Resonance type micromechanical accelerometer

An accelerometer and mechanical technology, applied in the direction of measuring acceleration, speed/acceleration/impact measurement, measuring devices, etc., can solve the problems of insufficient sensitivity and resolution, and achieve the effects of improving sensitivity, realizing differential output, and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

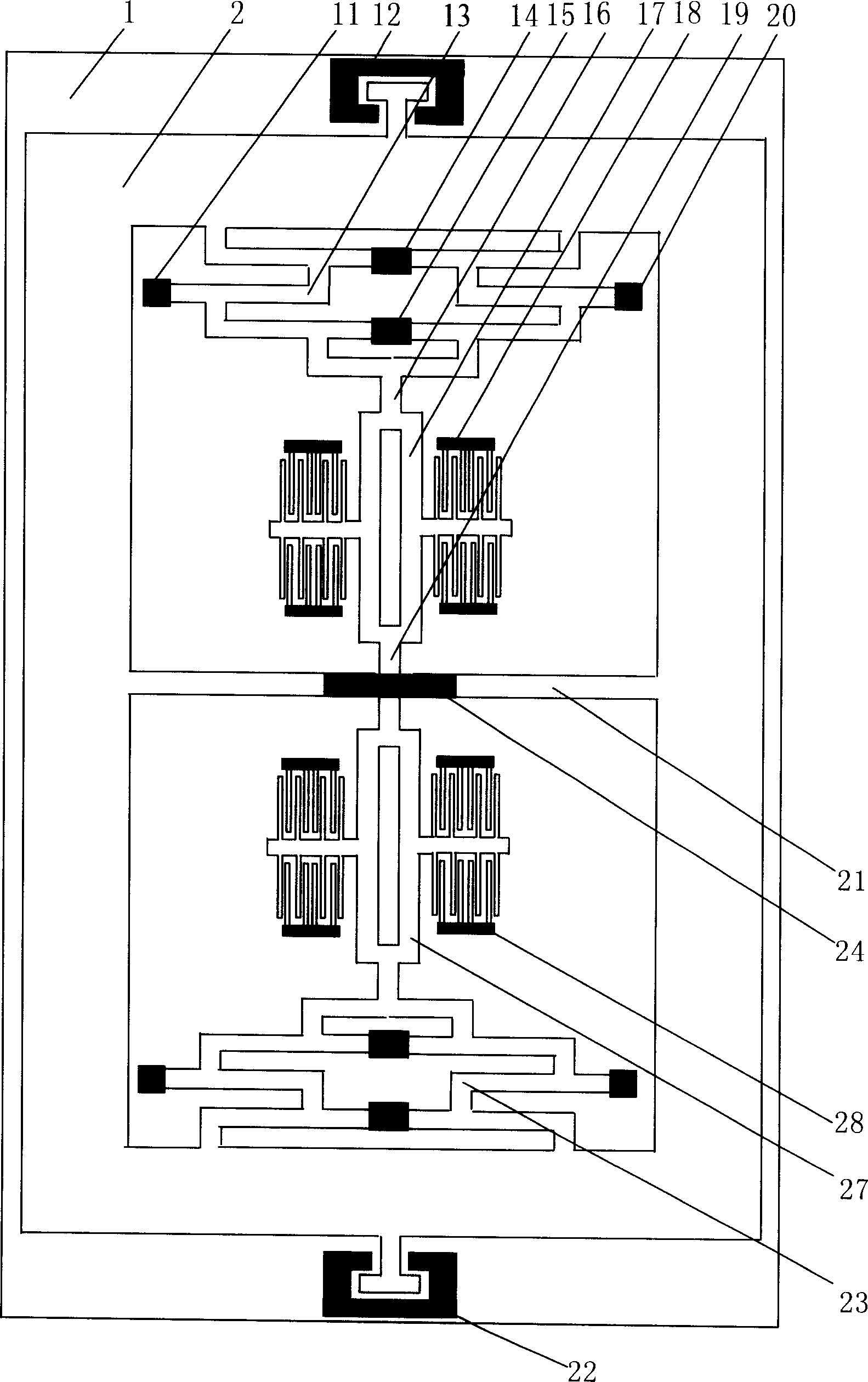

[0009] Such as figure 1 As shown, the present invention includes a substrate 1, a proof mass 2, a cantilever beam 21, two symmetrical lever amplification mechanisms 13, 23, two symmetrical tuning forks 17, 27, driving electrodes, detecting electrodes, tooth hubs 18, 28, The whole structure is an axisymmetric figure. The mass block 2 is in the shape of "back", and the middle of the mass block 2 is a cantilever beam 21, two lever amplification mechanisms 13, 23, two tuning forks 17, 27, tooth hubs 18, 28, driving electrodes, and detection electrodes. On the periphery of the mass block 2 are two stops 12,22. The "back"-shaped mass block 2 is designed to realize a larger mass block under the limited volume of the element, so that the acceleration can be efficiently converted into inertial force. The lever mechanism 13 is composed of three-stage enlarged rods. The anchor points 11, 14, 15, and 20 on the lever mechanism 13 are connected to the substrate through bonding. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com