Dot-matrix PET protective film and mesh roller thereof

A protective film, dot-matrix technology, applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problems of poor conductivity, low performance, easy peeling, etc., to achieve high performance and super exhaust High, stable peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

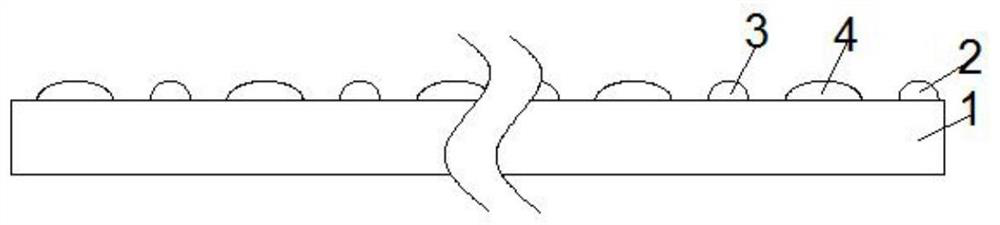

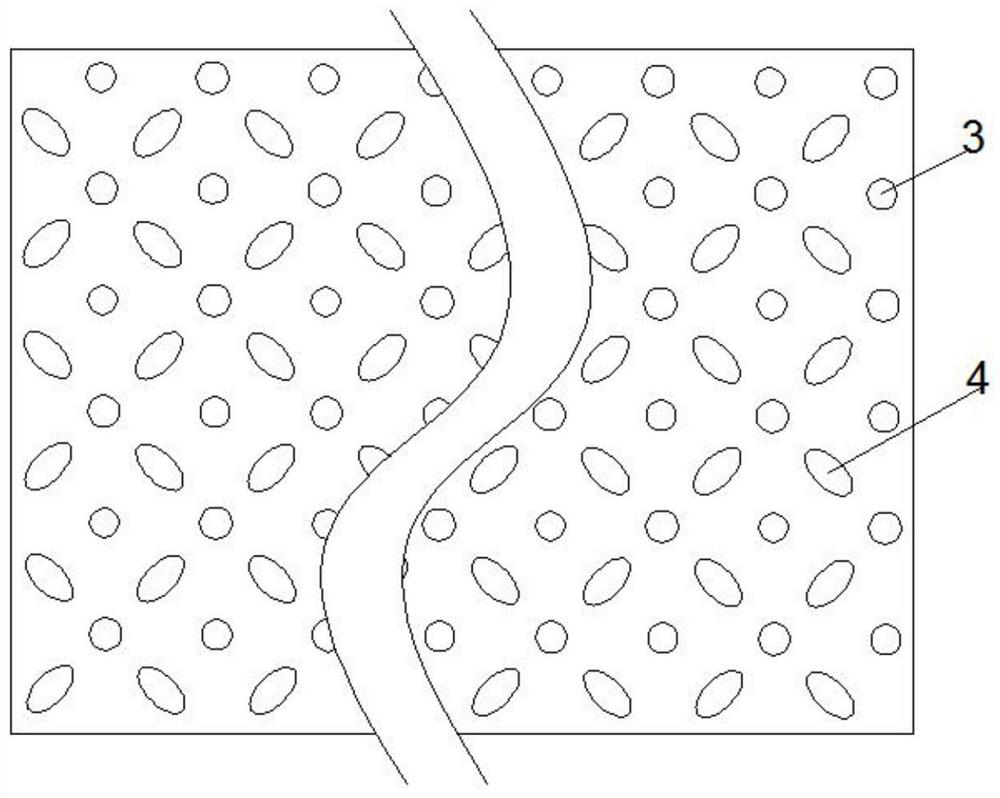

[0047] Such as figure 2 and 3 As shown, the dot-matrix PET protective film of this product is composed of hemispherical first bumps 3, semi-elliptical second bumps 4 and PET substrate, and has the characteristics of uniformly distributed dot arrays;

[0048] The PET base material is prepared by the net roll body 5 and the pressure roll 6 coated with silica gel to obtain the dot matrix PET protective film of this product.

Embodiment 2

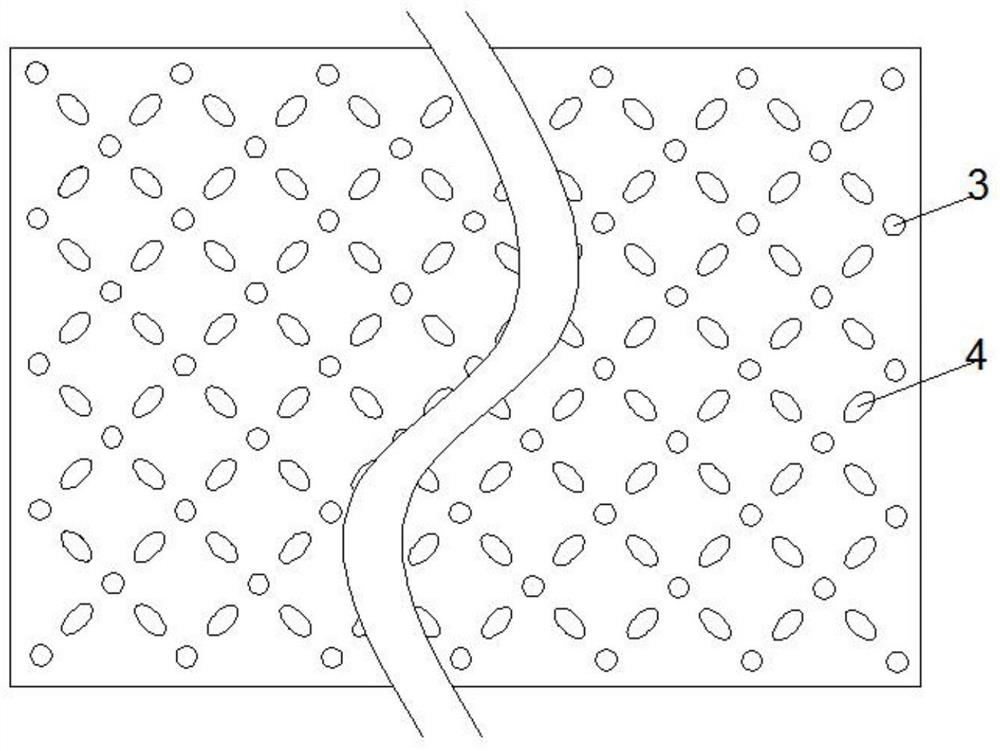

[0050] Such as Figure 4 and Figure 5 As shown in the figure, it is composed of a hemispherical first bump 3, a semi-elliptical second bump 4 and a PET substrate. figure 2 and 3 The first bump 3 and the second bump 4 are obtained by rotating 45°. In actual production, due to the effect of surface tension, after the silica gel falls from the mesh roller body 5 and bonds with the PET substrate, it will deform, so it will Produces inconsistent bumps and greatly reduces compatibility with graphite or electronics.

Embodiment 3

[0052] Such as Figure 6~9 As shown in the figure, it is composed of a hemispherical first bump 3, a diamond-shaped second bump 4 and a PET substrate, such as Figure 6 Rotate each point in 45° to get Figure 7 , Figure 8 Rotate each point in 45° to get Figure 9 , in actual production, due to the effect of surface tension, after the silica gel falls from the mesh roller body 5 and bonds with the PET substrate, some deformations will occur, and some bumps will become similar to those after curing. Figure 2~5 The corresponding shape in , so the effect in Example 2 will be produced, figure 2 and image 3 The dot matrix distribution is more high-performance, high compatibility, and ultra-high exhaust.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com