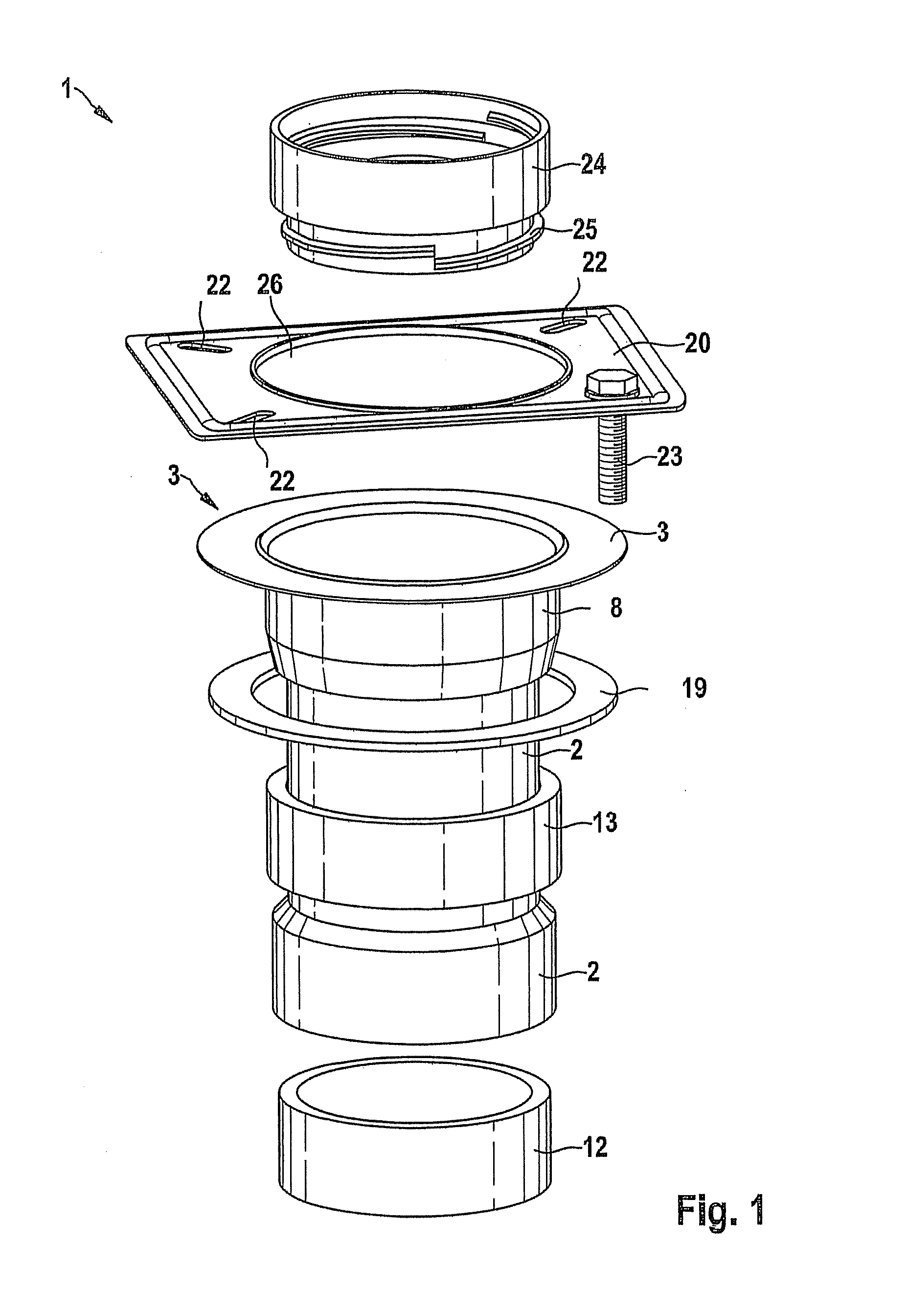

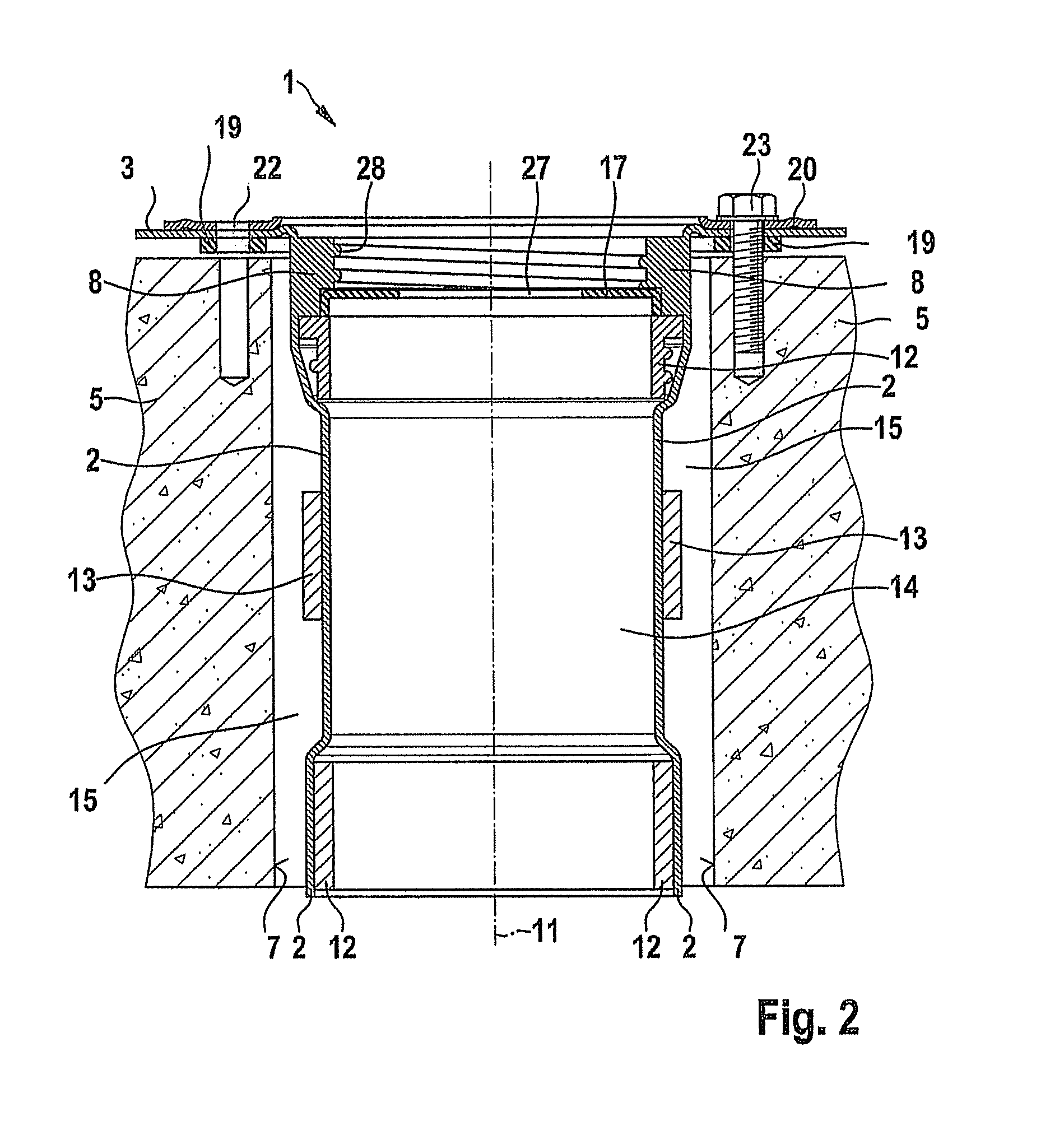

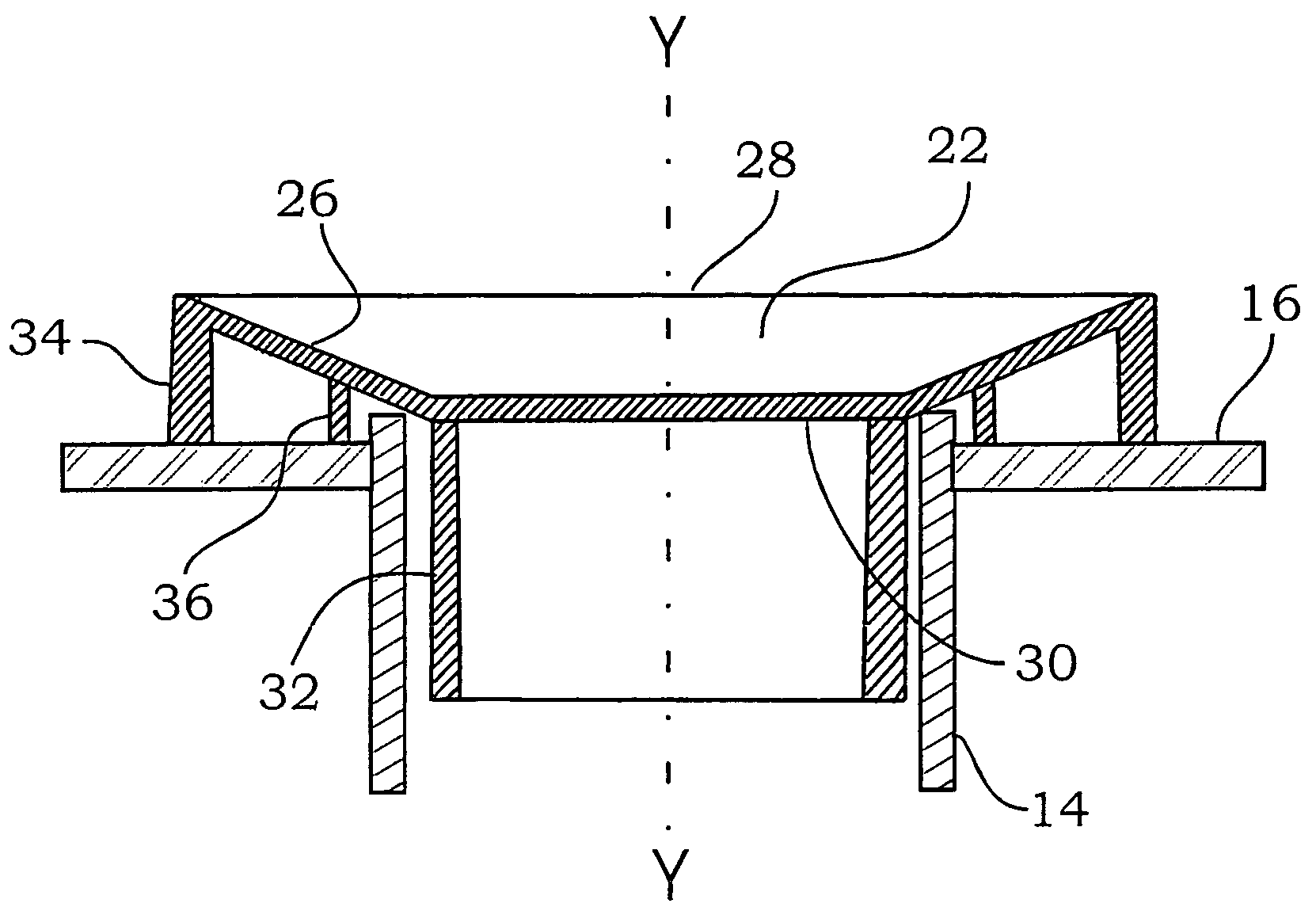

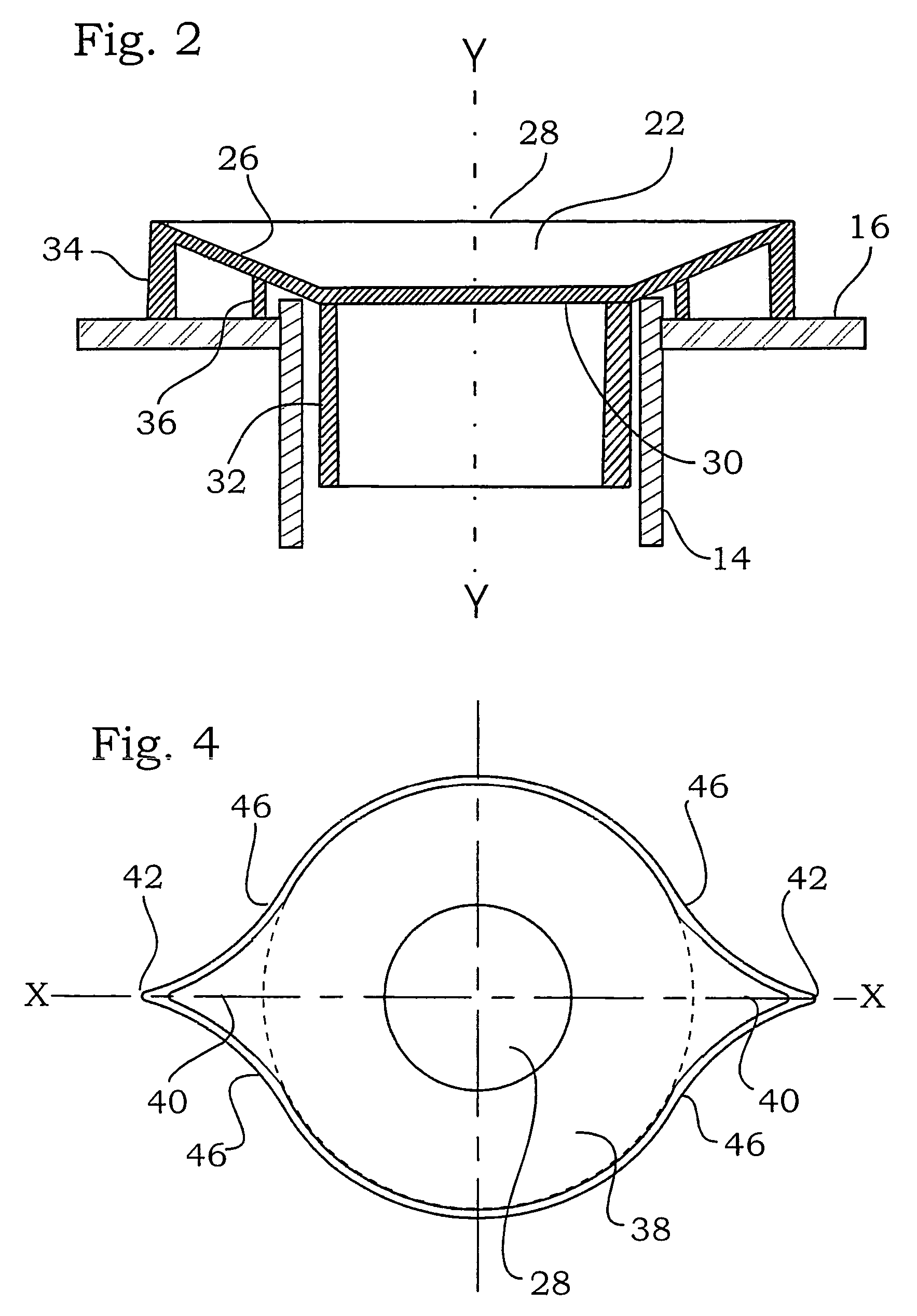

Fire Protection Module

A fire protection module is provided for wall and ceiling openings. The fire protection module includes a sheath for insertion into the wall or ceiling opening and a flange to be placed at the wall or ceiling. The assembly of the fire protection module may be performed with few steps. For example, the sheath and the flange are embodied in one piece.

