Hot-pressing carrier tape sealing mechanism

A carrier tape and heating rod technology, which is applied in packaging sealing/fastening, external support, transportation and packaging, etc., can solve the problems that the carrier tape is easy to deviate from the guide rail, the temperature of the sealing knife fluctuates greatly, and precise control cannot be achieved. Achieve good heat insulation effect, low noise and vibration, and stable peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

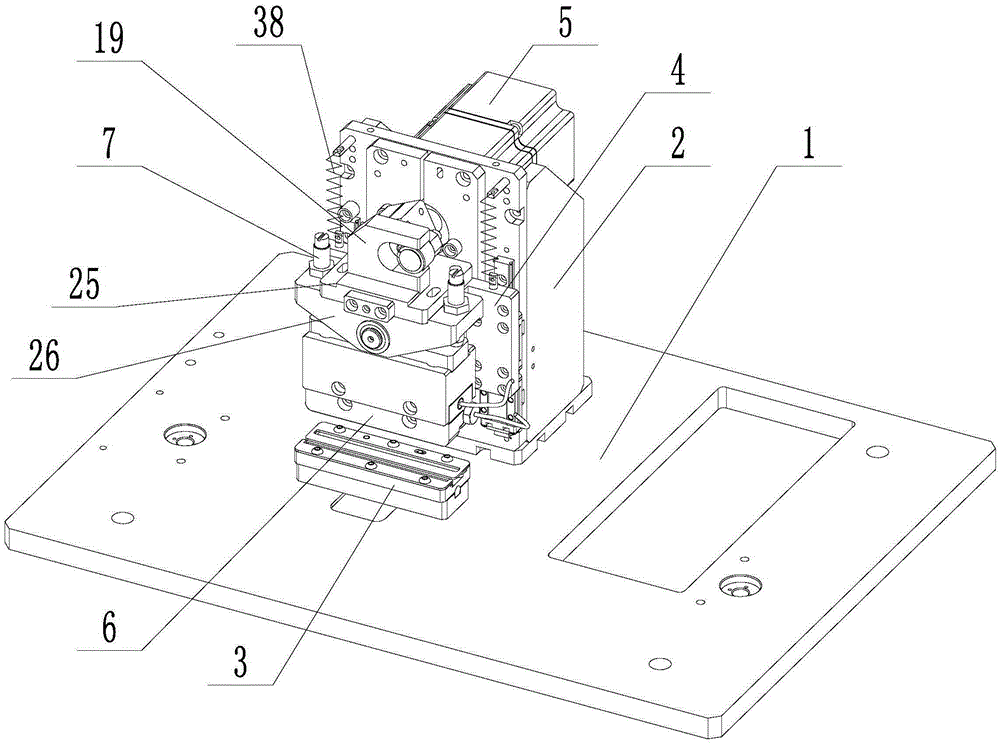

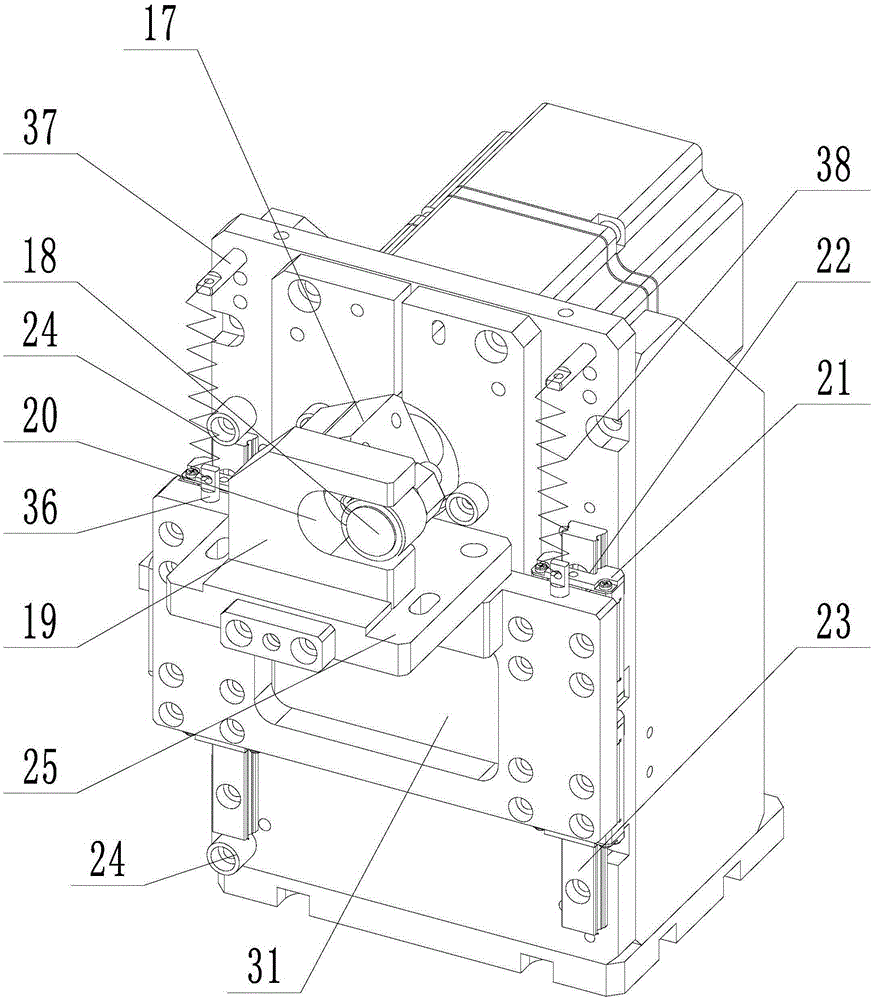

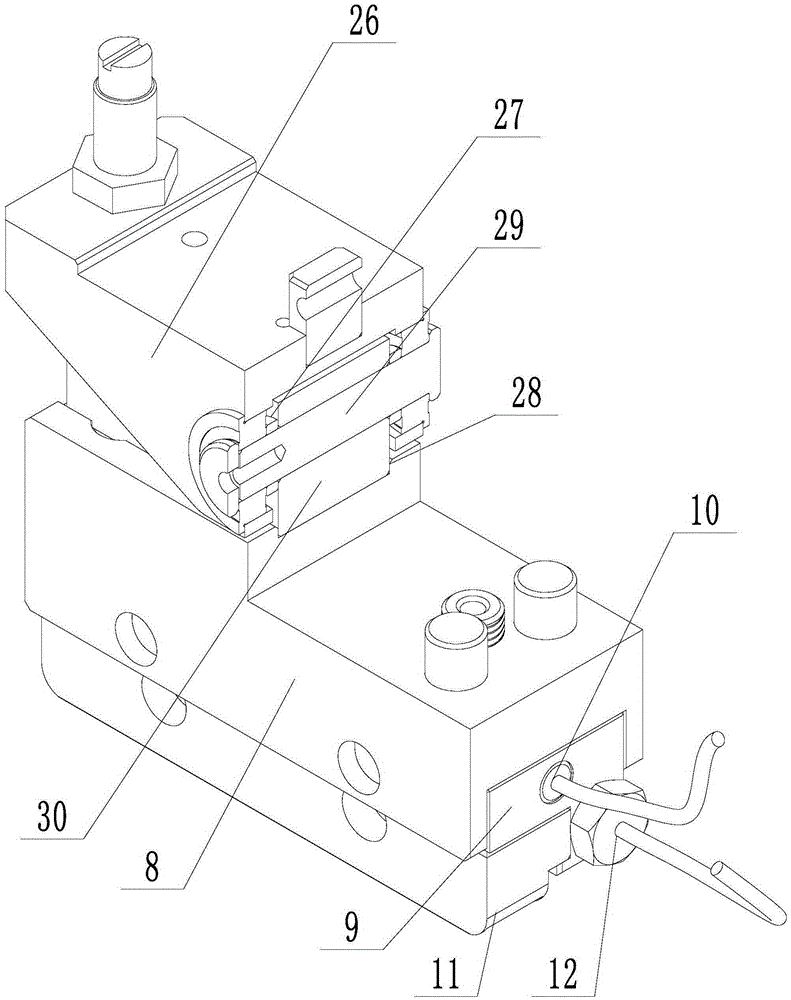

[0024] Embodiment: A kind of hot ballast belt sealing mechanism (see attached Figures 1 to 4), including a heat-seal base 1, which is connected with a driving part mounting seat 2 and a floating guide rail part 3, and the driving part mounting seat is slidably connected with a moving part 4 that can be lifted up and down, and is fixedly connected with a driving moving part for lifting A moving servo motor 5, the axis of the output shaft of the servo motor is set horizontally, the output shaft of the servo motor is fixedly connected with a motor shaft connector 17, and the edge of the motor shaft connector is provided with a cam follower 18 that deviates from the axis of the output shaft of the servo motor, and the moving parts A follower block 19 is provided on the follower block, and a U-shaped slot 20 is provided on the follower block. The opening of the U-shaped slot is to the right, and the cam follower is movably inserted in the slot. Two vertically arranged linear guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com