Preparation method of efficient antistatic process film for attachment of OLED module and product of preparation method

A process and anti-static technology, applied in the direction of film/sheet release liner, film/sheet release coating, film/sheet adhesive, etc., can solve the problems of screen breakdown, dust adsorption, etc. Achieve the effects of increasing safety, improving yield and efficiency, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

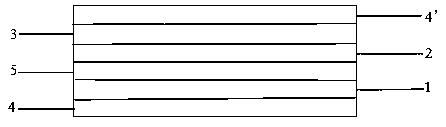

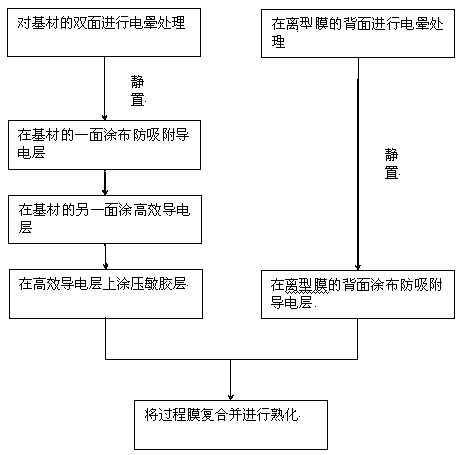

[0036] Such as figure 1 It is a structural schematic diagram and a process film for bonding of high-efficiency anti-static OLED modules. figure 2 It is a schematic diagram of the production process of a high-efficiency anti-static OLED module bonding process film.

[0037] A kind of high-efficiency anti-static OLED module bonding process film, such as figure 1 As shown, it includes from bottom to top: substrate 1, high-efficiency conductive layer 5, UV adhesive layer 2, release film 3, according to figure 2 Prepared by the steps shown:

[0038] (a) Corona treatment is performed on both sides of the substrate 1 and the back of the release film 3, and the substrate 1 and the release film 3 are corona treated for more than 3 days, and the storage environment is room temperature or a high temperature of 40-60°C, The surface tension to the surface of the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com