Owner:HILTI AG

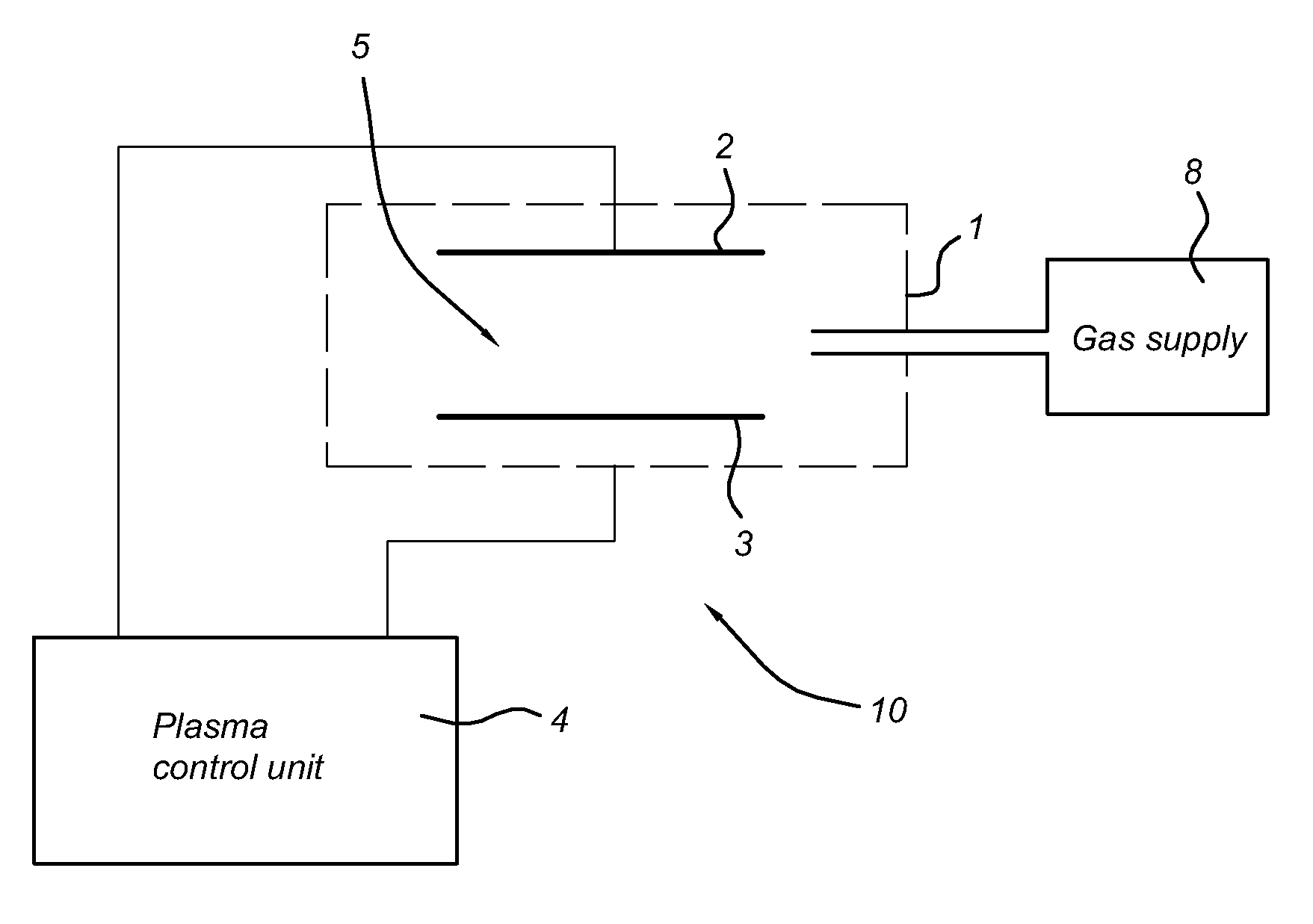

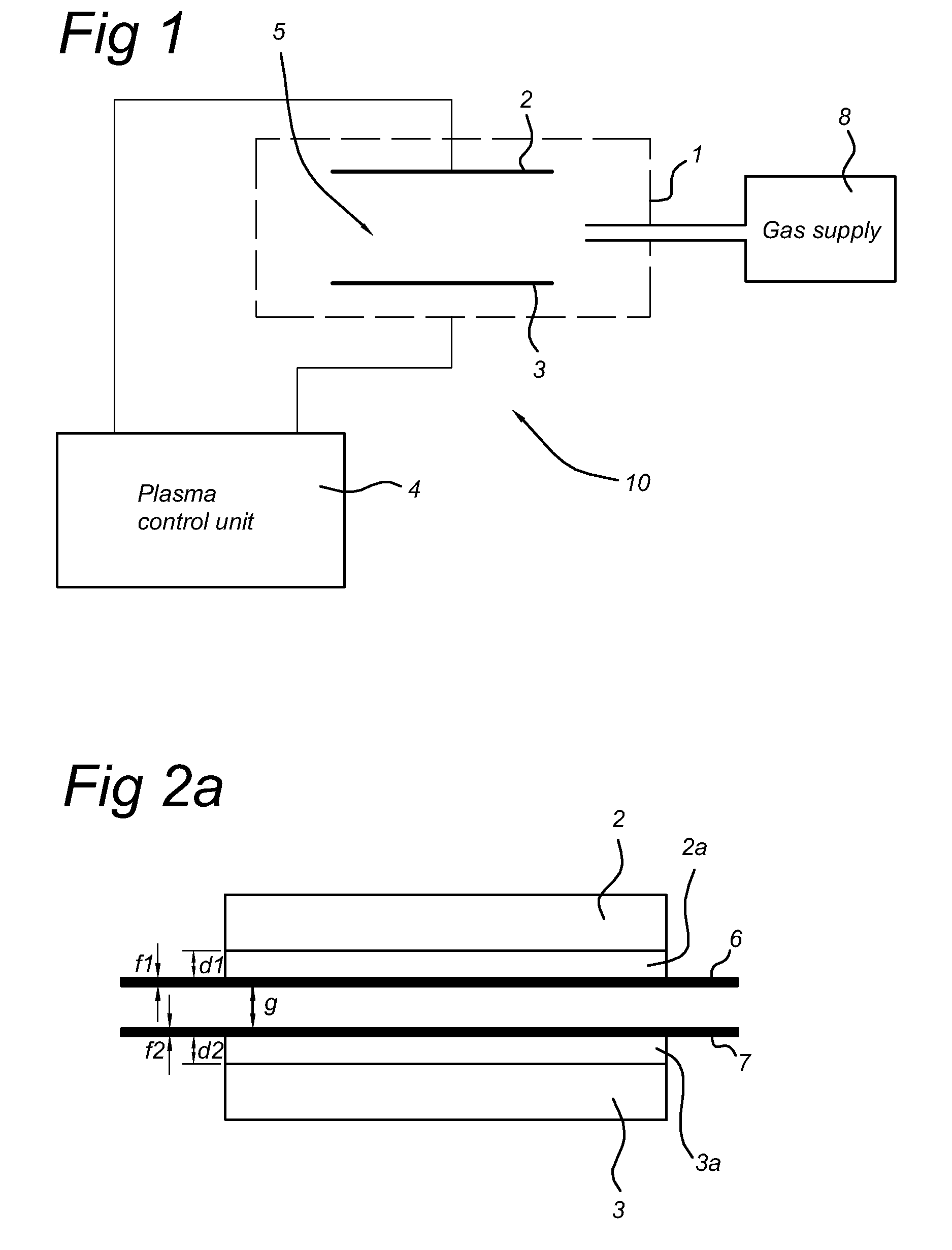

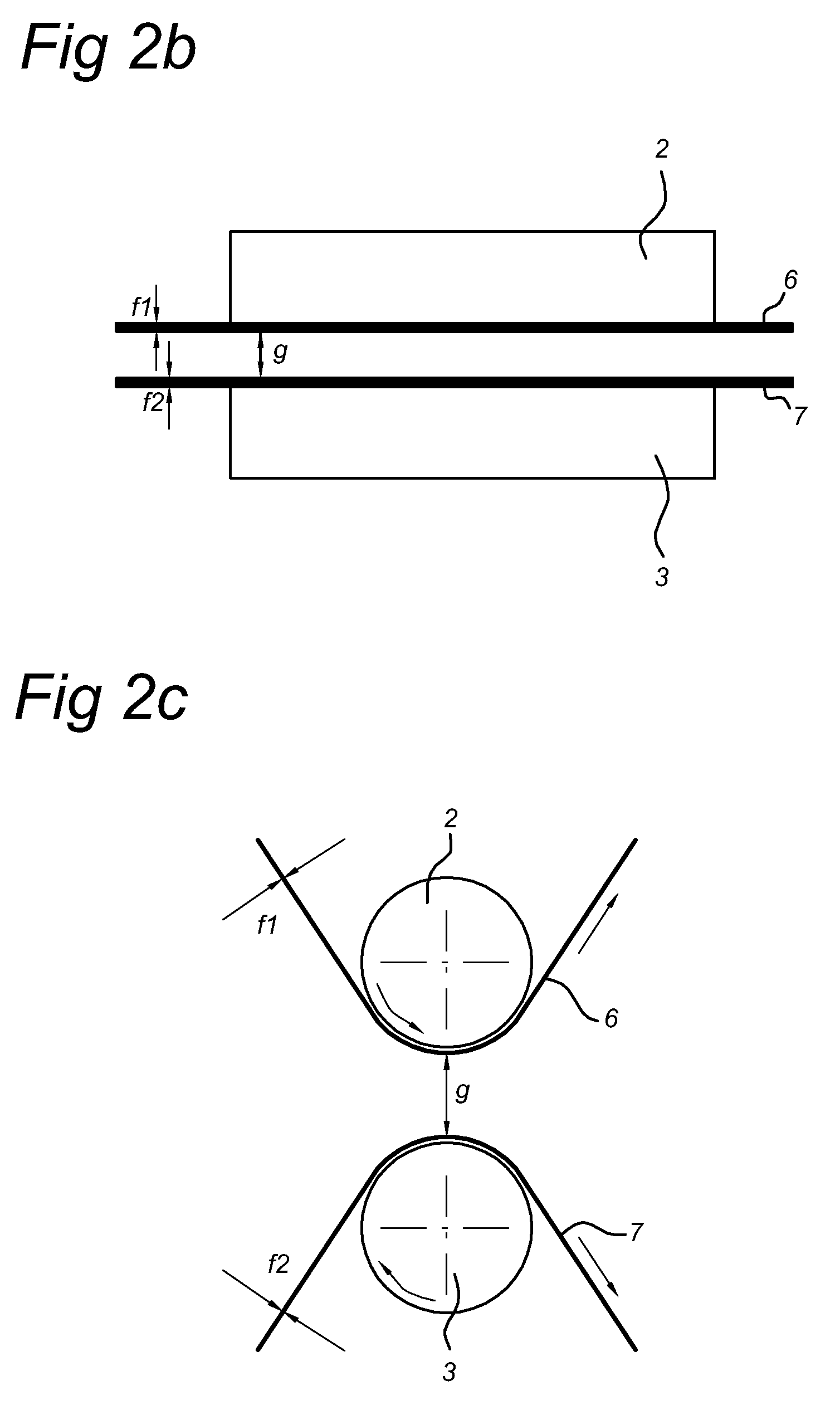

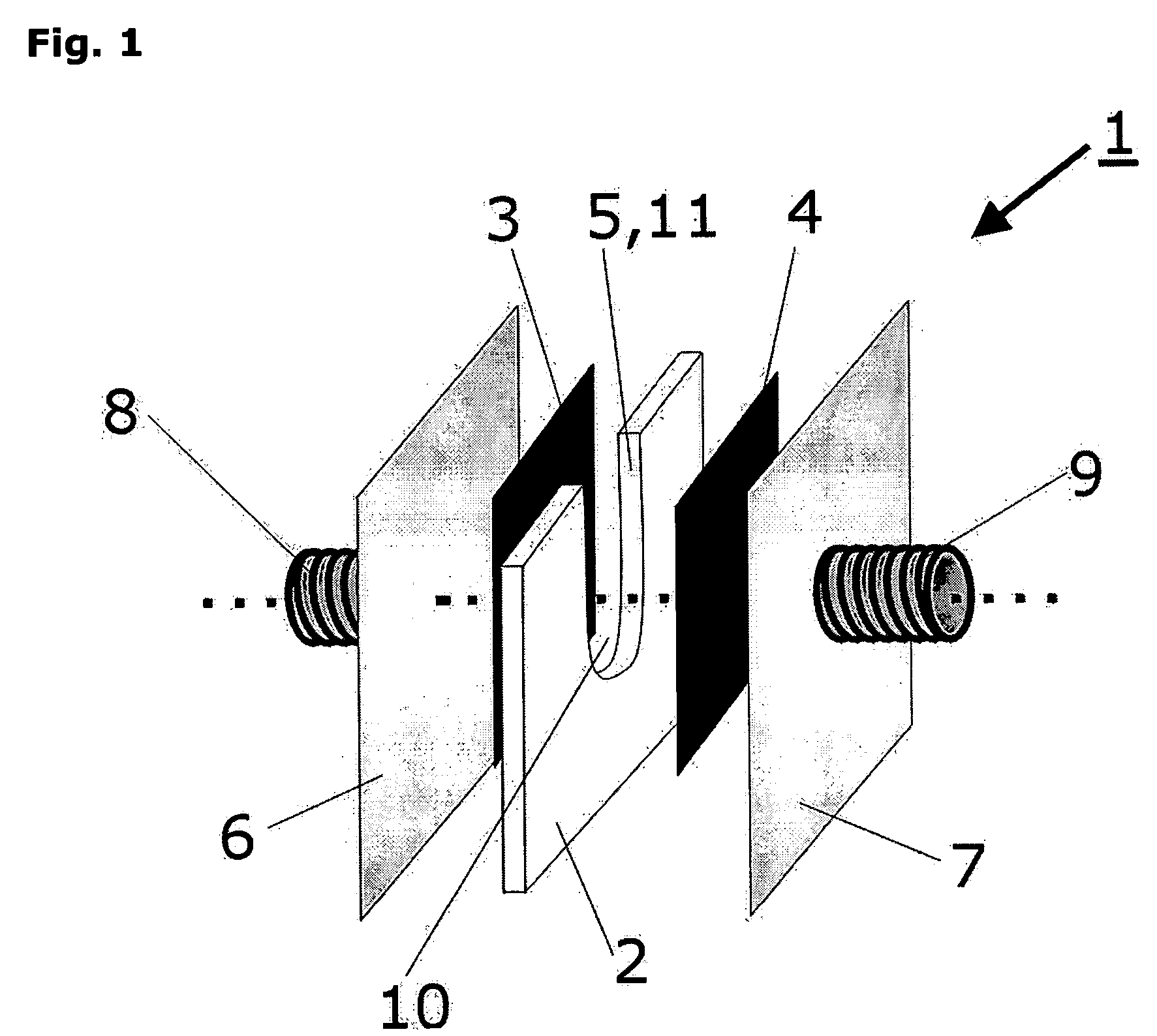

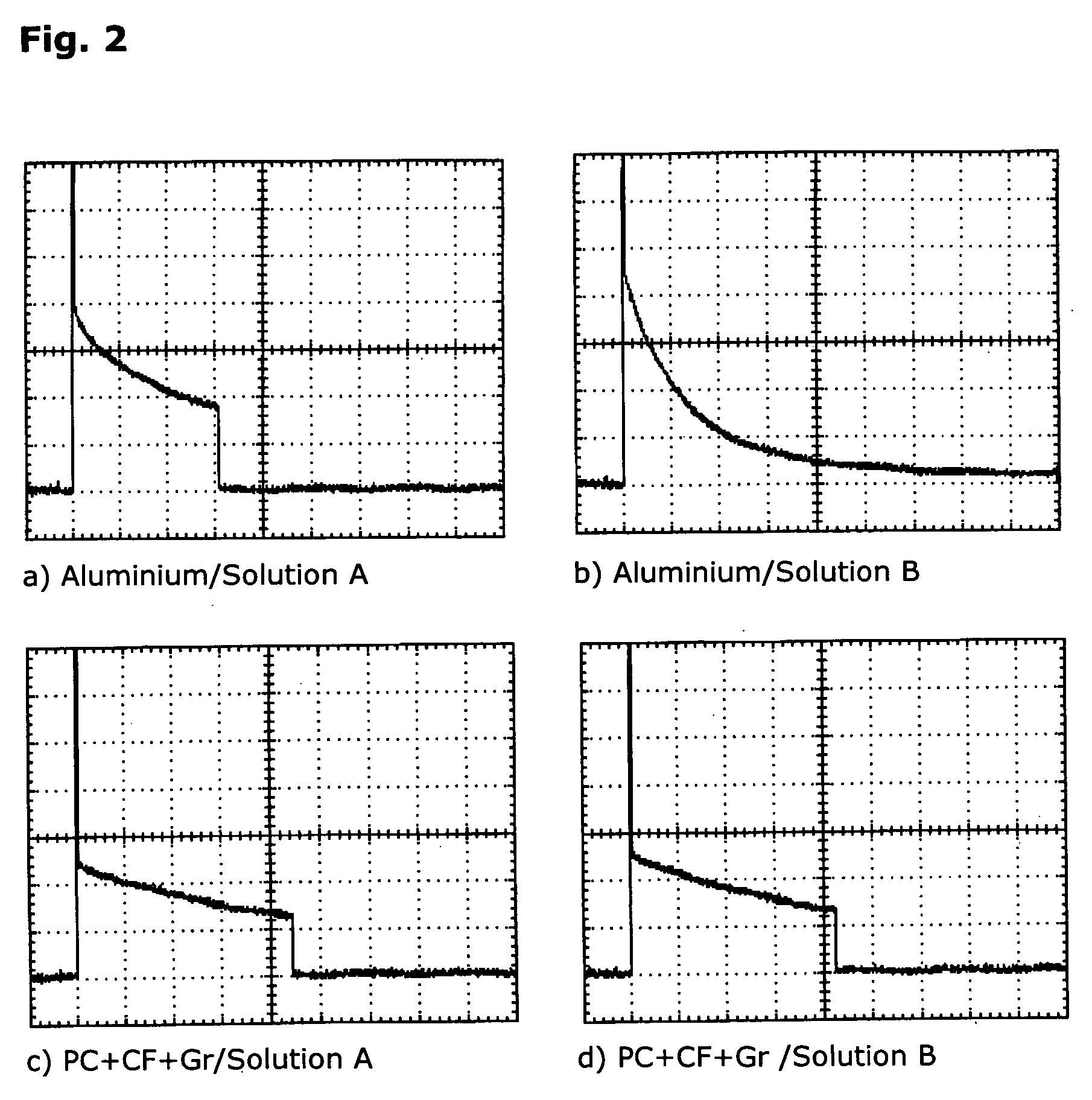

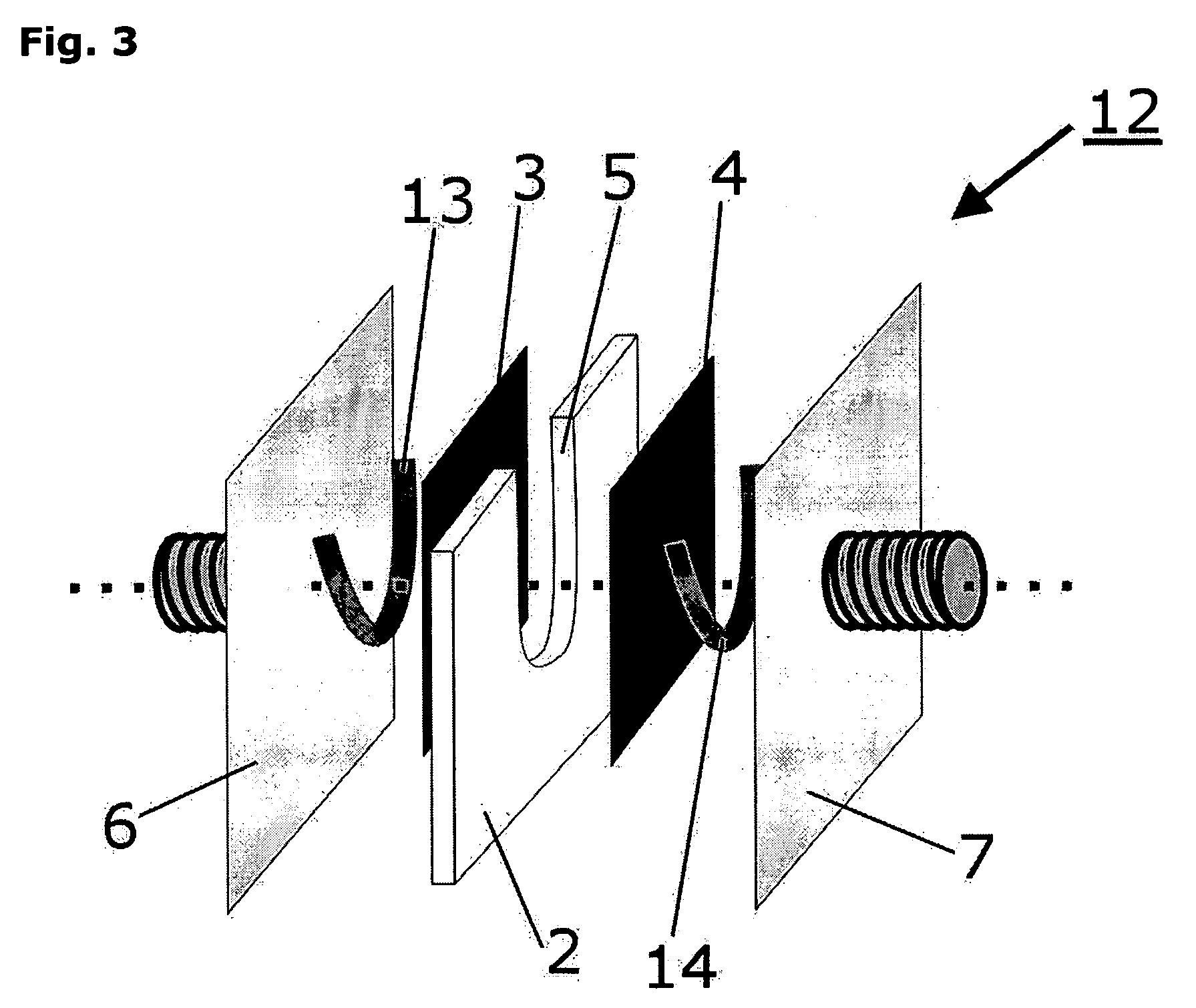

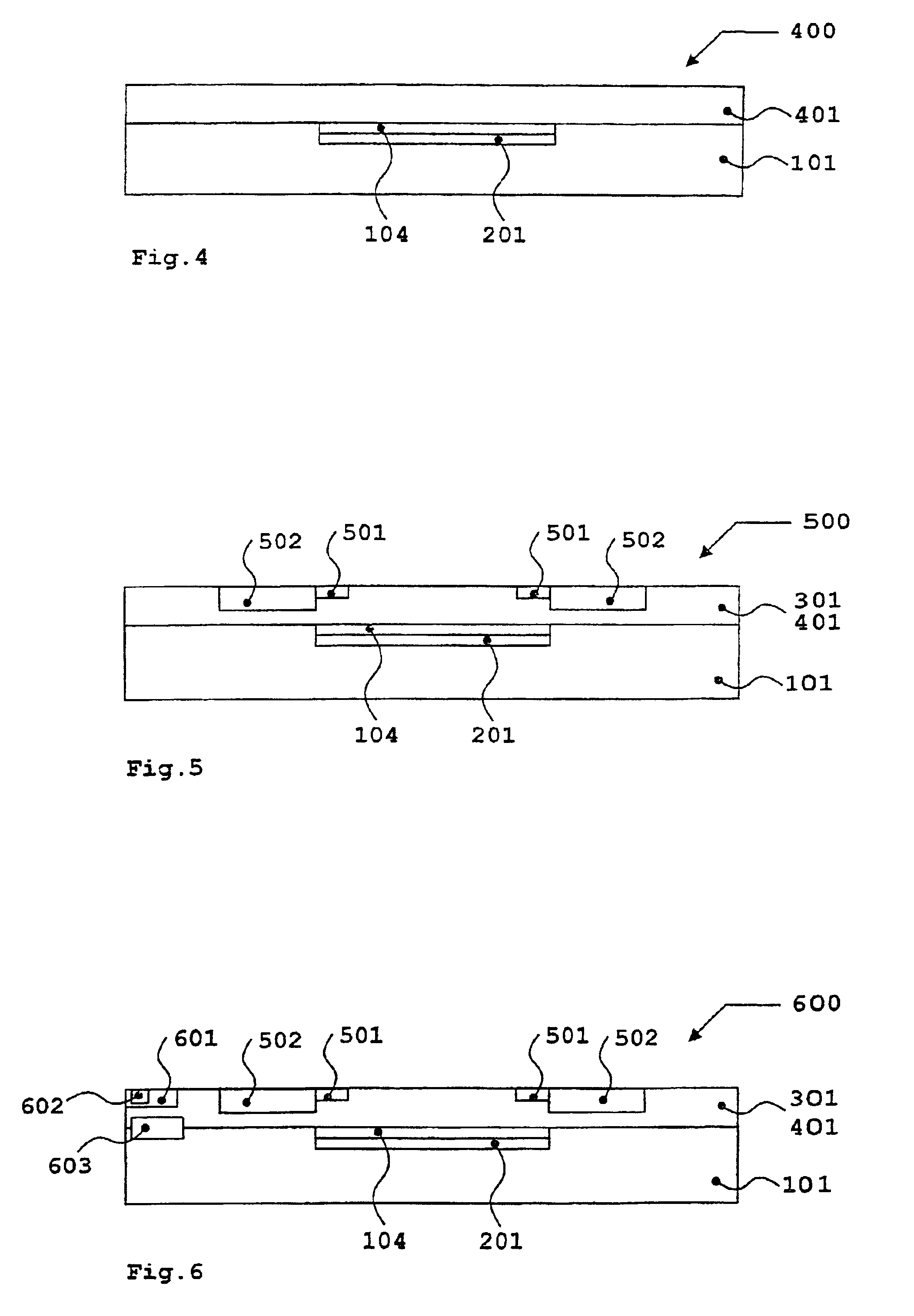

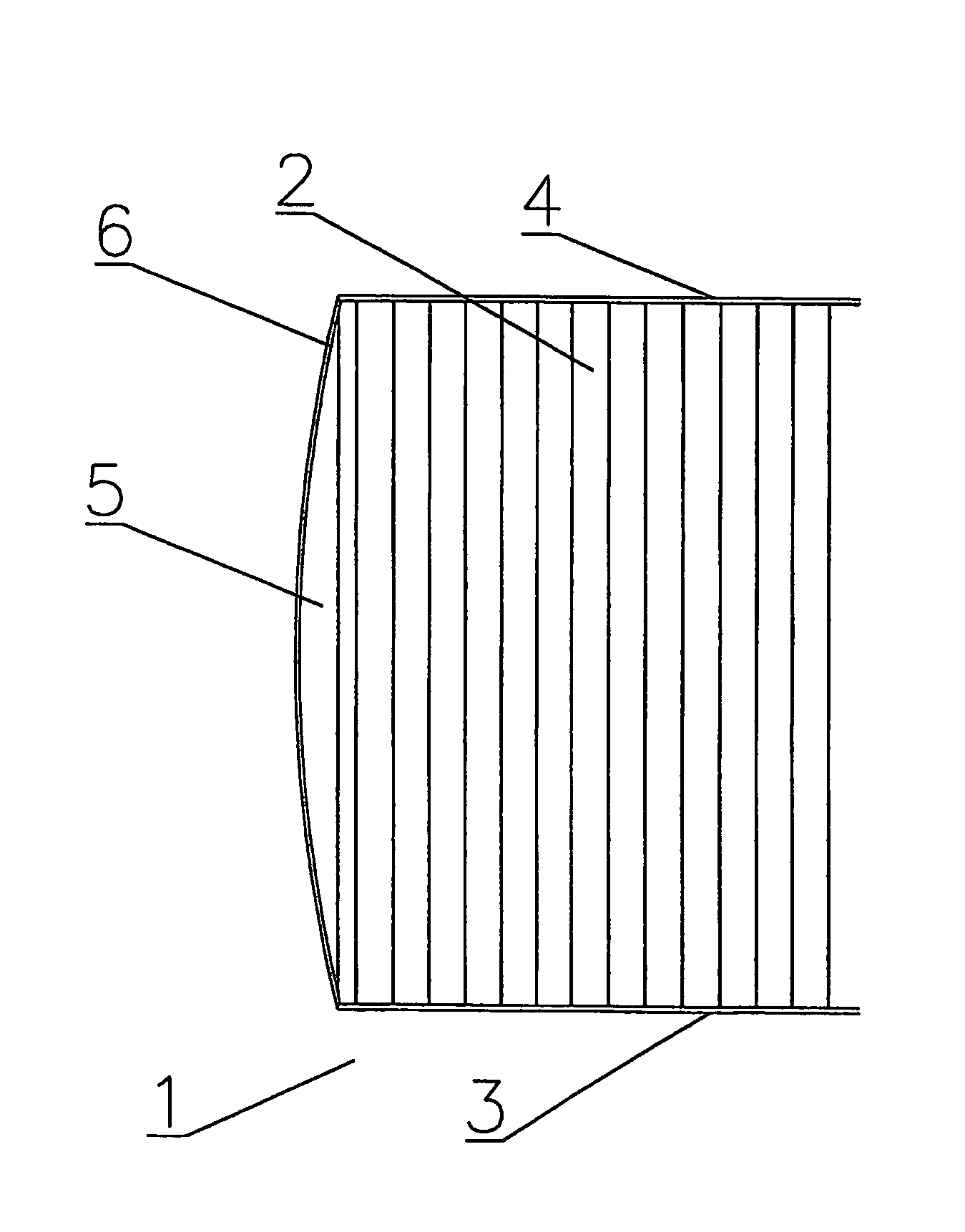

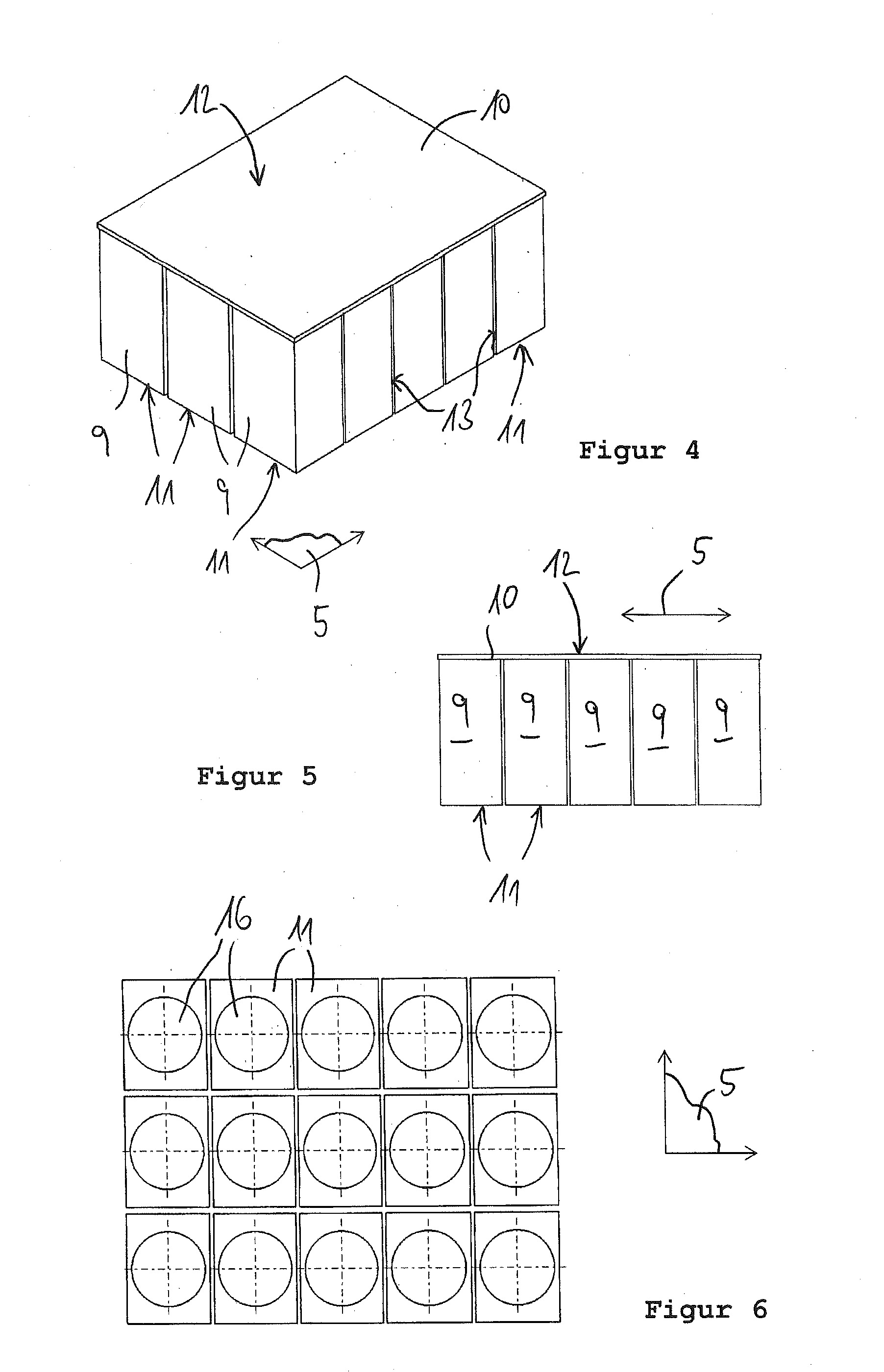

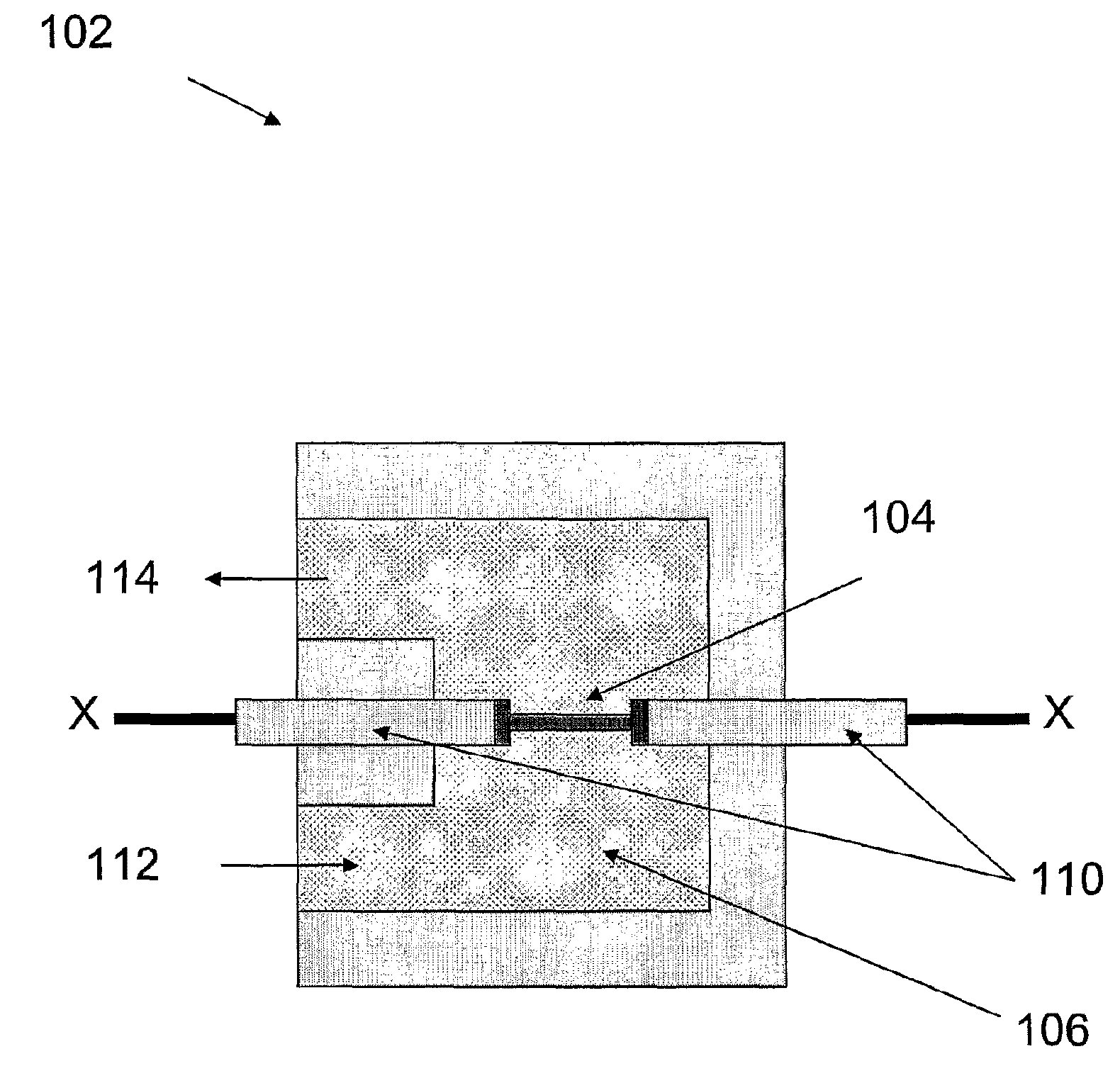

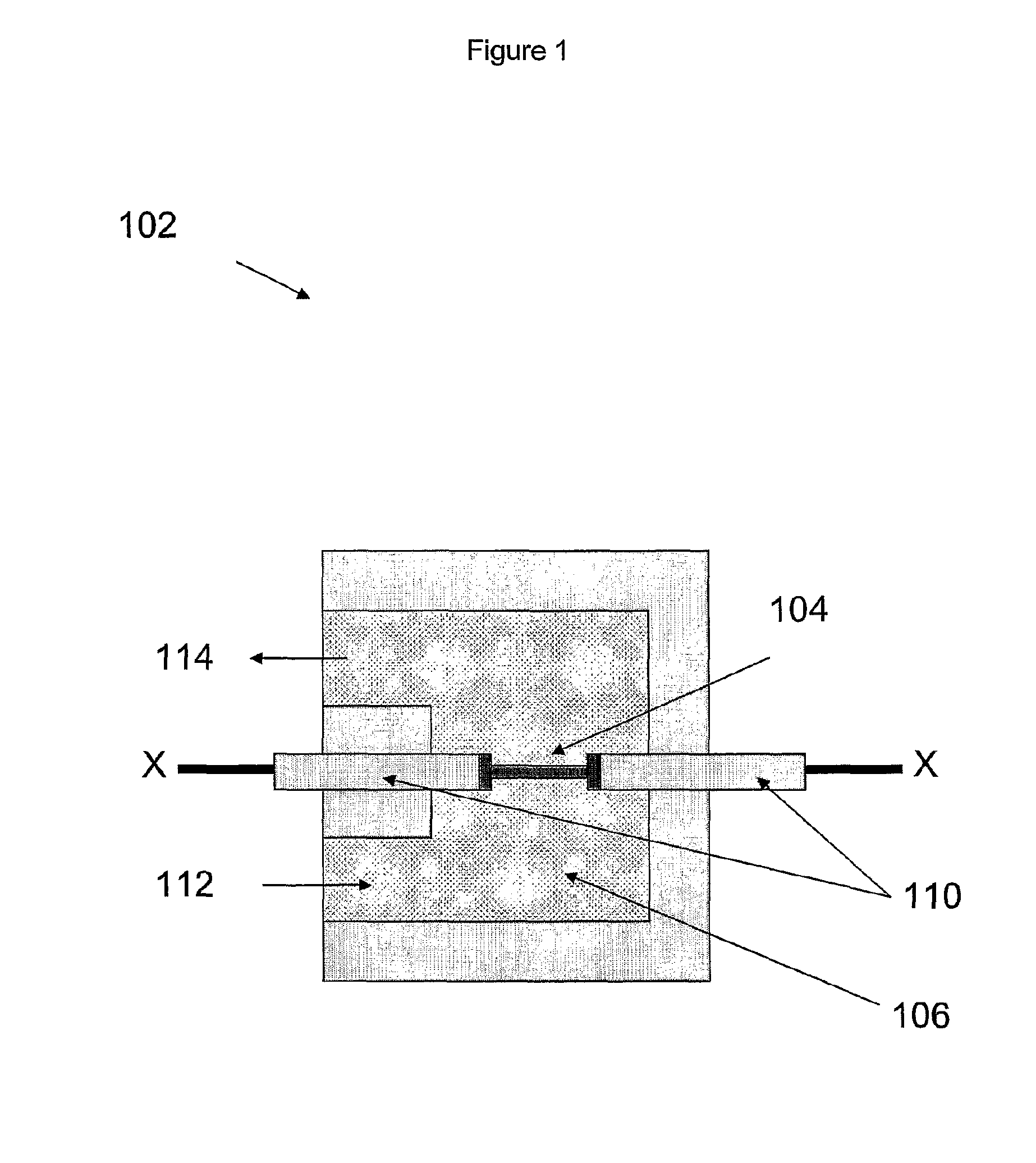

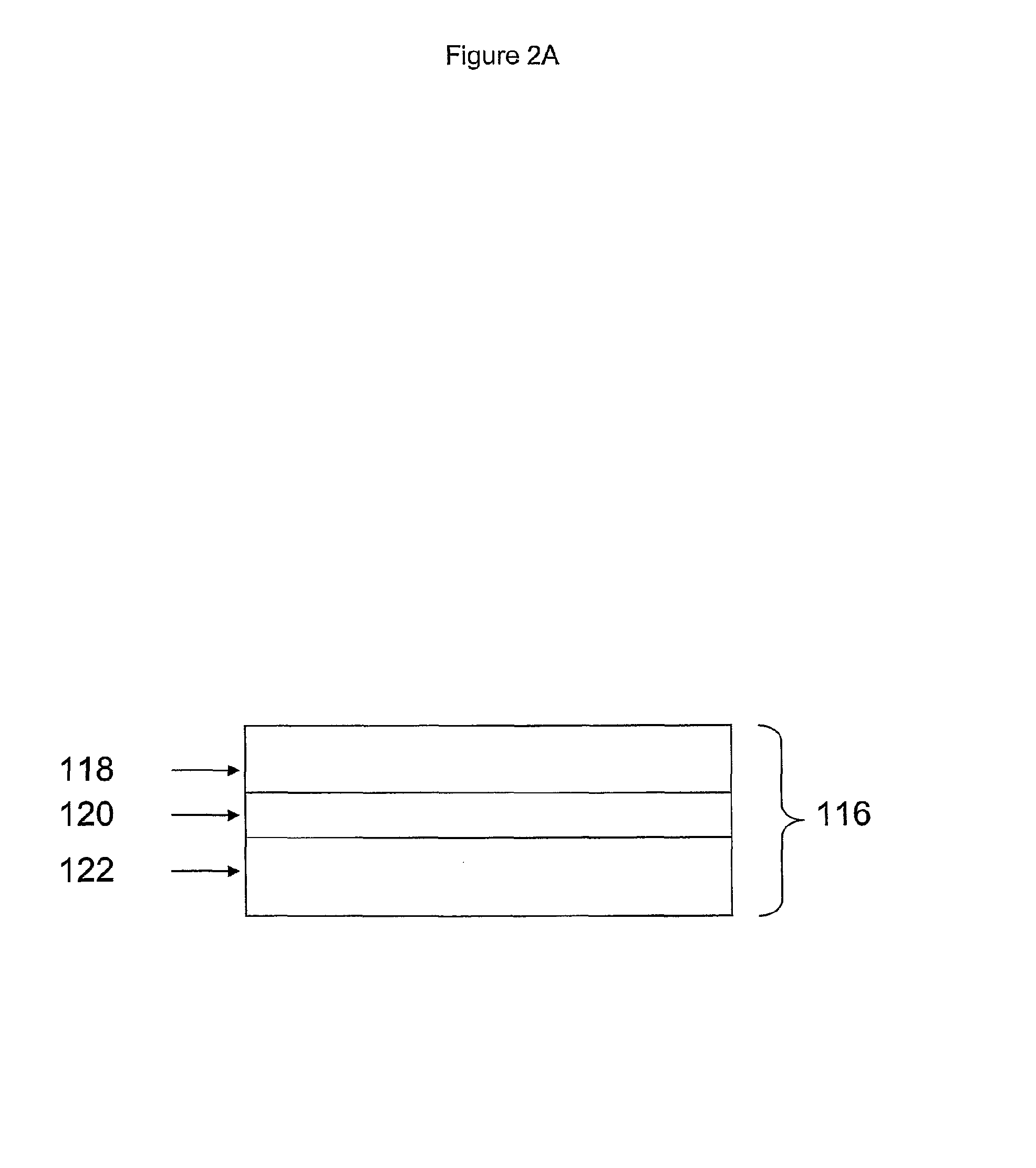

Plasma treatment apparatus and method for treatment of a substrate with atmospheric pressure glow discharge electrode configuration

InactiveUS20110014424A1Increase plasma stabilityImprove stabilityElectric discharge tubesLayered productsFree distanceEngineering

Plasma treatment apparatus and method for treating a substrate (6, 7) e.g. for deposition of a layer on the substrate (6, 7). Two opposing electrodes (2, 3) and a treatment space (5) are provided. A dielectric barrier (6, 7; 2a, 3a), comprising in operation the substrate, is provided in the treatment space (5) between the at least two opposing electrodes (2, 3) which are connected to a plasma control unit (4). A gap distance (g) is the free distance in the treatment space (5) of a gap between the at least two opposing electrodes (2, 3) in operation. A total dielectric distance (d) is the sum of the dielectric thickness of the dielectric layers (2a, 3a) and the substrate (6, 7). The product of gap distance (g) and total dielectric distance (d) is controlled to a value less than or equal to 1.0 mm2.

