A kind of release film for OCA optical glue and preparation method thereof

A technology of release film and optical adhesive, applied in the direction of film/sheet release liner, coating, etc., can solve the problems of large gap in quality requirements, low resin crosslinking degree, organic solvent volatilization, etc., and achieve low production cost , high production efficiency and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

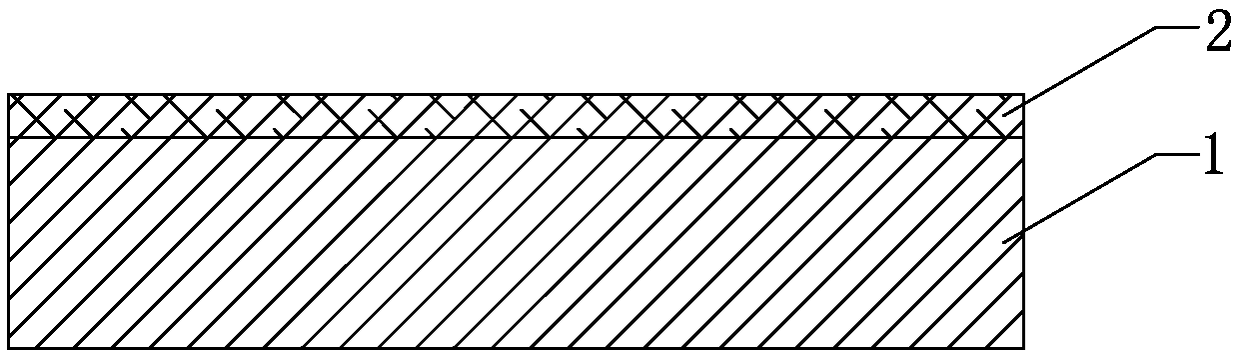

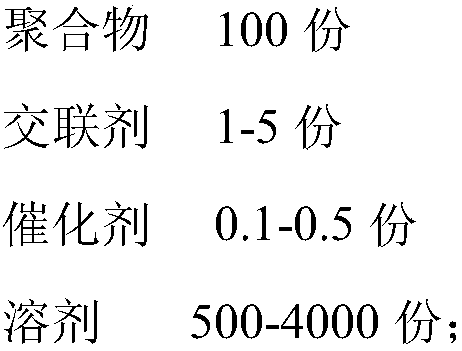

[0030] A release film for OCA optical glue, comprising a substrate layer 1 and a release layer 2 attached to the upper surface of the substrate layer 1, the release layer 2 is made by coating a release agent, the release layer Formulation comprises the raw material of following weight portion:

[0031] Polymer 100 parts

[0032] 1 part of cross-linking agent

[0033] Catalyst 0.1 part

[0034] 500 parts of solvent.

[0035] The thickness of the substrate layer 1 is 20 μm; the thickness of the release layer 2 is 0.1 μm.

[0036] The substrate layer 1 is a PET film with a light transmittance greater than 90%.

[0037] The polymer is polysiloxane, acrylate-modified silicone resin or silicone.

[0038] The crosslinking agent is methylmethoxysiloxane, N-2-(aminoethyl)-3 aminopropylmethyldimethoxysilane or vinyltriethoxysilane.

[0039] The catalyst is a platinum catalyst.

[0040] The solvent is 120# gasoline, toluene, xylene, dimethyl hydrogen silicone oil, butanone, petrol...

Embodiment 2

[0046] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0047] Described release agent comprises the raw material of following weight portion:

[0048] Polymer 100 parts

[0049] Cross-linking agent 2 parts

[0050] Catalyst 0.2 part

[0051] Solvent 1000 parts.

[0052] The thickness of the substrate layer 1 is 50 μm; the thickness of the release layer 2 is 0.3 μm.

[0053] The substrate layer 1 is a PEN film with a light transmittance greater than 90%.

[0054] The polymer is a mixture of any two of polysiloxane, acrylate-modified silicone resin and silicone.

[0055] The crosslinking agent is composed of any two of methylmethoxysiloxane, N-2-(aminoethyl)-3 aminopropylmethyldimethoxysilane and vinyltriethoxysilane mixture.

[0056] The catalyst is a silver-palladium catalyst.

[0057] The solvent is a mixture of any two of 120# gasoline, toluene, xylene, dimethylhydrogen silicone oil, butanone, petroleum ether, cyclohexane and tetrahydr...

Embodiment 3

[0062] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0063] Described release agent comprises the raw material of following weight portion:

[0064] Polymer 100 parts

[0065] 3 parts of cross-linking agent

[0066] Catalyst 0.3 parts

[0067] Solvent 2000 parts.

[0068] The thickness of the substrate layer 1 is 100 μm; the thickness of the release layer 2 is 0.25 μm.

[0069] The substrate layer 1 is a PC film with a light transmittance greater than 90%.

[0070] The polymer is a mixture composed of polysiloxane, acrylate-modified silicone resin and silicone in a weight ratio of 0.8:1.4:1.

[0071] Described cross-linking agent is by methyl methoxy siloxane, N-2-(aminoethyl)-3 aminopropyl methyl dimethoxy silane and vinyl triethoxy silane with weight ratio 1: A mixture composed of 0.5:1.5.

[0072] The catalyst is a platinum-rhodium catalyst.

[0073] The solvent is a mixture composed of dimethylhydrogen silicone oil, cyclohexane a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com