Method for making matte release paper for pressure sensitive tapes

A production method and technology of release paper, which are applied in paper, papermaking, paper coating, etc., can solve the problems of uneven haze on the pressure-sensitive adhesive surface, inconsistent grinding depth, and unstable peeling force of the release film. Achieve the effects of stable peeling force, good haze effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A kind of manufacture method of matte release paper for pressure-sensitive tape, its manufacture process is as follows:

[0036] Step 1: First, treat the surface of the base paper of the release paper so that there is no paper scraps or stains on the surface.

[0037] Step 2: On the surface of one side of the base paper of the release paper, use a laminating machine to coat a layer of PE coating layer, and then cool it; the laminating machine can use the high-speed extrusion single-sided flow produced by Changzhou Laiyi Plastic Machinery Co., Ltd. Extended composite unit type A.

[0038] Step 3: Prepare the matte release agent

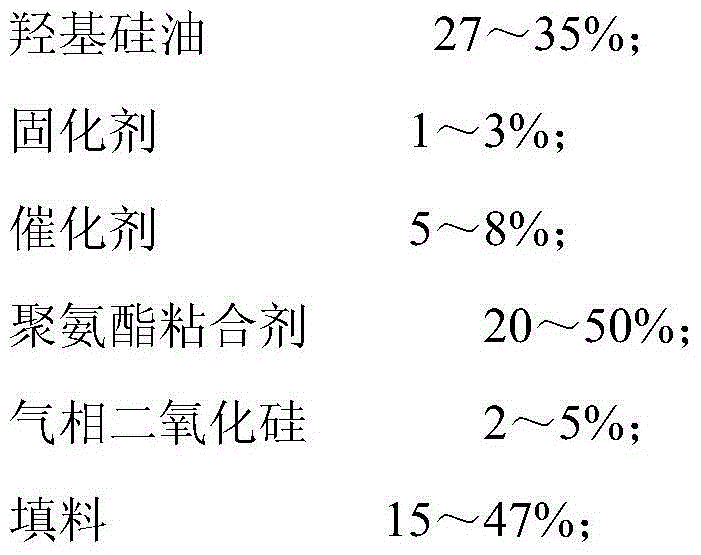

[0039] First, prepare the materials according to the following mass percentages:

[0040]

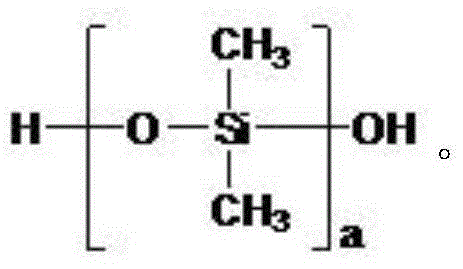

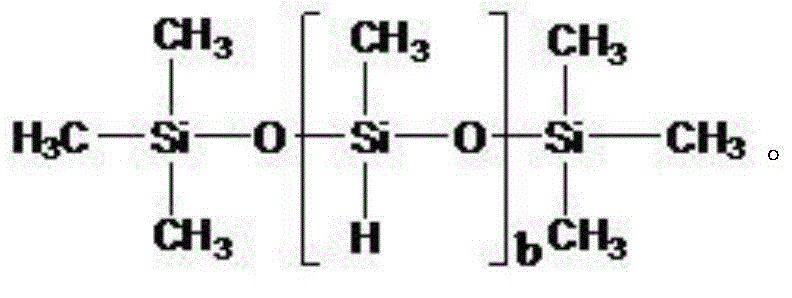

[0041] The curing agent is methyl hydrogen-containing silicone oil; the catalyst is platinum; the filler is talcum powder with a particle diameter less than or equal to 15 microns; the viscosity of the hydroxy silicone oil is 8000 cps. ...

Embodiment 2 3

[0047] Embodiments 2-3: A method for making a matte release paper for pressure-sensitive adhesive tape

[0048] 1. The raw material formula of the matte release agent is shown in the following table:

[0049]

[0050] Note, the % in the table represents the mass percent content.

Embodiment 2

[0051] The viscosity of the hydroxy silicone oil described in Example two is 14000cps. The viscosity of the hydroxy silicone oil described in Example three is 13000cps.

[0052] The viscosity of the polyurethane adhesive described in Example 2 is 2300cps. The viscosity of the polyurethane adhesive described in Example three is 2700cps.

[0053] Two, preparation method is the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com