Owner:FUJIFILM MFG EURO

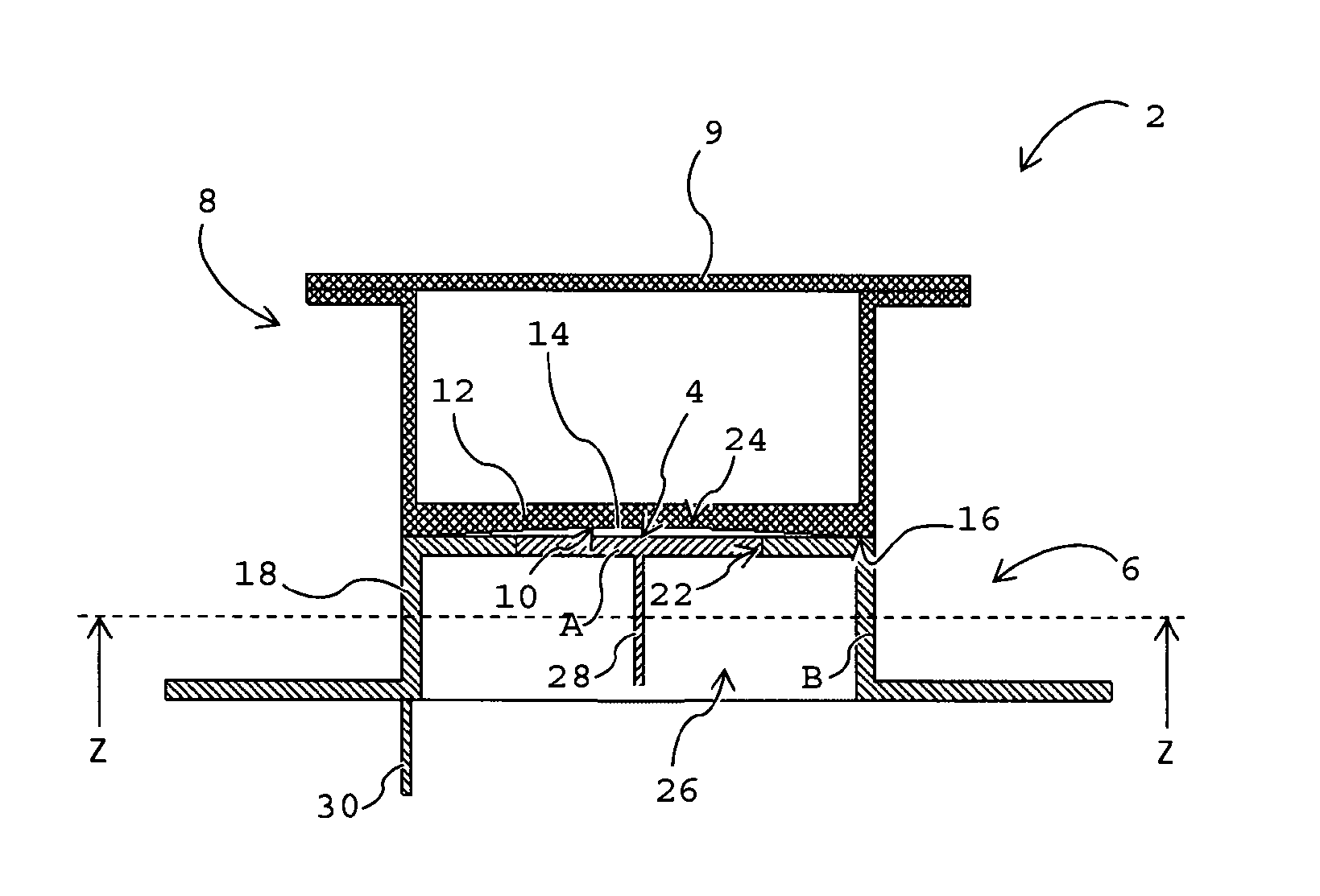

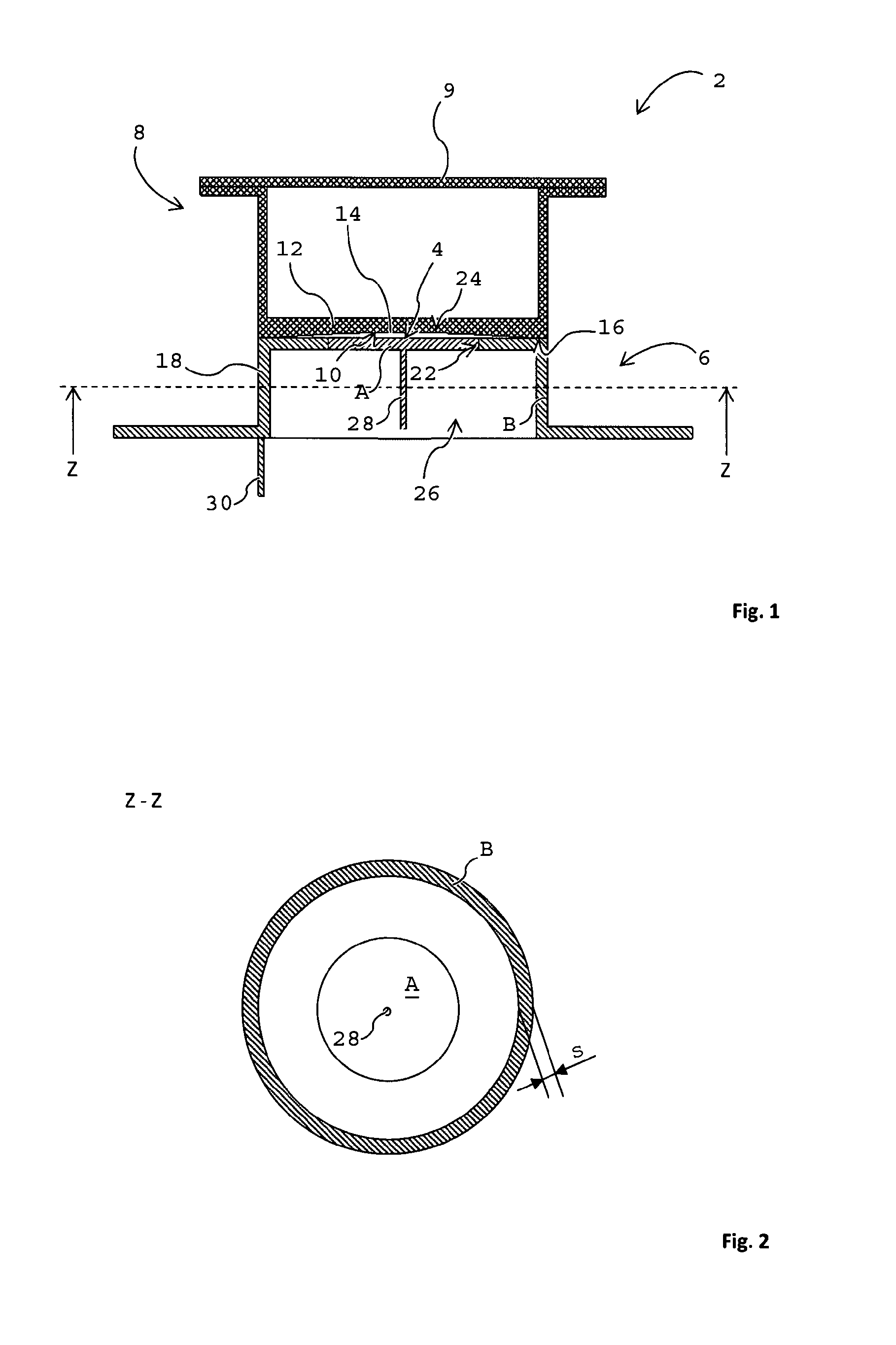

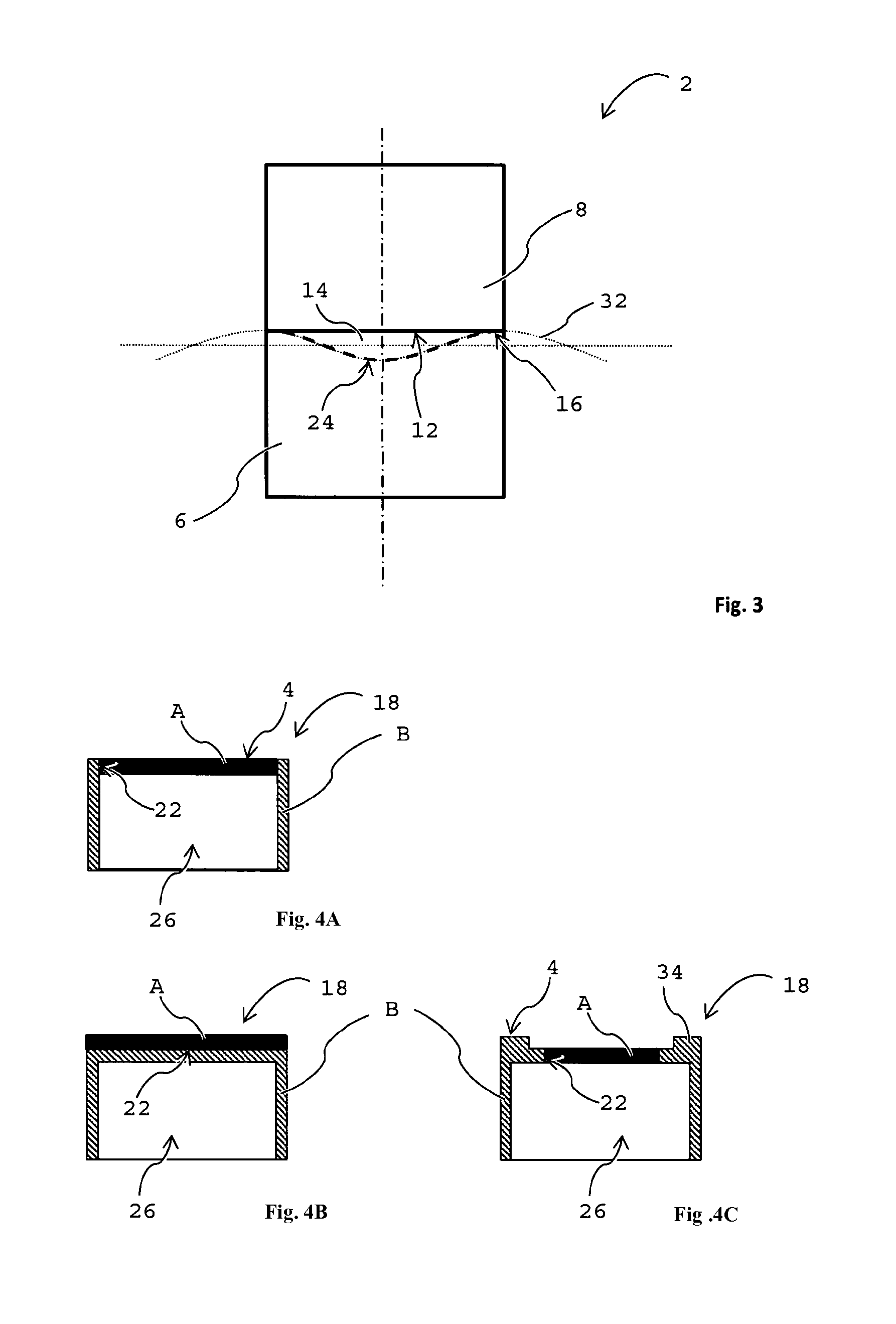

Container with at least one electrode

ActiveUS20050064578A1Effective treatmentProduced easily and cost-effectivelyBioreactor/fermenter combinationsBiological substance pretreatmentsAqueous solutionBiomedical engineering

The invention relates to a container 20, 30 for receiving an aqueous solution, which is formed at least partially by an outer limit 21 forming an inner chamber 22, 32 for receiving the solution, and which comprises at least one area which acts as an electrode 25, 26, 33, 34 when an electric voltage is applied and a subsequent discharge occurs, wherein at least one electrode 25, 26, 33, 34 is made of a conductive synthetic material at least based on a plastic material which is doped with at least one conductive substance. A container 20, 30 of the above-mentioned kind is created this way, which is simple and economical to produce and also, for example, enables an efficient transfection of living cells by means of electroporation or an effective electrofusion.

Owner:LONZA COLOGNE

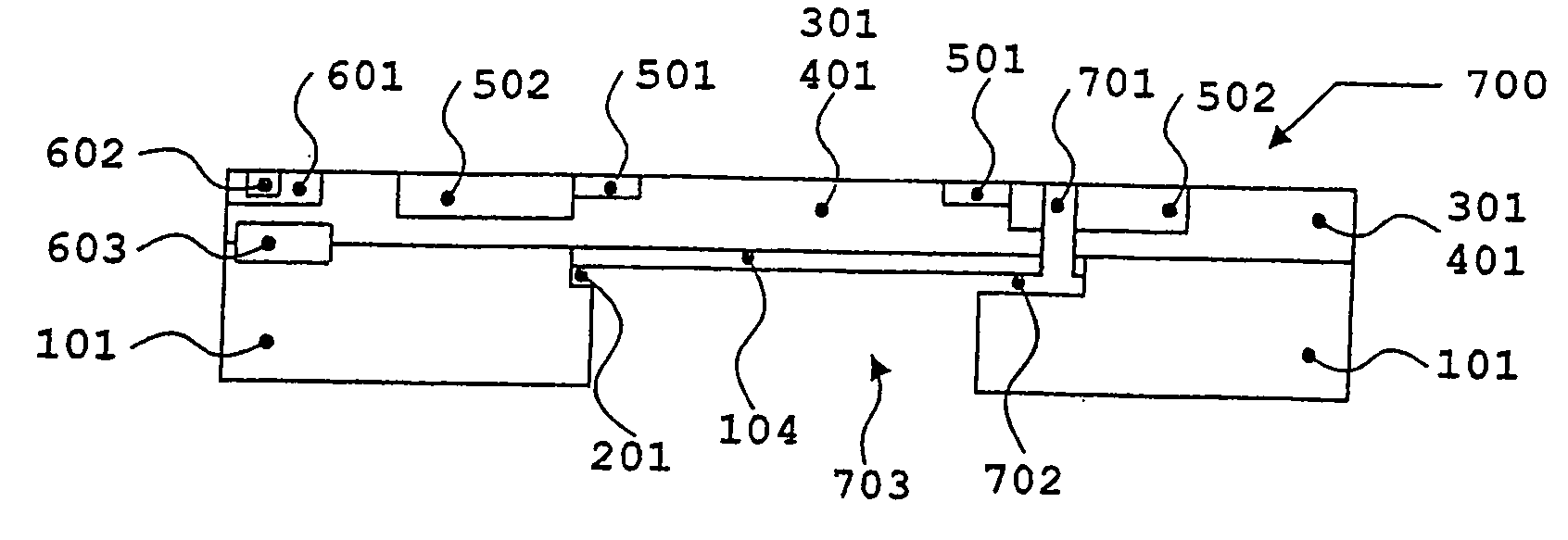

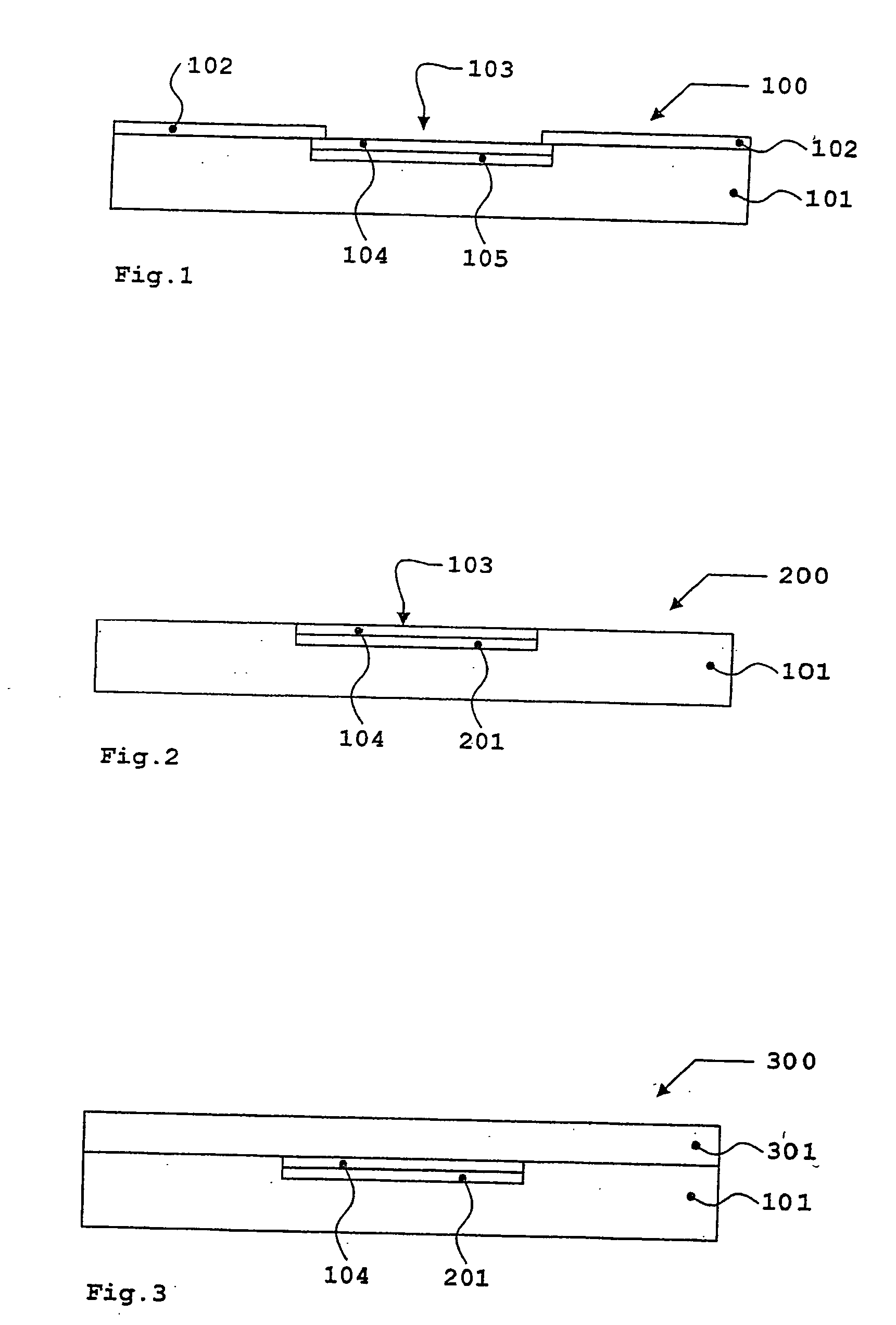

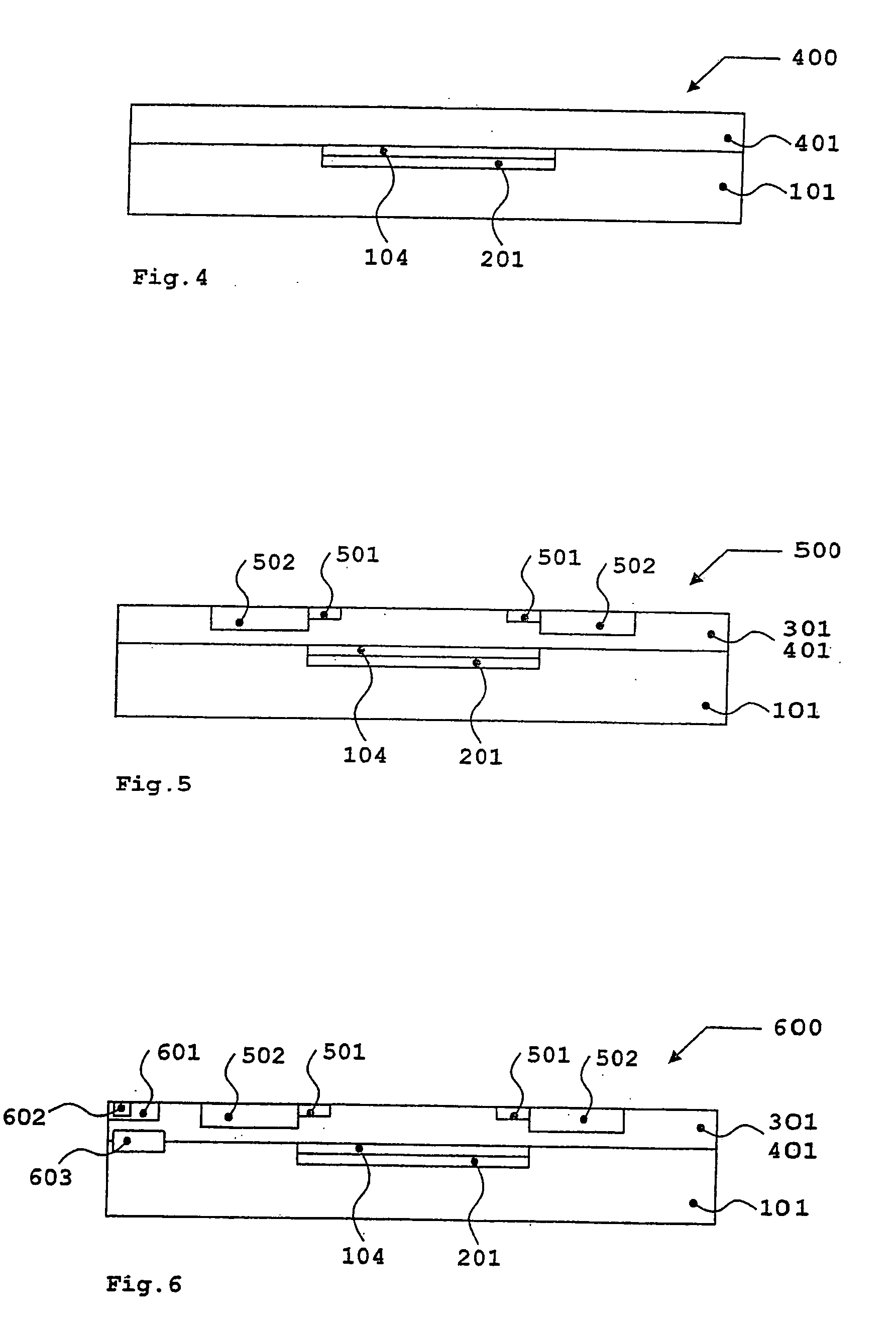

Method for production of a semiconductor component and a semiconductor component produced by said method

InactiveUS7037438B2Produced easily and cost-effectivelyRapid productionPaper/cardboard articlesDecorative surface effectsPorous layerSilicon

A method is for producing a semiconductor component, e.g., a multilayer semiconductor element, e.g., a micromechanical component, e.g., a pressure sensor, having a semiconductor substrate, e.g., made of silicon, and a semiconductor component produced according to the method. To reduce the production cost of such a semiconductor component, in a first step a first porous layer is produced in the semiconductor component, and in a second step a hollow or cavity is produced under or from the first porous layer in the semiconductor component, with the hollow or cavity capable of being provided with an external access opening.

Owner:ROBERT BOSCH GMBH

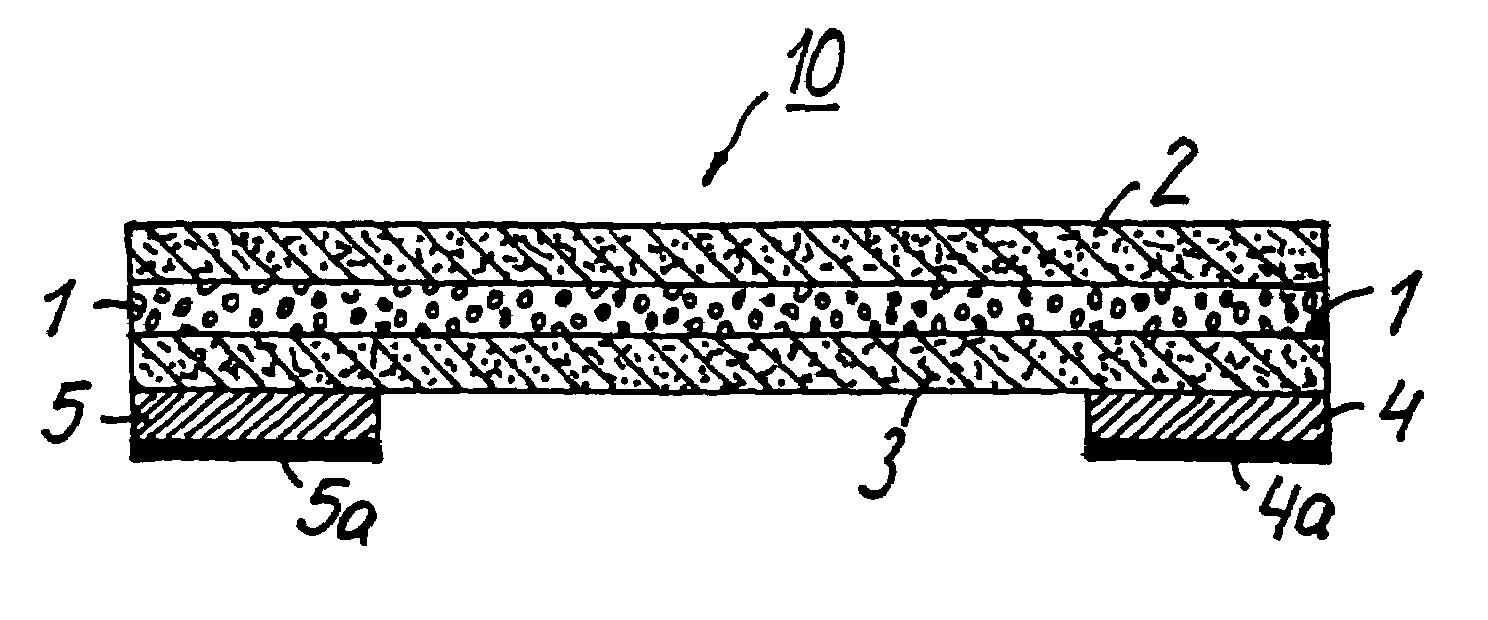

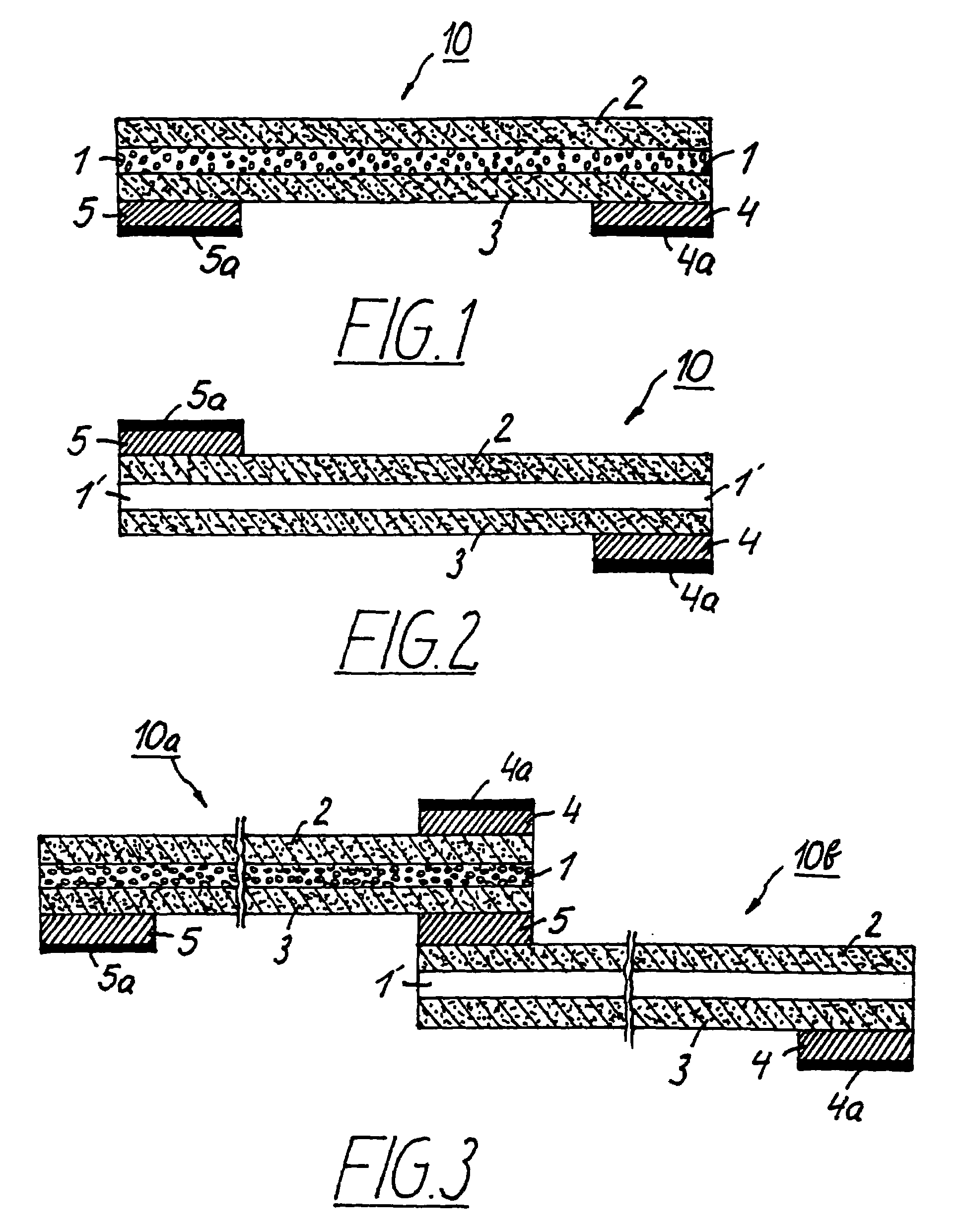

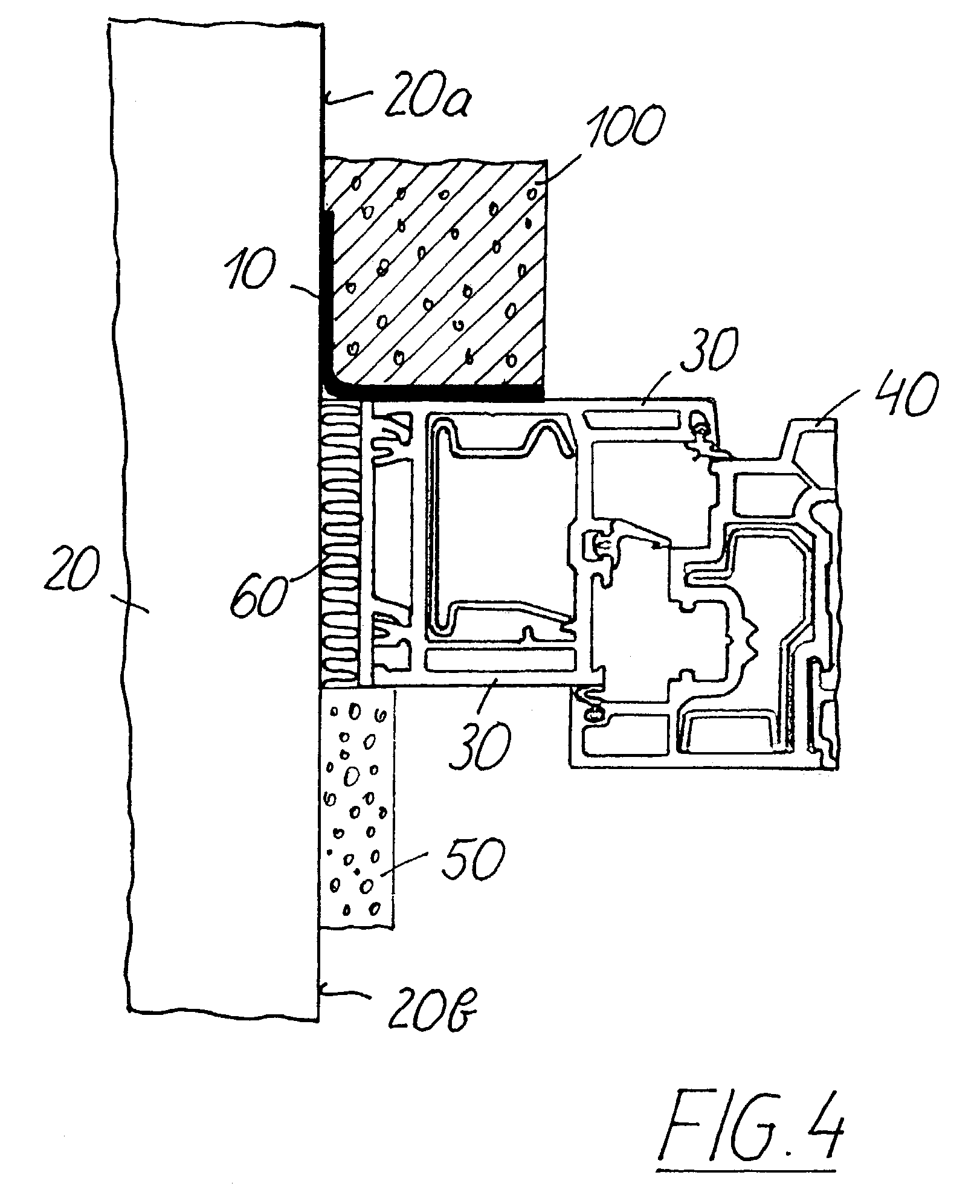

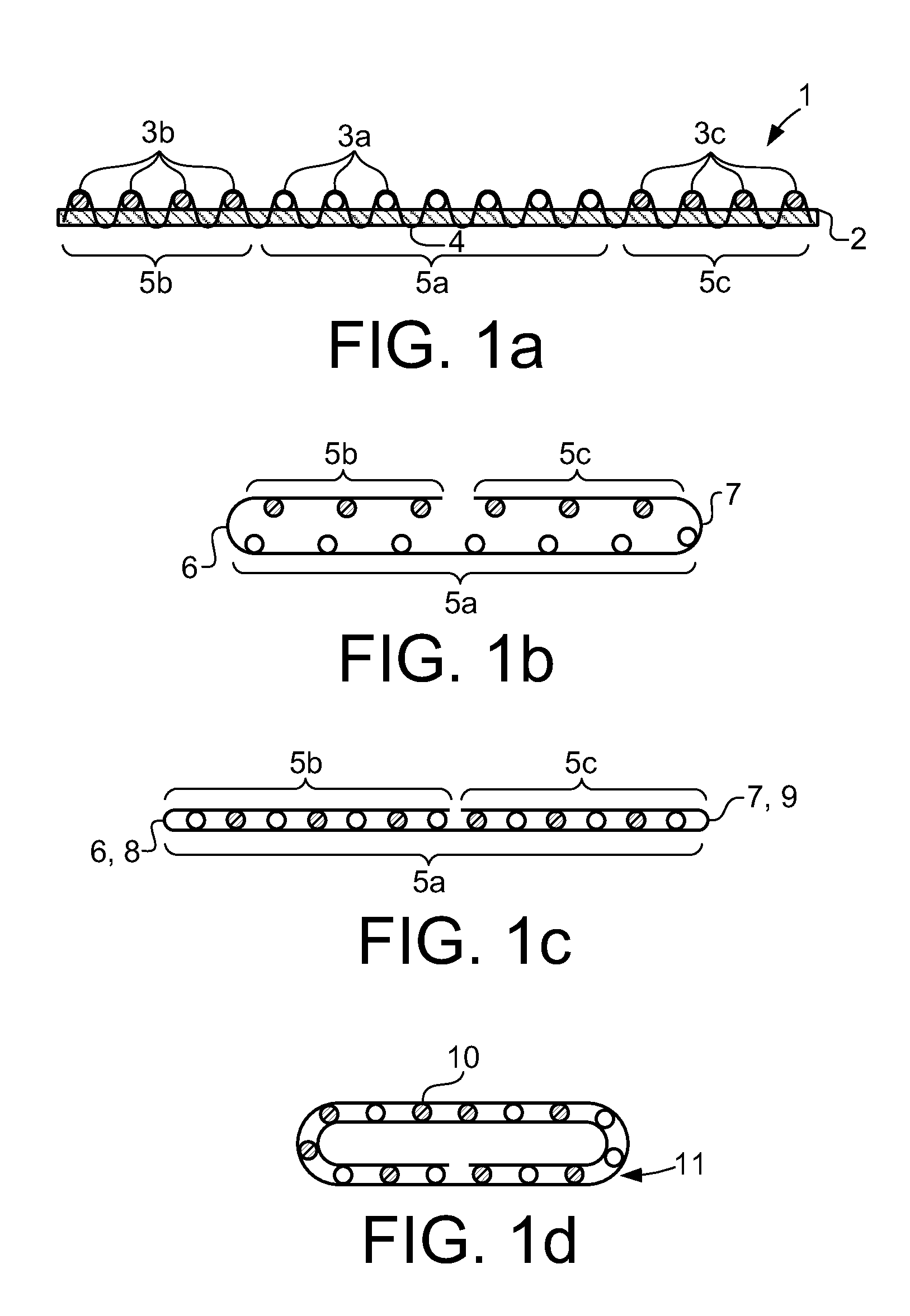

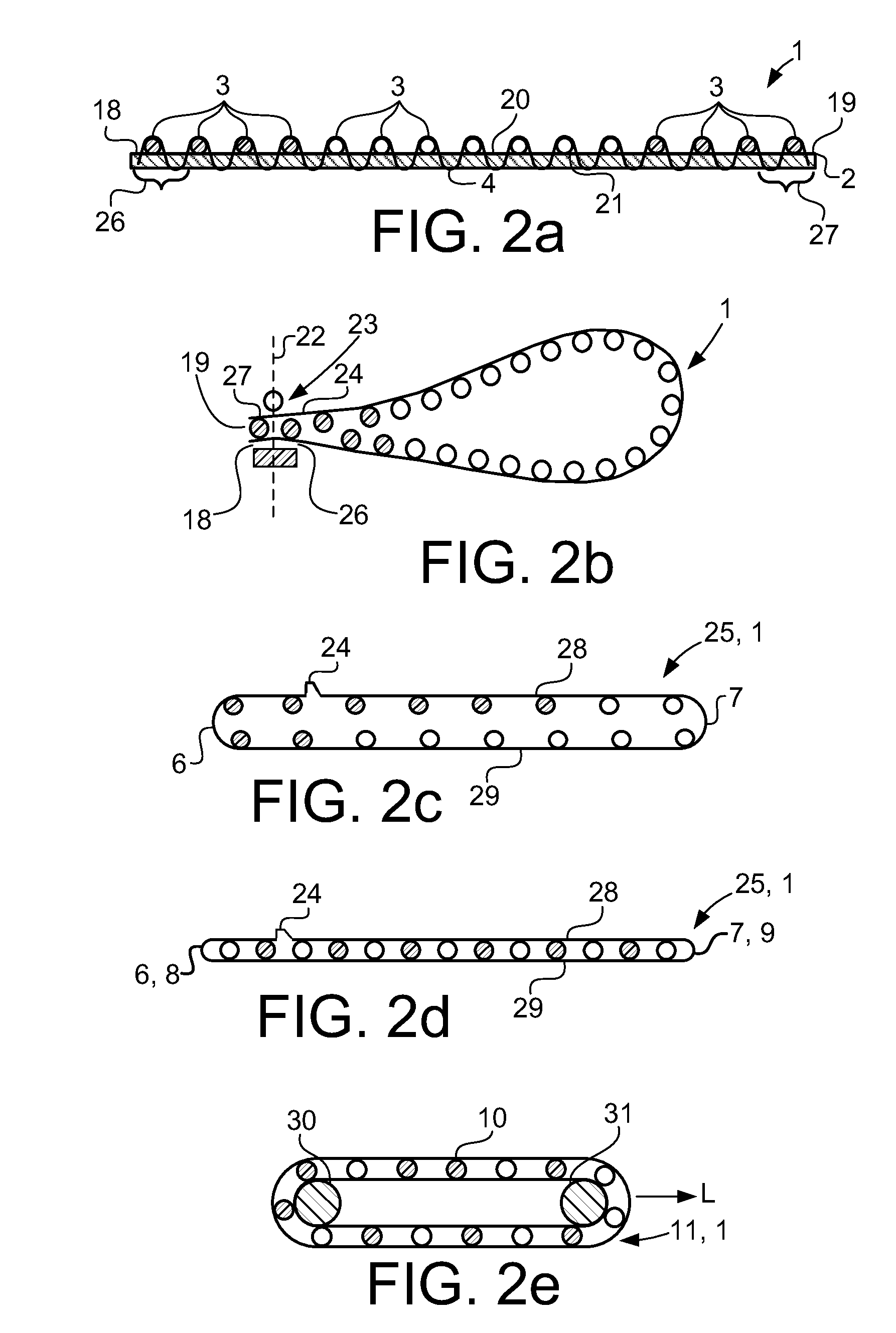

Sealing tape

InactiveUS7022631B2Produced easily and cost-effectivelyHigh yield strengthSynthetic resin layered productsJoints tightening/coveringOperating energyMechanical engineering

A sealing tape is provided for sealing connecting joints between a window frame and a window embrasure in a building. The sealing tape is for adhering to the window frame and the window embrasure. The tape has an elastically moldable membrane base material; and a nonwoven layer of adhesion material covering at least one surface of the base material and which is elastically expandable in a lateral direction of the sealing tape for absorbing movements between the window frame and the window embrasure and which is substantially non-expandable in a longitudinal direction of the sealing tape so as to provide a sufficiently high yield strength of the sealing tape during use. The nonwoven layer is such that stucco or plaster can adhere to it.

