3D curved surface AF coated screen mobile phone protective film and preparation method thereof

A technology of protective film and curved surface, applied in the field of 3D curved AF coating screen mobile phone protective film and its preparation, can solve the problems of low production efficiency, complex molding process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

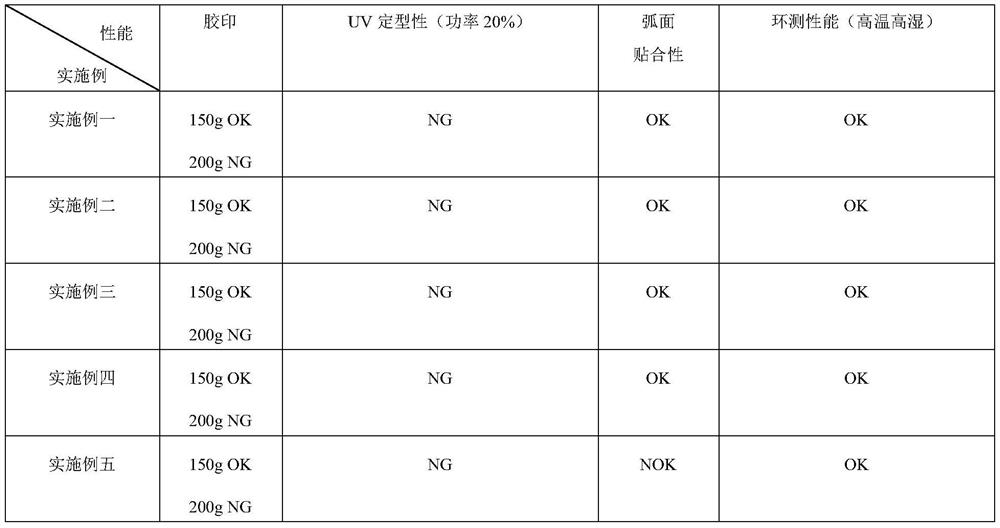

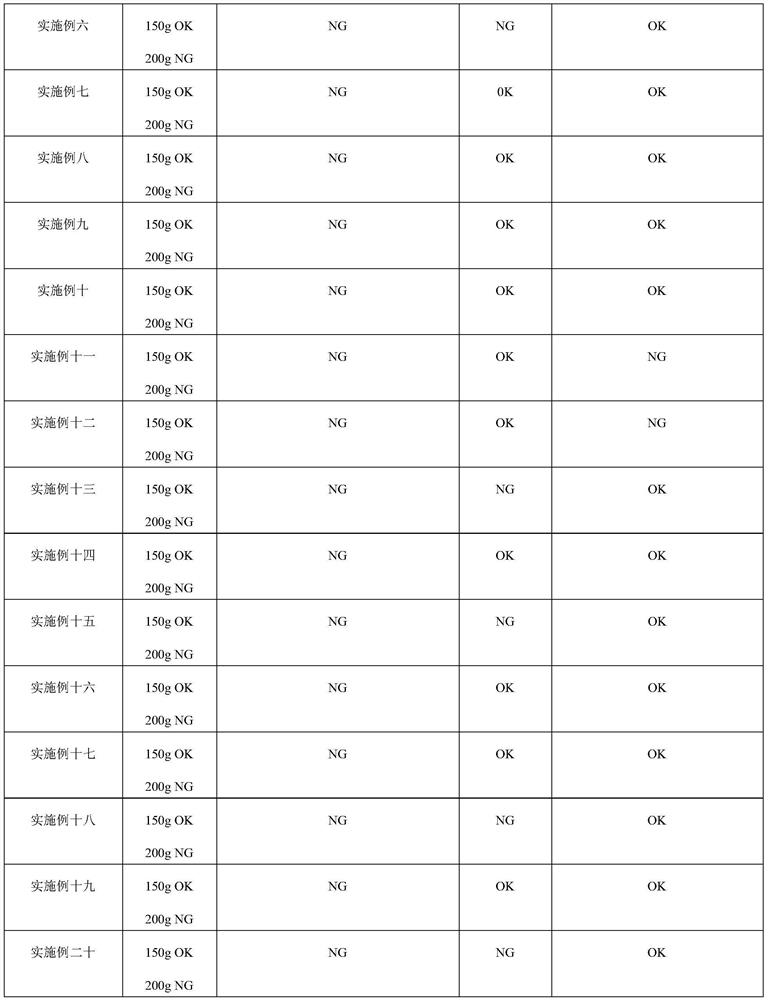

Examples

Embodiment 1

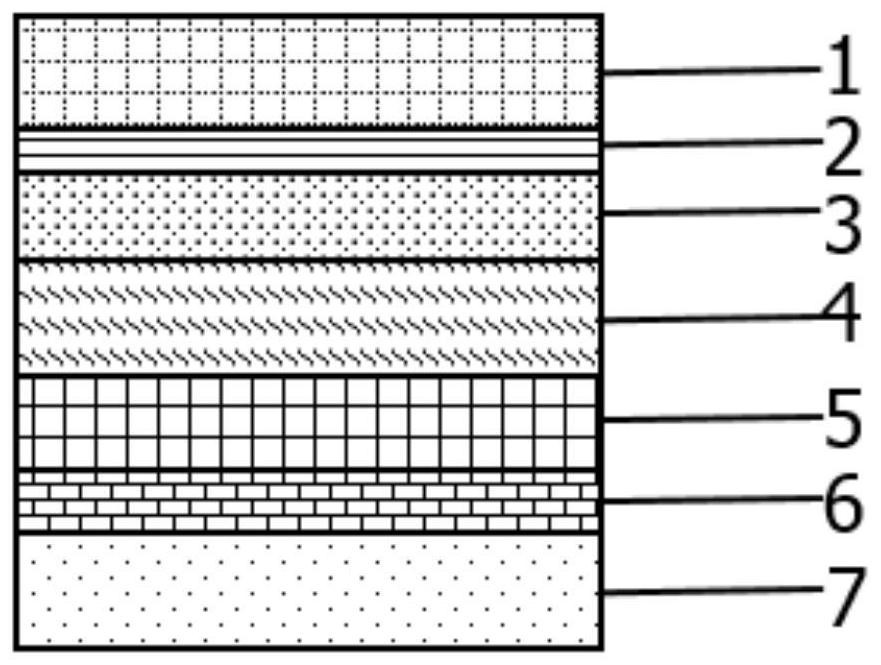

[0032] Embodiment one: if figure 1As shown, a 3D curved surface AF coated screen mobile phone protective film, including a top protection layer 1 laminated from top to bottom, a hardening layer 2, a PET layer 3 with a polarization angle of 90°, and a modified photothermal dual-curing acrylic polyurethane Layer 4, no optical axis optical elastic layer 5, special silicone pressure-sensitive adhesive layer 6 for AF screen and fluorine release film 7, the material components of the modified photothermal dual-curing acrylic polyurethane layer 5 are: 100 parts by weight of dual-curing resin (Ding Lisen DSU-1630A), 30 parts by weight photosensitive monomer (City Blue Material CM8003), 7 parts by weight curing agent (Ding Lisen DSU-1630B), 5 parts by weight photoinitiator (2-hydroxyl-2-methyl -1-[4-(2-hydroxyethoxy) phenyl]-1-acetone), 1 part by weight of UV absorber (477), 0.5 parts by weight of UV stabilizer (292) and 20 parts by weight of the first solvent ( (Toluene and ethyl est...

