Preparation method of nano TiO2 self-cleaning transparent coating

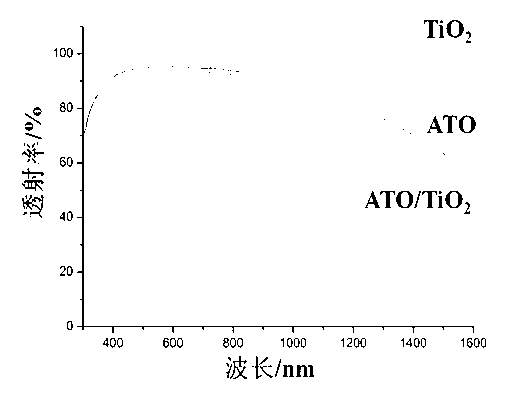

A technology of nano-titanium dioxide and transparent coating, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult control of film particle size, high equipment requirements, and inability to form large-scale uniform films, achieving good market prospects and The effect of application value, low cost, and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

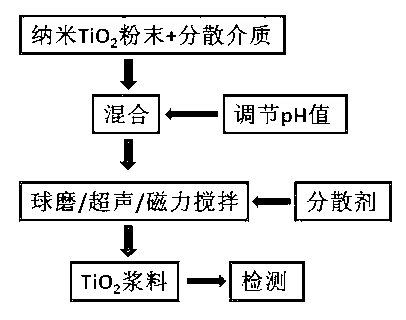

Method used

Image

Examples

Embodiment 1

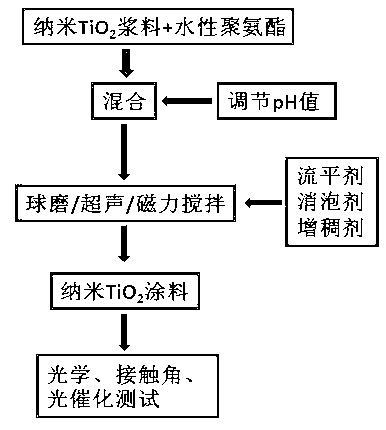

[0018] Embodiment 1, nano-TiO 2 Add the powder into the dispersant absolute ethanol, adjust the pH value at 7-8 to be alkaline, fully disperse and mix, put the mixture in a ball mill for 24 hours, and add a stabilizer at the same time to obtain dispersed nano-TiO 2 Slurry system, wherein the milling balls are agate beads with a diameter of 2-2.8 cm, and the rotation speed is 250 r / min. The prepared nano-TiO 2 The volume ratio of slurry and water-based polyurethane is V 纳米TiO2浆料 :V 水性聚氨酯 = 1:6 mixing, control the pH value to 7~8, and then carry out ball mill dispersion. During the dispersion process, add defoamer, leveling agent, and thickener to water-based polyurethane according to 0.1wt%, 4wt%, and 0.2wt% respectively. In the preparation of nano-TiO 2 coating. Ordinary glass slides soaked in NaOH solution were ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 15 minutes, and the pulling method was used to pull a film on a clean glass substrat...

Embodiment 2

[0019] Embodiment 2, nano-TiO 2 Add the powder into the dispersant n-butanol, adjust the pH value at 7-8 to be alkaline, fully disperse and mix, put the mixture into an ultrasonic generator for ultrasonic dispersion for 50 min, and add a stabilizer at the same time to obtain dispersed nano-TiO 2 Slurry system, wherein the ultrasonic generator frequency is 20000Hz. The prepared nano-TiO 2 The volume ratio of slurry and water-based polyurethane is V 纳米TiO2浆料 :V 水性聚氨酯 = 1:10 mixing, control the pH value to 7~8, and then carry out ball mill dispersion. During the dispersion process, add defoamer, leveling agent, and thickener to water-based polyurethane in sequence at 0.1wt%, 4wt%, and 0.2wt%. In the preparation of nano-TiO 2 coating. Ordinary glass slides soaked in NaOH solution were ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 15 minutes, and the pulling method was used to pull a film on a clean glass substrate. The number of pulls can be ch...

Embodiment 3

[0020] Embodiment 3, nano-TiO 2 Add the powder into the dispersant n-butanol, adjust the pH value at 7-8 to be alkaline, fully disperse and mix, put the mixture in a ball mill for 48 hours, and add a stabilizer at the same time to obtain dispersed nano-TiO 2 Slurry system, wherein the milling balls are agate beads with a diameter of 2-2.8 cm, and the rotation speed is 250 r / min. The prepared nano-TiO 2 The ratio of slurry and water-based polyurethane is V 纳米TiO2浆料 :V 水性聚氨酯 = 1:6 mixing, control the pH value to 7~8, and then carry out ball mill dispersion. During the dispersion process, add defoamer, leveling agent, and thickener to water-based polyurethane according to 0.1wt%, 4wt%, and 0.2wt% respectively. In the preparation of nano-TiO 2 coating. Ordinary glass slides soaked in NaOH solution were ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 15 min, and coated on a clean glass substrate by wire bar coating method, using an oven of 80 o C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com