Owner:SCHMID BAUKUNSTE

Fire protection module

A fire protection module is provided for wall and ceiling openings. The fire protection module includes a sheath for insertion into the wall or ceiling opening and a flange to be placed at the wall or ceiling. The assembly of the fire protection module may be performed with few steps. For example, the sheath and the flange are embodied in one piece.

Owner:HILTI AG

Loading device

InactiveUS7121309B2Cost-effectiveEasy to produceLiquid fillingSolid materialEngineeringMechanical engineering

Owner:BUCHEN ICS

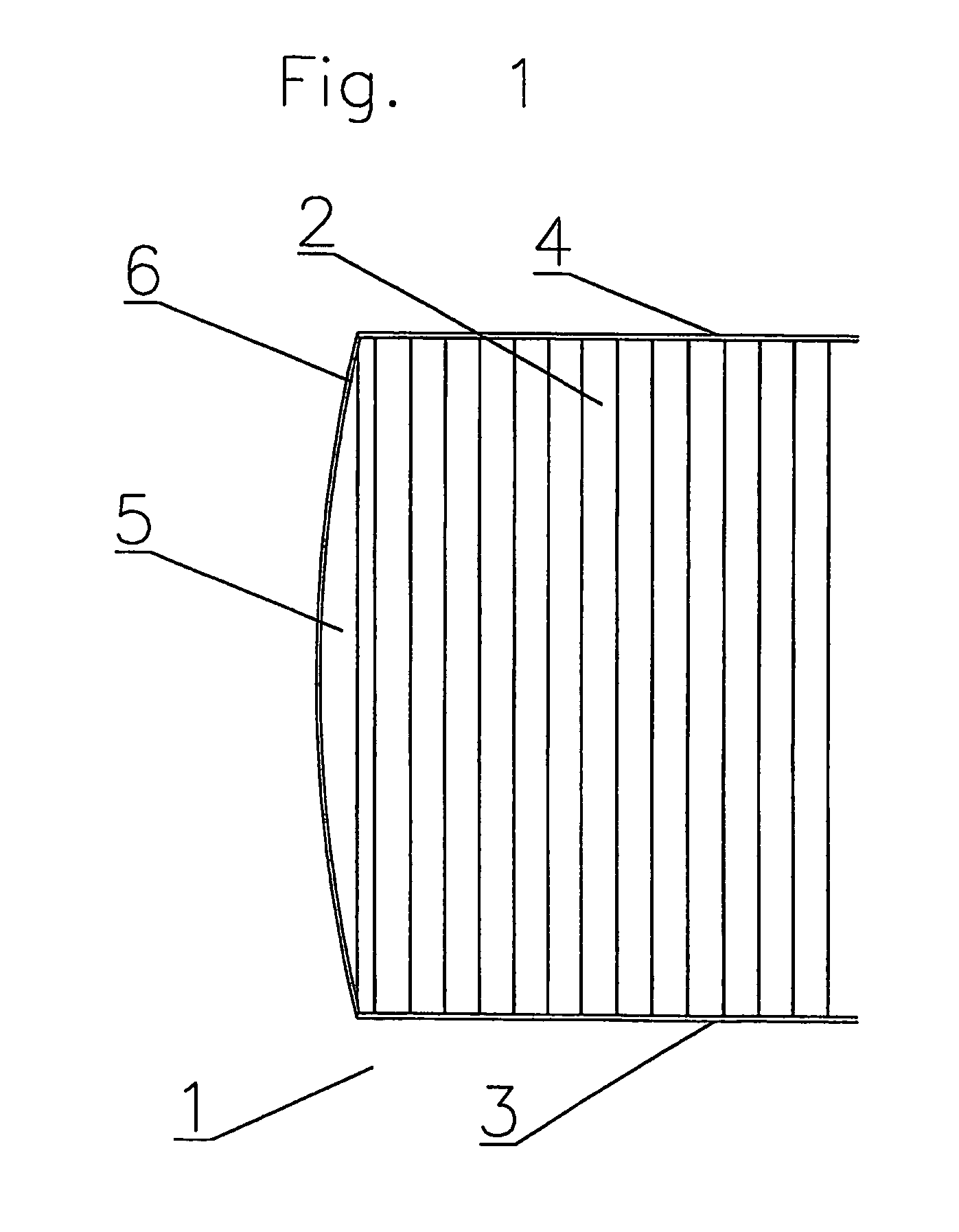

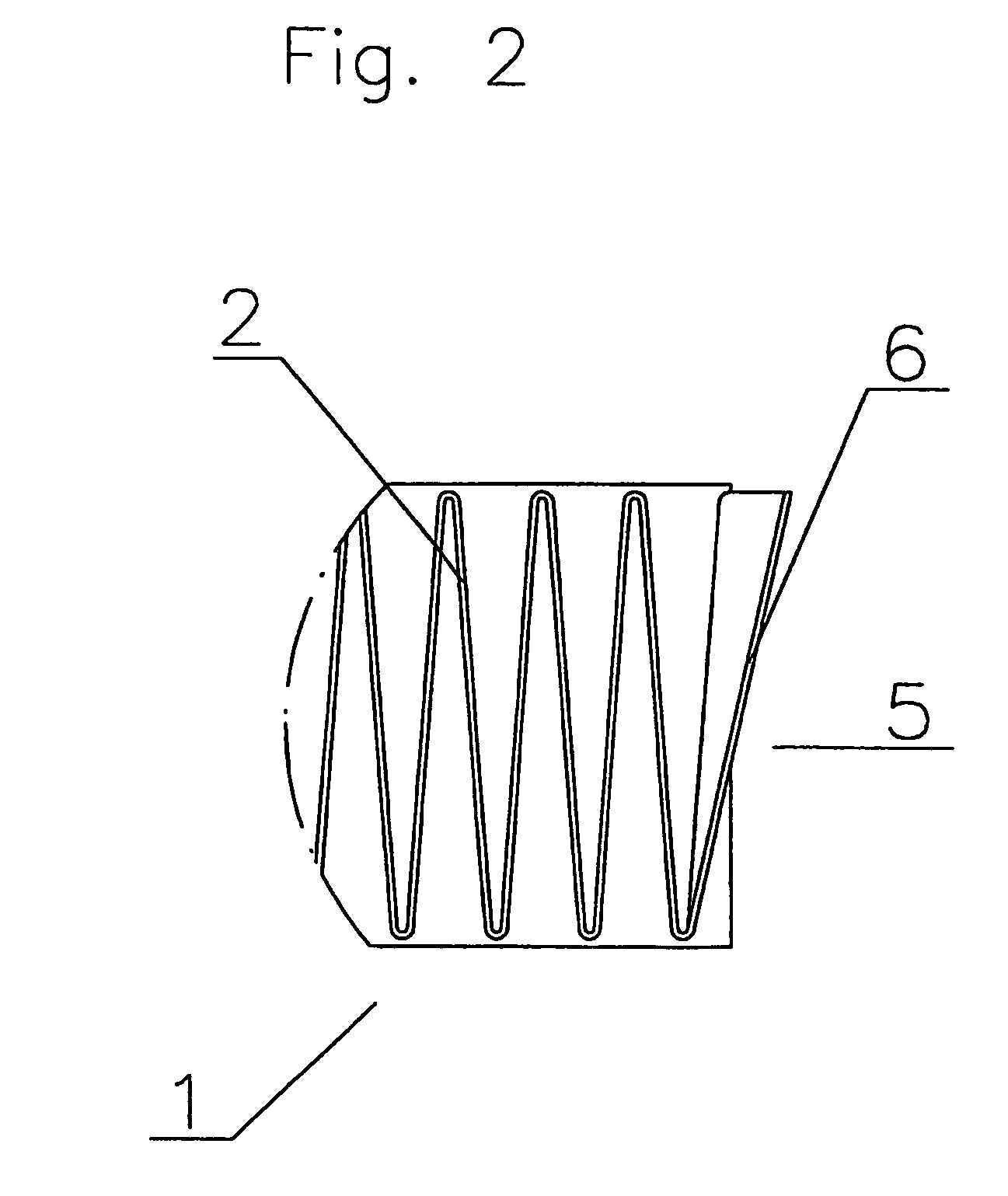

Filter element

ActiveUS7503954B2Improve sealingGood effectDispersed particle filtrationIsotope separationMechanical engineeringPleat

Owner:CARL FREUDENBERG KG

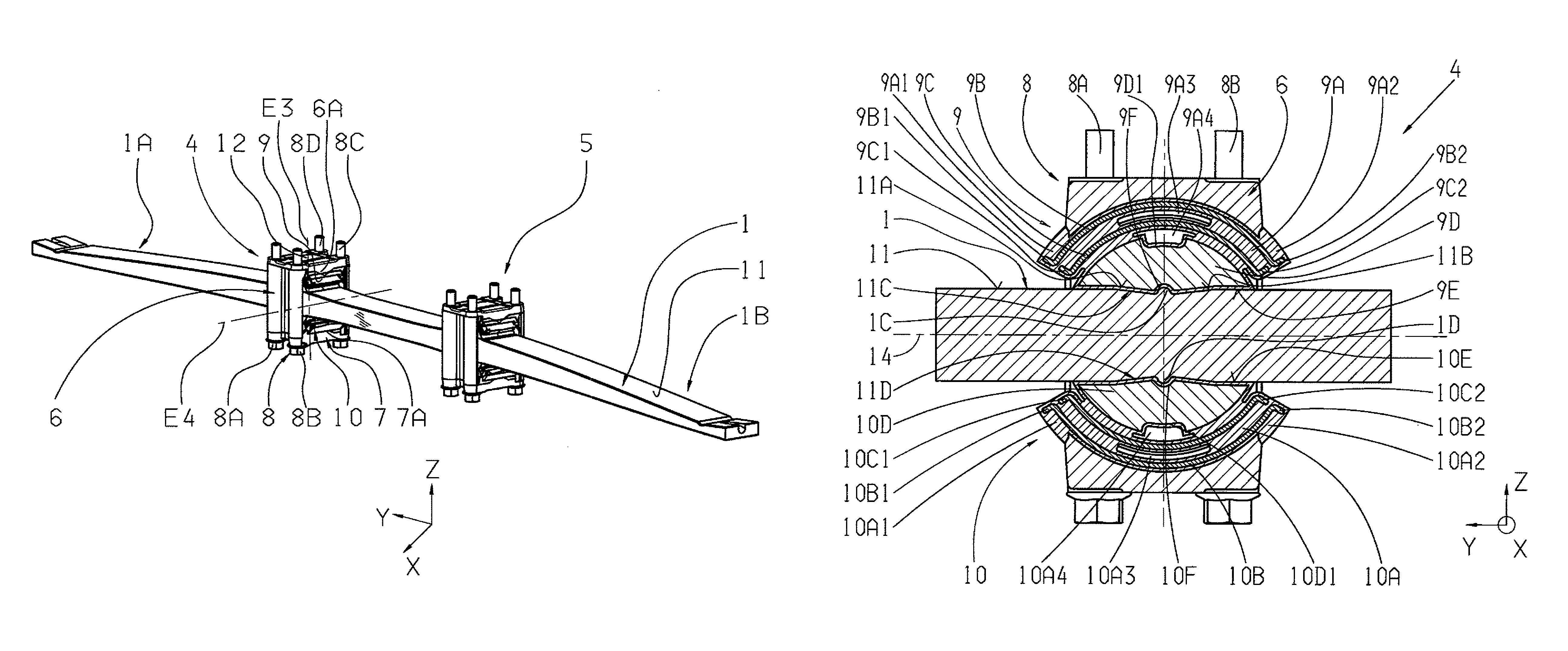

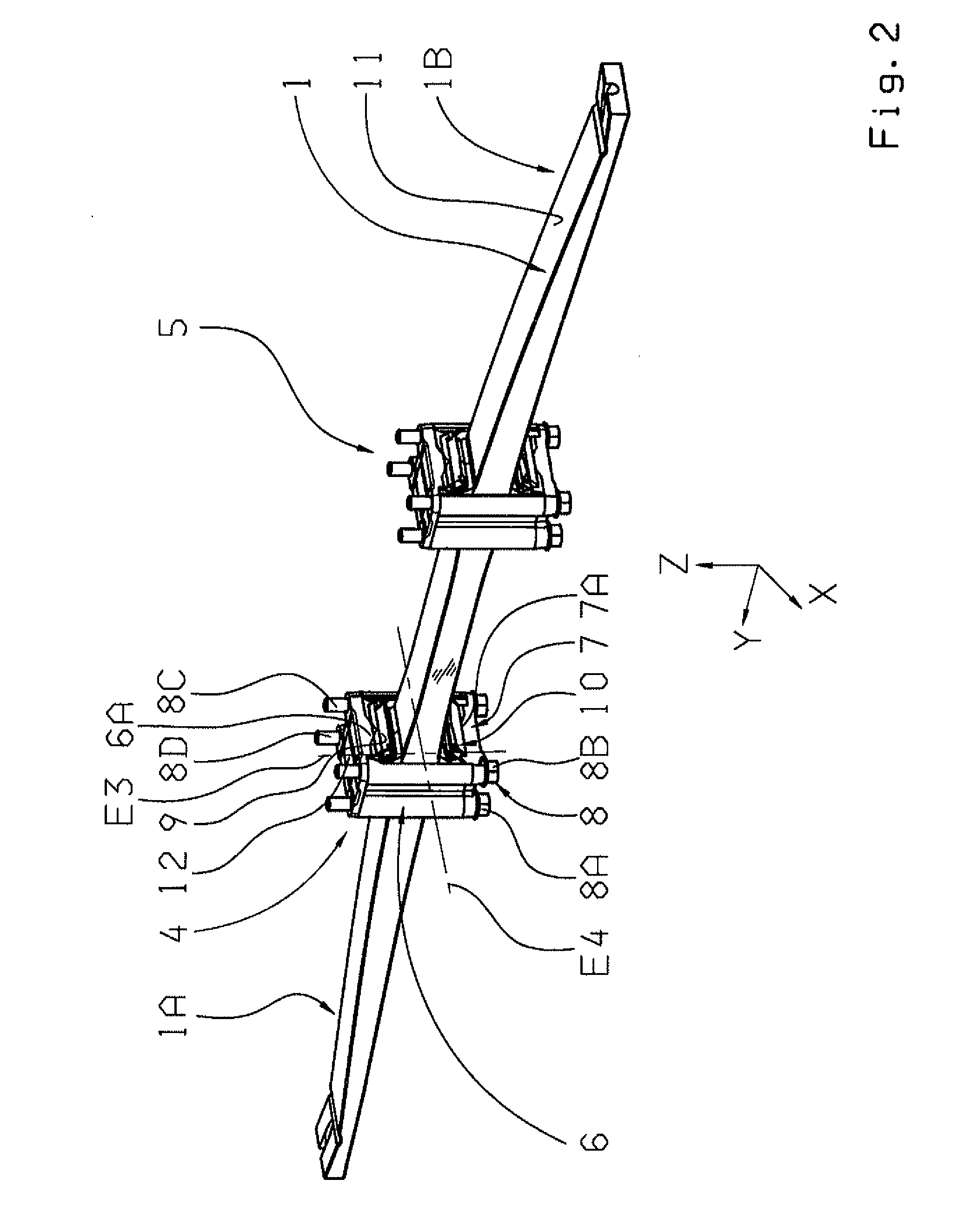

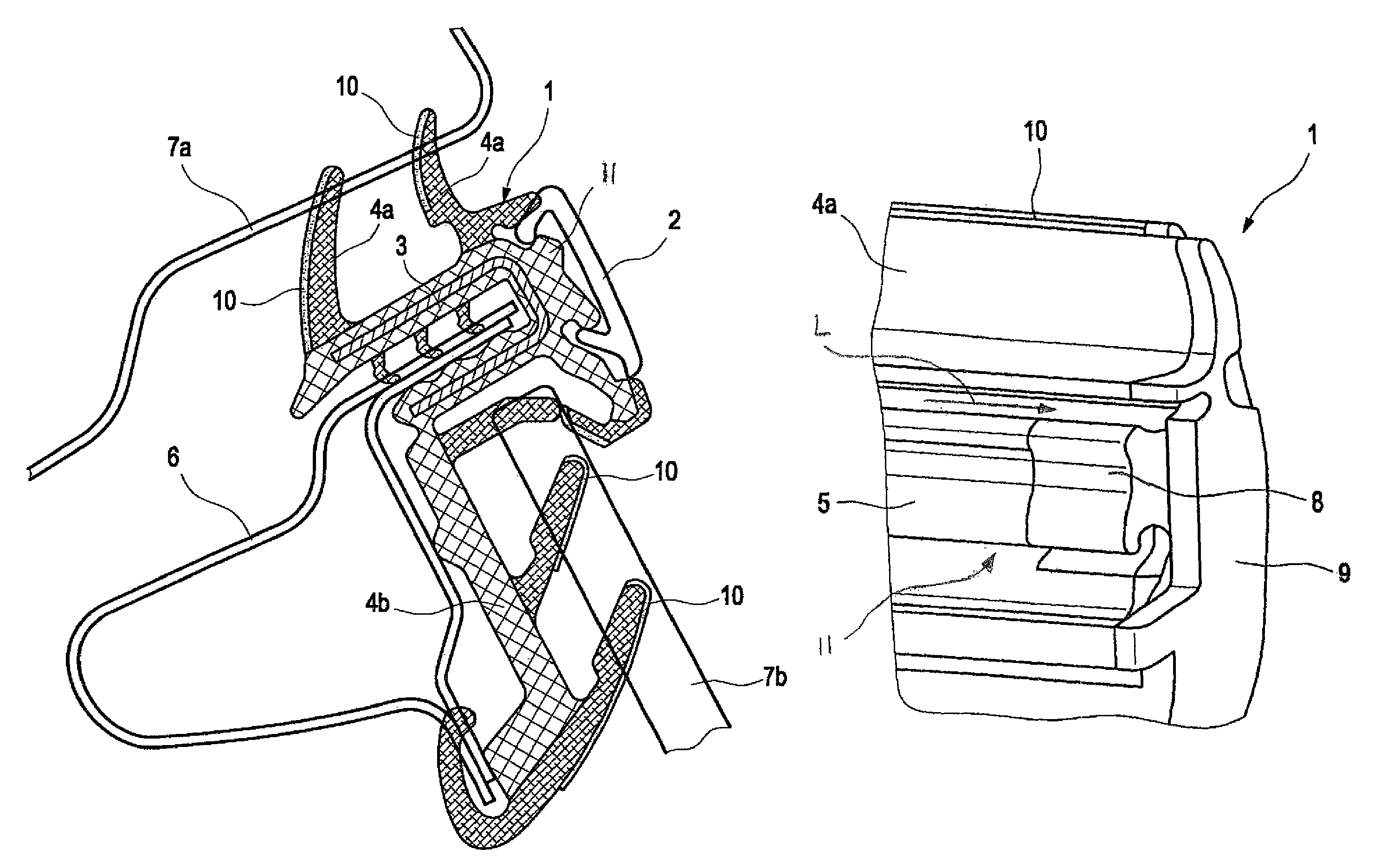

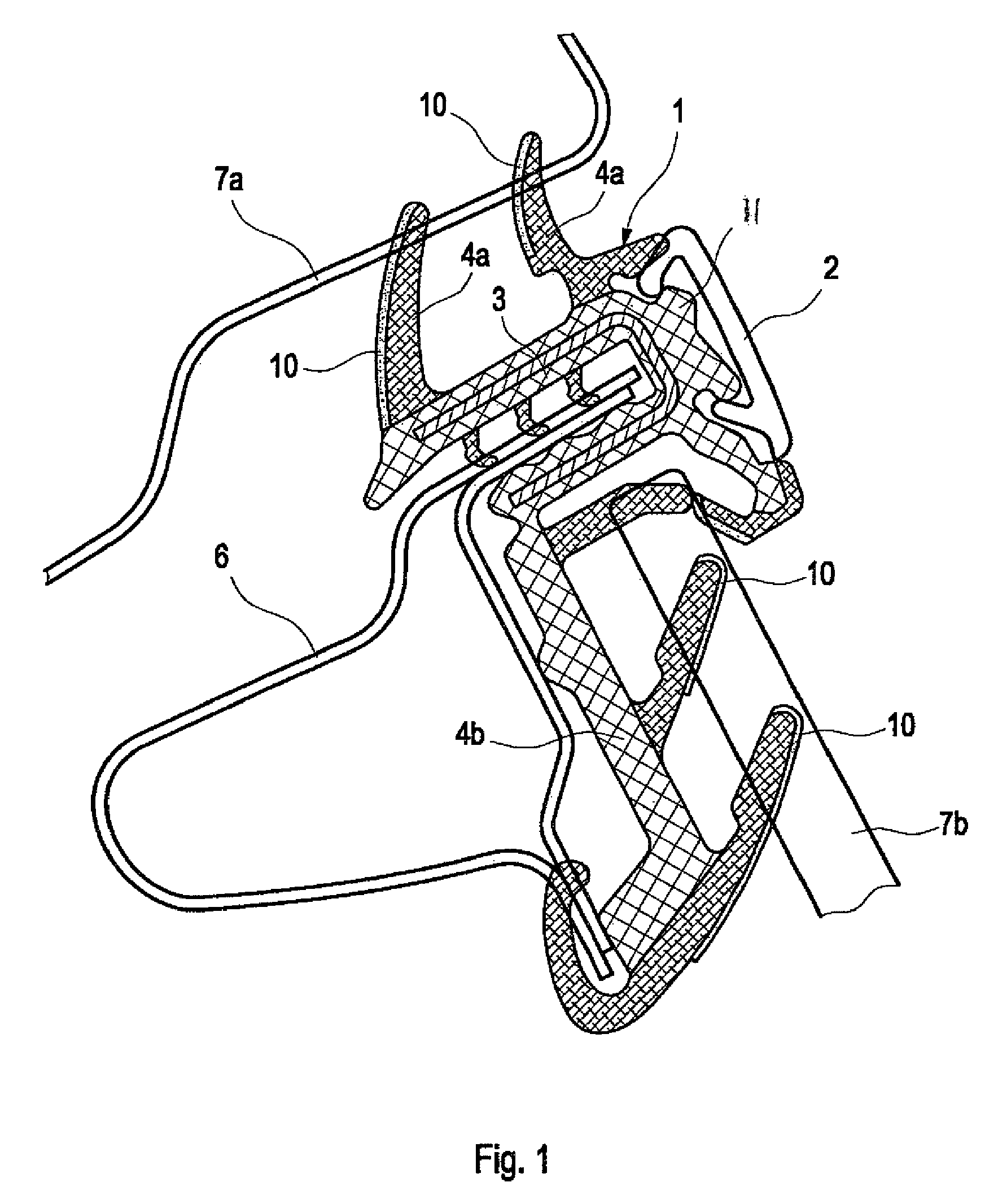

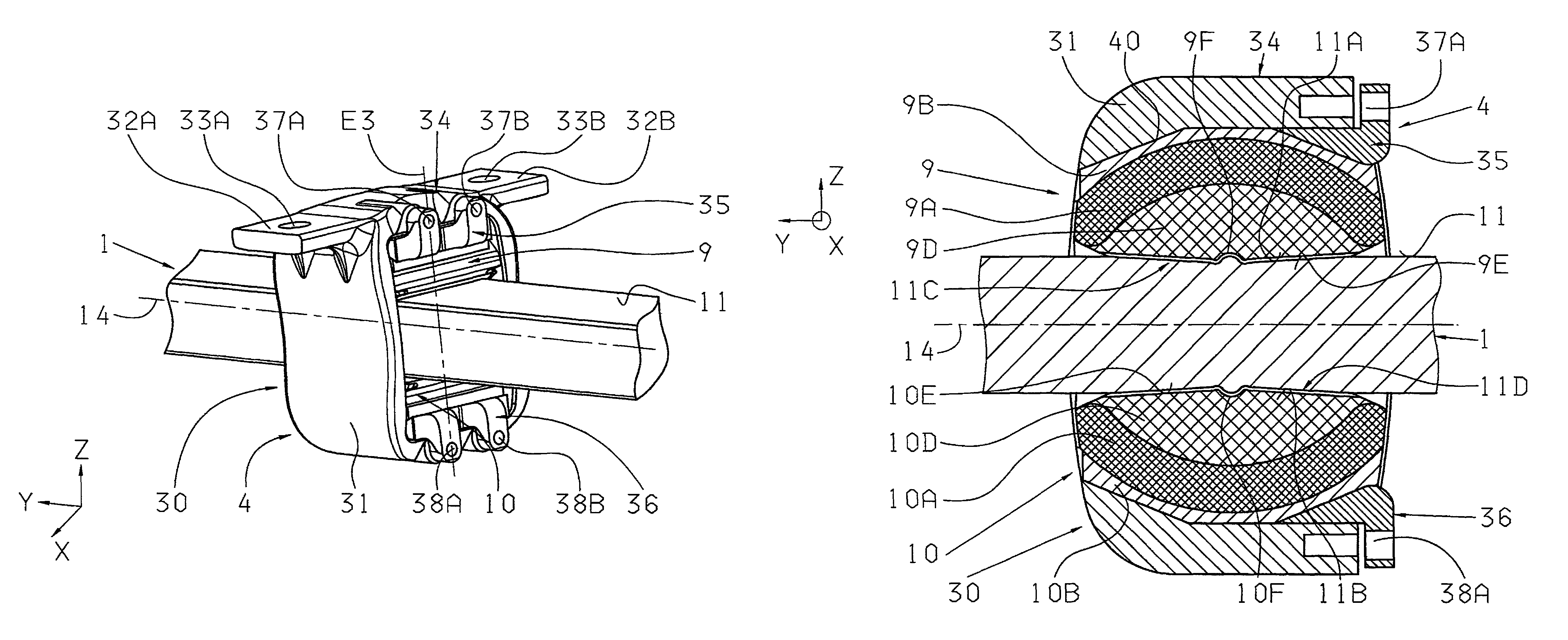

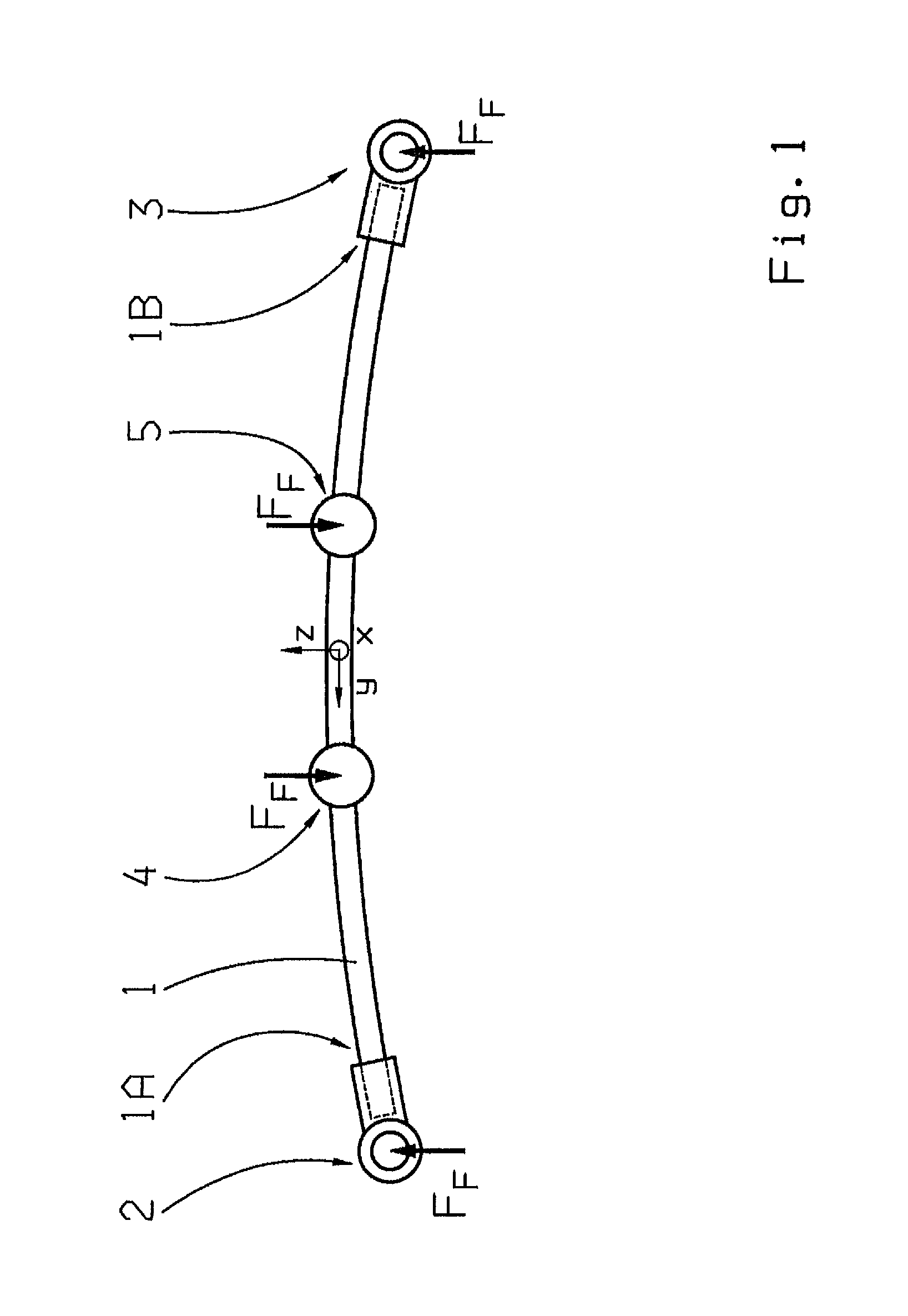

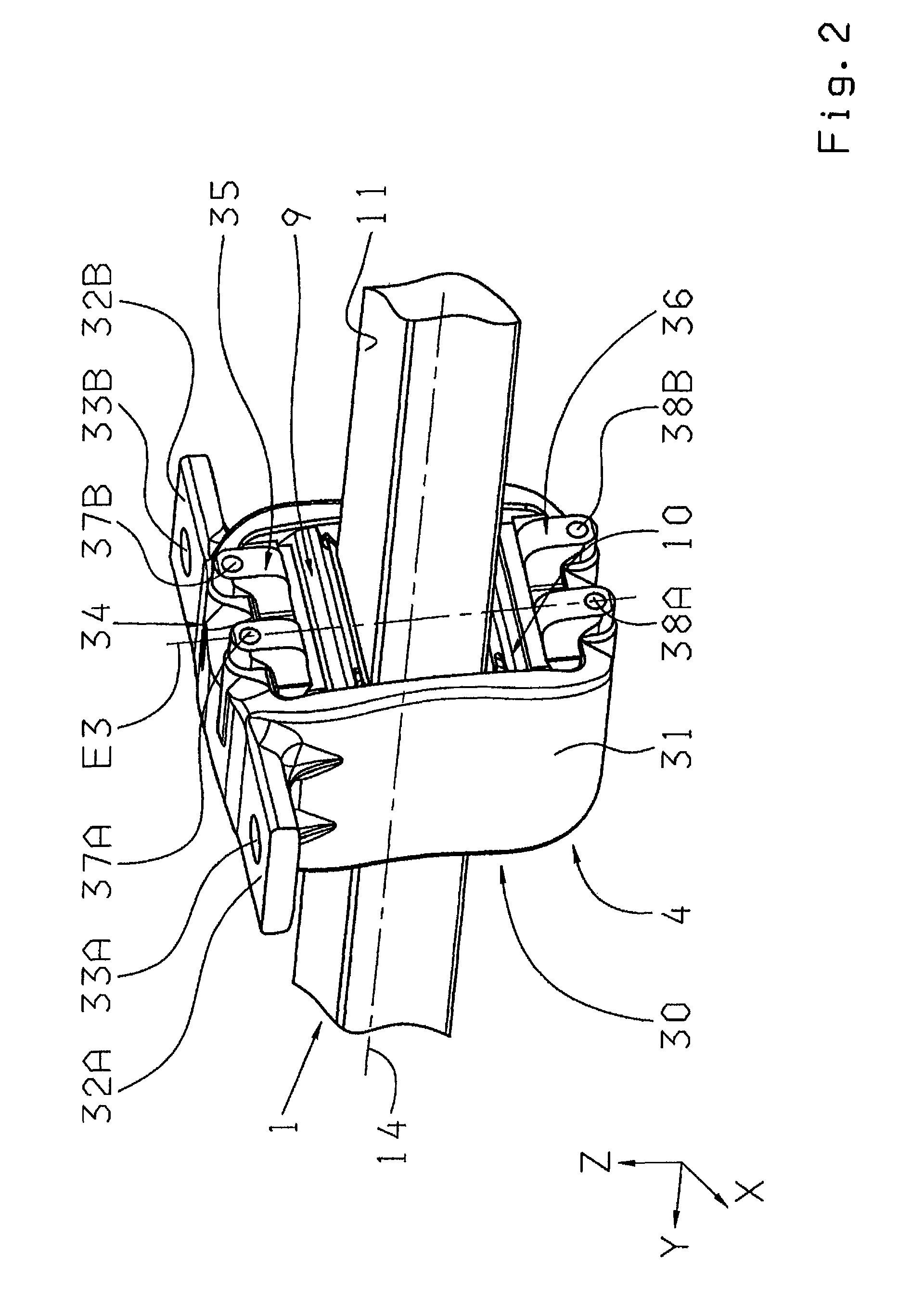

Bearing device of a transverse leaf spring that can be mounted in the region of a vehicle axle of a vehicle

