Method for preparing 6-inch P-type solar silicon single crystals through Czochralski method and zone melting method

A technology of Czochralski zone melting and silicon single crystal, which is applied in the fields of self-zone melting method, single crystal growth, chemical instruments and methods, etc., can solve the problem of not being able to produce low-cost P-type solar silicon single crystals and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the present invention more clearly, the present invention is described in detail in conjunction with the accompanying drawings and embodiments:.

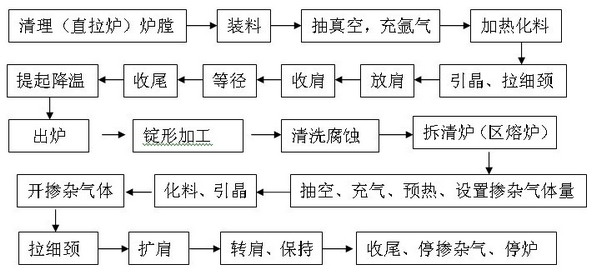

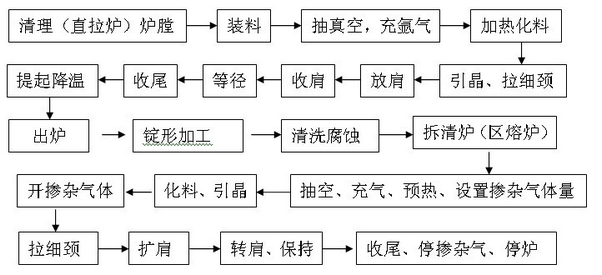

[0025] Such as figure 1 The process flow chart shown is a method for preparing a 6-inch P-type solar silicon single crystal by the Czochralski zone melting method, including cleaning the Czochralski furnace, charging, vacuuming, filling with argon, heating the chemical material, and introducing crystallization, thin neck, shoulder release, shoulder closing, equal diameter, finishing, lifting and cooling, and out of the furnace; then ingot shape processing, cleaning and corrosion, after meeting the material standards for zone melting, continue to draw gas-mixed sheets by zone melting Crystal, including dismantling the furnace, evacuating, inflating, preheating, setting the amount of doping gas, chemical material, seeding, starting doping gas, drawing thin neck, expanding shoulder, turning shoulder, maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com