Technical process film for laminating UV-irradiation viscosity reduction type OLED module and preparation method of technical process film

A process and module technology, applied in the direction of film/sheet adhesives, adhesives, pressure-sensitive films/sheets, etc., can solve the problems of adsorption screen, breakdown, etc., to prevent adsorption, easy to tear off, solve The effect of dust adsorption and screen breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

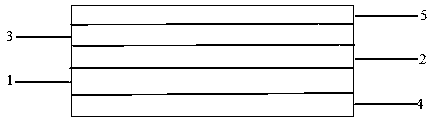

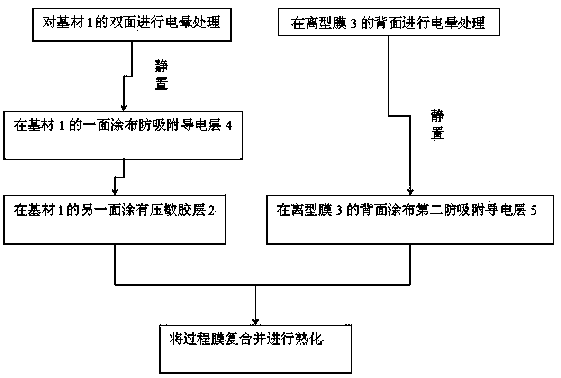

[0031] like figure 1 As shown, a UV irradiation viscosity-reducing type OLED module bonding process film, including: a substrate 1, a pressure-sensitive adhesive layer 2, a release film 3, an anti-adsorption conductive layer 4 and a second anti-adsorption conductive layer 5 ,in,

[0032] Both sides of the substrate 1 are subjected to corona treatment, a pressure-sensitive adhesive layer 2 is coated on one side of the substrate 1, and an anti-adsorption conductive layer 4 is coated on the other side, and the pressure-sensitive adhesive layer 2 is covered with PET release film 3 , the back of the release film 3 is also corona treated and coated with a second anti-adsorption conductive layer 5 .

[0033] The pressure-sensitive adhesive layer 2 of the present invention is a UV-viscosity-reducing adhesive layer on the basis of existing pressure-sensitive adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com