InactiveUS8459676B2Low construction space requirementProduced easily and cost-effectivelySpringsInterconnection systemsEngineeringInsertion device

A bearing mechanism (4) for a transverse leaf spring (1) for mounting in the region of a vehicle axle of a vehicle. The bearing mechanism (4) has two outer bearing shells (6, 7) that can be connected together and insertion devices (9, 10) with at least some regions of which are encompassed by the outer bearing shells (6, 7) and which each comprise at least two layer elements (9A, 9B, 9C and 10A, 10B, 10C) with different stiffnesses. In the assembled state, the insertion devices (9, 10) are each disposed between the outer bearing shells (6, 7) and the transverse leaf spring (1). The insertion devices (9, 10) can be connected to the outer bearing shells (6, 7) and the transverse leaf spring (1), via a bolt device (8) which connects the outer bearing shells (6, 7) together and to a vehicle chassis at least in a force locking manner.

Owner:ZF FRIEDRICHSHAFEN AG

Lighting device

InactiveUS20130094234A1Improve homogeneityProduced easily and cost-effectivelyVehicle headlampsOptical signallingLight guideLight beam

A lighting device for vehicles with multiple light sources arranged like a matrix in one light generation level, with a light forming optic unit arranged in front of the light sources, and with another optic unit arranged between the light forming optic unit and the light sources, comprising a plurality of optic elements that are arranged like a matrix and one optic element each being allocated at a face thereof to a light source and with the other optic unit in front of the optic elements being allocated to the light sources to coupling areas and at least one decoupling area facing the light forming optic unit, with the other optic unit being embodied as a widening optic unit for widening the partial light bundles emitted by the light sources with light guiding rods as optic elements.

Owner:HELLA KG HUECK & CO

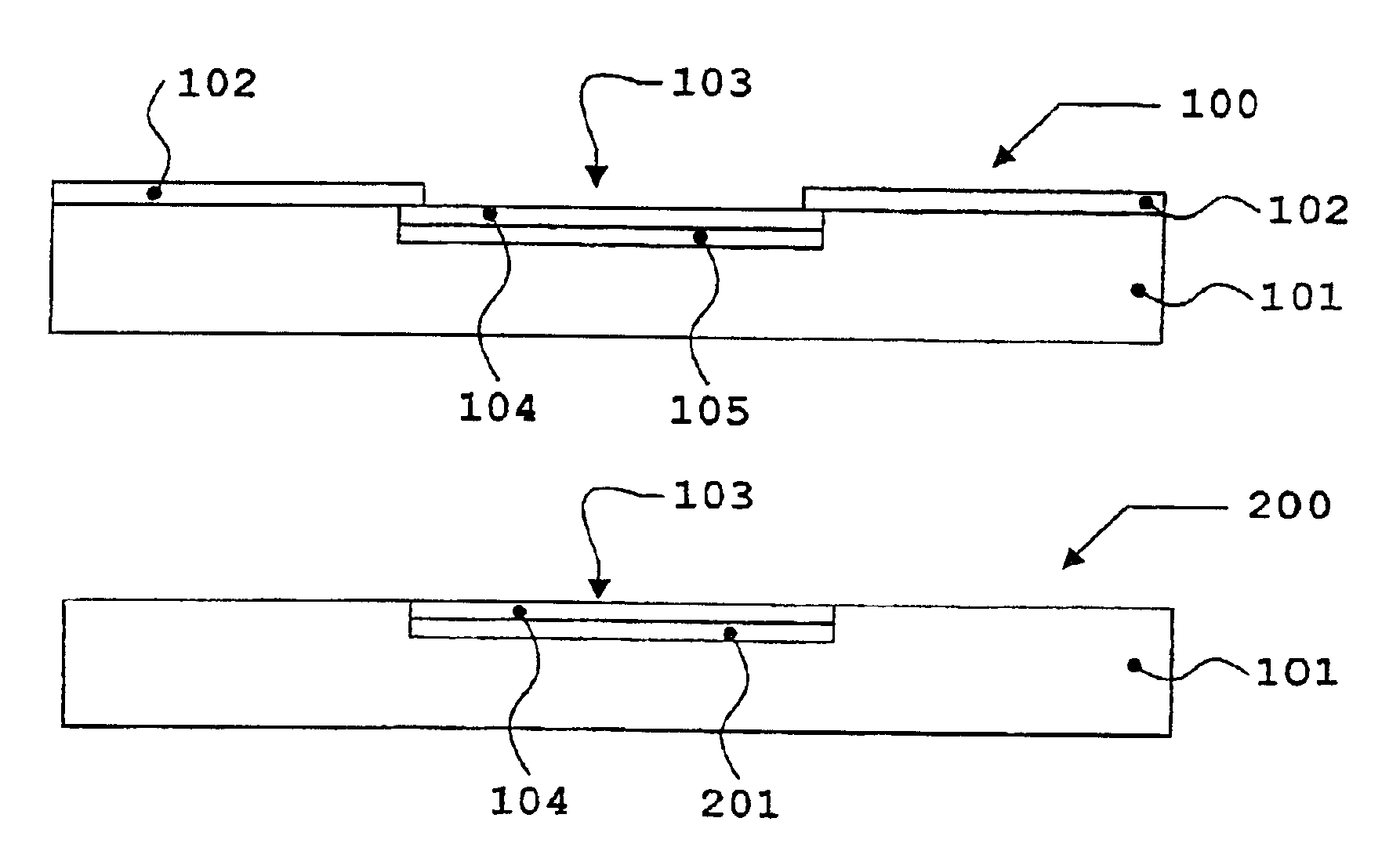

Nanowire sensor, nanowire sensor array and method of fabricating the same

InactiveUS8236595B2Produced easily and cost-effectivelyLow production costSequential/parallel process reactionsSolid-state devicesSensor arrayNanowire

A method of fabricating a sensor comprising a nanowire on a support substrate with a first semiconductor layer arranged on the support substrate is disclosed. The method comprises forming a fin structure from the first semiconductor layer, the fin structure comprising at least two supporting portions and a fin portion arranged there between; oxidizing at least the fin portion of the fin structure thereby forming the nanowire being surrounded by a first layer of oxide; and forming an insulating layer above the supporting portions; wherein the supporting portions and the first insulating layer form a microfluidic channel. A nanowire sensor is also disclosed. The nanowire sensor comprises a support substrate, a semiconducting fin structure arranged on the support substrate, the fin structure comprising at least two semiconducting supporting portions and a nanowire arranged there between; and a first insulating layer on a contact surface of the supporting portions; wherein the supporting portions and the first insulating layer form a microfluidic channel.

Owner:AGENCY FOR SCI TECH & RES

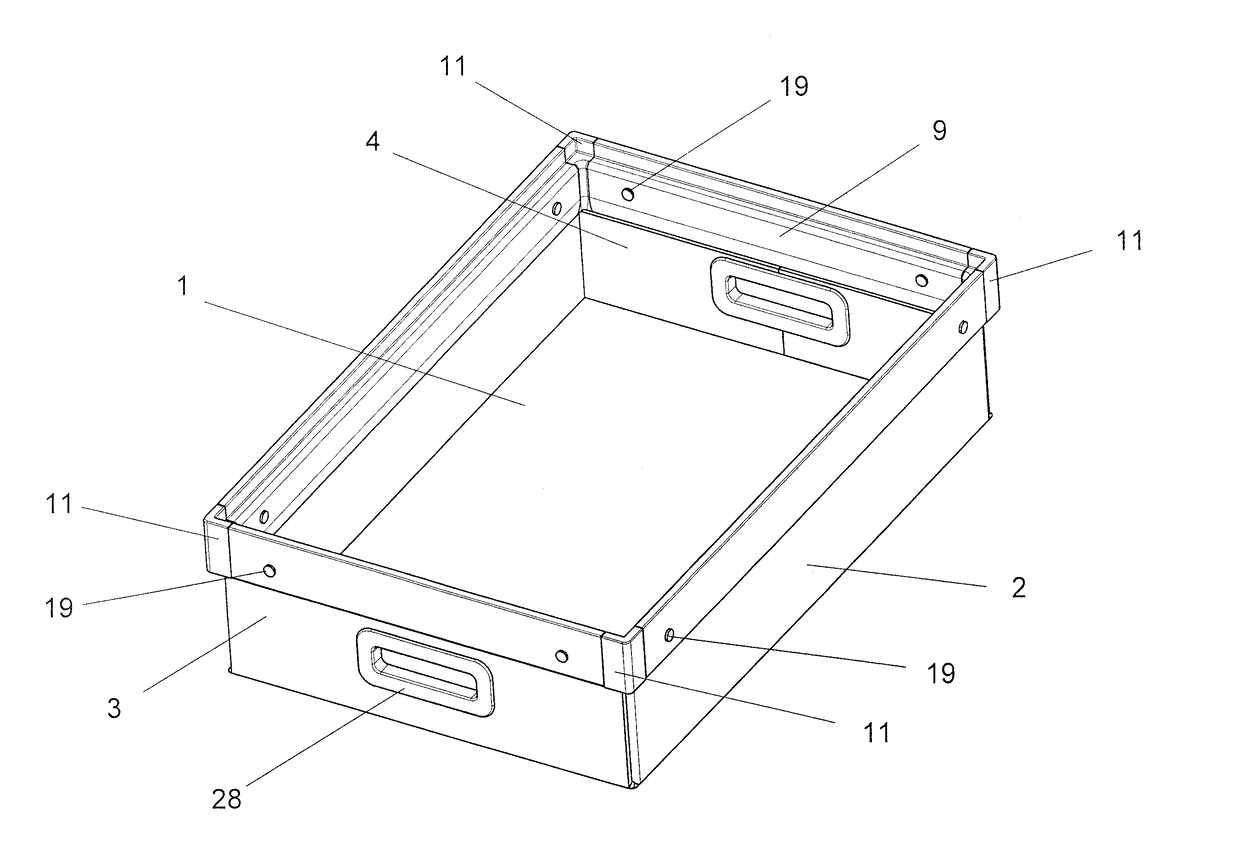

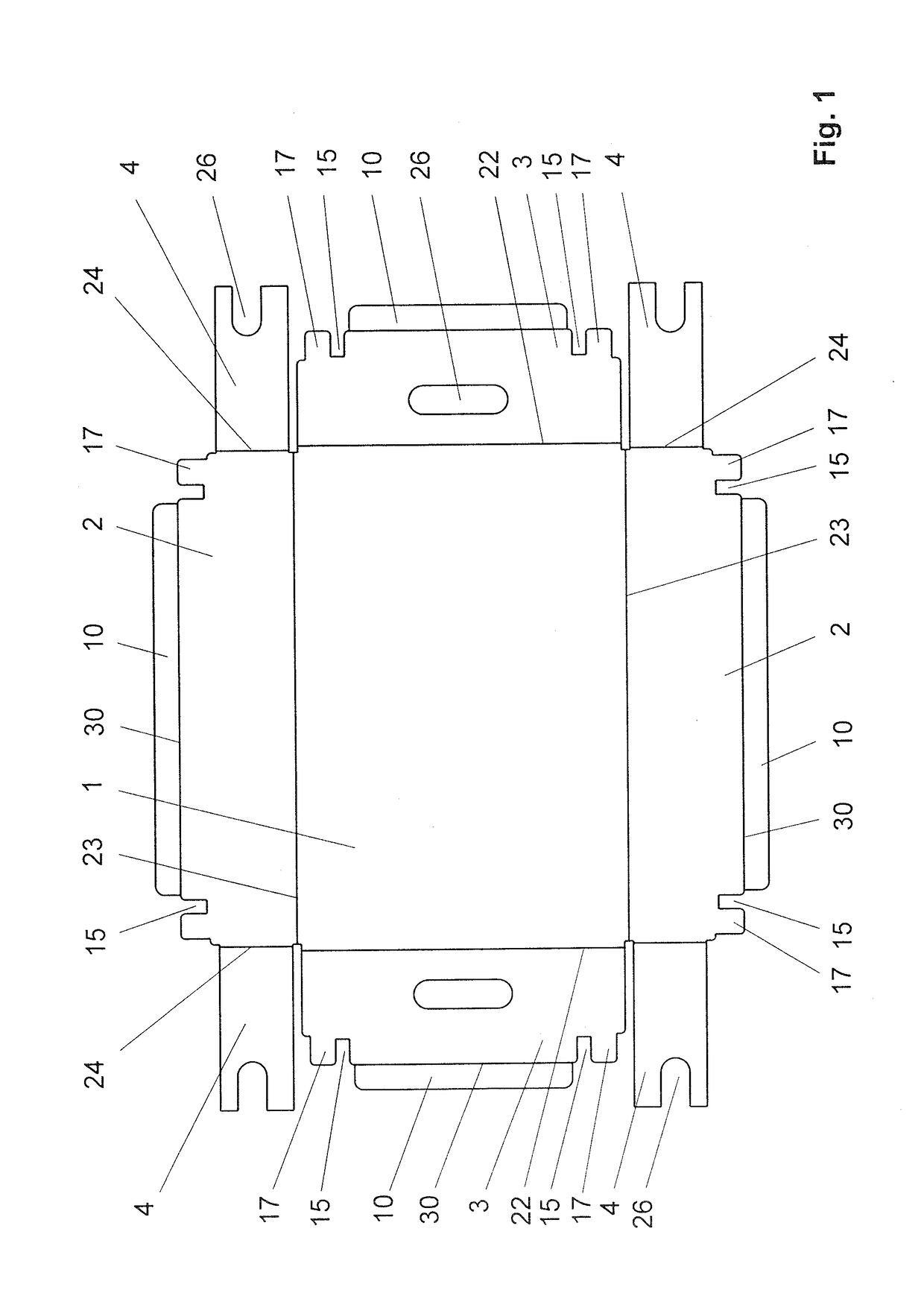

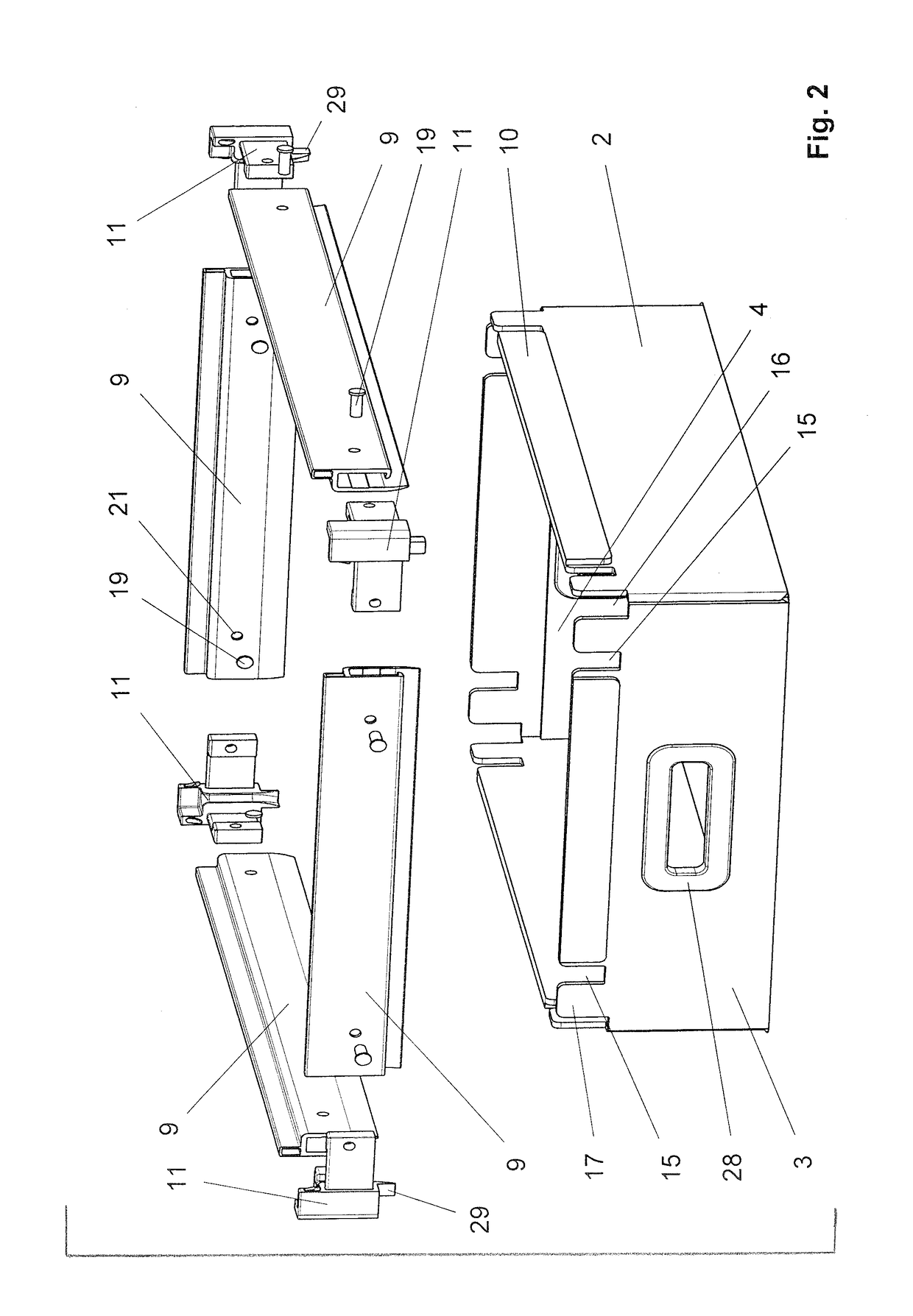

Transport and storage container

A storage and transport container, in an unassembled state, is composed of a single-piece container blank having a bottom, foldable side and end walls and four corner flaps foldable inwardly at the side walls or the end walls. Respective turnover rims are integrally formed on the side walls and the end walls so that when the turnover rims are folded over, a stacking profile having a hook rim can be attached over the same, Four corner pieces are provided, wherein each corner piece has a base body having an upper stacking rim. Two insertion profiles are integrally formed on the base body, each having an angled profile section at the front end. The angled profile section positively fits in a respective profile recess of the side walls and the end walls. The stacking profiles extend over the insertion profiles flush against the stacking rim.

