Stamping assembly of bottle moulding

A bottle and assembly technology, applied in the field of rough bottle processing accessories, can solve problems such as mouth swelling, unreasonable structural design, unfavorable bottle mouth forming, etc., and achieve the effects of rapid heat dissipation, improved molding, and improved processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

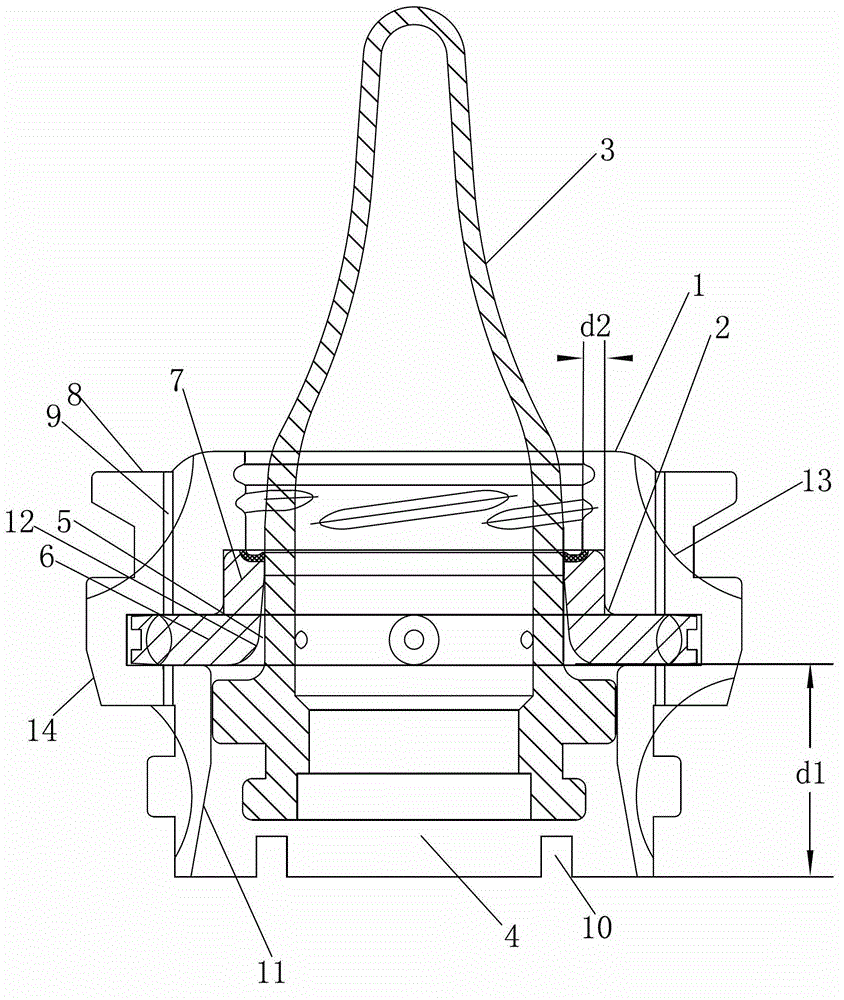

[0016] Embodiment: a kind of bottle forming stamping assembly, such as figure 1 As shown, it includes the die 1, the mouth ring 2 and the punch 3, and the first through hole 4 and the second through hole 5 for the punch to move in and out are respectively provided in the die 1 and the mouth ring 2, and the mouth ring 2 is set In the die 1, the mouth ring 2 is composed of a collar 6 and a supporting ring 7. The supporting ring 7 is located at the upper end of the collar 6. The diameter of the supporting ring 7 is smaller than that of the collar 6. The collar 6 clamps the die. 1, so that the mouth ring 2 is fixed in the mouth die 1.

[0017] The punch 3 is sleeved in the first through hole 4 and the second through hole 5, and the head of the punch 3 is exposed outside the die 1, and the die 1 is surrounded by a positioning ring 8 for connecting the clamp. The ring 8 is provided with a plurality of heat dissipation grooves 9 along the circumferential direction, and the heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com