Optical transparent double-sided tape

A double-sided tape, optically transparent technology, applied in the direction of adhesives, coatings, film/sheet release liners, etc., can solve the problems of unstable performance, poor weather resistance, etc., to reduce transfer rate and improve coating ductility and uniformity, and the effect of improving residual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

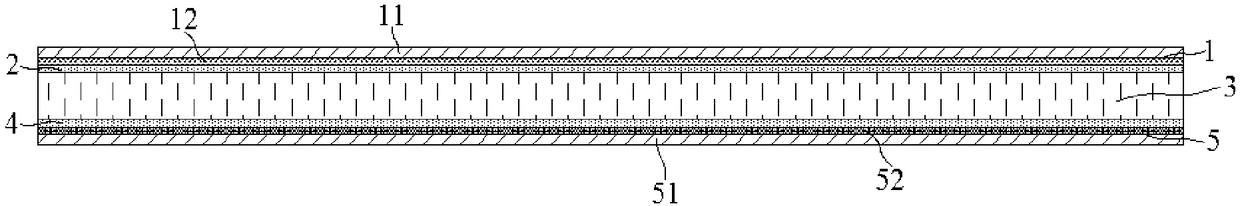

[0036] Example 1: An optically transparent double-sided adhesive tape, comprising a lightly peelable release film 1, a first optical adhesive layer 2, a transparent substrate layer 3, a second optical adhesive layer 4, and a heavy peelable release film 5;

[0037] The lightly peelable release film 1 consists of a first base film layer 11, a lightly peelable release agent layer 12 coated on the surface of the first base film layer 11, and the lightly peelable release agent layer 12 is composed of a lightly peelable release agent. After curing, the light-peeling release agent is obtained from the following parts by weight:

[0038] 100 parts of the first prepolymer resin,

[0039] 0.6 parts of methyl hydroquinone,

[0040] 12 parts of 2-hydroxymethyloxetane,

[0041] 25 parts of lauryl glycidyl ether,

[0042] 3.2 parts of 1-hydroxycyclohexyl benzophenone.

[0043] The first prepolymerized resin is obtained by the following steps:

[0044] Step 1. Put 45 parts of cyclohexyl methacrylate, 20...

Embodiment 2

[0059] Embodiment 2: An optically transparent double-sided adhesive tape, comprising a lightly peelable release film 1, a first optical adhesive layer 2, a transparent substrate layer 3, a second optical adhesive layer 4, and a heavy peelable release film 5;

[0060] The lightly peelable release film 1 consists of a first base film layer 11, a lightly peelable release agent layer 12 coated on the surface of the first base film layer 11, and the lightly peelable release agent layer 12 is composed of a lightly peelable release agent. After curing, the light-peeling release agent is obtained from the following parts by weight:

[0061] 100 parts of the first prepolymer resin,

[0062] 0.9 parts of methyl hydroquinone,

[0063] 15 parts of 2-hydroxymethyloxetane,

[0064] 22 parts of lauryl glycidyl ether,

[0065] 4 parts of 1-hydroxycyclohexyl benzophenone.

[0066] The prepolymerized resin is obtained by the following steps:

[0067] Step 1. Put 48 parts of cyclohexyl methacrylate, 25 part...

Embodiment 3

[0082] Embodiment 3: An optically transparent double-sided adhesive tape, comprising a lightly peelable release film 1, a first optical adhesive layer 2, a transparent substrate layer 3, a second optical adhesive layer 4, and a heavy peelable release film 5;

[0083] The lightly peelable release film 1 consists of a first base film layer 11, a lightly peelable release agent layer 12 coated on the surface of the first base film layer 11, and the lightly peelable release agent layer 12 is composed of a lightly peelable release agent. After curing, the light-peeling release agent is obtained from the following parts by weight:

[0084] 100 parts of the first prepolymer resin,

[0085] 0.6 parts of methyl hydroquinone,

[0086] 18 parts of 2-hydroxymethyloxetane,

[0087] 28 parts of lauryl glycidyl ether,

[0088] 4.2 parts of 1-hydroxycyclohexyl benzophenone.

[0089] The first prepolymerized resin is obtained by the following steps:

[0090] Step 1. Put 42 parts of cyclohexyl methacrylate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com