Owner:MONTARA VERPACKEN MIT SYST

Profile seal with trim strip for a vehicle

Owner:AUDI AG

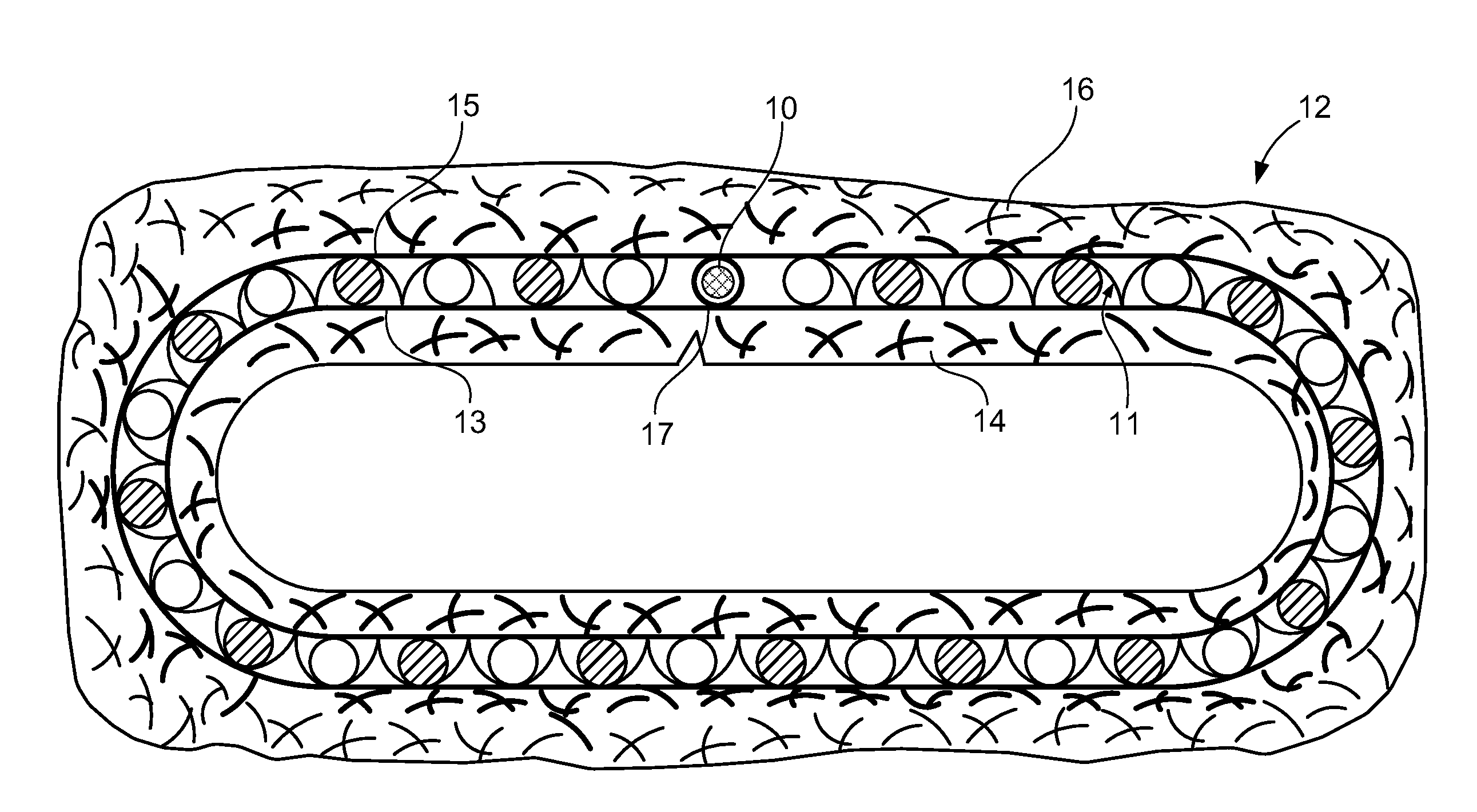

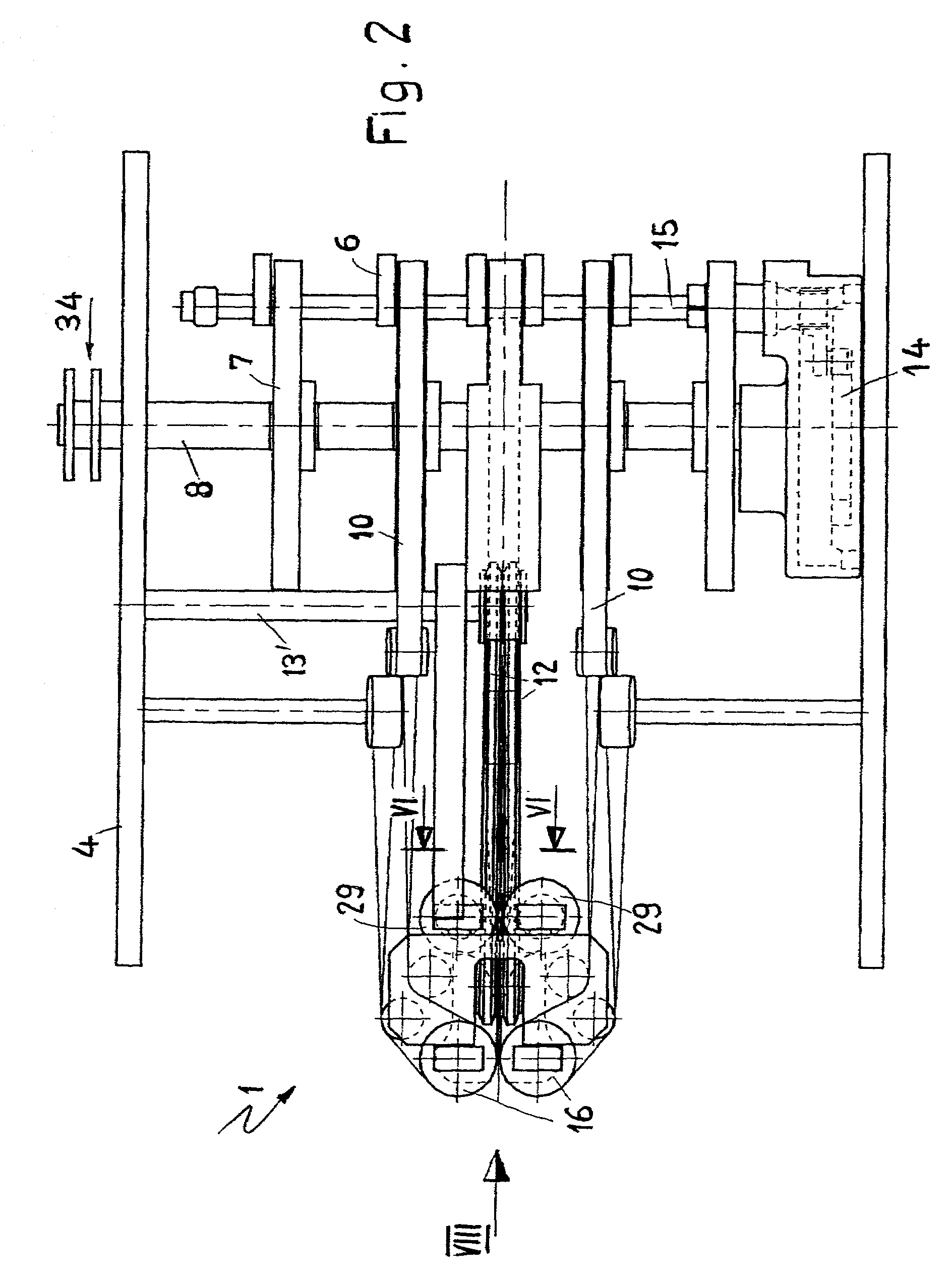

Seamable press felt with flat manufactured carrier structure which is not woven

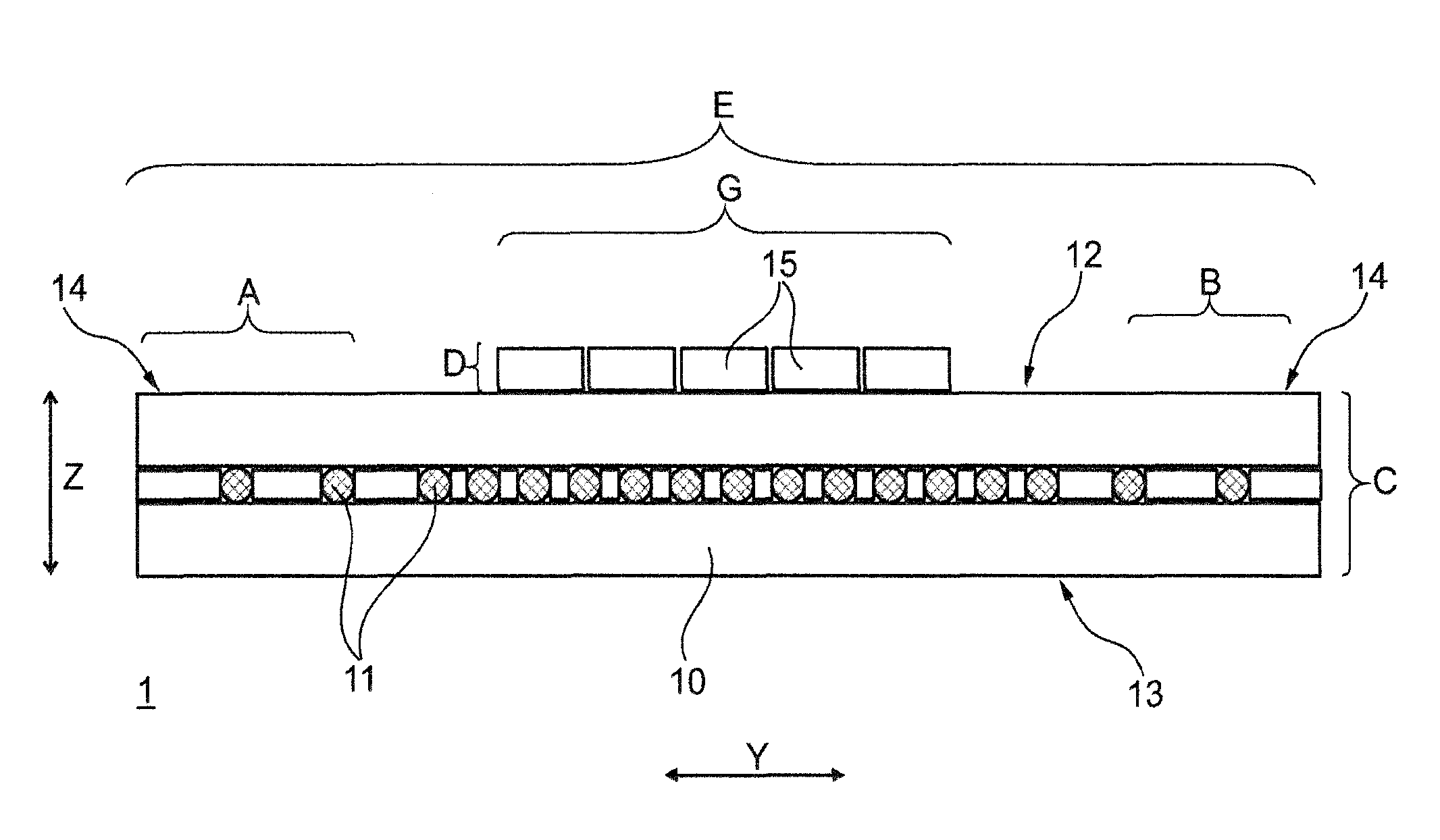

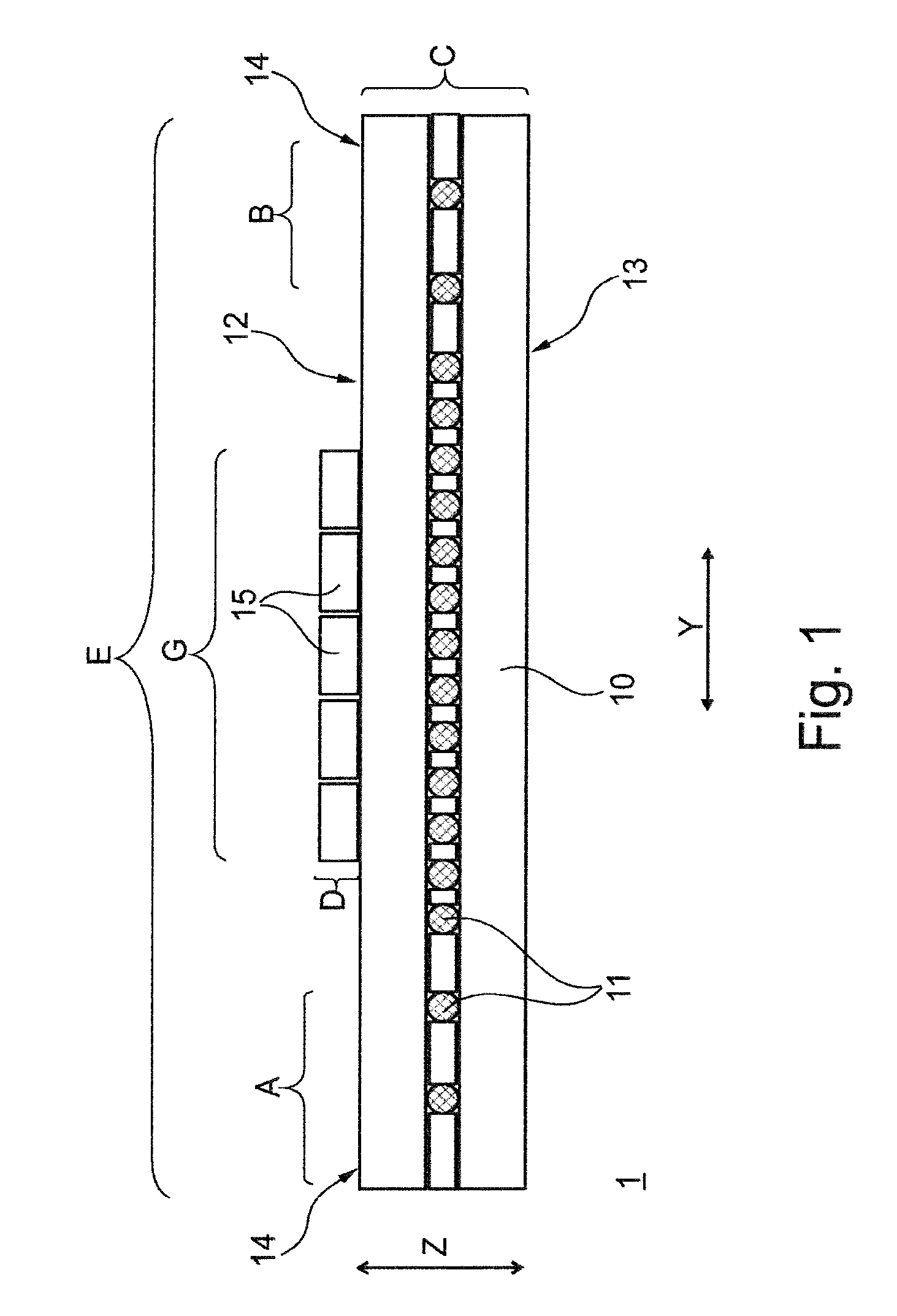

The present invention relates to a press felt for a machine for the production and / or processing of a fibrous web including a carrier structure which fundamentally influences the dimensional stability of the felt. The carrier structure includes a flat manufactured textile fabric formed from longitudinal threads, transverse threads crossing the longitudinal threads, and sewing threads which connect the longitudinal and transverse threads with each other at the crossing points. The textile fabric is longer than the carrier structure and is laid onto itself in sections such that the carrier structure is formed by several layers of the textile fabric, extending respectively along the entire length of the carrier structure. The layers are connected with each other, at least in sections. Due to the placement of the sections of the textile fabric on top of each other, turned over edges which extend transversely to the longitudinal direction of the carrier structure are formed defining transverse ends of the carrier structure. In an area of the turned over edges, the longitudinal threads have a curved progression to form seam loops on the respective transverse ends, whereby the carrier structure is seamable in a paper machine in that the two transverse ends of the carrier structure are brought together to make the carrier structure continuous and the seam loops are meshed with each other, thus forming a connecting channel extending in the cross direction of the carrier structure. To make the carrier structure continuous, a pintle wire is inserted through the connecting channel.

Owner:VOITH PATENT GMBH

Tubular conveyor belt or pocket conveyor belt having a chevron profile arrangement on the carrying side thereof

ActiveUS9463930B2Produced easily and cost-effectivelyEasily and cost-effectively and transportedConveyorsEngineeringConveyor belt

A conveyor belt includes a carrying-side cover plate and a running-side cover plate. The cover plates conjointly define a belt body having a plurality of reinforcement elements embedded therein. The belt body has edge zones and is closable so as to cause the edge zones to overlap and be in mutual contact engagement to form a tube conveyor belt or a pocket conveyor belt. The carrying-side cover plate has a chevron profile arrangement which includes a plurality of diagonal elements extending in both a longitudinal direction and a transverse direction of the conveyor belt. Each two of the diagonal elements conjointly defines a pair with multiple pairs defining a V-formation having a tip aligned in a direction opposite to the direction of movement of the belt.

Owner:CONTITECH TRANSPORTBANDSYSTEME GMBH

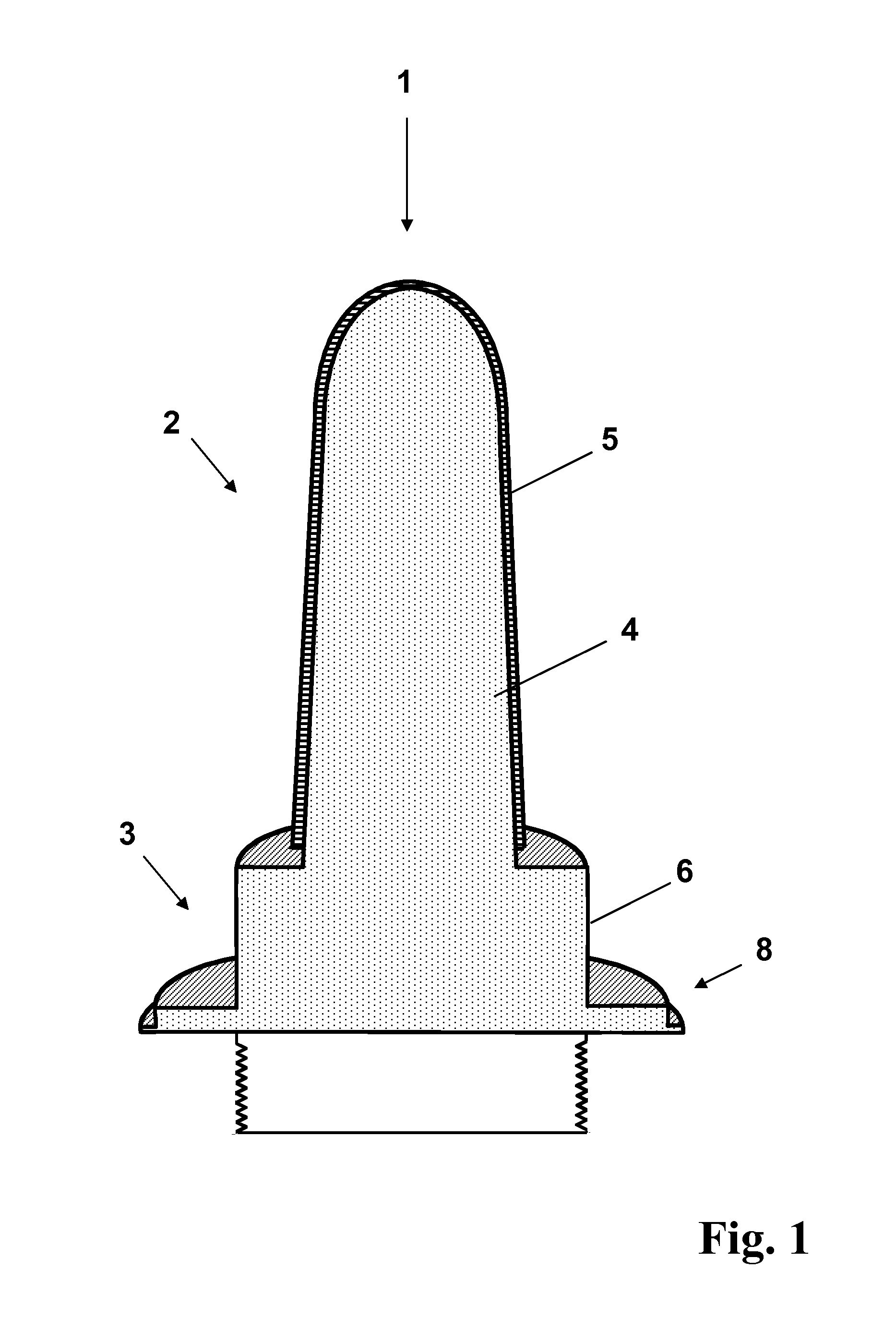

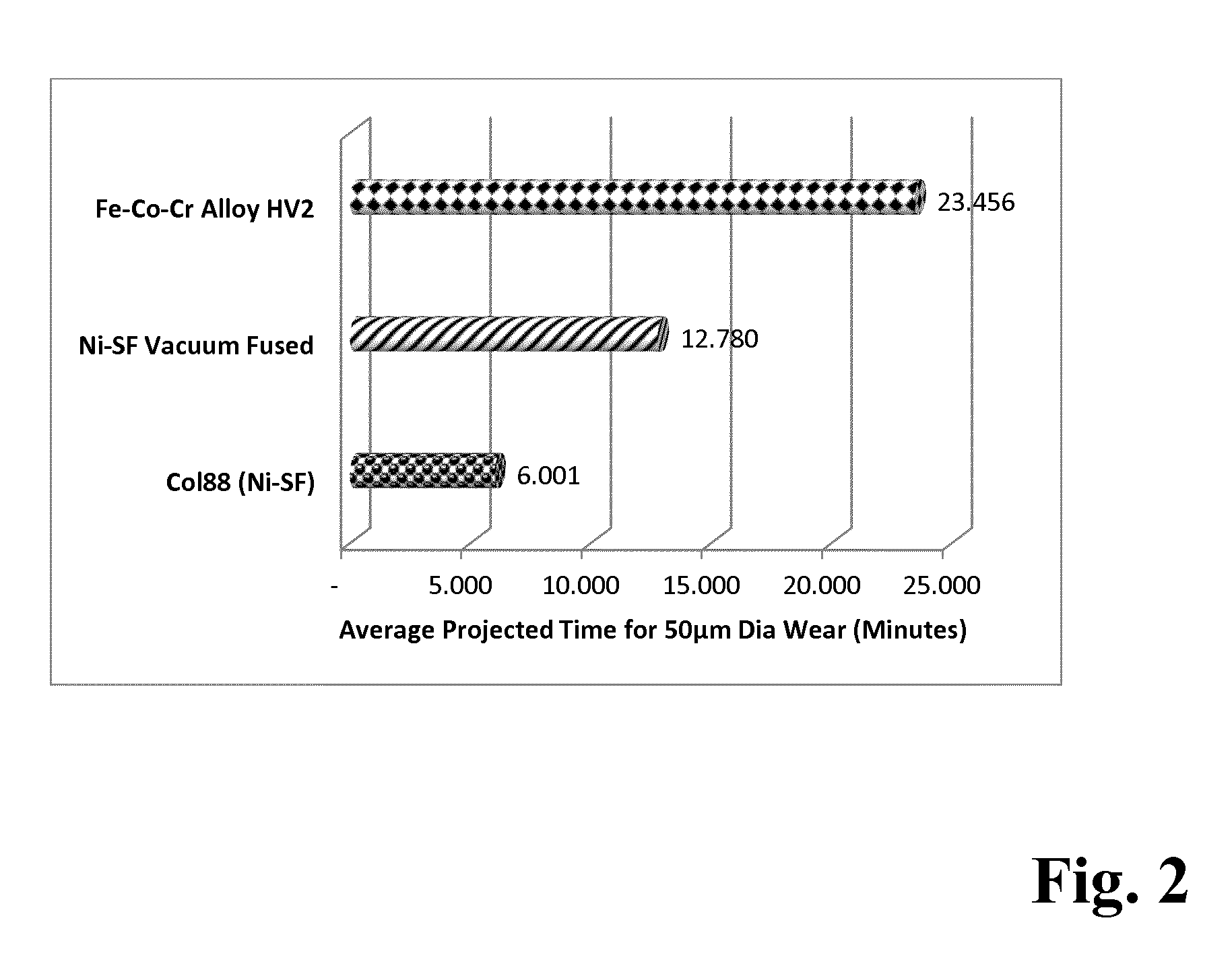

Plunger for use in manufacturing glass containers

InactiveUS20150000347A1Produced easily and cost-effectivelyIncrease resistanceHot-dipping/immersion processesMolten spray coatingMetal coatingAlloy

A plunger for use in manufacturing glass containers comprises a first portion configured for contact with a gob of molten glass, and a second portion. At least the first portion has a metal coating of a self-fluxing Fe-based alloy and with a microhardness between 300 HV0.3 and 900 HV0.3. The Fe-based alloy comprises in wt. %): C, 0.5-2.5; Si, 1.0-4.0; B, 1.5-6.0; Cr, 15.0-30.0; Ni, 0-5.0; Co, 15.0-40.0; W, 1.2-5.0; Mo, 0-5.0; Cu, 0-5.0; P, 0-3.0; and N, 0-1.0. The Fe-based alloy may further comprise metals selected from Al, Mn, Nb, S, Ti, V, Zn And Zr each in an individual amount that ranges from 0.01 wt. % to about 2 wt. %, with the overall content of the additional metals less than 10 wt. %.

Owner:MEC - HLDG

Apparatus for the continuous filtering of impurities from a flowable compound

ActiveUS7820039B2Rapid and smooth exchangeDismounted easilyWater/sewage treatment by centrifugal separationPlastic recyclingRotational axisEngineering

The invention relates to an apparatus for the continuous filtering of impurities from a flowable compound, especially a plastic melt, comprising a filter insert (3) in the form of a hollow rotary body which is held to rotate about its rotational axis (A) relative to a housing (1, 2) and is flowed through by the flowable compound and which is arranged in a flow conduit of the housing (1, 2) between a feed conduit (7) for the compound to be filtered and a discharge conduit (8) for the filtered compound, and a discharge apparatus for impurities held back by the filter, which apparatus comprises a feed screw (9) cooperating with the filter insert (3). In order to provide advantageous constructional conditions it is proposed that the filter insert (3) comprises a disk-like filter (5) which is arranged on the face side of the rotary body and is coaxial to the rotational axis (A).

Owner:SCHULZ KATHARINA

Method for producing a semiconductor component and a semiconductor component produced according to the method

InactiveUS20060014392A1Produced easily and cost-effectivelyRapid productionPaper/cardboard articlesDecorative surface effectsPorous layerSilicon

A method is for producing a semiconductor component, e.g., a multilayer semiconductor element, e.g., a micromechanical component, e.g., a pressure sensor, having a semiconductor substrate, e.g., made of silicon, and a semiconductor component produced according to the method. To reduce the production cost of such a semiconductor component, in a first step a first porous layer is produced in the semiconductor component, and in a second step a hollow or cavity is produced under or from the first porous layer in the semiconductor component, with the hollow or cavity capable of being provided with an external access opening.

Owner:ROBERT BOSCH GMBH

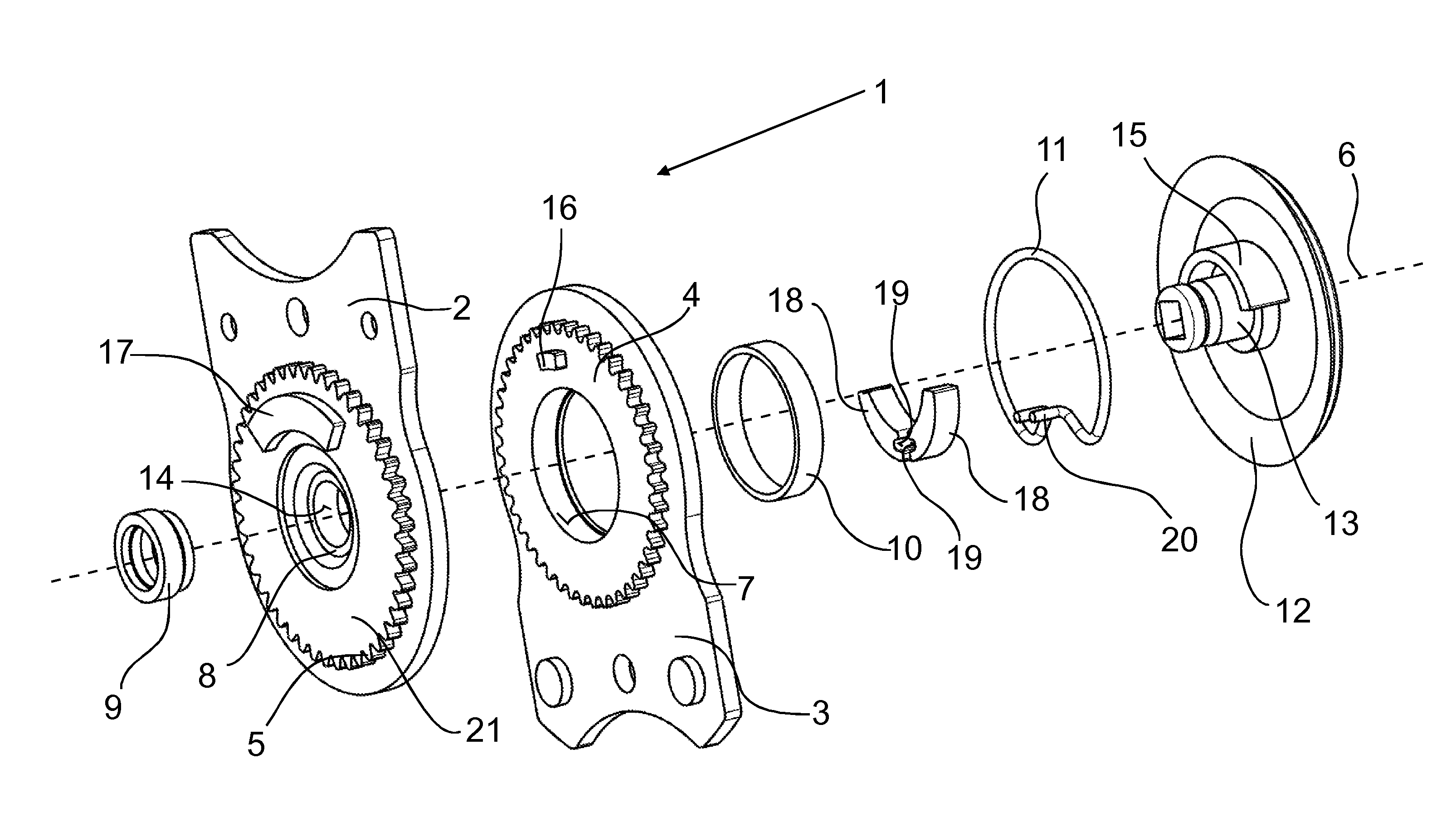

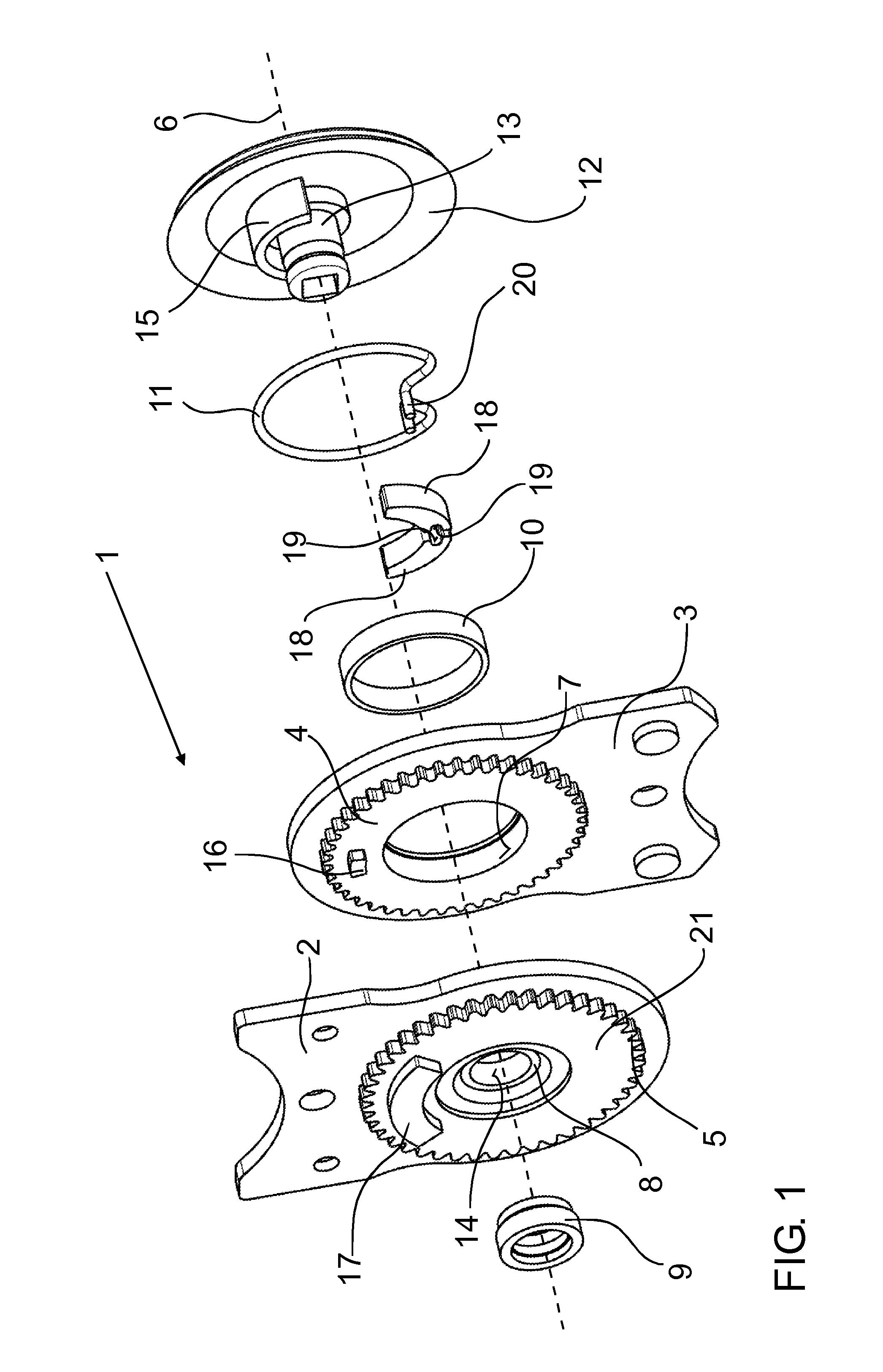

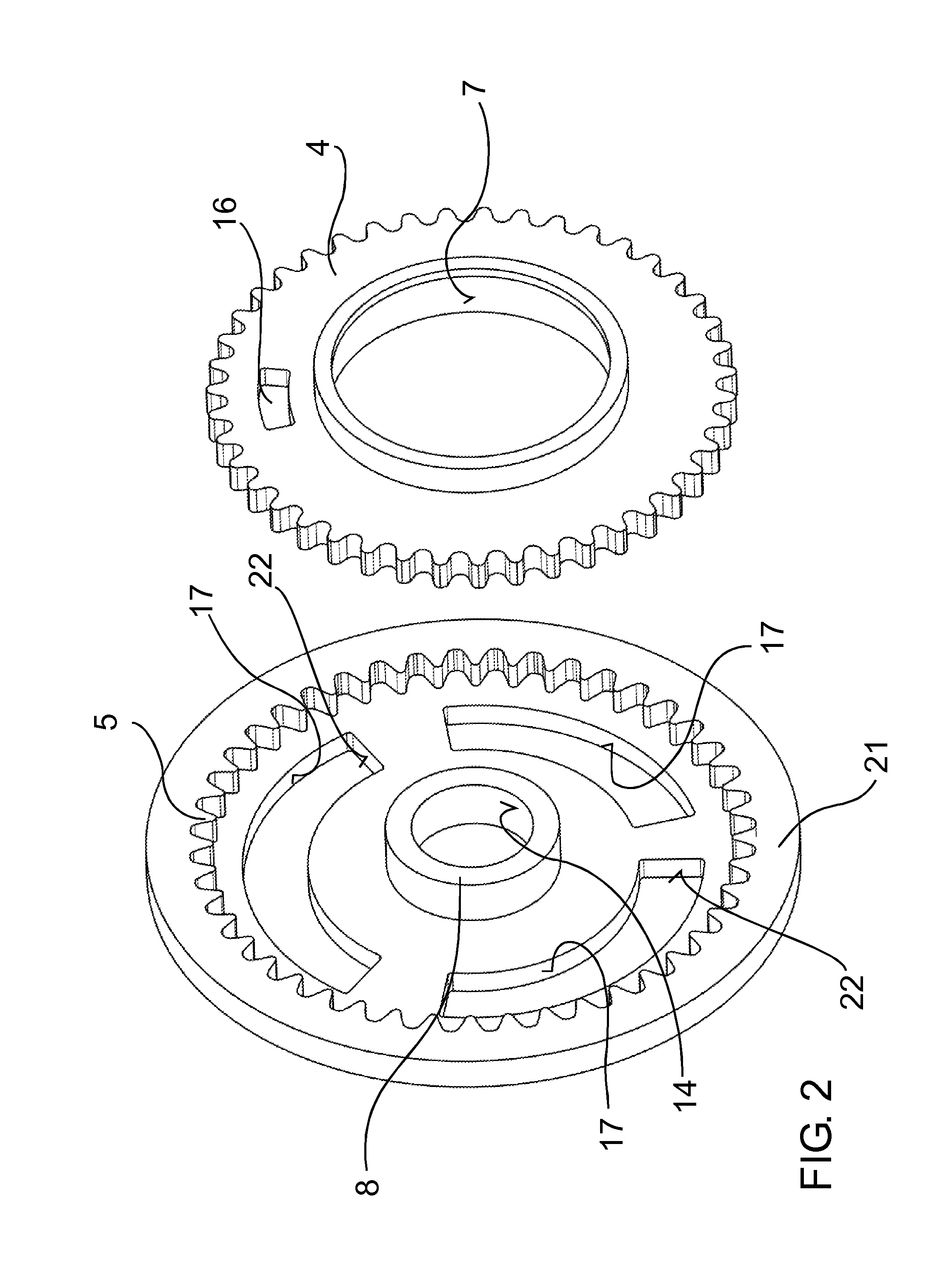

Seat fitting for a motor vehicle seat

ActiveUS20140162827A1Preventing seizingCost effective productionVehicle seatsToothed gearingsMotor vehicle partDrive shaft

A motor vehicle seat fitting includes a fitting top part with a ring gear (21) having internal toothing, a fitting bottom part with a gear wheel (4), having external toothing and which is in engagement with the ring gear, an eccentric arranged rotatably in a bore (7) of the bottom part running axially to the gear wheel, for rolling adjustment of the gear wheel relative to the hollow gear, and a drive shaft, which drives the eccentric and extends axially to the ring gear. A cam receptacle (17) is arranged on one of the gear wheel or the ring gear (21) and a stop cam (16), that engages in the cam receptacle, is arranged on the other of the gear wheel or ring gear, in a ring portion between the external toothing and the bore and on the ring gear in a zone which may overlap the ring portion.

Owner:ADIENT US LLC

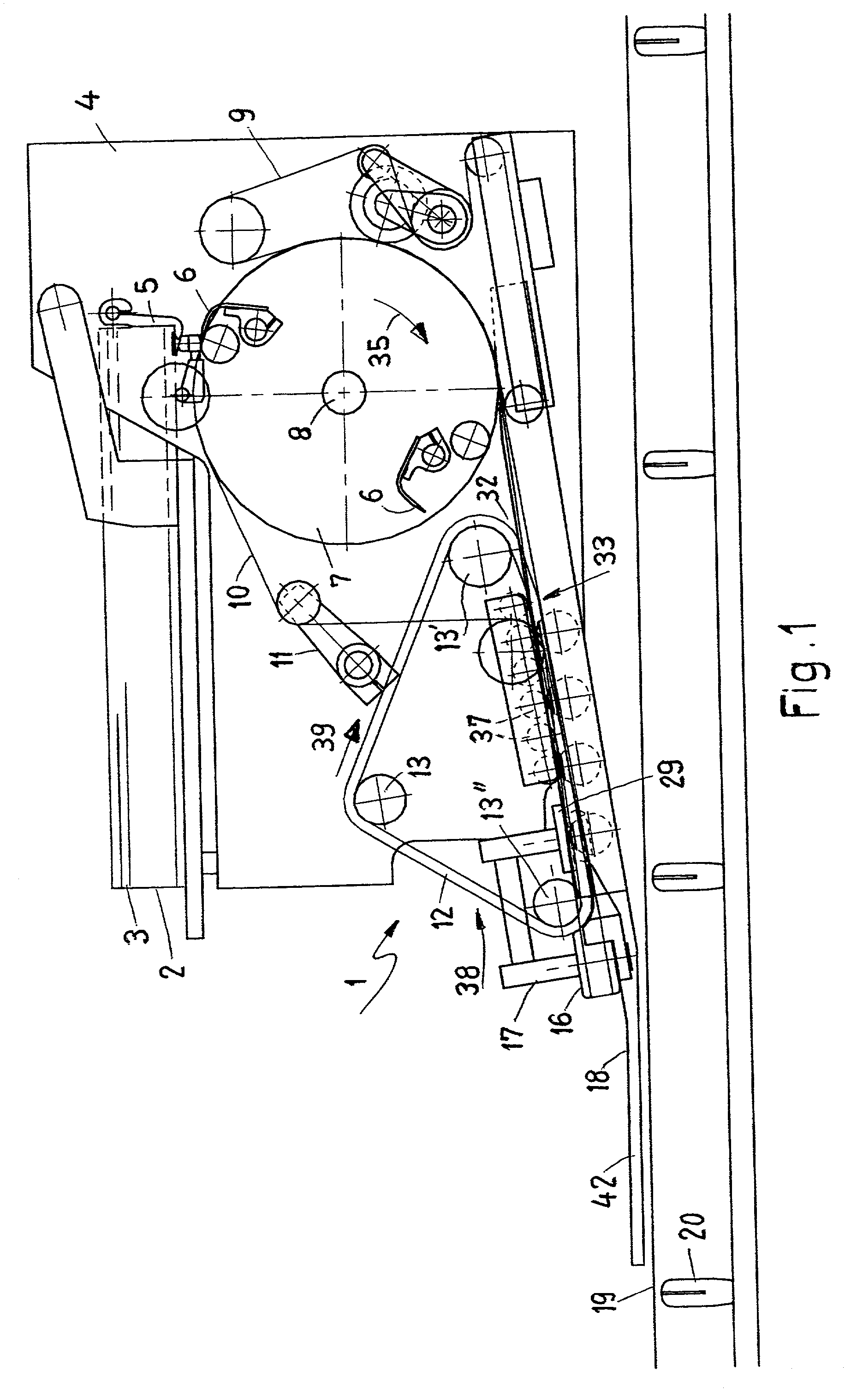

Signature folding device

InactiveUS7097608B2Stable guidanceEffectively prevented sliding offMechanical working/deformationFolding thin materialsEngineeringSaddle shape

A folding device for signatures includes a saddle-shaped folding sword having an upright folding edge and an inside guide element below the upright folding edge on which the signatures are folded while passing through the folding device. An outside folding element follows and operates jointly with the inside guide element for folding the signatures.