Embodiment 2

[0041] Embodiment 2: This embodiment is basically the same as Embodiment 1, the only difference is that in this embodiment, the PET layer 3 with a polarization angle of 70° and the optical elastic layer 5 without an optical axis are optical-grade soft TPU elastic layers. The optical grade soft TPU elastic layer has a thickness of 20 μm and a Young’s modulus of 58.6 MPa (5% tensile strain).

Embodiment 3

[0042] Embodiment 3: This embodiment is basically the same as Embodiment 1, except that the preparation method is different. The 3D curved surface AF coated screen mobile phone protective film of this embodiment is prepared by the following method:

[0043] (1) Coating the glue used to prepare the hardened layer on the upper surface of the PET layer 3 with a thickness of 25 μm and a polarization angle of 90°, the coating thickness is 3 μm, and the glue is cured under UV curing to form a hardened layer;

[0044] (2) Coat the optical grade glue on the lower surface of the PET release film, dry the optical grade glue at 90-135°C to form an optical elastic layer without optical axis, and cure it at 40°C for 5 hours, the optical grade is hard The modulus of the TPU layer is 1500MPa (5% tensile strain), and the special silicone pressure-sensitive glue for AF screen is coated on the lower surface of the school-grade hard TPU glue, and the special silicone pressure-sensitive glue for A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com