Four-drip multifunctional bottle making machine and small-opening press-and-blow production process implemented by same

A bottle-making machine and multi-functional technology, which is applied in the field of bottle-making machines, can solve the problems of small center distance of four drops, limited popularization and application, and non-universal molds, etc., and achieves small mold wear, stable molding action, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

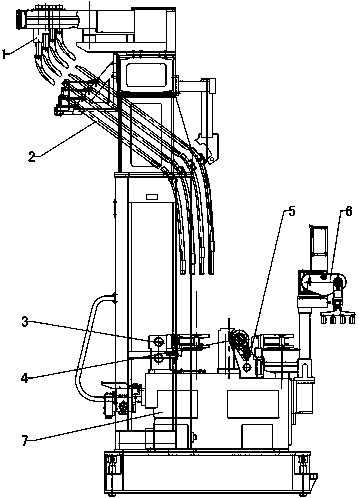

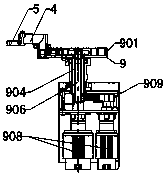

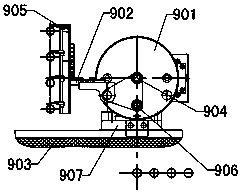

[0049] Figure 1~11 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~11 The present invention will be further described.

[0050] Refer to attached Figure 1~11 : a four-drop material multifunctional bottle making machine, comprising a main frame 7, a servo distributing mechanism 1 installed on the main frame 7, a preliminary mold forming mechanism 3 and a forming mold forming mechanism 5, a preliminary mold forming mechanism 3 and The forming mechanism 5 of the forming mold adopts a parallel switch structure, and a servo turning mechanism is provided between the preliminary mold forming mechanism 3 and the forming mechanism 5 of the forming mold; The module 105 is provided with a detachable distributor, which is provided with at least two groups of discharge openings, and a four-cavity independent small-mouth quick-change pressure-blowing mechanism 15 is provided under the preliminary mold forming mechanism 3; the forming mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com