Owner:GRAPHA HLDG AG

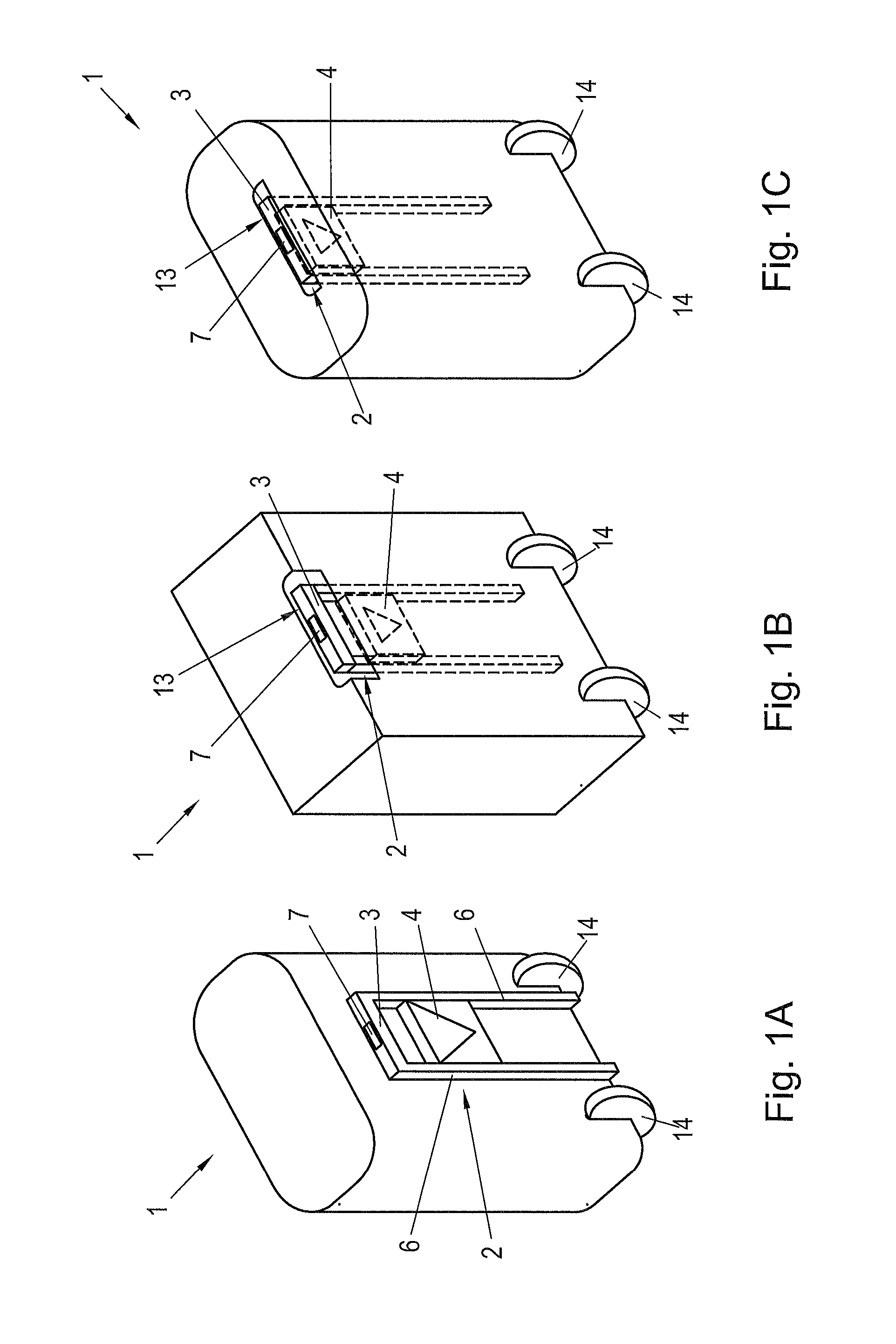

Handle construction for an item of luggage and item of luggage comprising such a handle construction

InactiveUS20150027834A1Avoid damageProduced easily and cost-effectivelyTravelling carriersPursesEngineeringBuilding construction

A handle construction for an item of luggage, in particular a suitcase, and an item of luggage, in particular a suitcase, including such a handle construction, has a hand grip and at least one rod or the like connected to the hand grip, the rod being able to be transferred between a stowed position and a position of use. A pouch with an opening is connected to at least one rod or the like or the hand grip. To permit rapid and simple storage and removal of objects, the pouch is integrated in the handle construction and together with the hand grip is able to be transferred between the stowed position and the position of use.

Owner:VOY GEAR

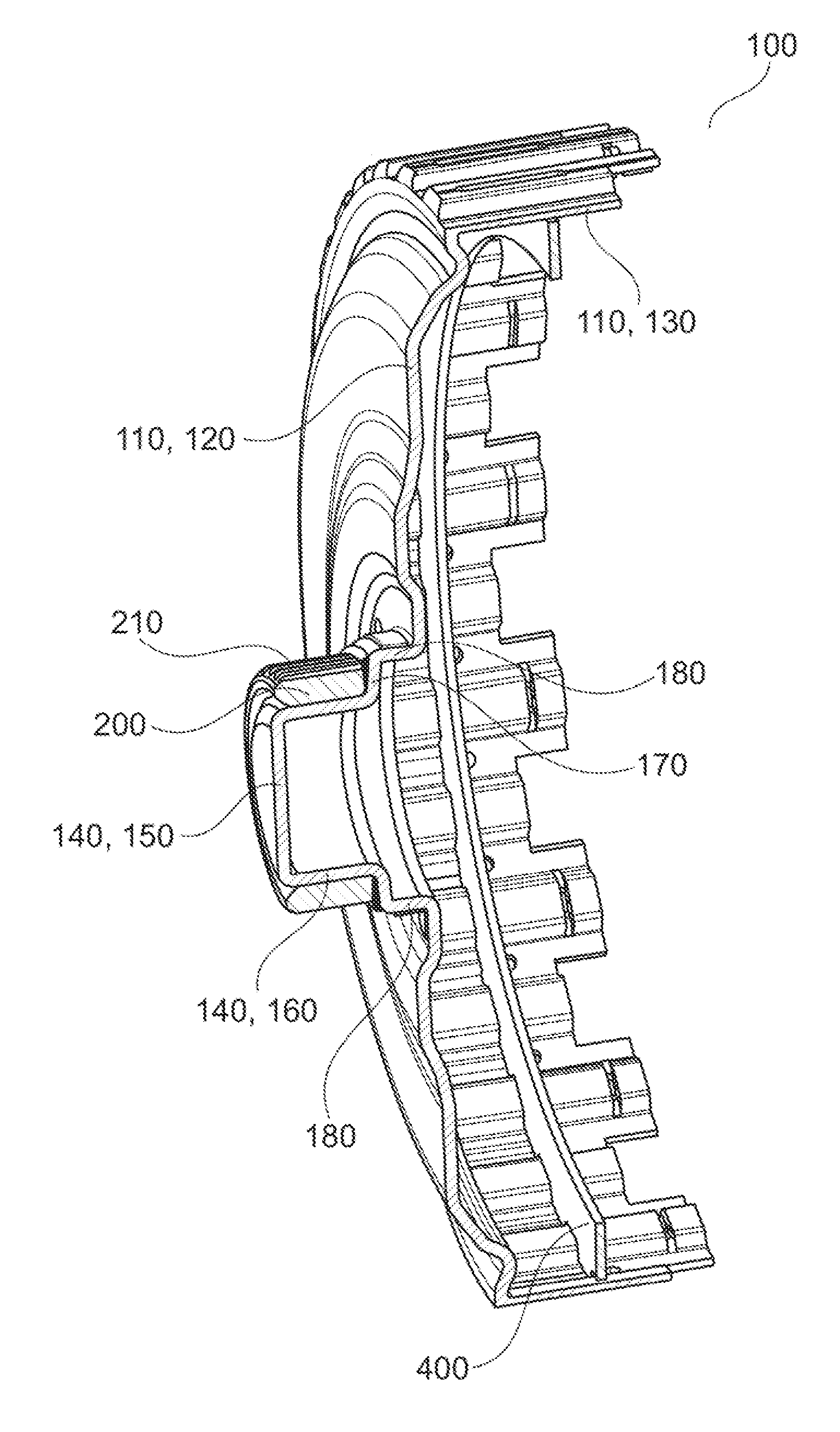

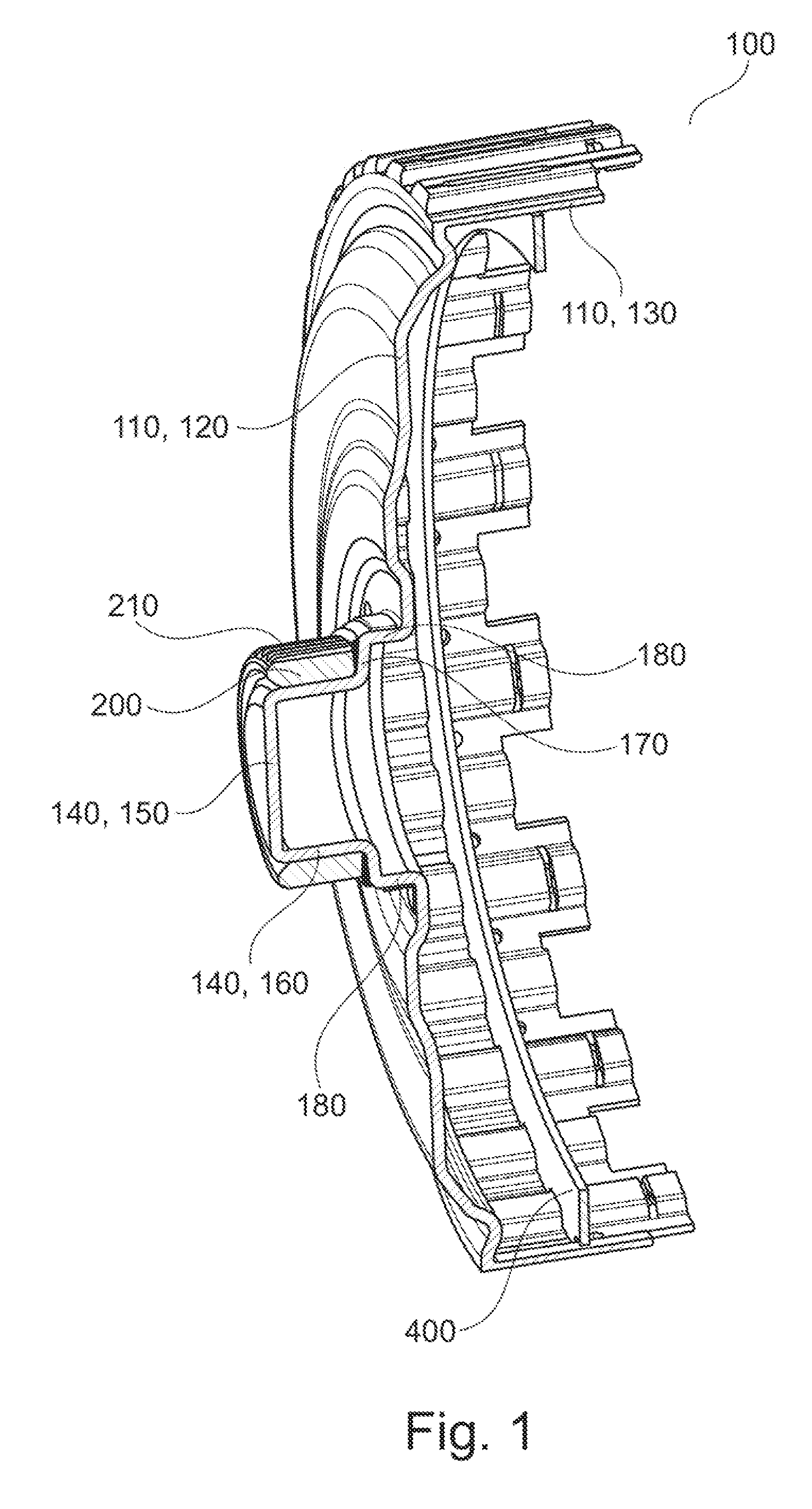

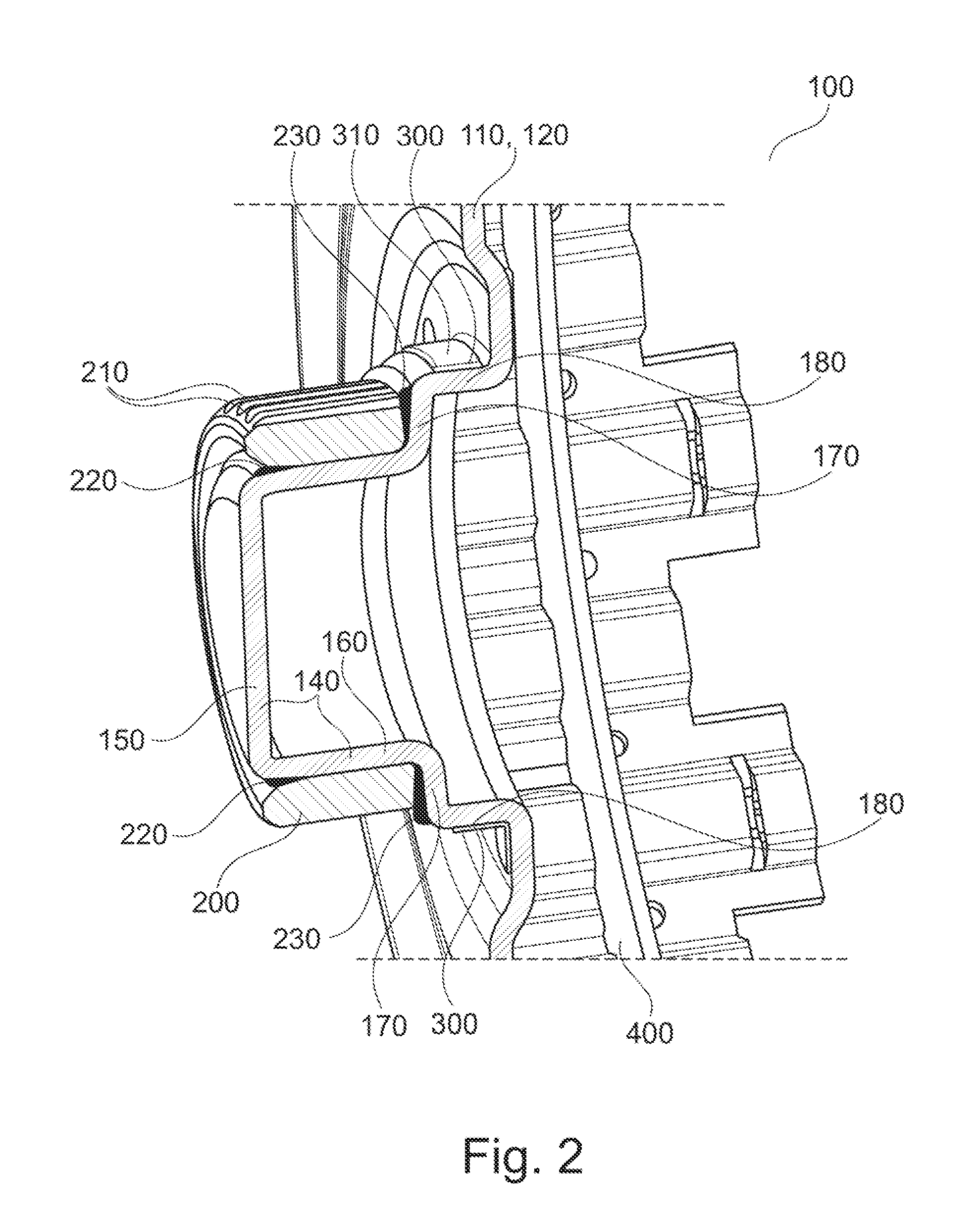

Outer plate carrier

ActiveUS20120267211A1Simple and cost-effectiveAvoid changeFriction clutchesGearing detailsEngineeringMechanical engineering

An outer plate carrier, including a cup-shaped embodied carrier plate (110) comprising a cylinder-shell shaped cylindrical section (130) and a circular-disk shaped bottom section (120). The bottom section (120) of the carrier plate (110) carries a cup-shaped hub section (140), arranged centrally. The cup-shaped hub section includes a cylindrical-shell shaped hub jacket (160) and a circular-disk shaped hub bottom (150). The hub bottom (150) has a smaller diameter than the bottom section (120) of the carrier plate (110). The hub bottom (150) is continuous and embodied in one piece with the carrier plate (110).

Owner:SCHAEFFLER TECH AG & CO KG

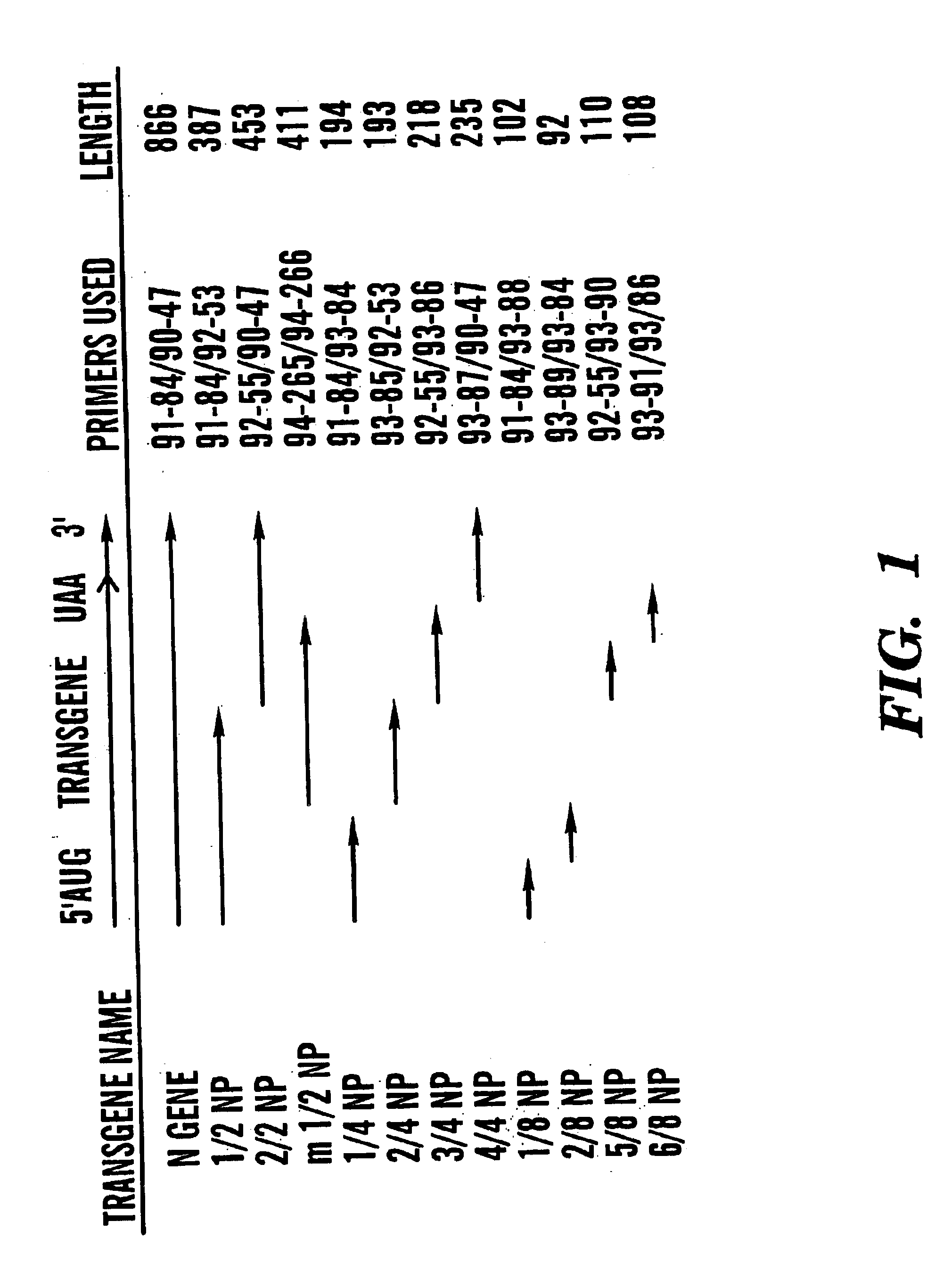

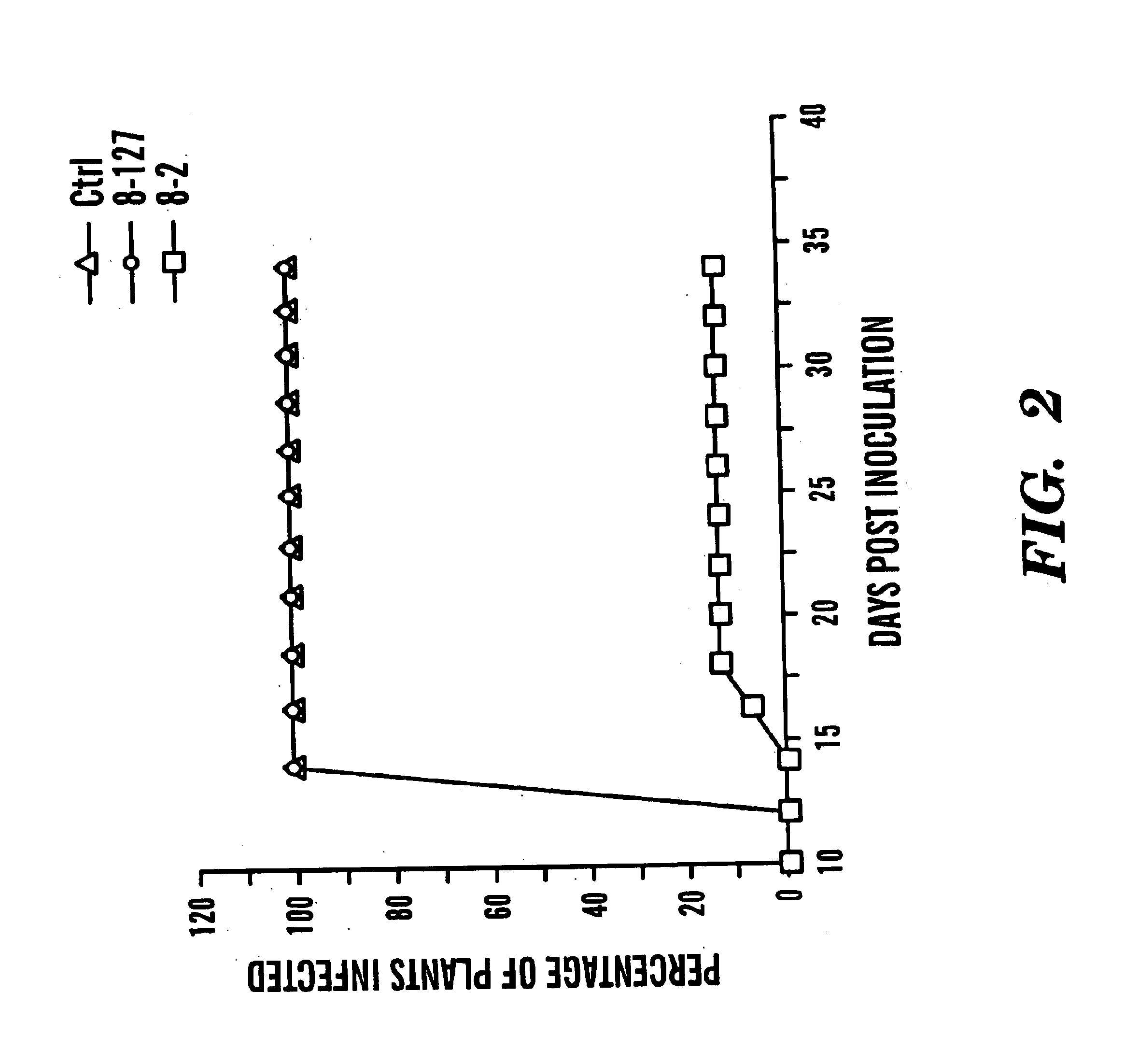

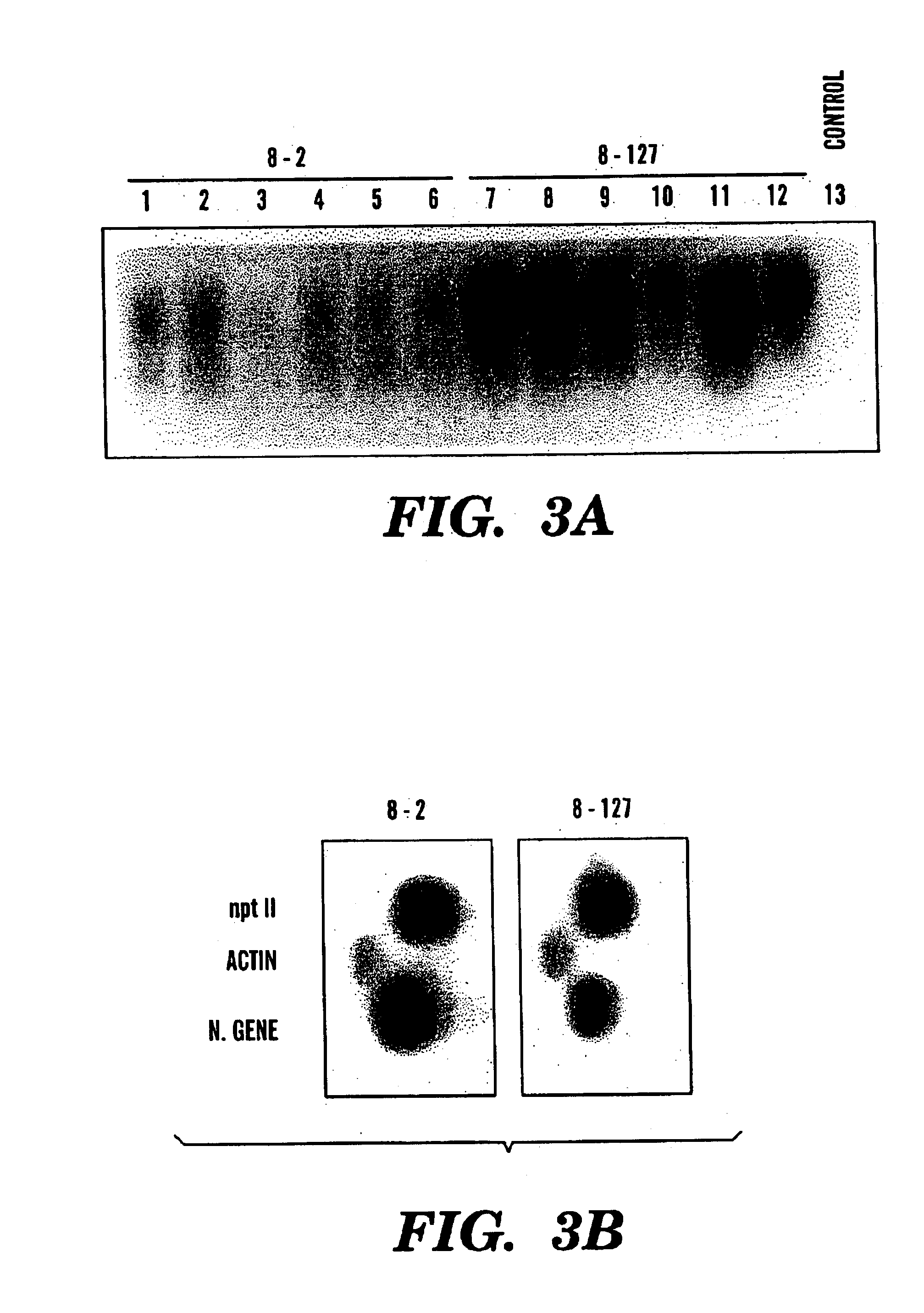

DNA constructs and methods to impart resistance to at least one virus on plants

InactiveUS6903248B2Impart resistanceProduced easily and cost-effectivelyBiocideSugar derivativesDNA constructViral gene

The present invention is directed to a DNA construct comprising a first DNA molecule having a length insufficient to independently impart resistance to a virus to plants transformed with said first DNA molecule, wherein the first DNA molecule is from a viral coat protein gene and is at least 110 nucleotides in length. The construct also comprises a second DNA of at least 400 nucleotides in length, which is coupled to the first DNA molecule so that the first and second DNA molecules collectively achieve post-transcriptional silencing and impart resistance to the virus. Alternately, the DNA construct can comprise a plurality of DNA molecules each of which is at least 110 nucleotides in length and from a viral gene, wherein the plurality of DNA molecules are at least 510 nucleotides in length.

Owner:CORNELL RES FOUNDATION INC

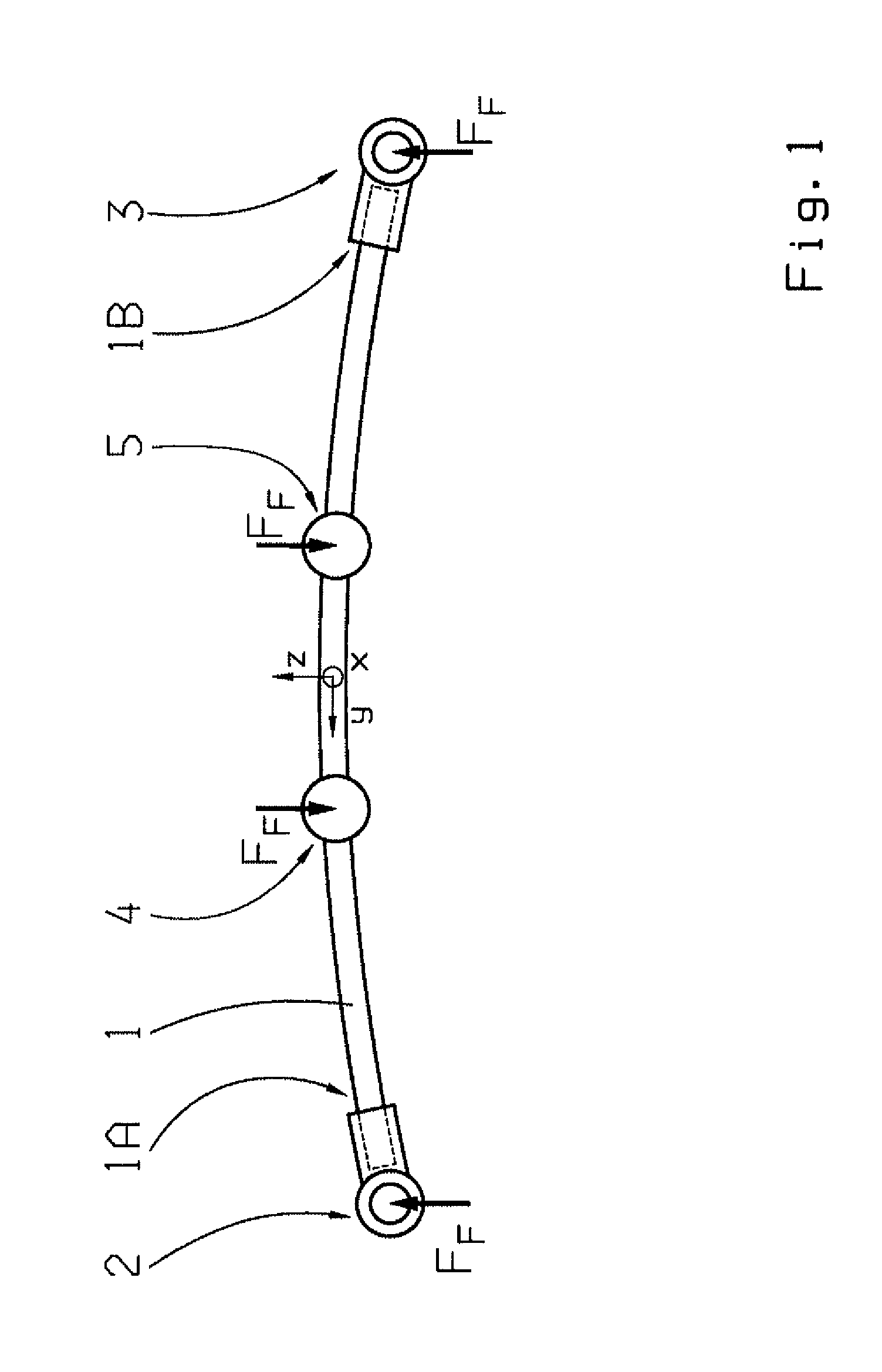

Bearing mechanism for a transverse leaf spring, mountable in the area of a vehicle axle

InactiveUS8444162B2Low construction space requirementProduced easily and cost-effectivelySpringsResilient suspensionsPhysicsLeaf spring

A bearing mechanism for a transverse leaf spring that can be mounted near an axle of a vehicle. The bearing mechanism has an outer bearing shell device and insertion devices which have at least some regions encompassed by the outer bearing shell device. Each of the insertion devices comprise at least two layer elements which have different stiffness. In the assembled state, the insertion devices are each disposed between the outer bearing shell device and the transverse leaf spring. The outer bearing shell device comprises a one-piece bearing ring element, and the insertion devices can be operatively connected, at least in a force locking manner, to the bearing ring element and the transverse leaf spring, via tensioning elements.

