Surface mount component carrier tape upper cover tape and processing method thereof

A processing method and technology of cover tape, applied in chemical instruments and methods, flexible coverings, packaging, etc., can solve the problems of difficult selection of adhesives, unacceptable customers, and large changes in peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

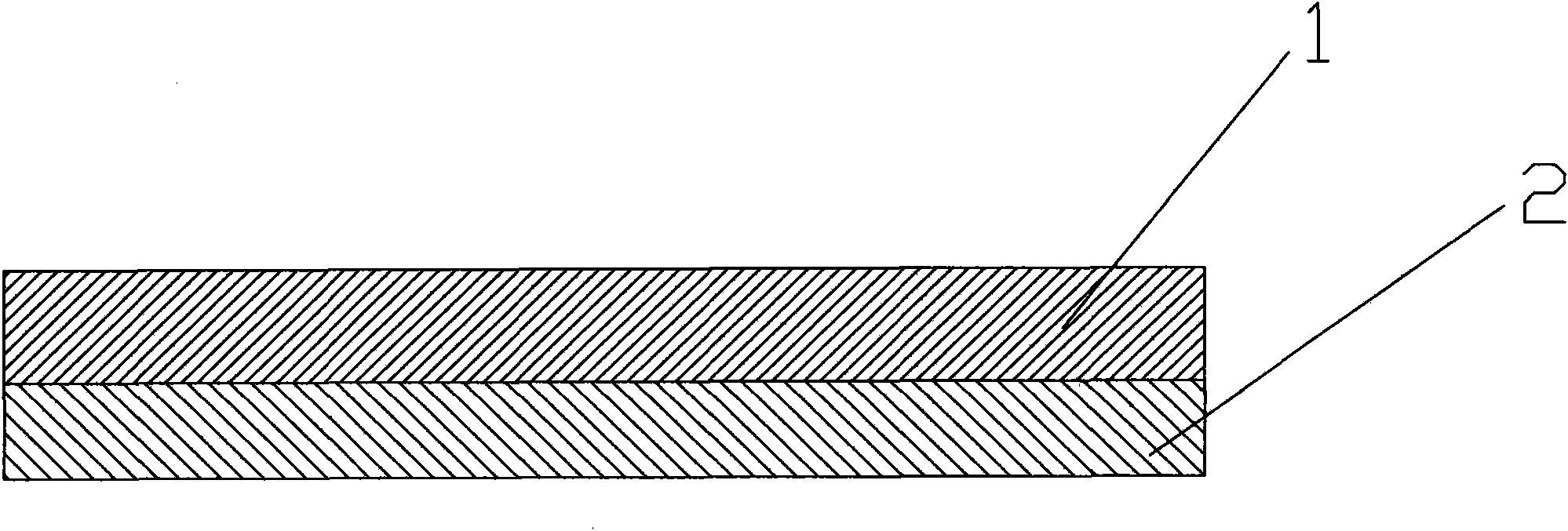

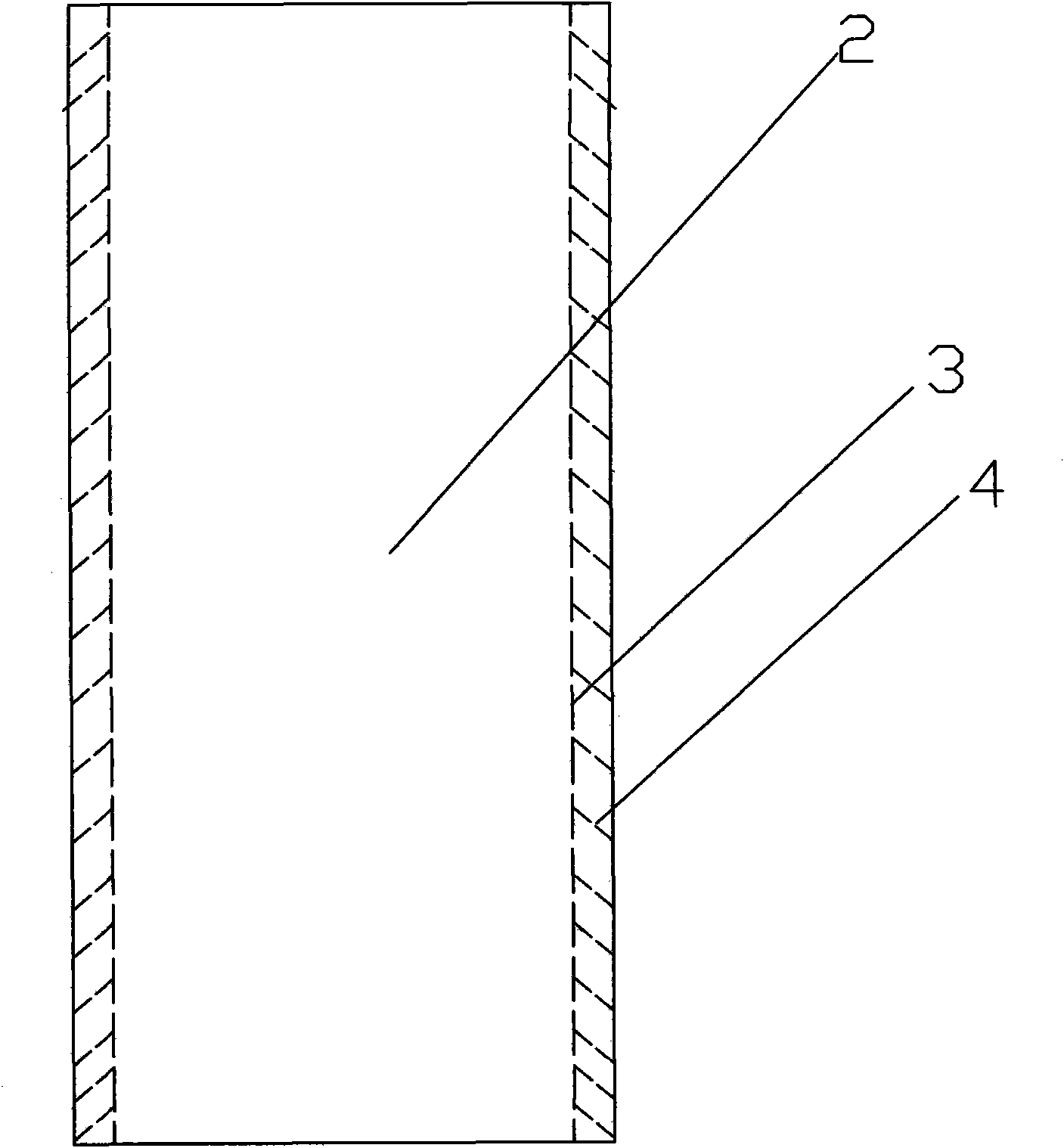

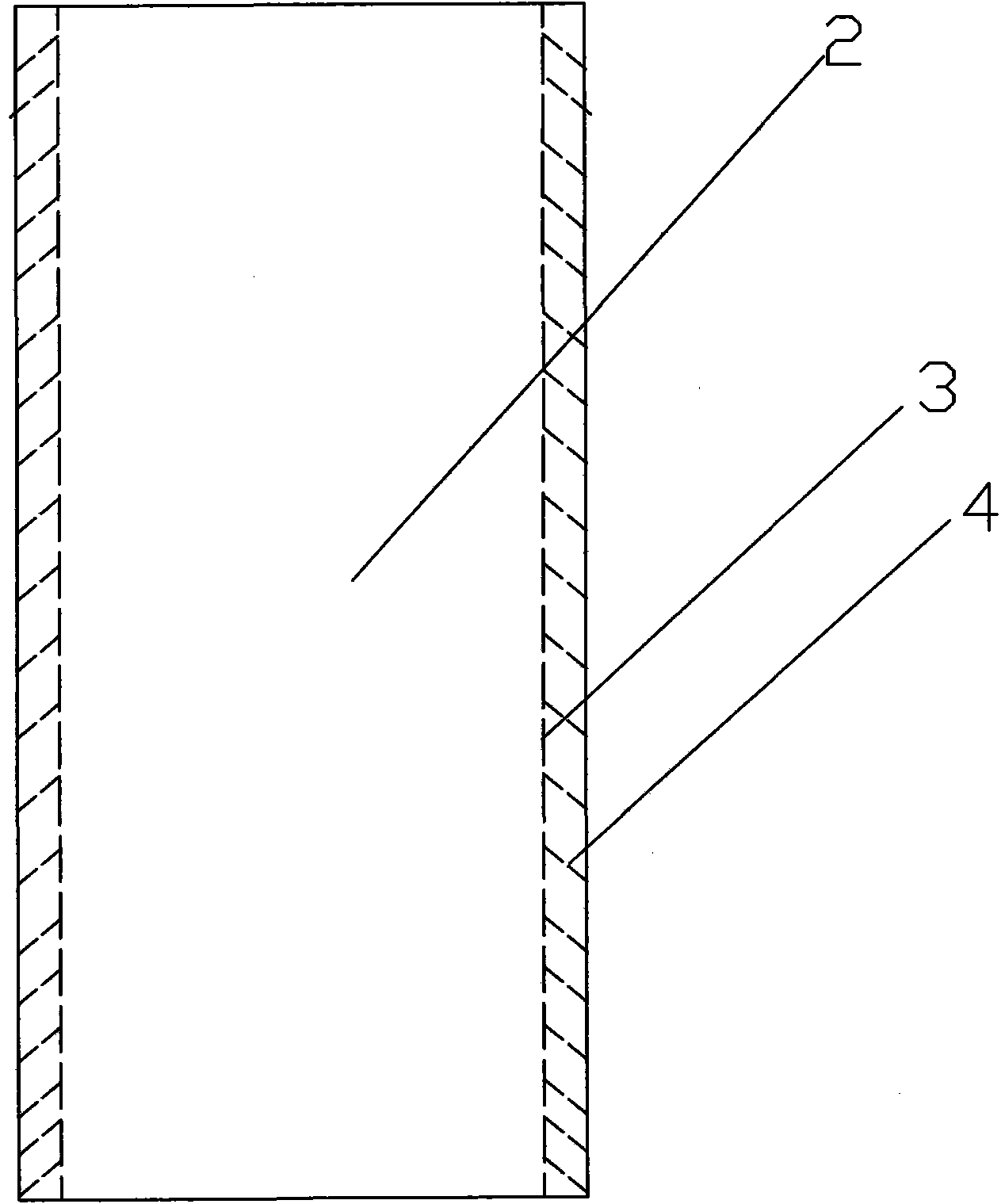

[0016] Such as figure 1 , 2 As shown, the sheet component carrier tape cover tape includes a PET film 1, the lower surface of the PET film 1 is coated with hot melt adhesive to form a hot melt adhesive layer 2, and the coated hot melt adhesive can be PE glue or EVA glue. Two parallel longitudinal die lines 3 are formed on the hot melt adhesive layer 2 , and the left and right outer sides of the two longitudinal die lines 3 form a "eight" shaped die line 4 . The distance between the two longitudinal die lines 3 and the edge of the upper cover belt corresponding to the row is 0.5 to 1 mm, and the distance between two adjacent "eight" shaped die lines 4 is 3-5 mm.

[0017] The processing method of the above-mentioned patch component carrier tape and cover tape includes the following steps: first, apply hot melt adhesive on the surface of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com