Owner:ZF FRIEDRICHSHAFEN AG

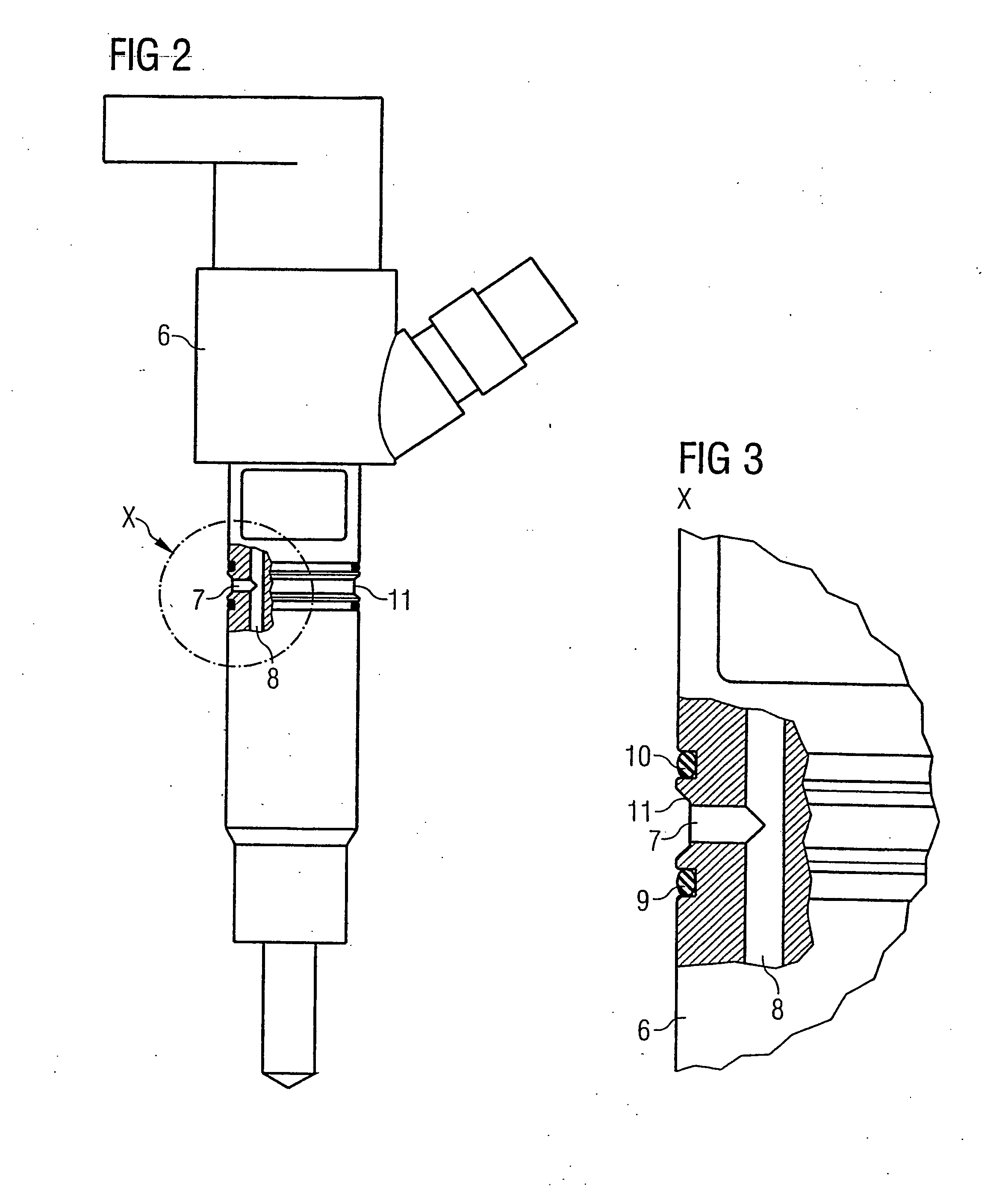

Leakage connection for a fuel injector

InactiveUS20050045154A1Easy to installFacilitates secure sealCylinder headsCylindersCombustion chamberInternal combustion engine

The invention relates to a leakage connection for an injector, which inject fuel into a combustion chamber of an internal combustion engine. The leakage connection is configured as one piece with an injector component. In addition, a leakage nipple is integrated into the leakage connection, for attaching a leakage return line.

Owner:SIEMENS AG

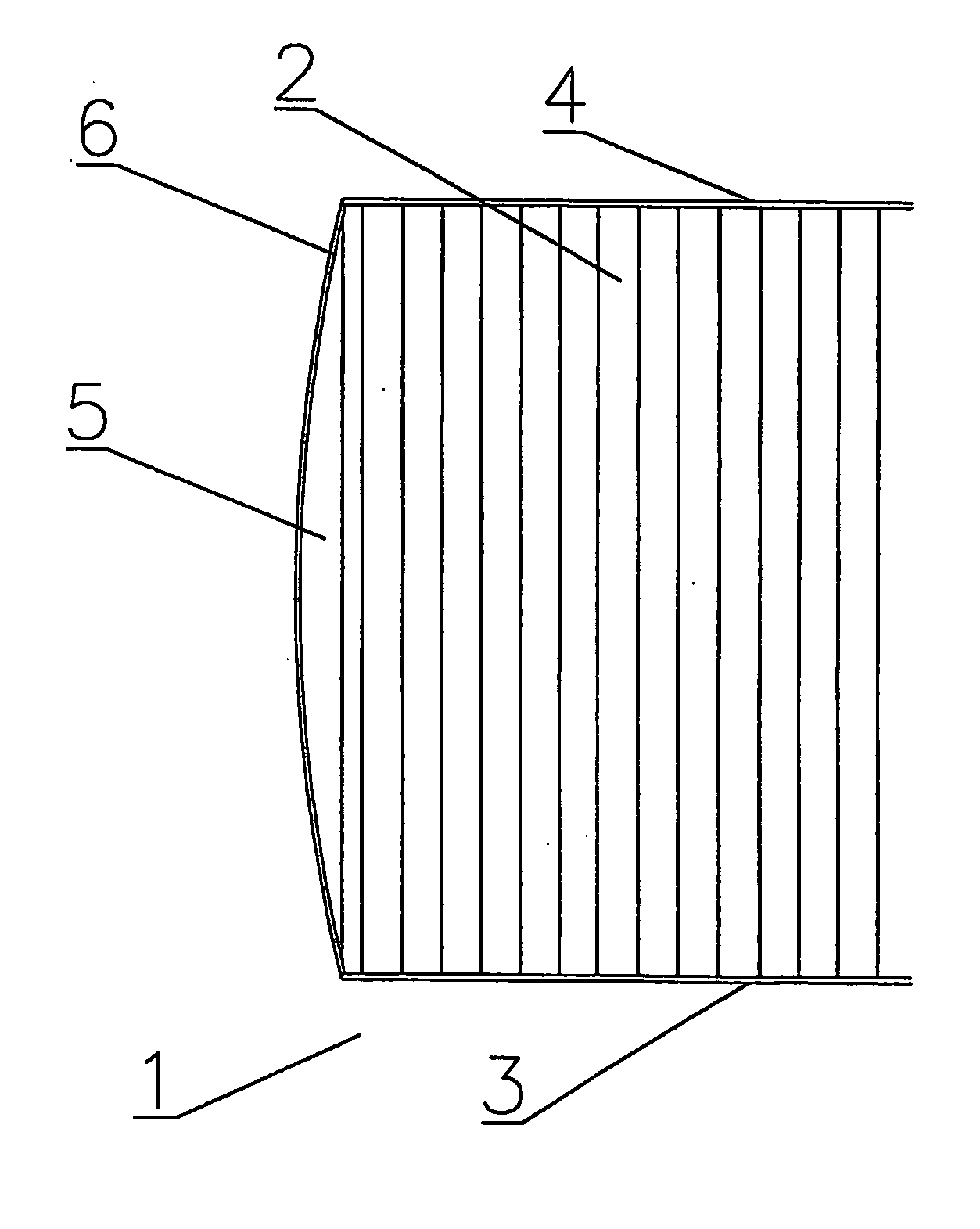

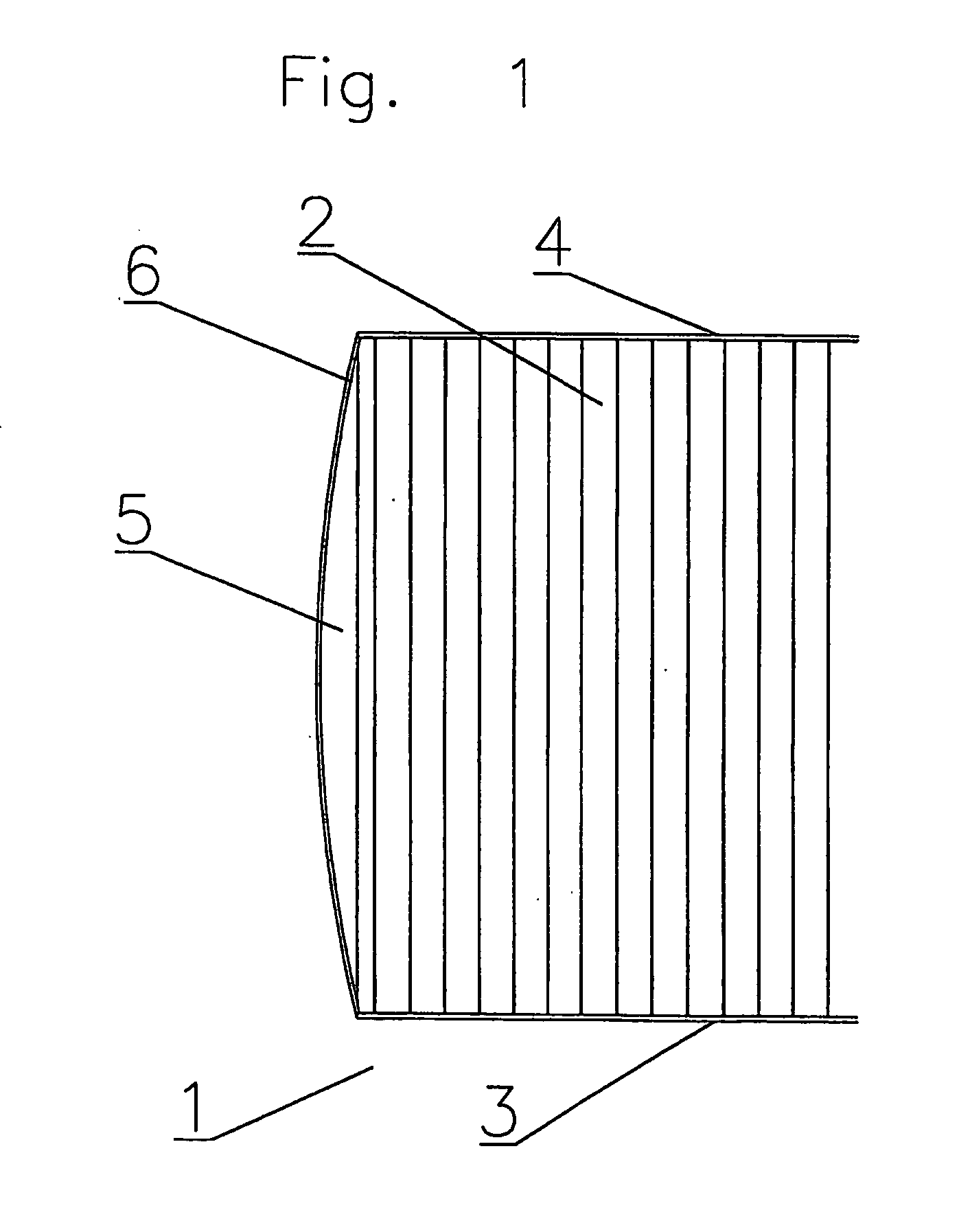

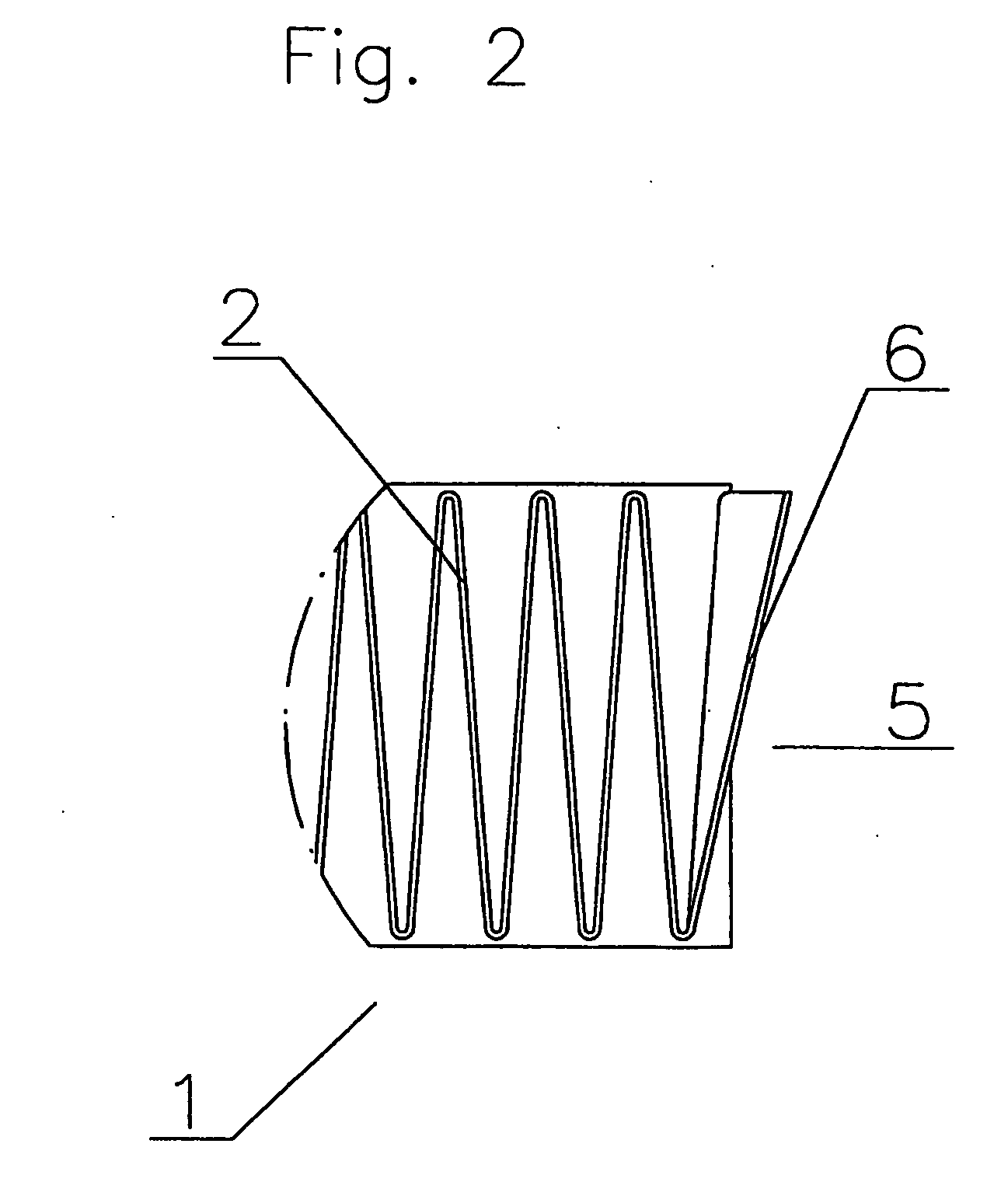

Filter element

ActiveUS20060000197A1Improve sealingGood effectDispersed particle filtrationIsotope separationEngineeringMechanical engineering

A filter element includes a filter web pleated in an essentially zigzag manner and made, in particular, of a nonwoven material, for insertion into a holder such as a filter frame and / or a filter housing, having at least one end-positioned wall of an essentially flat design. The filter element includes at least one end face, viewed in the direction of the pleats. To achieve a tighter seal, the end face of the filter element is curved outward in a defined convex manner, and the filter web material is selected and / or its end face conditioned so that, when inserted into the holder, the end face of the filter web may be placed leak-tight against the end wall of the holder without corrugation under elastic pre-tension.

Owner:CARL FREUDENBERG KG

Method And Device For Material Analysis

ActiveUS20150369765A1Produce easily and cost-effectivelyAvoid High Precision RequirementsMaterial heat developmentMetal working apparatusHeat flowEngineering

Method and thermal analysis device including a sample holder and at least one temperature detector which is assigned to the holder. The invention further relates to a production method for a temperature detector. A heat flow to be detected is conveyed to the temperature detector between a support surface and the sample holder, wherein the support surface and / or the sample holder include elevations or depressions forming contact points, which define a relevant heat flow zone assigned to the support surface. A thermocouple, which includes at least two elements made of different metals, a first metallic element A, with a higher expansion coefficient compared to a second metallic element B, is introduced in a precisely fitting manner into second metallic element B constituted as a hollow profile and the two elements A, B are heated in a first operational step and then cooled again in a second operational step.

Owner:NETZSCH GERATEBAU GMBH

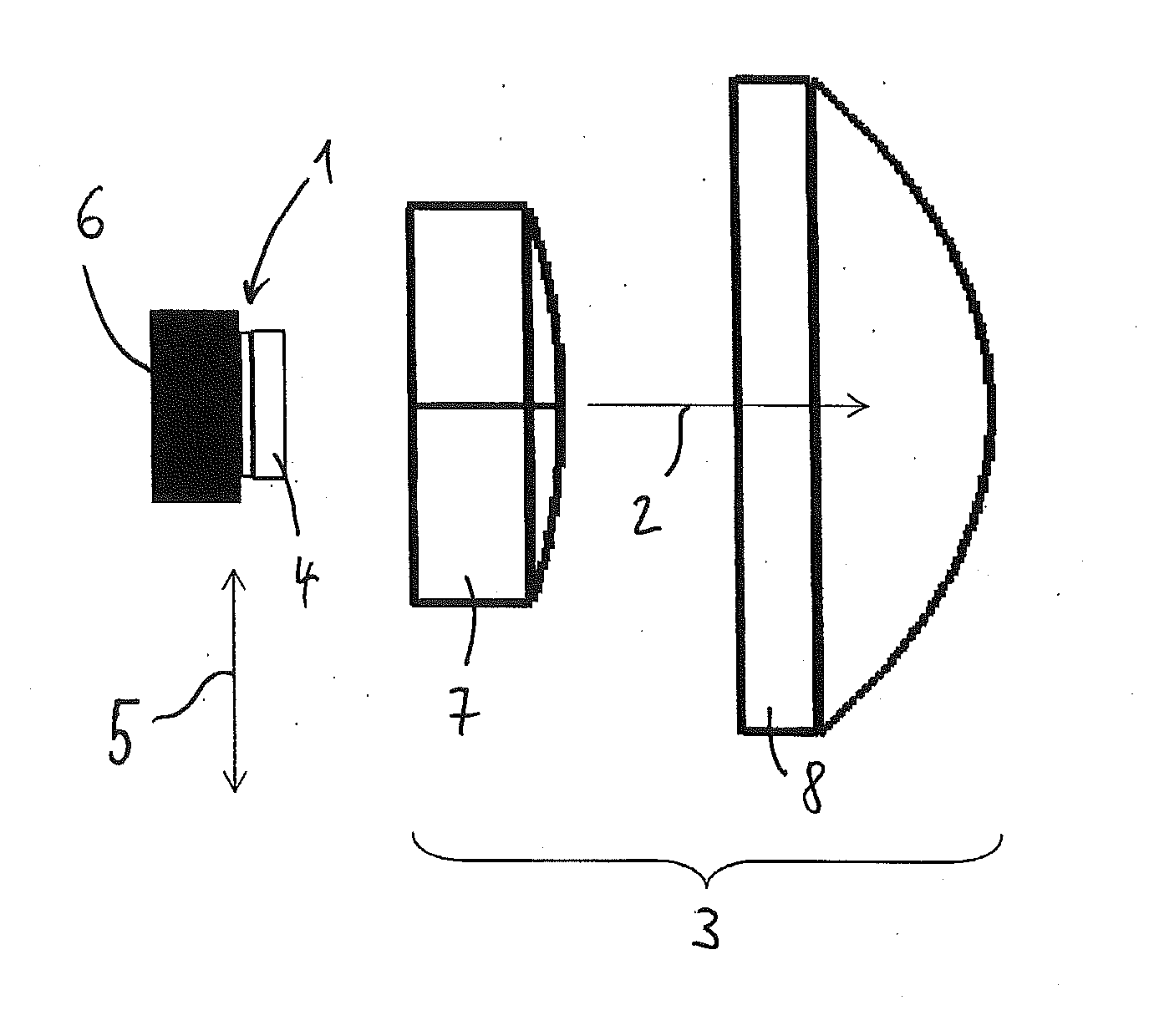

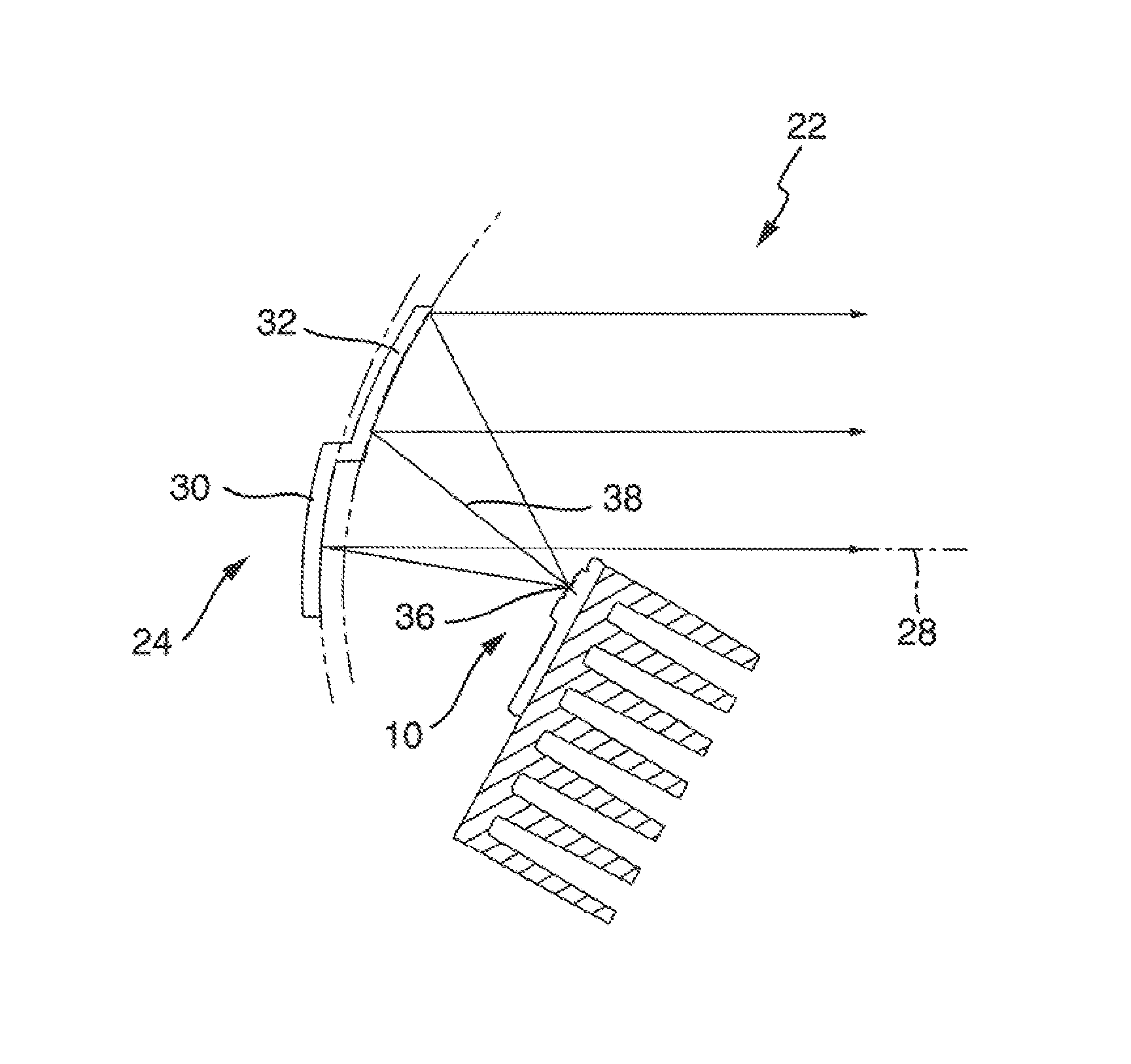

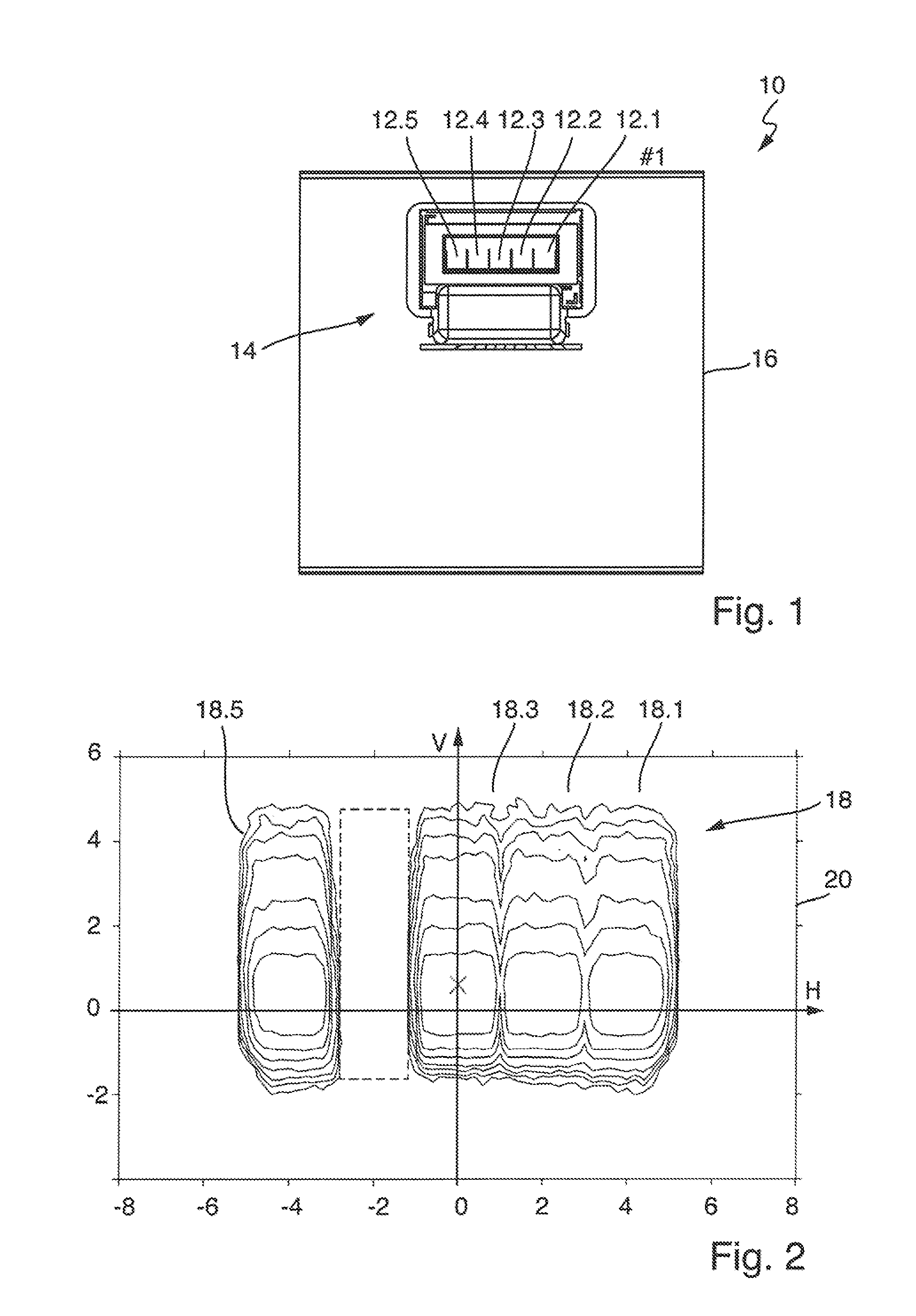

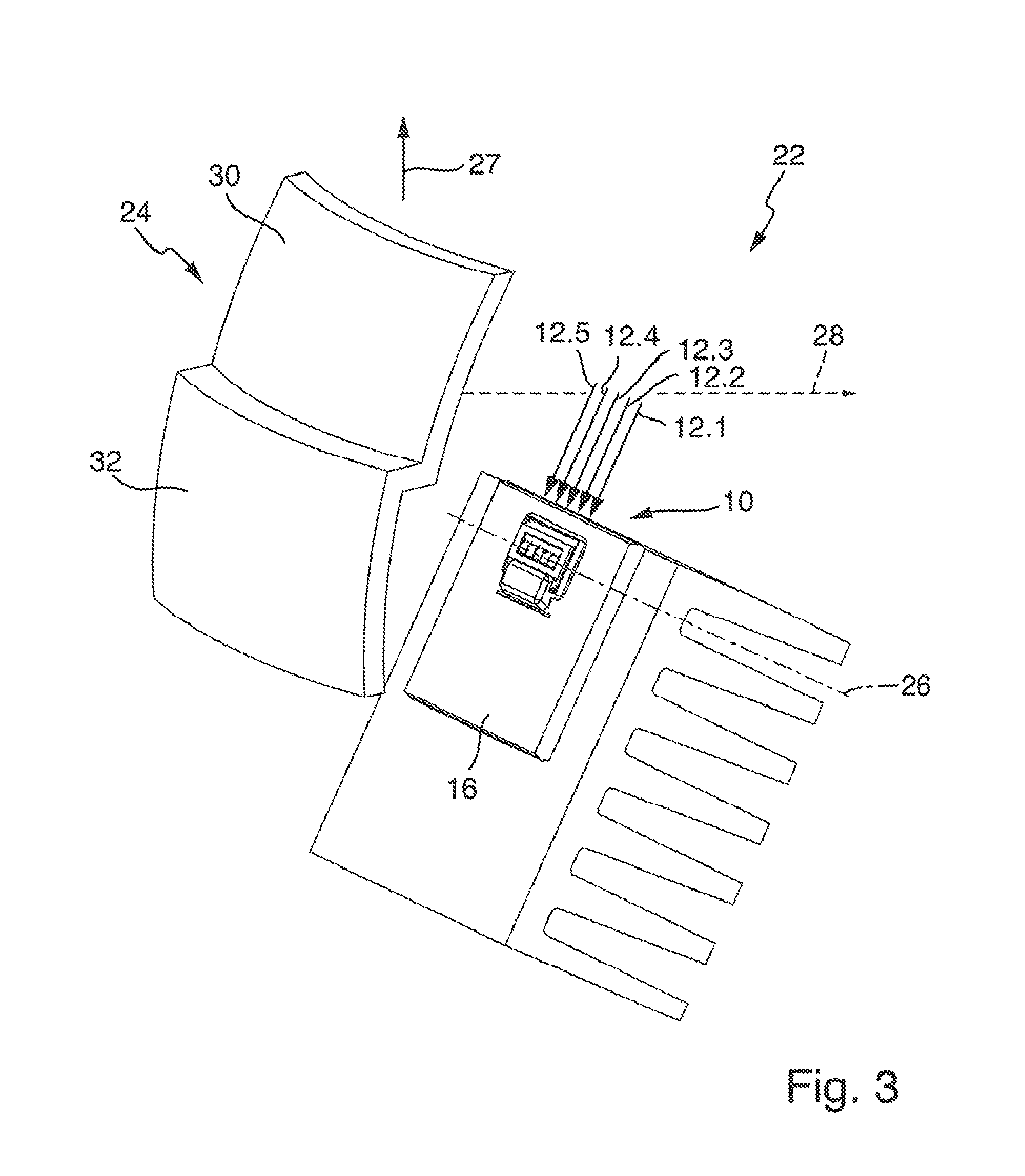

Lamp module for a glare-free motor vehicle high beam

InactiveUS8801248B2Reduce riskProduced easily and cost-effectivelyVehicle headlampsLighting support devicesMobile vehicleIntermediate image

A lamp module for a motor-vehicle headlamp. The lamp module comprises a light source defining at least one light-emitting surface that emits a luminous flux and defines a horizontally oriented longitudinal edge and at least one other edge running at a right angle thereto. A reflector maps the light-emitting surface without generating an actual intermediate image in front of the lamp module and defines at least two reflecting and strip-shaped facets longitudinal axes of which are more parallel rather than transversal to the longitudinal edge of the light-emitting surface and disposed at a spacing to the light source where the light-emitting surface is mapped with the same mapping scale in front of the lamp module such that the light-emitting surface is mapped with a longitudinal edge running horizontally and another edge running vertically.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com